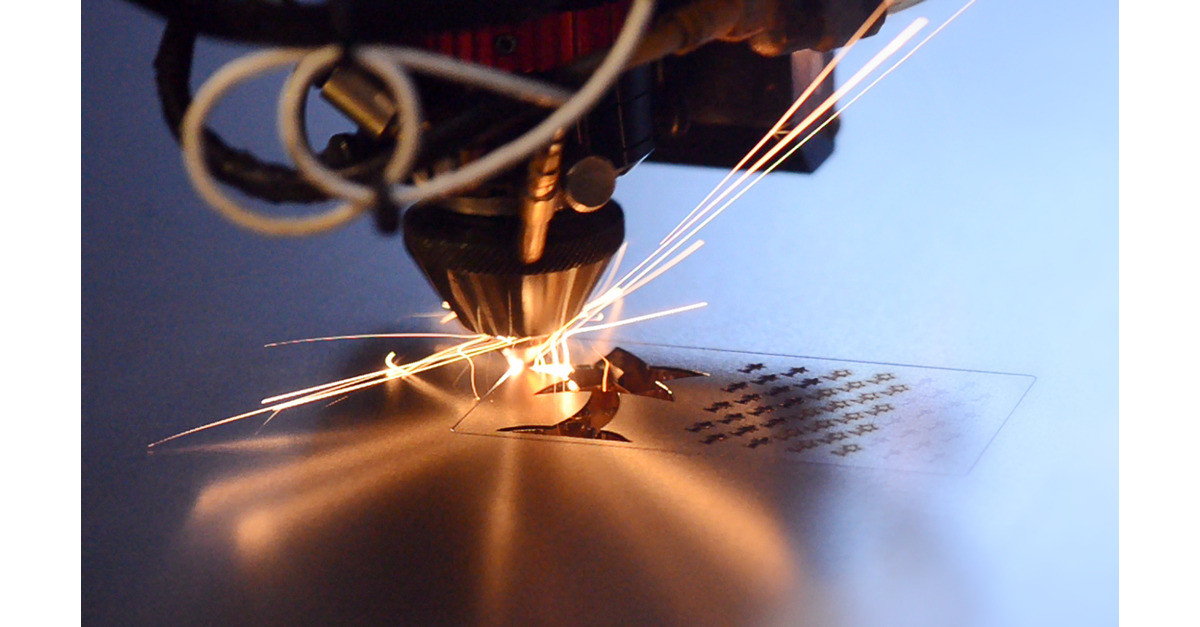

Introduction: Navigating the Global Market for laser cutter services

In today’s rapidly evolving manufacturing landscape, sourcing reliable laser cutter services can be a daunting challenge for B2B buyers, especially when navigating the complexities of international markets. The demand for precision and customization in cutting materials such as metals, plastics, and wood is growing, making it essential for businesses to identify suppliers that not only meet quality standards but also align with their specific production needs. This comprehensive guide delves into the multifaceted world of laser cutting services, covering various types, applications, and critical factors such as supplier vetting, pricing, and delivery logistics.

Designed specifically for international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including industrial powerhouses such as Germany and emerging markets like Vietnam—this guide empowers you to make informed purchasing decisions. By providing insights into the latest technology trends, material capabilities, and case studies from diverse industries, we equip you with the knowledge necessary to navigate the global market effectively. Whether you are seeking cost-effective solutions for prototype development or high-volume production runs, understanding the nuances of laser cutter services will enhance your competitive edge and streamline your procurement process. Explore how to optimize your sourcing strategy and establish partnerships that drive your business forward.

Understanding laser cutter services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Laser Cutting | Utilizes fiber and CO2 lasers, capable of cutting thick metals up to 4 inches. | Aerospace, automotive, construction, and machinery fabrication. | Pros: High precision, versatile material options. Cons: Limited to material thickness. |

| Plastic Laser Cutting | Specialized in cutting various plastics, including acrylic and foam. | Consumer products, packaging, signage, and prototypes. | Pros: Clean cuts, minimal waste, quick turnaround. Cons: Limited to specific plastic types. |

| Wood Laser Cutting | Focuses on cutting various wood types with fine detail. | Furniture, decorative items, and architectural models. | Pros: High detail, suitable for intricate designs. Cons: Not suitable for high-volume metalwork. |

| Acrylic Laser Cutting | Offers clear and colored acrylic cutting, emphasizing aesthetics. | Displays, signage, and art installations. | Pros: Excellent finish, versatile applications. Cons: Can be more expensive than standard plastic cutting. |

| Custom Laser Engraving | Provides engraving services on various materials, enhancing branding. | Promotional products, awards, and custom gifts. | Pros: Adds value through personalization, versatile. Cons: Slower process compared to cutting. |

What Are the Key Characteristics of Metal Laser Cutting Services?

Metal laser cutting services are characterized by their ability to cut through various types of metals, including stainless steel, aluminum, and copper, using advanced laser technology. This method is ideal for industries such as aerospace and automotive, where precision and durability are paramount. When considering metal laser cutting, buyers should evaluate the thickness of the materials they need to process, as this service typically accommodates materials up to 4 inches thick. Additionally, understanding the types of metals that can be cut will help in selecting the right service provider.

How Does Plastic Laser Cutting Differ from Other Services?

Plastic laser cutting is tailored for a wide range of plastic materials, including acrylic and rubber. This service is especially valuable in consumer product manufacturing and signage, where clean cuts and minimal waste are critical. Businesses should consider the specific type of plastic they intend to use, as not all laser cutting services handle every plastic material. The turnaround time is generally quick, making it an excellent choice for prototypes and small batch productions.

Why Choose Wood Laser Cutting for Your Projects?

Wood laser cutting is recognized for its precision and ability to create intricate designs in various wood types. This service is particularly beneficial for industries focusing on furniture design, decorative items, and architectural models. Buyers should consider the type of wood required and whether the designs demand high detail. While wood cutting is effective for artistic applications, it may not be suitable for high-volume metal production.

What Are the Benefits of Acrylic Laser Cutting?

Acrylic laser cutting services provide an exceptional finish and are available in both clear and colored options. This method is widely used in displays, signage, and art installations, where aesthetics play a crucial role. When choosing acrylic laser cutting, businesses should assess the cost implications, as this service can be pricier than standard plastic cutting. However, the visual appeal and quality of the finished product often justify the investment.

How Can Custom Laser Engraving Enhance Your Brand?

Custom laser engraving services allow businesses to personalize products, enhancing branding and customer engagement. This service is applicable across various materials and is ideal for promotional items, awards, and custom gifts. Companies should consider the engraving speed and the material compatibility when selecting a service provider. While the process may take longer than standard cutting, the added value of customization can significantly boost brand recognition and customer loyalty.

Key Industrial Applications of laser cutter services

| Industry/Sector | Specific Application of laser cutter services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | High accuracy and repeatability in producing complex parts | Certification for aerospace standards and materials |

| Automotive | Prototype and production of parts | Rapid prototyping and cost-effective production runs | Material compatibility and lead times |

| Electronics | Custom enclosures and circuit boards | Enhanced design flexibility and reduced time to market | Sourcing advanced materials and ensuring compliance |

| Architecture & Design | Decorative elements and prototypes | Unique designs with intricate details and fast turnaround | Design file formats and finishing options |

| Medical Devices | Surgical instruments and device housings | High precision and biocompatibility of materials | Regulatory compliance and material traceability |

How is Laser Cutting Used in Aerospace Manufacturing?

In the aerospace industry, laser cutter services are crucial for the production of precision components such as brackets, frames, and other intricate parts. These components often require high accuracy and tight tolerances to ensure safety and performance in flight. The ability to cut various materials, including lightweight alloys and composites, allows manufacturers to optimize their designs while minimizing weight. International buyers must consider certification for aerospace standards, ensuring that the suppliers can meet rigorous quality and safety regulations.

What Role Does Laser Cutting Play in the Automotive Sector?

The automotive industry benefits significantly from laser cutting services for both prototype development and mass production of parts. Laser cutting allows for rapid prototyping, enabling manufacturers to iterate designs quickly and efficiently. This process reduces time to market and lowers production costs, making it ideal for competitive automotive landscapes. Buyers should focus on material compatibility with automotive applications and the lead times for parts, especially when sourcing from international suppliers to ensure timely project completion.

How is Laser Cutting Transforming Electronics Manufacturing?

In electronics, laser cutting services are employed to create custom enclosures and printed circuit boards (PCBs). The precision offered by laser cutting is essential for producing intricate designs and ensuring proper fit and function of electronic components. This technology facilitates design flexibility, allowing for rapid adjustments and modifications. Buyers should prioritize sourcing advanced materials that meet electrical standards and ensuring compliance with international regulations, particularly in regions with stringent electronics manufacturing guidelines.

In What Ways Does Laser Cutting Enhance Architectural Design?

Architects and designers utilize laser cutter services to create decorative elements and detailed prototypes. The precision of laser cutting allows for unique designs that can incorporate intricate patterns and shapes, enhancing aesthetic appeal. Quick turnaround times enable designers to present prototypes to clients faster, facilitating better decision-making. Buyers need to provide accurate design file formats and consider various finishing options to achieve the desired look and feel in their projects.

How is Laser Cutting Beneficial in Medical Device Manufacturing?

Laser cutting services are essential in the medical device sector for producing surgical instruments and device housings with high precision. The ability to work with biocompatible materials ensures that devices meet health and safety standards. Laser cutting reduces the risk of human error and enhances the overall quality of the products. Buyers in this field must consider regulatory compliance and material traceability, ensuring that all components meet the necessary health regulations in their respective markets.

3 Common User Pain Points for ‘laser cutter services’ & Their Solutions

Scenario 1: Navigating Material Compatibility Issues

The Problem:

B2B buyers often face challenges when selecting the right materials for laser cutting. Different projects may require various materials, such as metals, plastics, or wood, and each material has unique properties and cutting requirements. For instance, a buyer in the aerospace industry may need intricate parts made from titanium, while a retail company may require high-quality acrylic displays. Misunderstanding material compatibility can lead to subpar results, increased costs, and delays in production, creating frustration and potential revenue loss.

The Solution:

To overcome material compatibility issues, buyers should first conduct thorough research on the specific material properties and their implications for laser cutting. Engaging with suppliers who offer detailed material guides can be invaluable. Buyers should also utilize instant quoting engines that allow for material selection based on project specifications. For example, platforms like Xometry provide extensive material lists and instant quotes based on CAD files, allowing buyers to select the best-suited material for their needs. Establishing a clear communication channel with the supplier can also help in understanding the material’s cutting limitations and capabilities. Finally, requesting samples or test cuts can help ensure that the chosen material meets the project’s requirements before committing to larger orders.

Scenario 2: Overcoming Lead Time and Delivery Concerns

The Problem:

In today’s fast-paced market, lead time is a critical factor for B2B buyers relying on laser cutter services. Companies often face pressure to deliver products quickly, whether for prototypes, urgent orders, or client demands. Delays in the laser cutting process can cascade into broader supply chain issues, affecting timelines and customer satisfaction. Buyers may find it challenging to determine which service providers can meet their tight deadlines without sacrificing quality.

The Solution:

To mitigate lead time concerns, buyers should prioritize laser cutting services that specialize in rapid prototyping and quick turnaround times. When selecting a provider, look for companies that guarantee same-day or next-day delivery and have a transparent order tracking system. Services like Ponoko offer same-day delivery for custom parts, which can significantly reduce downtime. Additionally, establishing a long-term relationship with a reliable supplier can lead to prioritized service and better communication during urgent requests. It’s also beneficial to have backup suppliers on hand in case of unexpected delays, ensuring that production schedules remain on track. Lastly, clearly communicating deadlines and project requirements with the service provider can help align expectations and facilitate timely delivery.

Scenario 3: Managing Cost Overruns and Budget Constraints

The Problem:

B2B buyers often operate under strict budget constraints, making it essential to manage costs effectively when utilizing laser cutting services. The complexity of designs, choice of materials, and additional services like finishing can lead to unexpected expenses. Buyers may struggle to obtain accurate quotes, resulting in cost overruns that jeopardize project profitability and cause friction with stakeholders.

The Solution:

To manage costs effectively, buyers should leverage platforms that provide transparent pricing models, allowing for comprehensive cost breakdowns. Utilizing instant quoting tools, like those from Xometry, enables buyers to receive accurate, real-time estimates based on their specifications. It’s advisable to define project requirements clearly, including tolerances and material choices, to avoid surprises. Additionally, consider bulk ordering or establishing contracts for ongoing projects to negotiate better rates. Regularly reviewing and comparing quotes from multiple suppliers can also help identify the best value without compromising quality. Finally, engaging in regular budget reviews throughout the project lifecycle can help track expenses and make necessary adjustments to stay within financial limits. By adopting a proactive approach to budgeting, buyers can significantly reduce the risk of cost overruns while maximizing the value of laser cutting services.

Strategic Material Selection Guide for laser cutter services

When selecting materials for laser cutting services, understanding the properties, advantages, and limitations of each material is crucial for international B2B buyers. Below, we analyze four common materials used in laser cutting—steel, acrylic, wood, and rubber—highlighting their key characteristics and considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Laser Cutting?

Steel is a widely used material in laser cutting due to its strength and versatility. It boasts high tensile strength, excellent durability, and good corrosion resistance, particularly when using stainless steel variants. Steel can withstand high temperatures, making it suitable for applications requiring heat resistance.

Pros and Cons: The primary advantage of steel is its durability and structural integrity, making it ideal for heavy-duty applications like automotive and construction. However, it can be more expensive than other materials and may require additional surface treatments to enhance corrosion resistance. The complexity of manufacturing with steel can also increase costs, especially for intricate designs.

Impact on Application: Steel is commonly used in automotive parts, machinery, and structural components. Its compatibility with various media, including welding and painting, makes it a preferred choice in many industries.

Considerations for International Buyers: Buyers must consider compliance with international standards such as ASTM for the U.S. and DIN for Europe. Understanding local regulations regarding material sourcing and environmental impact is also essential.

How Does Acrylic Perform in Laser Cutting Applications?

Acrylic is a popular choice for laser cutting due to its clarity and aesthetic appeal. It offers good impact resistance and is lightweight, making it suitable for a variety of applications, including signage and displays.

Pros and Cons: The key advantage of acrylic is its versatility and ease of fabrication, allowing for intricate designs and smooth finishes. However, it can be prone to scratching and may not be as durable as metals. Additionally, acrylic can be more expensive than other plastics, affecting overall project budgets.

Impact on Application: Acrylic is often used in applications requiring transparency, such as display cases and lighting fixtures. Its compatibility with various colors and finishes enhances its appeal in design-focused industries.

Considerations for International Buyers: Buyers should be aware of the differing quality standards for acrylic across regions. Compliance with safety regulations, particularly in signage and consumer products, is crucial.

What Are the Advantages of Using Wood in Laser Cutting?

Wood is a traditional material that remains popular in laser cutting due to its natural aesthetic and ease of manipulation. It is available in various types, each with unique properties, such as hardness and grain patterns.

Pros and Cons: The primary advantage of wood is its availability and cost-effectiveness, making it suitable for prototypes and decorative items. However, wood can be inconsistent in quality, and its susceptibility to moisture can limit its application in outdoor environments. Additionally, the cutting process may produce smoke and residue, requiring proper ventilation.

Impact on Application: Wood is commonly used in furniture, crafts, and architectural elements. Its natural finish and ability to be stained or painted make it a favored choice in the home décor sector.

Considerations for International Buyers: Buyers should consider sourcing wood from sustainable suppliers to meet environmental regulations. Compliance with local forestry standards and certifications can also impact procurement decisions.

What Are the Key Features of Rubber in Laser Cutting?

Rubber is often used in applications requiring flexibility and resilience. It is available in various formulations, including natural and synthetic types, each offering different properties such as temperature resistance and durability.

Pros and Cons: The main advantage of rubber is its excellent shock absorption and flexibility, making it ideal for gaskets and seals. However, it can be less durable than other materials and may degrade over time when exposed to certain chemicals or UV light.

Impact on Application: Rubber is widely used in automotive, aerospace, and industrial applications where flexibility and durability are critical. Its compatibility with various adhesives and coatings enhances its usability.

Considerations for International Buyers: Buyers must ensure compliance with international standards for rubber materials, particularly in industries like automotive and aerospace, where safety and performance are paramount.

Summary Table of Material Selection for Laser Cutting

| Material | Typical Use Case for laser cutter services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, machinery | High durability and strength | Higher cost, complex manufacturing | High |

| Acrylic | Signage, displays | Versatile, aesthetic appeal | Prone to scratching, higher cost | Medium |

| Wood | Furniture, crafts | Cost-effective, natural aesthetic | Moisture susceptibility, quality inconsistency | Low |

| Rubber | Gaskets, seals | Excellent flexibility and shock absorption | Less durable, potential chemical degradation | Medium |

This guide provides essential insights into material selection for laser cutting services, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for laser cutter services

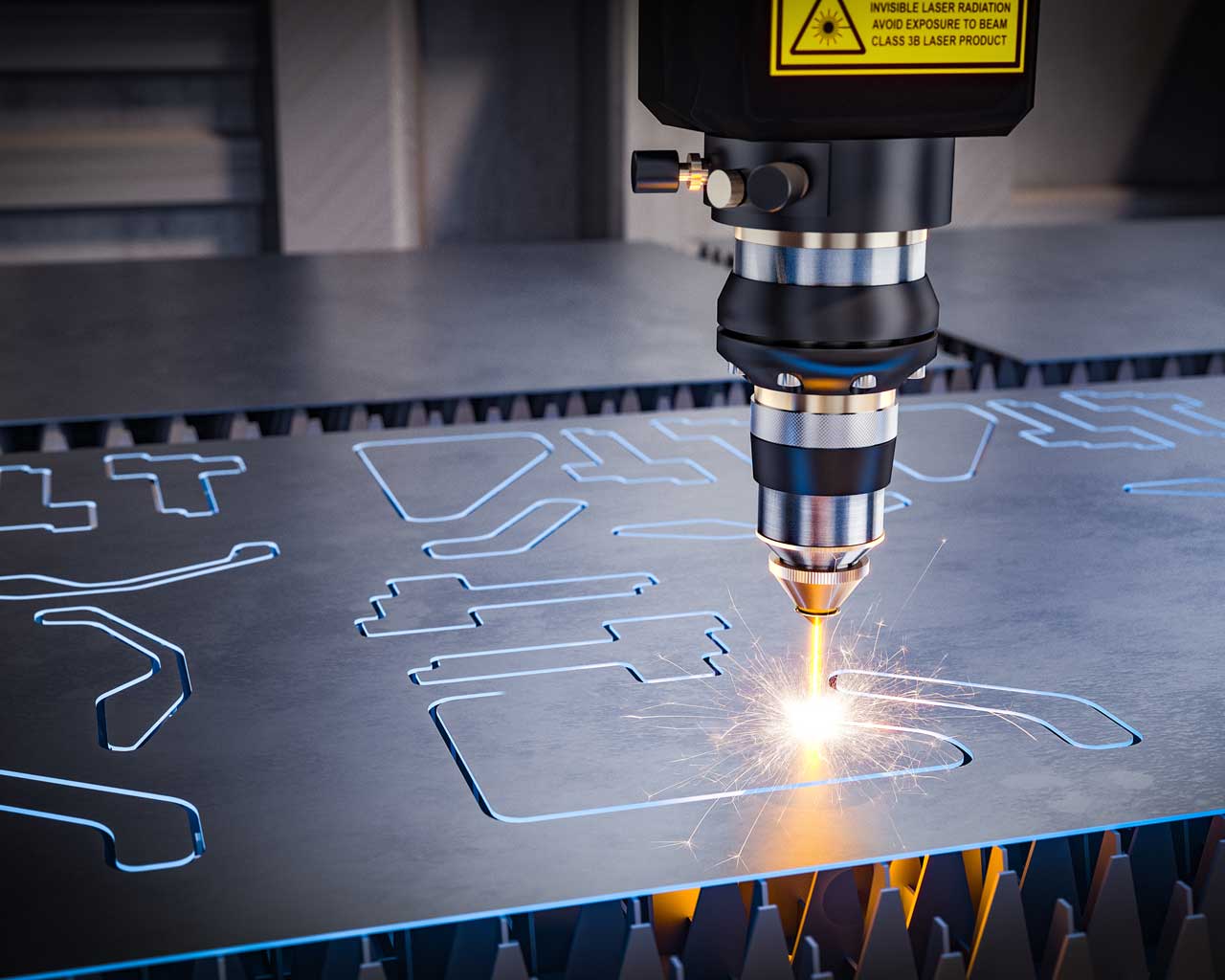

What Are the Main Stages in the Manufacturing Process of Laser Cutter Services?

Laser cutting services encompass a series of well-defined manufacturing processes that ensure precision and quality in the final products. The primary stages of manufacturing typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting and preparing the raw materials, which can include metals, plastics, and wood. Suppliers often provide detailed specifications on material types, thicknesses, and grades to ensure compatibility with laser cutting technology. The material is then cut into manageable sheets or blocks, ready for the laser cutting operation.

-

Forming: In this stage, the actual laser cutting occurs. Advanced laser cutting machines use either CO2 or fiber lasers, depending on the material type and desired precision. The laser beam is focused on the material to achieve clean cuts with minimal kerf. Depending on the design specifications, additional processes like engraving or marking may also take place during this stage.

-

Assembly: For projects requiring multiple components, the assembly process follows cutting. This involves fitting together the laser-cut parts, which may require additional techniques such as welding, fastening, or adhesive bonding. Precision during assembly is critical, especially for complex parts that must align perfectly.

-

Finishing: The final stage involves applying surface treatments to enhance aesthetics and durability. Common finishing processes include sanding, painting, anodizing, or applying protective coatings. This stage not only improves the product’s appearance but also adds value by increasing resistance to wear and corrosion.

How Do Quality Assurance Protocols Enhance Laser Cutting Services?

Quality assurance (QA) is integral to the manufacturing of laser-cut products, ensuring that they meet international and industry-specific standards. Key quality assurance practices typically include adherence to ISO 9001 standards, which focus on quality management systems, and additional certifications such as CE marking or API standards relevant to specific industries.

-

International Standards: ISO 9001 establishes a framework for maintaining quality in processes, emphasizing continuous improvement and customer satisfaction. Companies seeking to engage in international trade, especially in regions like Africa, South America, the Middle East, and Europe, benefit from ISO certification as it reassures buyers of consistent quality.

-

Quality Control Checkpoints: The QA process often includes several checkpoints to monitor quality throughout production:

– Incoming Quality Control (IQC): This initial check ensures that raw materials meet specified criteria before production begins.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to verify that processes are being followed and that products meet quality standards.

– Final Quality Control (FQC): After production, a thorough inspection ensures that the finished products conform to design specifications and quality requirements.

What Common Testing Methods Are Used in Laser Cutting Services?

Testing methods play a vital role in ensuring that laser-cut products are fit for purpose and meet the required specifications. Common testing methods include:

- Dimensional Accuracy Testing: This involves measuring the dimensions of cut parts to ensure they adhere to specified tolerances. Precision is often measured in millimeters or inches, with standards typically ranging from ±0.003 inches (0.08 mm) for intricate parts.

- Material Integrity Testing: Tests such as tensile strength and hardness assessments help verify that the materials used can withstand operational stresses.

- Surface Finish Testing: Depending on the application, the surface finish may be critical. Testing methods may include visual inspections and measurements of surface roughness.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control measures of their suppliers to mitigate risks associated with product quality. Here are some strategies for effective verification:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s quality management practices firsthand. Audits can help identify potential weaknesses in the manufacturing process and ensure compliance with required standards.

-

Quality Reports and Certifications: Requesting documentation of quality control processes, such as ISO 9001 certification or results from quality testing, provides insight into a supplier’s commitment to quality. Regularly updated quality reports can also demonstrate ongoing compliance.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. These services can perform inspections at various stages of production, ensuring adherence to specified standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances that can differ significantly across regions. Key considerations include:

-

Understanding Local Regulations: Countries may have specific regulations regarding product safety and quality, such as CE marking in Europe or API standards in the oil and gas industry. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary globally. For instance, European buyers may have stringent quality expectations compared to counterparts in other regions. This necessitates clear communication with suppliers about quality standards and specifications.

-

Logistics and Shipping Considerations: International shipping can complicate quality assurance. Buyers should ensure that quality remains consistent throughout transportation and that products arrive in a condition that meets agreed-upon standards.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices in laser cutting services is essential for B2B buyers. By leveraging these insights, buyers can make informed decisions, ensuring they partner with reliable suppliers that deliver high-quality products tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘laser cutter services’

The purpose of this guide is to equip B2B buyers with a structured approach for sourcing laser cutter services effectively. By following these steps, you will ensure that your procurement process is thorough, leading to high-quality results that meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing laser cutting services. Consider factors such as material types, thicknesses, tolerances, and the complexity of designs. Providing detailed specifications will help potential suppliers understand your needs and avoid miscommunications later in the process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in laser cutting services. Look for companies with a proven track record in your industry and regions of interest, such as Africa, South America, the Middle East, and Europe. Pay attention to their online presence, customer reviews, and case studies to gauge their reliability and service quality.

Step 3: Evaluate Supplier Capabilities

Before making a decision, assess each supplier’s capabilities. Confirm that they possess the appropriate technology (fiber lasers, CO2 lasers, etc.) to meet your material and design requirements. Additionally, inquire about their production capacity, lead times, and whether they can handle both prototype and large-scale production.

Step 4: Request Quotes and Compare Pricing

Once you have narrowed down your options, request quotes from multiple suppliers. Ensure that the quotes include all relevant costs, such as material, labor, shipping, and any additional fees. Comparing pricing will help you identify the best value while ensuring that you are not compromising on quality.

Step 5: Verify Certifications and Compliance

It’s essential to verify that potential suppliers meet relevant industry certifications and compliance standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. This step is crucial for ensuring that the supplier adheres to international standards, especially when sourcing from different regions.

Step 6: Assess Quality Control Processes

Inquire about the quality control measures each supplier employs. A robust quality assurance process is vital for ensuring that the final products meet your specifications. Ask about their inspection protocols, testing methods, and how they handle errors or defects in production.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Ensure that your chosen supplier has established protocols for updates, feedback, and issue resolution. Regular communication will help you stay informed about project status and enable quick adjustments if necessary.

By following this checklist, you will be better prepared to select a laser cutter service provider that aligns with your operational requirements and business goals, ultimately enhancing your manufacturing processes.

Comprehensive Cost and Pricing Analysis for laser cutter services Sourcing

What Are the Key Cost Components of Laser Cutter Services?

When sourcing laser cutter services, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The choice of material significantly impacts costs. Metals like stainless steel and aluminum typically incur higher costs compared to plastics or wood. For instance, high-grade metals and specialized plastics may require premium pricing due to their properties and availability.

-

Labor: Skilled labor is necessary for operating laser cutting machines and performing quality checks. Labor costs can vary depending on the region, with countries in Europe generally having higher labor costs compared to regions in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to the facilities, utilities, and equipment maintenance. Efficiently managed operations can help reduce these costs, thereby benefiting the buyer.

-

Tooling: Initial setup and tooling costs can influence the overall pricing structure, particularly for custom parts requiring unique configurations.

-

Quality Control: Rigorous QC processes ensure that the final products meet the required specifications, which can add to the cost but is crucial for maintaining product integrity.

-

Logistics: Shipping costs, especially for international orders, can add significant expenses. Understanding Incoterms can help buyers negotiate better shipping arrangements.

-

Margin: Suppliers typically add a margin to cover their risks and profit objectives. This can fluctuate based on market conditions, competition, and the supplier’s operational efficiency.

How Do Price Influencers Affect Laser Cutter Services?

Several factors can influence pricing in laser cutting services.

-

Volume/MOQ: Larger orders often benefit from economies of scale, resulting in lower per-unit costs. Negotiating minimum order quantities (MOQs) can yield better pricing, especially for high-volume needs.

-

Specifications and Customization: Highly customized parts may come with additional costs due to increased design time and setup requirements. Standard designs usually have lower costs due to pre-existing processes.

-

Material Choice: The cost of raw materials fluctuates based on market demand and availability. Buyers should consider stable and readily available materials to control costs.

-

Quality and Certifications: Suppliers with industry certifications (e.g., ISO) may charge a premium for their services, reflecting their commitment to quality and reliability.

-

Supplier Factors: The supplier’s location, reputation, and capacity can influence pricing. Local suppliers may offer lower shipping costs but could lack the specialized capabilities of larger international firms.

-

Incoterms: Understanding terms of trade can help manage logistics costs effectively. Buyers should clarify who bears the risk and cost at each shipping stage.

What Are the Best Buyer Tips for Cost-Efficiency in Laser Cutting Services?

To optimize costs when sourcing laser cutter services, buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, especially for larger volumes or long-term contracts. Leverage competition among suppliers to achieve better rates.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial pricing, assess the long-term costs associated with maintenance, logistics, and potential delays. A cheaper service may lead to higher costs down the line.

-

Understand Pricing Nuances for International Buyers: When sourcing from different regions, consider the impact of tariffs, taxes, and currency fluctuations on the final price. Familiarize yourself with local market conditions and supplier capabilities in regions like Africa, South America, the Middle East, and Europe.

-

Request Quotes from Multiple Suppliers: Always gather multiple quotes to compare prices and services. This not only helps in identifying the best deal but also provides leverage during negotiations.

-

Stay Informed on Market Trends: Keeping abreast of material prices and technological advancements in laser cutting can provide insights into potential cost savings and innovations that could benefit your projects.

Disclaimer on Indicative Prices

The prices for laser cutting services can vary widely based on numerous factors, including material selection, design complexity, order volume, and supplier location. The insights provided are meant to serve as a general guideline and should not be considered definitive quotes. Always consult with suppliers for accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing laser cutter services With Other Solutions

Introduction: Exploring Alternatives to Laser Cutting Services

In the realm of manufacturing and fabrication, laser cutting services have gained prominence due to their precision and versatility. However, there are alternative technologies that can effectively fulfill similar requirements. This section evaluates two primary alternatives: waterjet cutting and plasma cutting. Understanding the strengths and weaknesses of each method allows B2B buyers to make informed decisions based on their specific project needs.

Comparison Table

| Comparison Aspect | Laser Cutter Services | Waterjet Cutting | Plasma Cutting |

|---|---|---|---|

| Performance | High precision; ideal for intricate designs | Excellent for thick materials; can cut complex shapes | Fast cutting speed; good for thicker metals |

| Cost | Moderate; varies by material and complexity | Generally higher due to equipment and operational costs | Typically lower for thicker materials but varies with precision |

| Ease of Implementation | User-friendly online quoting and order systems | Requires specialized setup and skilled operators | Simpler setup; can be operated by less skilled workers |

| Maintenance | Relatively low; periodic lens cleaning and calibration needed | Higher; requires regular maintenance of pumps and nozzles | Moderate; consumable parts need regular replacement |

| Best Use Case | Thin to medium materials; intricate designs | Thick metals, stone, glass; where heat sensitivity is a concern | Heavy-duty cutting of metals, including aluminum and steel |

Detailed Breakdown of Alternatives

Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water, often mixed with abrasives, to cut through materials. This method excels in cutting thick materials such as metals, stone, and glass without inducing heat, which minimizes the risk of warping. The primary advantage of waterjet cutting is its ability to handle a wide variety of materials and thicknesses while maintaining high precision. However, the initial investment in equipment and the operational costs can be higher than laser cutting services, making it less suitable for low-volume projects or startups.

Plasma Cutting

Plasma cutting employs a high-velocity jet of ionized gas to melt and remove material. It is particularly effective for cutting ferrous and non-ferrous metals at high speeds, making it a favored choice for heavy-duty applications. The advantages of plasma cutting include speed and cost-effectiveness for thicker materials. However, the precision is generally lower than that of laser cutting, making it less suitable for intricate designs. Additionally, the kerf (the width of material removed during cutting) can be wider, which may lead to more material waste.

Conclusion: Making the Right Choice for Your B2B Needs

Choosing the right cutting technology hinges on several factors including the type of material, project complexity, and budget. Laser cutting services are ideal for projects requiring high precision and intricate designs, particularly with thinner materials. In contrast, waterjet cutting is preferable for thicker materials or sensitive substances, while plasma cutting offers speed and efficiency for heavy-duty applications. B2B buyers should evaluate their specific requirements and consider not only the immediate costs but also the long-term implications of maintenance, operational efficiency, and quality of output when making their decision.

Essential Technical Properties and Trade Terminology for laser cutter services

What Are the Essential Technical Properties of Laser Cutting Services?

Understanding the technical specifications of laser cutting services is crucial for B2B buyers aiming to make informed decisions. Here are several critical specifications that impact the efficiency, quality, and applicability of laser cutting for various projects:

-

Material Grade: The type of material being cut—such as steel, aluminum, or acrylic—affects the choice of laser cutting technology and settings. Different materials have unique properties, such as thermal conductivity and melting points, which can influence the cutting speed and quality. Selecting the appropriate material grade ensures compatibility with the intended application, whether for prototypes or large-scale production.

-

Tolerance: Tolerance refers to the allowable deviation from a specified dimension. In laser cutting, typical tolerances can range from ±0.003 inches (0.08 mm) for intricate designs to ±0.1 inches (2.54 mm) for larger components. Precise tolerances are critical in industries such as aerospace and automotive, where even minor inaccuracies can lead to significant operational issues.

-

Thickness Capacity: This specification indicates the maximum material thickness that a laser cutter can effectively handle. Most laser cutting services can process materials up to 4 inches thick, but this may vary based on the type of laser technology employed (e.g., CO2 vs. fiber lasers). Understanding thickness capacity helps buyers choose the right service provider based on their project requirements.

-

Cutting Speed: Measured in inches per minute (IPM), cutting speed indicates how quickly a laser cutter can process a given material. Higher cutting speeds can lead to reduced lead times and increased productivity. However, faster cutting speeds may compromise quality, so it’s essential to balance speed with the required finish and detail for specific applications.

-

Surface Finish: The quality of the cut edge, often described in terms of roughness or smoothness, plays a vital role in the final product’s appearance and functionality. Different materials and cutting parameters can yield varying surface finishes, impacting post-processing requirements. Understanding the expected surface finish helps in planning further manufacturing stages.

What Are Common Trade Terminologies Used in Laser Cutting Services?

Familiarity with industry jargon is essential for effective communication and negotiation in the laser cutting market. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In laser cutting, OEMs often require precise specifications and high-quality parts to meet their design and performance criteria.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers, especially startups or small businesses that may not need large volumes but still require high-quality laser-cut components.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing information for specific services or products. For B2B buyers, crafting a detailed RFQ can ensure that they receive accurate quotes that reflect their requirements, including material specifications, tolerances, and delivery timelines.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations associated with their laser cutting orders.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the finished product. Understanding lead times is crucial for project planning and can influence decisions on which supplier to choose based on their ability to meet deadlines.

-

Prototyping: This is the process of creating a preliminary model of a product to test concepts and functionalities. Laser cutting is frequently employed in prototyping due to its speed and precision, allowing businesses to iterate designs quickly before moving to full production.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when selecting laser cutting services, ultimately leading to better project outcomes and enhanced supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the laser cutter services Sector

What Are the Current Market Dynamics and Key Trends in the Laser Cutter Services Sector?

The laser cutter services sector is experiencing dynamic growth driven by several global factors. The rise of advanced manufacturing technologies, including Industry 4.0, is facilitating the adoption of laser cutting services across various industries such as automotive, aerospace, and electronics. In regions like Africa, South America, the Middle East, and Europe, particularly in countries like Germany and Vietnam, there is an increasing demand for precision manufacturing and rapid prototyping. This trend is being propelled by the need for efficient supply chains and reduced lead times, prompting B2B buyers to seek out services that offer on-demand capabilities.

Emerging technologies such as AI and machine learning are enhancing the efficiency and accuracy of laser cutting processes, allowing for more complex designs and faster turnaround times. Buyers are also gravitating towards platforms that provide instant quoting and online order management, simplifying the procurement process. Additionally, the expansion of e-commerce and digital platforms is enabling international buyers to access a broader range of suppliers, thus fostering competition and innovation in the sector.

Another significant trend is the growing preference for custom and low-volume production runs, which align with the rise of personalization in consumer products. As businesses strive to differentiate themselves, they increasingly rely on laser cutting services that can accommodate unique designs without substantial upfront costs. This shift towards customization is particularly relevant for sectors like fashion and consumer electronics, where design innovation is crucial for market competitiveness.

How Is Sustainability and Ethical Sourcing Shaping the Laser Cutter Services Landscape?

Sustainability is becoming a pivotal concern in the laser cutter services sector, with international buyers increasingly prioritizing environmental impact in their sourcing decisions. The manufacturing process for laser cutting, while efficient, can produce waste and emissions that necessitate careful management. As a result, companies are adopting practices that minimize their ecological footprint, such as utilizing energy-efficient machinery and sustainable materials.

Ethical sourcing is equally vital, as buyers are seeking transparency in their supply chains. This includes understanding the origins of materials and the labor practices involved in their production. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for wood-based materials are becoming essential for suppliers aiming to appeal to conscientious businesses. Furthermore, the use of recycled materials in laser cutting processes not only reduces waste but also aligns with the values of environmentally aware consumers and businesses.

B2B buyers are encouraged to engage with suppliers that demonstrate a commitment to sustainability and ethical practices. This not only enhances brand reputation but also mitigates risks associated with regulatory compliance and consumer backlash. As businesses navigate these evolving expectations, they are likely to find that sustainable practices can lead to cost savings and improved operational efficiencies in the long run.

What Is the Brief Evolution of Laser Cutter Services and Its Importance to B2B Buyers?

The evolution of laser cutter services can be traced back to the late 1960s when the first laser cutting systems were developed. Initially used primarily in industrial applications, the technology has undergone significant advancements, including improvements in laser types and cutting speeds. By the 1990s, the introduction of computer numerical control (CNC) technology allowed for greater precision and automation, making laser cutting accessible to a wider range of industries.

Today, laser cutting services are integral to modern manufacturing, offering unparalleled accuracy and versatility across materials such as metals, plastics, and wood. This evolution is particularly relevant for B2B buyers, as it enables them to leverage cutting-edge technology for efficient production processes, rapid prototyping, and intricate designs. Understanding this historical context can help buyers appreciate the value of laser cutting services as they seek reliable partners capable of meeting their unique manufacturing needs in an increasingly competitive global market.

Frequently Asked Questions (FAQs) for B2B Buyers of laser cutter services

-

How do I ensure the quality of laser cut parts from a supplier?

To ensure the quality of laser cut parts, it’s essential to verify the supplier’s certifications, such as ISO 9001, which indicates adherence to quality management standards. Request samples of their previous work to assess precision and finish. Additionally, inquire about their quality assurance processes, including inspections and testing methods used during production. Establishing clear communication regarding your specifications and tolerances is also crucial, as it allows the supplier to meet your expectations effectively. -

What materials can be used for laser cutting?

Laser cutting services can accommodate a wide range of materials, including metals (such as stainless steel, aluminum, and brass), plastics (like acrylic and nylon), wood, rubber, and foam. The choice of material will depend on the intended application, desired finish, and budget. For specific projects, consult with your supplier to understand the capabilities and limitations of their equipment regarding different materials, as well as the best options for your needs. -

What are the typical lead times for laser cutting services?

Lead times for laser cutting services can vary based on factors such as order size, material availability, and the complexity of the design. Generally, suppliers may offer rapid turnaround options, with some providing same-day or next-day delivery for simple projects. For larger orders or more complex designs, expect lead times ranging from a few days to several weeks. It’s advisable to discuss your timeline with the supplier upfront to align expectations and avoid delays. -

Are there minimum order quantities (MOQ) for laser cutting services?

Many laser cutting service providers have flexible policies regarding minimum order quantities. Some may accept single-item orders, while others might have a MOQ based on production efficiency. When sourcing a supplier, inquire about their MOQ to ensure it aligns with your project needs. If you are a startup or working on prototypes, look for suppliers who specifically cater to low-volume production to avoid excess costs. -

What payment terms are typically offered by laser cutting service providers?

Payment terms can vary widely among laser cutting service providers. Many offer standard payment options such as upfront payment, while others may provide net 30 or net 60 terms, especially for established business relationships. When negotiating terms, ensure clarity on payment methods, currency considerations, and any potential fees for international transactions. It’s also beneficial to discuss any volume discounts or credit options that may be available to your business. -

How can I vet a laser cutting supplier for international trade?

Vetting a laser cutting supplier for international trade involves several steps. Start by checking their reputation through online reviews and industry references. Verify their certifications and compliance with international quality standards. Request detailed information about their production capabilities, lead times, and shipping logistics. Additionally, consider visiting their facility if feasible, or arrange a virtual meeting to discuss your requirements and gauge their professionalism. -

What logistics considerations should I keep in mind when sourcing laser cutting services internationally?

When sourcing laser cutting services internationally, consider logistics such as shipping options, customs duties, and lead times. Ensure the supplier provides clear information about shipping methods, costs, and estimated delivery times. Understanding import regulations in your country is crucial to avoid unexpected fees or delays. Additionally, discuss options for tracking shipments and managing any potential issues that may arise during transport. -

Can I customize designs for laser cutting services?

Yes, customization is a key feature of laser cutting services. Most suppliers allow clients to submit their own CAD designs, accommodating various file formats. Ensure your design meets the supplier’s specifications regarding dimensions and tolerances. Some providers also offer design assistance, helping you optimize your files for laser cutting. If you need adjustments or iterations, communicate this with your supplier early in the process to facilitate a smooth production experience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Laser Cutter Services Manufacturers & Suppliers List

1. Ponoko – Custom Laser Cutting Solutions

Domain: ponoko.com

Registered: 2006 (19 years)

Introduction: Metal & plastic laser cutting, online quote in seconds, custom parts delivered in hours, no minimum order quantity, $0 setup fee, free shipping, dimensional accuracy ±0.003in / 0.08mm, made in USA, on demand 1 to 10,000 parts, online DFM report, quotes, delivery times, collaborate with sales engineer, white glove service for 1 to 100,000 parts, upload CAD files (supports various file types), same …

2. SendCutSend – Fast Online Laser Cutting Services

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers fast online laser cutting services using high powered lasers (4kW to 12kW) for accurate cuts on various materials including metals, plastics, composites, and woods. Key features include precision cuts with tolerances as tight as ±0.005″, kerf compensation, automatic nesting, and quick turnarounds with standard orders shipping in 1-3 days. They provide services for a wide range o…

3. PCBWay – CNC Laser Cutting Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Laser Cutting Services for custom parts, offering fast and reliable solutions. Features include: rapid prototyping, low-volume production parts, turnaround time as fast as 2 days, precision cutting with clean edges, and the ability to fabricate complex geometries with distortion-free finishes. Materials used include sheet metal and plastic. Applications span various industries such as automoti…

4. Serralaser – Precision Laser Cutting Services

Domain: serralaser.com

Registered: 1997 (28 years)

Introduction: Precision Laser Cutting Services including 2-D Laser Cutting, 5-Axis 3D Laser Cutting, Waterjet Cutting Services, Tube Laser Cutting, Bending & Forming, Edge Rounding & Deburring, CNC Milling, Inspection & Reverse Engineering. Capabilities include achieving position tolerance of 0.00039 in. and repeatability tolerance of 0.00019 in. Services are available for OEMs, steel suppliers, and sheet metal…

5. eMachineShop – Custom Laser Cutting Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: Custom laser cutting service for sheet metal parts with a turnaround time of as little as 3 days. Offers over 50 materials, including metals, wood, and plastics. Features include precision cutting of almost any 2D shape, fast processing times, and the ability to etch materials. Utilizes fiber laser technology for increased speed, accuracy, and lower power consumption. Services include cutting, eng…

6. Laser Alliance – Precision Laser Cutting & Engraving Solutions

Domain: laseralliance.com

Registered: 1998 (27 years)

Introduction: Laser Cutting, Laser Engraving, Marking Services; Specialization in visual graphic products; Advanced CO2 industrial laser systems; Services offered to domestic and international clients; Capabilities include cutting and engraving in metals, plastics, woods, and more; Customization options with thousands of material combinations; Located in Milpitas, California; Servicing all 50 states with a focu…

7. Yelp – Laser Cutting Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Laser Cutting services in San Francisco, CA include a variety of offerings such as laser engraving, metal fabrication, wood engraving, custom signs, acrylic signs, custom stencils, and personalized gifts. Notable businesses in the area include New Wave GraphiX, which specializes in engraving and printing services, and Heirloom Engravers, known for its deep engraving techniques and history with hig…

Strategic Sourcing Conclusion and Outlook for laser cutter services

In today’s competitive landscape, the strategic sourcing of laser cutter services can significantly enhance operational efficiency and product quality for international B2B buyers. Key takeaways from this guide highlight the importance of selecting providers that offer flexibility in material options, rapid turnaround times, and transparent pricing models. With capabilities ranging from metal to plastic and even wood, sourcing partners like Xometry and Ponoko demonstrate the versatility and cost-effectiveness of laser cutting technologies, allowing businesses to scale production without compromising on quality.

As companies in Africa, South America, the Middle East, and Europe navigate complex supply chains, leveraging online platforms for instant quoting and order management can streamline procurement processes. Moreover, understanding the nuances of different laser cutting technologies empowers businesses to make informed decisions tailored to their specific needs.

Looking ahead, the demand for precision manufacturing will continue to grow, making it essential for B2B buyers to engage with innovative laser cutting service providers. Embrace the opportunity to transform your manufacturing capabilities—explore your options today and forge strategic partnerships that propel your business forward.