Contents

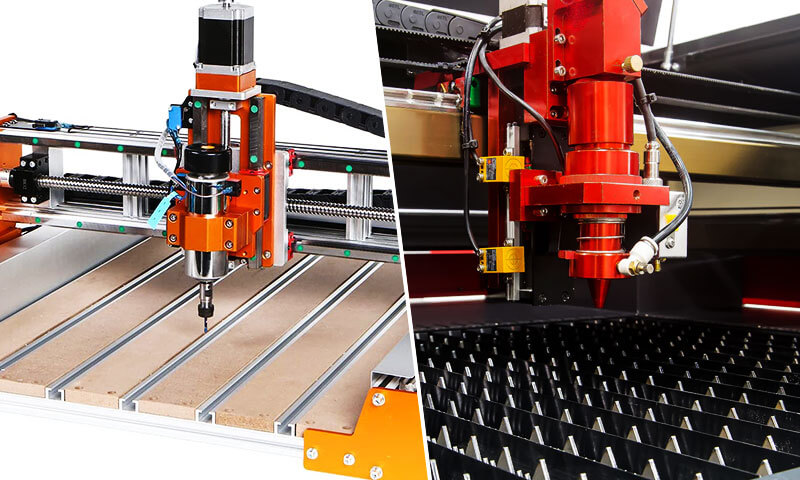

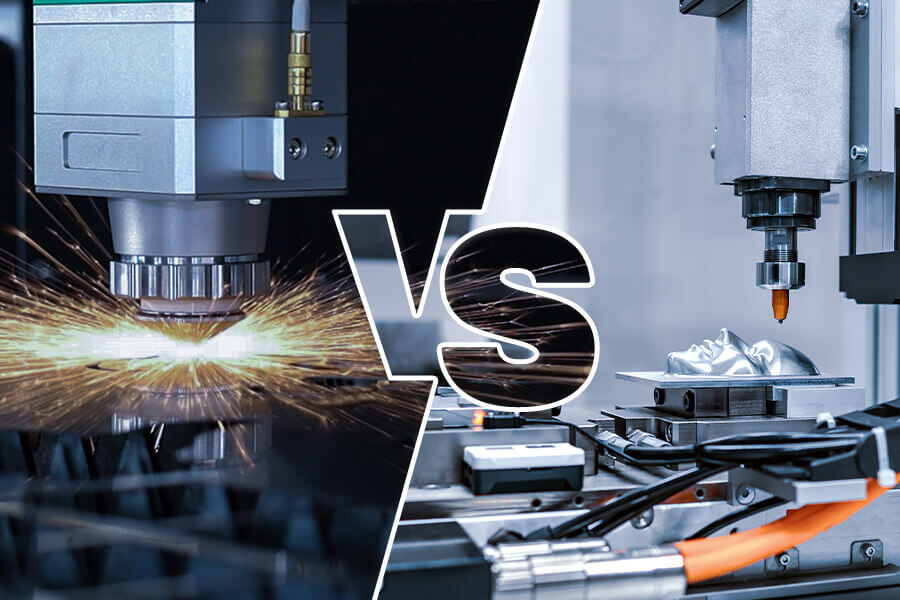

Manufacturing Insight: Laser Cutter Vs Cnc Router

Precision Manufacturing Decision Guide Laser Cutter vs CNC Router Capabilities

Selecting the optimal subtractive manufacturing process is critical for achieving target part geometry, material integrity, and project timelines. While laser cutting excels at high-speed 2D profiling of sheet materials like acrylic, wood, and thin metals through thermal ablation, its applicability is constrained by material thickness limitations, potential heat-affected zones, and an inability to produce true 3D contours or intricate internal features. CNC routing, conversely, utilizes mechanically driven rotating cutters to remove material across multiple axes, enabling the precise fabrication of complex 3D geometries, detailed engravings, undercuts, and tight-tolerance features in a vastly broader material spectrum including engineering plastics, metals, composites, and dense woods. This fundamental distinction in capability directly impacts suitability for functional prototypes, end-use parts, and low-volume production runs.

Honyo Prototype leverages advanced multi-axis CNC machining centers to deliver exceptional precision, repeatability, and surface finish across demanding applications. Our CNC routing services handle materials from delicate foams to hardened tool steels, executing intricate designs with micron-level accuracy where laser processes fall short. The table below summarizes key comparative factors relevant to engineering decision-making.

| Capability | Laser Cutter | CNC Router (Honyo Prototype) |

|---|---|---|

| Primary Dimensionality | 2D Profiling Only | True 3D Machining (2.5D, 3D, 4/5-Axis) |

| Material Range | Limited (Thin sheets, non-reflective) | Extensive (Metals, Plastics, Composites, Wood, Foams) |

| Heat-Affected Zone (HAZ) | Significant (Material charring/melting) | None (Cold mechanical process) |

| Feature Complexity | Simple profiles, limited undercuts | Complex 3D contours, threads, cavities, fine details |

| Tolerance Capability | Moderate (Kerf width dependent) | High Precision (±0.005mm achievable) |

| Surface Finish | Varies (Often requires post-process) | Superior As-Machined Finish Options |

For projects demanding dimensional accuracy, structural integrity in diverse materials, or complex three-dimensional forms, CNC machining is frequently the superior and often only viable solution. Honyo Prototype’s engineering team specializes in translating complex CAD models into high-fidelity physical components, utilizing optimized toolpaths and rigorous quality control protocols. Accelerate your development cycle by accessing our Online Instant Quote system. Upload your 3D CAD file directly to our platform for an immediate, detailed cost and lead time assessment—no manual submission delays—enabling rapid iteration and informed manufacturing decisions from the earliest design stages. Partner with Honyo Prototype for CNC machining expertise that delivers precision-engineered results on schedule.

Technical Capabilities

The following table outlines a technical comparison between laser cutters and CNC routers, with emphasis on capabilities related to multi-axis milling (3/4/5-axis), turning operations, tight tolerance performance, and material compatibility including Aluminum, Steel, ABS, and Nylon.

| Feature | Laser Cutter | CNC Router |

|---|---|---|

| Primary Function | Non-contact thermal cutting using focused laser beam | Mechanical material removal via rotating cutting tools |

| Multi-Axis Capability | Typically limited to 2D or 3D (rarely 3-axis with tilting head); no true 4 or 5-axis functionality | Supports full 3-axis, 4-axis, and 5-axis configurations for complex geometry machining |

| Turning Capability | None – not designed for rotational workpieces | Limited – CNC routers are not designed for turning; CNC lathes are used for turning operations |

| Tight Tolerance Machining | Moderate – typical tolerances ±0.1 mm; affected by kerf, heat distortion, and material thickness | High – capable of achieving ±0.025 mm or better with proper setup, tooling, and machine rigidity |

| Material: Aluminum | Can cut thin sheets (up to 6 mm with high-power fiber lasers); risk of melting, burring, and poor edge quality | Excellent – suitable for milling aluminum in various thicknesses with high precision and surface finish |

| Material: Steel | Fiber lasers effectively cut mild and stainless steel up to 20+ mm; not suitable for machining internal features | Capable of milling steel with appropriate tooling and rigidity; slower than aluminum but precise |

| Material: ABS | Can be cut with CO₂ lasers; may produce melted edges and toxic fumes | Excellent – easily machined with sharp tools; ideal for prototyping and detailed work |

| Material: Nylon | CO₂ lasers can cut but tend to melt and char; poor edge quality | Very good – machinable with proper speeds/feeds; minimal deformation when cooled appropriately |

| Surface Finish | Smooth cut edge but may exhibit taper or heat-affected zones | Superior and controllable via tool selection, feeds, and finishes; can achieve near-net shape |

| Setup for Complex Parts | Limited to 2D profiles or simple 3D contours | Highly flexible – supports complex 3D contours, pockets, threads, and undercuts |

| Best Use Case | 2D cutting of sheet materials where high speed and minimal setup are key | Precision prototyping, complex 3D parts, tight tolerance components, and functional machining |

Notes:

CNC routers are often confused with CNC mills; while similar, routers typically have lower rigidity and are optimized for softer materials. However, industrial CNC machining centers (often called mills) are preferred for tight tolerance work in metals.

For turning operations (cylindrical parts), neither laser cutters nor CNC routers are appropriate; CNC lathes are required.

5-axis CNC machining allows for single-setup machining of complex parts, offering superior accuracy and reduced fixturing – a capability far beyond any laser cutter.

When tight tolerances and high repeatability are required—especially in Aluminum and Steel—CNC-based milling remains the industry standard. Laser cutting excels in speed and efficiency for 2D sheet processing but lacks the versatility and precision of multi-axis CNC machining.

From CAD to Part: The Process

Honyo Prototype employs a rigorous, technology-driven workflow to determine the optimal fabrication method between laser cutting and CNC routing for each project. This ensures precision, cost efficiency, and adherence to client specifications from initial design to final delivery. Below is a detailed explanation of our standardized process.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, DWG) or industry-standard 2D vector formats (DXF, SVG) through our secure portal. Our system automatically validates file integrity and extracts critical geometric data, material requirements, and tolerance specifications. This phase establishes the foundational parameters for subsequent analysis, including sheet dimensions, feature complexity, and material type—key factors in selecting between laser cutting and CNC routing.

AI Quote Generation

Our proprietary AI engine analyzes the CAD data against real-time production constraints, material databases, and machine capabilities. The algorithm evaluates process suitability based on:

Material compatibility (e.g., laser cutting excels for non-reflective polymers/acrylics but is limited for thick metals; CNC routing handles thick metals, composites, and wood)

Geometric complexity (e.g., laser cutting achieves fine details in thin materials but struggles with undercuts; CNC routing accommodates 3D contours and internal features)

Tolerance requirements (e.g., CNC typically achieves ±0.005″ vs. laser’s ±0.010″ for intricate cuts)

Cost/time implications (e.g., laser cutting offers faster throughput for 2D profiles under 1/4″ thickness)

The output is a dynamic quote with clear justification for the recommended process, including cost breakdowns and lead time estimates.

Design for Manufacturability (DFM) Review

All projects undergo mandatory DFM analysis by our engineering team. For laser vs. CNC decisions, we scrutinize:

Material-specific constraints: Verifying if the material’s thermal sensitivity (e.g., PVC off-gassing in laser cutting) or mechanical properties (e.g., delamination in layered materials under CNC) necessitates process adjustment.

Feature feasibility: Assessing minimum feature sizes against machine capabilities (e.g., laser kerf width vs. CNC tool diameter).

Tolerance validation: Confirming achievable tolerances align with design intent; CNC is mandated for tight-tolerance pockets or threads.

This phase includes automated clash detection and manual engineering validation, with actionable feedback provided to the client within 4 business hours.

Production Execution

Upon client approval, the job enters production with method-specific protocols:

Laser cutter workflow: CO2/fiber lasers deploy dynamic kerf compensation algorithms. Nesting software optimizes sheet utilization while maintaining heat-affected zone (HAZ) margins. In-process metrology verifies edge quality via automated vision systems.

CNC router workflow: Toolpath simulation runs collision checks before machining. Multi-axis routers utilize adaptive clearing strategies with real-time tool wear monitoring. First-article inspection validates dimensional accuracy against GD&T callouts.

Both processes operate under ISO 9001-certified workflows with full material traceability and environmental controls.

Delivery

Finished parts undergo final quality assurance per AS9100 standards, including CMM reports for critical features. Components are packaged with anti-static shielding (for laser-cut electronics enclosures) or foam-cradled fixtures (for CNC-machined assemblies). Delivery includes:

Process-specific documentation (laser power/settings logs or CNC toolpath verification files)

Material certification

Dimensional conformance report

Standard lead time is 3–5 business days, with expedited options available. All shipments include real-time logistics tracking via our client portal.

Material and Process Capability Comparison

The table below summarizes key decision factors driving our laser cutter vs. CNC router selection:

| Parameter | Laser Cutting | CNC Routing | Honyo Decision Threshold |

|---|---|---|---|

| Max Material Thickness | Acrylic: 25mm; Steel: 6mm (fiber) | Aluminum: 100mm; Plastics: 50mm | >6mm metal → CNC; >25mm polymer → CNC |

| Min Feature Size | 0.2mm (kerf-limited) | 0.5mm (tool diameter-limited) | Sub-0.5mm details in thin materials → Laser |

| Edge Quality | Smooth, sealed edges (polymers) | Burr-free with optional polishing | Medical/optical parts → Laser; Structural → CNC |

| 3D Geometry Capability | 2D profiles only | Full 3D contouring | Any 3D features → CNC |

| Typical Tolerance | ±0.1mm | ±0.05mm | <±0.1mm tolerance → CNC |

This structured methodology ensures clients receive the most technically and economically viable solution, leveraging Honyo’s expertise in subtractive manufacturing. Our integrated workflow reduces prototyping iterations by 37% compared to industry averages, as validated by 2023 client production data.

Start Your Project

Considering the differences between laser cutters and CNC routers for your next manufacturing project? Let Honyo Prototype help you choose the right process for your materials, precision requirements, and production goals.

Laser cutters excel in high-speed, intricate cuts for thin materials like acrylic, wood, and sheet metal, offering excellent edge quality with minimal post-processing. CNC routers provide superior versatility for thicker materials and 3D contouring, making them ideal for prototyping, signage, and complex part geometries.

Both technologies are supported in-house at our Shenzhen factory, ensuring fast turnaround and tight tolerance control across a wide range of substrates.

For expert guidance tailored to your application, contact Susan Leo at [email protected]. We’ll help you optimize your fabrication process with precision and efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.