Contents

Manufacturing Insight: Laser Engraving Plastic Sheets

Precision Plastic Engraving Integrated with Sheet Metal Fabrication Expertise

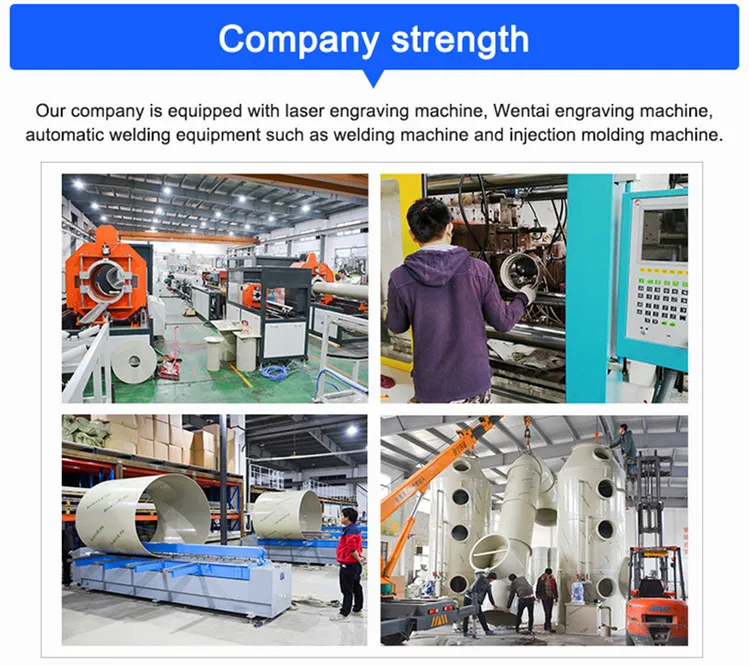

Honyo Prototype delivers comprehensive sheet metal fabrication solutions where secondary processes like laser engraving on plastic components directly enhance the functionality and traceability of your final metal assemblies. Our industrial-grade CO2 and fiber laser systems precisely mark acrylic, polycarbonate, ABS, and other engineering-grade plastics with serial numbers, barcodes, logos, or critical assembly guides—ensuring permanent identification that withstands harsh operational environments. This capability is not an isolated service but a strategically integrated offering within our end-to-end metal fabrication workflow. When your project requires plastic overlays, control panels, or insulating components paired with precision-formed sheet metal, Honyo eliminates supply chain fragmentation by managing both material streams under one quality-controlled process.

The synergy between our metal fabrication and plastic engraving services reduces lead times and mitigates interface errors common when sourcing from multiple vendors. All engraving parameters—including depth, contrast, and edge quality—are validated against your engineering specifications during our DFM review, ensuring compatibility with subsequent metal bending, welding, or finishing stages. For rapid project initiation, leverage Honyo’s Online Instant Quote platform to receive validated pricing and lead times for combined sheet metal fabrication and plastic engraving within minutes. Upload your STEP or DWG files to instantly assess manufacturability and accelerate prototyping or low-volume production.

Partner with Honyo to transform integrated metal-plastic assemblies from concept to certified reality with seamless process ownership and technical accountability.

Technical Capabilities

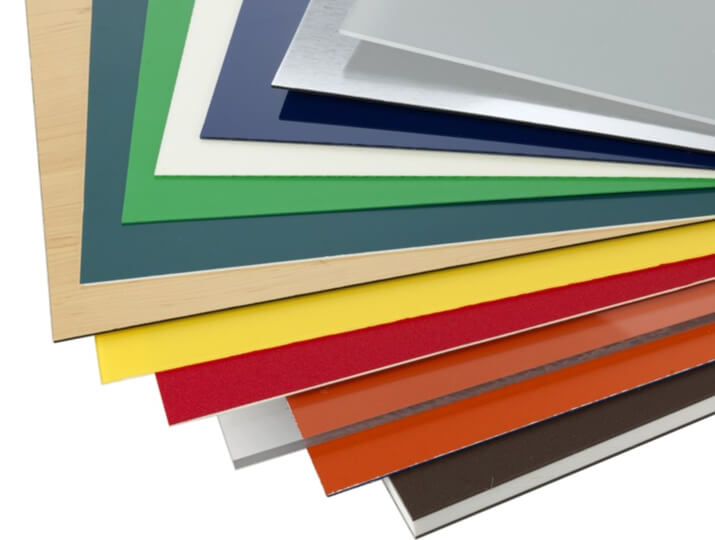

Honyo Prototype provides precision laser processing services for both metal and plastic sheet materials. While laser engraving is commonly applied to plastics for marking and surface detailing, the broader capabilities in laser cutting, bending (post-processing), and welding are critical for functional prototyping and low-volume production. Below are the technical specifications and material considerations for laser processing, with a focus on plastics such as ABS and Nylon, and comparative notes for metals like Aluminum and Steel.

| Process | Material | Laser Type | Thickness Range | Power Requirement | Tolerance | Edge Quality | Notes |

|---|---|---|---|---|---|---|---|

| Laser Cutting | ABS | CO₂ Laser | 0.5 – 10 mm | 30 – 100 W | ±0.1 mm | Smooth, slightly melted edge | High precision; minimal post-processing; flammable—requires ventilation |

| Laser Cutting | Nylon | CO₂ Laser | 1 – 12 mm | 40 – 120 W | ±0.15 mm | Smooth, may show slight browning | Good for gears and insulators; absorbs moisture—pre-dry recommended |

| Laser Cutting | Aluminum | Fiber Laser | 0.8 – 15 mm | 500 – 4000 W | ±0.2 mm | Clean, oxidized edge | Reflective—requires anti-reflective coating or pulsed mode |

| Laser Cutting | Steel | Fiber Laser | 0.5 – 20 mm | 500 – 3000 W | ±0.1 mm | Smooth, dross possible on thick cuts | Mild steel cuts efficiently; stainless requires assist gas (N₂/O₂) |

| Bending | ABS | Not applicable (thermal forming post-cut) | Up to 6 mm | N/A | ±0.5° angular | Smooth inner radius | Requires heated bending jig; not laser-bent directly |

| Bending | Nylon | Not applicable (thermal forming post-cut) | Up to 8 mm | N/A | ±0.5° angular | Moderate springback | Preheating to 80–100°C recommended for clean bends |

| Bending | Aluminum | Press brake (post-laser cut) | 0.8 – 6 mm | N/A | ±0.2° | Clean, no cracking if grain direction controlled | Laser cutting precedes bending; avoid bending over cut edges |

| Bending | Steel | Press brake (post-laser cut) | 0.5 – 8 mm | N/A | ±0.2° | Clean, sharp bend lines | High tensile steels may require annealing prior to bending |

| Laser Welding | ABS | Diode/Transmission Laser (via through-transmission welding) | 1 – 5 mm | 50 – 150 W | Joint-dependent | Hermetic, minimal flash | Requires one transparent and one absorptive part; additives may be needed |

| Laser Welding | Nylon | Diode/Transmission Laser | 1 – 6 mm | 60 – 200 W | Joint-dependent | Strong, chemically resistant | Excellent for fluid housings; moisture content affects weld strength |

| Laser Welding | Aluminum | High-power Fiber Laser | 0.5 – 8 mm | 1000 – 4000 W | ±0.1 mm | Deep penetration, spatter possible | Requires shielding gas (Ar/He); high reflectivity and thermal conductivity challenges |

| Laser Welding | Steel | Fiber Laser | 0.5 – 12 mm | 500 – 3000 W | ±0.1 mm | High strength, low distortion | Ideal for structural joints; stainless benefits from nitrogen shielding |

Notes on Process Compatibility

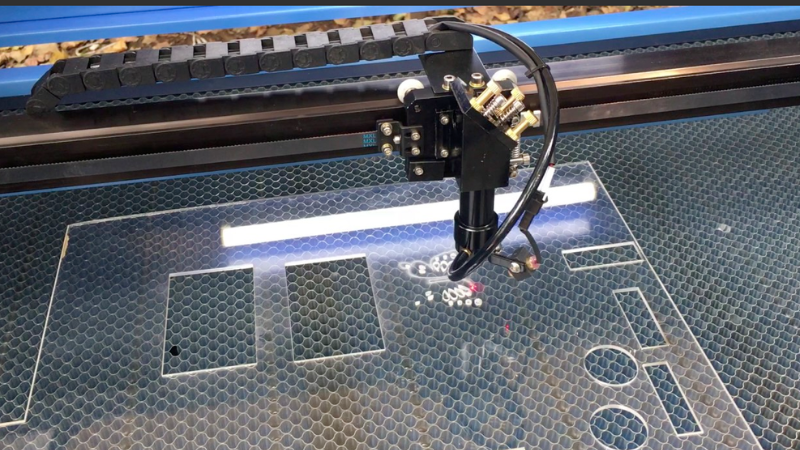

Laser engraving of plastics (ABS, Nylon) is typically performed using CO₂ lasers (10.6 μm wavelength) due to high absorption rates. Engraving depth can be controlled via power and speed adjustments, typically ranging from 0.05 mm to 1.5 mm. For ABS, engraving produces high-contrast marks with minimal charring when parameters are optimized. Nylon engraves well but may require marking additives for enhanced contrast.

Laser cutting of plastics achieves tight tolerances and is ideal for intricate geometries. However, thermal effects such as melting and recast layers must be managed through assist gas (e.g., compressed air for plastics, inert gas for metals).

Welding of plastics via laser transmission welding (LTW) is a non-contact, precise method suitable for medical and automotive sensors. Metals require high-energy fiber lasers, with joint design and surface preparation being critical for weld integrity.

All processes are supported by CNC-controlled systems at Honyo Prototype, ensuring repeatability and integration across hybrid material assemblies.

From CAD to Part: The Process

Honyo Prototype executes laser engraving of plastic sheets through a rigorously controlled five-stage workflow designed for precision, speed, and manufacturability assurance. This integrated process minimizes errors and ensures optimal results for engineering thermoplastics.

CAD Upload and Material Specification

Clients initiate the process by uploading native CAD files (STEP, IGES, or native CAD formats preferred) via our secure portal. Concurrently, the required plastic sheet material, grade, thickness, and finish must be specified. Our system validates file integrity and identifies critical engraving features such as line widths, depth requirements, and text height. Material selection is critical at this stage as it directly impacts laser parameters and feasibility.

AI-Powered Quoting and Feasibility Assessment

Our proprietary AI engine analyzes the CAD geometry against Honyo’s extensive material database and laser processing rules. The quote generated within minutes includes not only cost and lead time but also preliminary feasibility flags. Key parameters evaluated include minimum feature size relative to material type, thermal sensitivity thresholds, and potential for edge charring or melting. The AI cross-references historical production data for similar materials like acrylic, polycarbonate, ABS, or polyimide to predict optimal laser power, speed, and frequency settings. Example material considerations include:

| Material Type | Key Laser Parameter Considerations | Common Applications |

|---|---|---|

| Acrylic (PMMA) | Low power, high speed; minimal charring risk | Displays, signage, lenses |

| Polycarbonate (PC) | Moderate power; requires assist gas to prevent yellowing | Enclosures, automotive parts |

| ABS | Lower power settings; high risk of melting | Prototypes, housings |

| Polyimide (Kapton) | Precise pulse control; sensitive to overscanning | Flexible circuits, insulation |

Engineering DFM Review

Every job undergoes mandatory Design for Manufacturability (DFM) analysis by Honyo’s senior manufacturing engineers. This step validates the AI’s preliminary assessment and addresses nuanced technical constraints. Engineers verify engraving depth consistency across complex geometries, assess thermal distortion risks for thin sheets, and confirm minimum feature resolution aligns with material properties. Critical checks include evaluating whether fine text or intricate logos will vaporize rather than engrave cleanly on the specified plastic. Clients receive a formal DFM report with actionable recommendations—such as adjusting line widths or suggesting alternative materials—before proceeding to production. No job advances without explicit DFM sign-off.

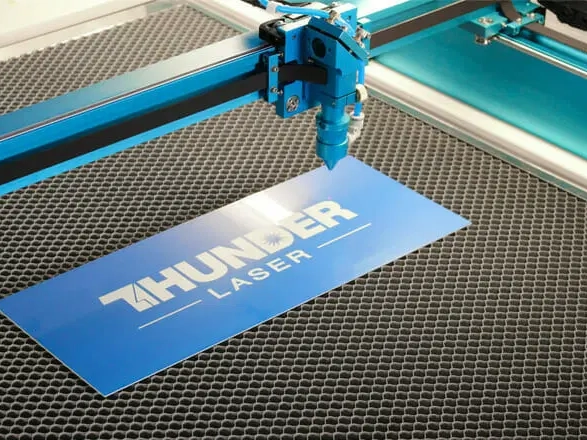

Precision Laser Engraving Production

Approved jobs move to production using Class 4 fiber lasers with 10–50 W power ranges, selected based on material and depth requirements. Plastic sheets are fixtured under inert gas (typically nitrogen) to prevent oxidation and melting artifacts. Our CNC-controlled systems execute engraving paths with ±0.025 mm positional accuracy, dynamically adjusting pulse duration and spot size per the pre-validated parameters. In-process metrology checks occur at 30% and 70% job completion to verify depth consistency and edge quality. All operations adhere to ISO 9001 environmental controls, maintaining temperature and humidity stability to prevent material warpage.

Quality-Controlled Delivery

Post-engraving, each sheet undergoes 100% visual inspection under calibrated lighting for debris, incomplete vaporization, or surface damage. Dimensional verification uses coordinate measuring machines (CMM) for critical features. Cleaned parts are packaged in anti-static, non-abrasive materials with humidity control for sensitive polymers. Delivery includes a traceability report documenting laser parameters, inspection results, and material lot numbers. Standard lead time is 3–5 business days from DFM approval, with real-time production tracking available via client portal. Rush services achieve 24-hour turnaround for qualified geometries and materials.

Start Your Project

Looking to precision laser engrave plastic sheets for your next project? Honyo Prototype delivers high-accuracy engraving services with fast turnaround times, leveraging our Shenzhen-based manufacturing facility for cost-effective, scalable production.

Contact Susan Leo today at [email protected] to discuss your design specifications and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.