Contents

Manufacturing Insight: Laser Cutting Online Quote

Accelerate Your Prototyping and Production with Precision Laser Cutting and CNC Machining

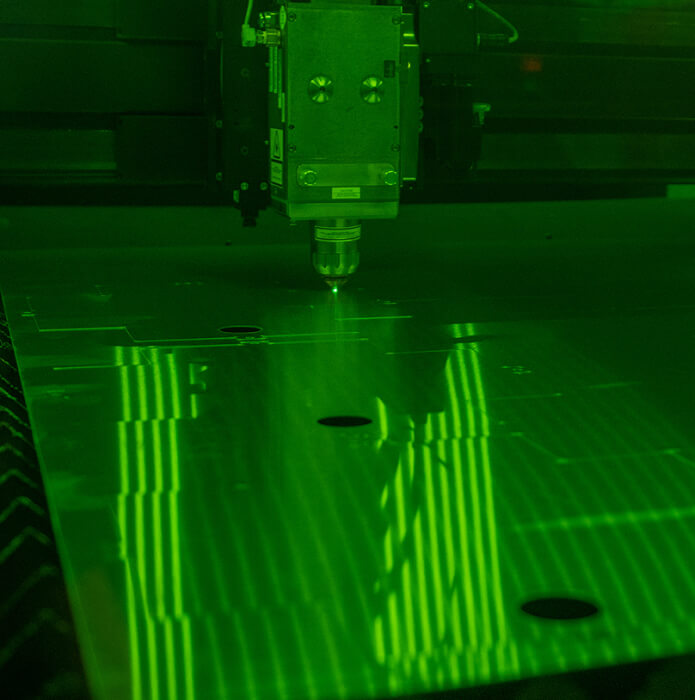

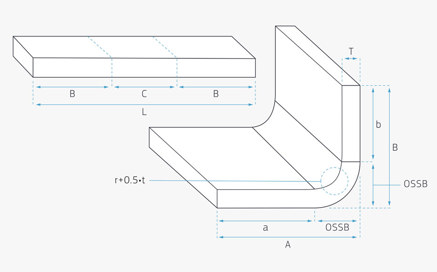

At Honyo Prototype, we understand that rapid, accurate manufacturing decisions hinge on immediate cost transparency. Our integrated CNC Machining services—encompassing 3-, 4-, and 5-axis milling, turning, and multi-axis complex part fabrication—form the backbone of our high-precision production ecosystem. Complementing this, our industrial-grade laser cutting capabilities deliver exceptional edge quality, tight tolerances (±0.1 mm), and material versatility across stainless steel, aluminum, carbon steel, and exotic alloys up to 25 mm thickness.

Eliminate quoting delays with Honyo’s Online Instant Quote system. Upload your DXF, DWG, or STEP file directly to our platform, and receive a detailed, factory-calibrated cost assessment in under 60 seconds. This tool leverages real-time production parameters, including material utilization, machine time, and finishing requirements, ensuring accuracy reflective of actual shop-floor conditions. No manual submissions, no waiting—just actionable data to streamline your RFQ process and accelerate time-to-part. Trust Honyo’s engineering-led approach to transform your designs into dimensionally reliable components with uncompromised material efficiency and accelerated turnaround.

Technical Capabilities

Laser Cutting Online Quote – Technical Specifications Overview

While laser cutting is a distinct process from milling and turning, Honyo Prototype integrates advanced 3-axis, 4-axis, and 5-axis CNC milling, CNC turning, and precision laser cutting services under a unified online quoting system. The platform is engineered for high accuracy, fast turnaround, and support for tight-tolerance components across a range of engineering materials.

Below are the key technical specifications relevant to parts requiring high-precision machining and laser cutting, including supported capabilities and material compatibility:

| Parameter | Specification |

|---|---|

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning; multi-axis mill-turning |

| Laser Cutting Compatibility | 2D and 3D laser cutting on flat and formed sheet metal; integration with CNC-machined assemblies |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) for critical features; ±0.025 mm (±0.001″) typical for milled/turned parts |

| Minimum Feature Size | 0.5 mm internal radii (milling); 0.8 mm kerf width (laser cutting, steel) |

| Surface Finish (Milling) | As-machined: 3.2 μm (125 μin); optional polishing, bead blasting, anodizing |

| Surface Finish (Laser) | Smooth cut edge; oxidation possible; post-processing available |

| Max Work Envelope (Milling) | 1000 x 600 x 500 mm (X-Y-Z) for 3-axis; reduced for 4/5-axis configurations |

| Max Turning Diameter | 300 mm; max length: 600 mm |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (6 & 6/6), PEEK, Delrin |

| Aluminum Processing | High-speed milling and laser cutting; anodizing and deburring options |

| Steel Processing | Precision milling and laser cutting up to 25 mm thickness; post-cut machining available |

| ABS & Nylon Compatibility | CNC milling only (not recommended for laser cutting due to melting risk); tight tolerance achievable |

| Lead Time (Standard) | 5–7 business days; expedited options (2–3 days) for simple geometries |

| Design File Support | STEP, IGES, X_T, SLDPRT, DWG, DXF; auto-DFA and DFM feedback in quoting tool |

| Quality Standards | ISO 9001:2015 compliant; first-article inspection (FAI) and CMM reporting available |

This integrated online quote system enables real-time pricing and manufacturability feedback for complex components requiring combinations of laser cutting and high-precision CNC operations. Material selection, tolerance requirements, and axis complexity are factored automatically to ensure accuracy and production feasibility.

From CAD to Part: The Process

Honyo Prototype delivers a streamlined laser cutting workflow engineered for precision manufacturing partners requiring rapid, reliable prototyping and low-volume production. Our process eliminates traditional quoting bottlenecks through integrated digital systems while maintaining rigorous engineering oversight. The sequence begins with CAD file submission via our secure web portal, which accepts industry-standard DXF and DWG formats with automated validation for layer integrity and unit consistency. Invalid geometries trigger immediate client notification with specific error diagnostics, preventing downstream delays.

The AI-powered quoting engine processes validated files using a statistically validated cost model incorporating 18+ parameters beyond basic material thickness. This includes dynamic calculation of kerf compensation requirements, nesting efficiency algorithms optimizing sheet utilization, edge quality grading based on material grade and thickness, and machine-specific acceleration profiles affecting cut time. Quotes are generated in under 90 seconds with full cost transparency showing material, machine time, and finishing cost breakdowns.

All quotes undergo mandatory Design for Manufacturability review by our AS9100-certified engineering team. This phase identifies critical manufacturability constraints including minimum feature sizes relative to material thickness, thermal distortion risks in complex geometries, and recommendations for tab retention strategies. Clients receive annotated DFM reports with actionable suggestions, such as adjusting internal corner radii to prevent melt accumulation in 6mm+ stainless steel. Complex geometries triggering potential tolerance stack-up issues receive personalized engineer consultation.

Production leverages our fiber laser fleet (4kW to 12kW IPG resonators) with real-time process monitoring. Each job includes first-article inspection against ASME Y14.5 geometric dimensioning standards, with CMM reports available upon request. Material traceability is maintained via QR-coded inventory tags linking to mill certificates. Secondary operations like deburring or edge rounding are integrated within our 72-hour production window for standard orders.

Final delivery utilizes our climate-controlled logistics network with real-time shipment tracking. All parts ship in ESD-safe packaging with serialized work orders matching the original DFM documentation. Typical lead time from approved quote to shipment is 3-5 business days for quantities under 50 units, with rush options available for time-critical projects. This closed-loop system ensures dimensional accuracy within ±0.1mm while reducing time-to-part by 65% compared to traditional manufacturing procurement cycles.

Material capability summary for laser cutting:

| Material Type | Thickness Range | Max Sheet Size | Tolerance Standard | Common Applications |

|---|---|---|---|---|

| Stainless Steel (304/316) | 0.5mm – 25mm | 1500 x 3000mm | ±0.1mm | Medical components, fluid systems |

| Aluminum (5052/6061) | 0.8mm – 20mm | 1500 x 3000mm | ±0.12mm | Aerospace brackets, enclosures |

| Carbon Steel (A36/1018) | 1.0mm – 25mm | 2000 x 4000mm | ±0.15mm | Industrial frames, machinery guards |

| Brass | 0.5mm – 12mm | 1200 x 2400mm | ±0.1mm | Electrical contacts, decorative elements |

Start Your Project

Get a fast and accurate online quote for your laser cutting project today.

Contact Susan Leo at [email protected] to discuss your requirements and receive expert support from our engineering team.

Our advanced laser cutting facility is located in Shenzhen, China, ensuring high precision, rapid turnaround, and competitive pricing for prototypes and production runs.

Let Honyo Prototype be your trusted partner for precision sheet metal fabrication. Reach out now to start your project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.