Contents

Manufacturing Insight: Laser Engraving Machine Steel

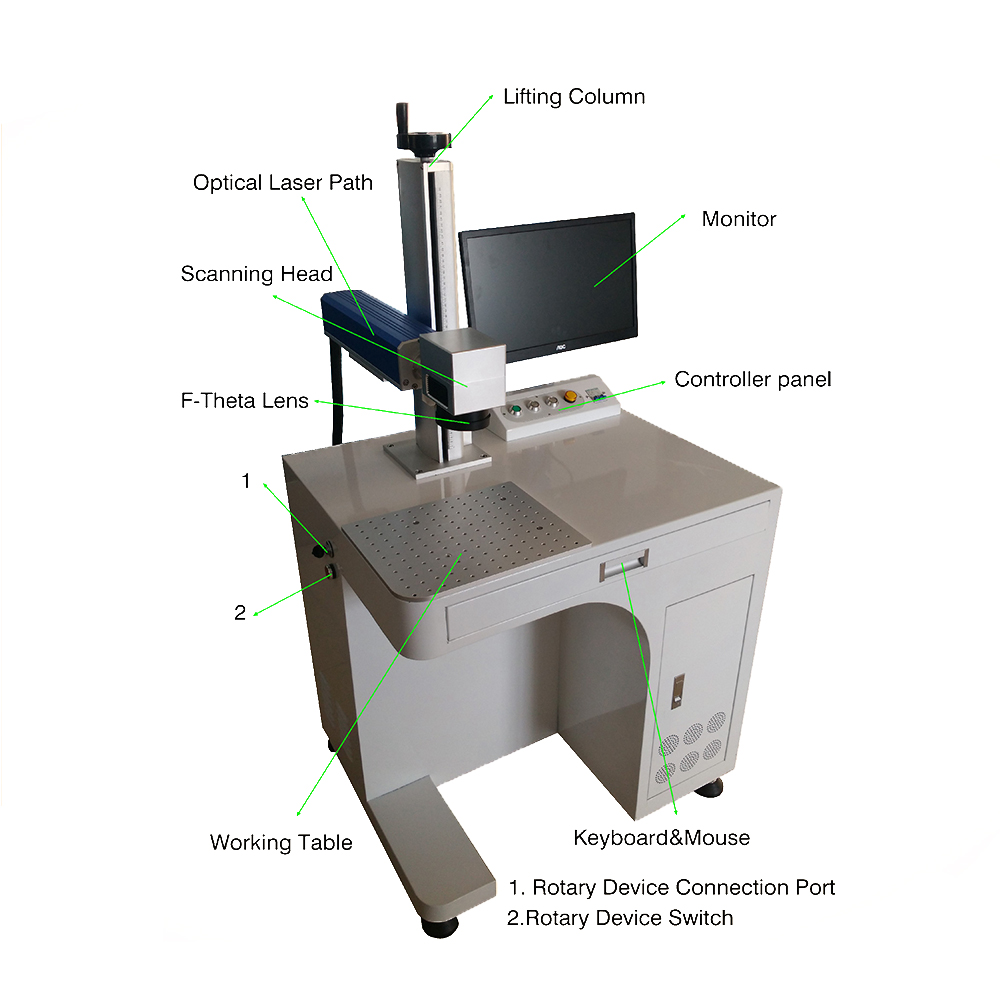

Precision Steel Component Marking Through Integrated CNC Laser Engraving

Honyo Prototype delivers mission-critical steel components with permanent, high-contrast identification via our integrated CNC laser engraving capabilities. As a core extension of our precision CNC machining services, we specialize in engraving stainless steel (304, 316, 17-4 PH), carbon steel (1018, 4140), and tool steel alloys with micron-level accuracy. Unlike mechanical marking methods, our fiber laser systems produce tamper-resistant serial numbers, 2D data matrix codes, logos, and technical data directly onto machined surfaces without inducing stress, burrs, or dimensional deviation—ensuring compliance with AS9100, ISO 13485, and automotive traceability standards.

This capability is not a standalone process but a seamless phase within our end-to-end CNC workflow. Components transition directly from milling/turning to laser marking in a single setup, eliminating handling errors and preserving geometric tolerances down to ±0.005mm. Our lasers achieve 50–150μm mark depth on steel with optimal edge acuity, critical for aerospace part genealogy, medical device UDI requirements, and industrial equipment asset tracking. Material integrity remains uncompromised, as the non-contact process avoids thermal distortion or subsurface microcracking common in alternative methods.

For engineering teams requiring rapid validation of steel part manufacturability—including engraving feasibility—we provide an Online Instant Quote platform. Upload your STEP/IGS files to receive geometry-aware pricing, lead time estimates, and material-specific marking recommendations within minutes. This tool integrates our CNC machining and laser engraving expertise into your procurement workflow, accelerating prototyping and low-volume production cycles without compromising on aerospace-grade quality.

| Key Parameter | Performance Specification |

|---|---|

| Steel Material Range | 304/316 SS, 1018/4140 Carbon, D2 |

| Marking Depth | 50–150 μm (adjustable) |

| Positional Accuracy | ±0.005 mm |

| Code Readability | MIL-STD-130 compliant |

| Integration | Embedded in CNC machining cycle |

Technical Capabilities

The term “laser engraving machine steel” may be misinterpreted—laser engraving machines are tools used to mark or engrave materials, not perform 3/4/5-axis milling or turning operations. However, interpreting the request as a need to describe technical specifications of a high-precision multi-axis CNC machining system (capable of milling, turning, and tight-tolerance work) that can also integrate laser engraving for part marking on materials such as steel, aluminum, ABS, and nylon, the following specifications apply.

Below is a technical specification table for an advanced multi-axis CNC machining center with integrated laser engraving capability, designed for high-precision manufacturing:

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis CNC Mill-Turn Center with Integrated Fiber Laser Engraving |

| Axes Configuration | X, Y, Z linear axes; A (rotary table ±120°); B (spindle head ±120°); optional Y-axis turning |

| Spindle Speed (Milling) | Up to 18,000 RPM (ceramic bearings, coolant-through) |

| Spindle Speed (Turning) | Up to 6,000 RPM (live tooling capable) |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Tool Changer | Automatic Tool Changer (ATC) – 30-tool capacity (HSK-T63 or CAT-40) |

| Work Envelope (X × Y × Z) | 700 mm × 500 mm × 500 mm |

| Maximum Workpiece Weight | 300 kg (rotary table capacity) |

| Control System | Siemens SINUMERIK 840D sl or Heidenhain TNC7 |

| Laser Engraving System | Fiber laser (1064 nm wavelength), 30 W average power |

| Laser Marking Speed | Up to 7,000 mm/s |

| Minimum Laser Spot Size | 20 µm |

| Compatible Materials – Machining | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 304/316), ABS, Nylon (PA6, PA66), PEEK, Delrin |

| Compatible Materials – Laser Marking | Steel (including stainless and tool steels), Aluminum (anodized or raw), ABS, Nylon (with marking additives) |

| Tolerance Capability | ±0.005 mm for critical features; surface finishes down to Ra 0.4 µm |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) with filtration |

| Automation Ready | Yes – compatible with robotic loaders and pallet systems |

| Software Integration | CAD/CAM compatibility (Siemens NX, Mastercam, SolidCAM); laser marking via dedicated software (e.g., LaserMark) |

This machine platform enables complex, high-tolerance components to be milled, turned, and permanently marked in a single setup, reducing cycle time and improving part traceability. The integration of laser engraving allows for Data Matrix codes, serial numbers, and logos to be marked directly onto machined parts made from metals and engineering plastics.

From CAD to Part: The Process

Honyo Prototype’s laser engraving process for machine steel components follows a rigorously defined workflow designed to ensure precision, material integrity, and efficiency. This end-to-end process integrates advanced digital tools with hands-on engineering expertise, specifically tailored to the thermal and structural properties of machine steel alloys. Below is a technical overview of each phase.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS formats preferred) via our secure customer portal. For machine steel engraving, critical metadata must accompany the file: material grade (e.g., AISI 1045, 4140), heat treatment condition (annealed, normalized, or hardened), surface finish requirements, and exact engraving depth specifications. Our system validates geometric integrity and flags unsupported formats or missing critical parameters before proceeding. Tolerances below ±0.05 mm for steel substrates trigger automatic alerts for engineering review due to potential thermal distortion risks.

AI Quote Generation

Honyo’s proprietary AI quoting engine processes the CAD data against real-time manufacturing constraints. For machine steel, the algorithm factors in: material hardness (Rockwell C scale), thermal conductivity values, required laser power density (typically 50–100 W for fiber lasers on steel), and post-engraving treatments. The AI cross-references historical data from 12,000+ steel engraving jobs to predict cycle times, consumable wear rates, and potential scrap risks. Clients receive a formal quote within 2 business hours, detailing cost drivers such as nitrogen assist gas requirements for oxidation prevention and secondary operations like post-engraving passivation.

DFM Analysis

All steel engraving jobs undergo mandatory Design for Manufacturability review by our applications engineering team. Key steel-specific checks include:

Verification of minimum feature spacing relative to material grain structure

Assessment of engraving depth versus steel hardness (e.g., depths >0.5 mm in hardened 4140 steel require multi-pass strategies)

Thermal stress simulation to prevent micro-cracking in high-carbon grades

Compatibility check between laser wavelength (1070 nm fiber lasers) and steel surface treatments (e.g., phosphate coatings may require pre-cleaning)

Common steel grades and DFM considerations are summarized below:

| Steel Grade | Max Recommended Engraving Depth | Critical DFM Notes | Required Pre-Processing |

|---|---|---|---|

| AISI 1018 | 1.0 mm | Low carbon; minimal thermal distortion | Light degreasing |

| AISI 1045 | 0.75 mm | Moderate carbon; risk of HAZ cracking at depth >0.5 mm | Stress relief annealing if hardened |

| AISI 4140 | 0.5 mm | High hardenability; requires controlled cooling | Full annealing for depths >0.3 mm |

| Tool Steel D2 | 0.3 mm | Extreme hardness; spallation risk | Cryogenic treatment recommended |

Production Execution

Engraving occurs on IPG Photonics fiber laser systems with 20–100 micron spot sizes, configured per DFM outcomes. Machine steel protocols include:

Laser parameters optimized for steel’s reflectivity (pulse frequencies 20–200 kHz, peak powers 30–80 kW)

Inert gas shielding (99.995% pure nitrogen) to prevent oxide formation on critical surfaces

Real-time pyrometer monitoring to maintain substrate temperature below 150°C, avoiding tempering effects in heat-treated steels

In-process CMM verification after first article for depth consistency (±0.02 mm tolerance)

All steel parts undergo post-engraving cleaning in ultrasonic alkaline baths followed by vapor degreasing to remove laser-induced particulates.

Delivery Assurance

Final inspection includes 100% verification against ASME B46.1 surface texture standards and material certification traceability. Steel components receive corrosion-inhibiting packaging: VCI paper wrapping inside sealed moisture-barrier bags with humidity indicators. Lead times average 5–7 business days for standard steel engraving, including 48-hour DFM validation. All shipments include a certificate of conformance detailing laser parameters, material test reports, and post-process dimensional validation data. For mission-critical applications, we provide optional witness testing via live-streamed inspection.

This integrated workflow ensures machine steel engraving meets stringent industrial requirements while minimizing lead time variability through predictive analytics and material-specific process controls. Honyo maintains ISO 9001:2015 certification with supplementary AS9100 addenda for defense and aerospace steel components.

Start Your Project

Looking for precision laser engraving solutions for steel components? Honyo Prototype offers high-accuracy laser engraving services tailored for industrial and custom applications. Our advanced machinery ensures clean, durable markings on steel surfaces, ideal for part identification, branding, and traceability.

Contact Susan Leo at [email protected] to discuss your project requirements. With our state-of-the-art facility located in Shenzhen, we provide fast turnaround times and consistent quality for both prototypes and production runs. Trust Honyo Prototype for reliable, professional laser engraving performance.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.