Contents

Manufacturing Insight: Laser Cutter Services

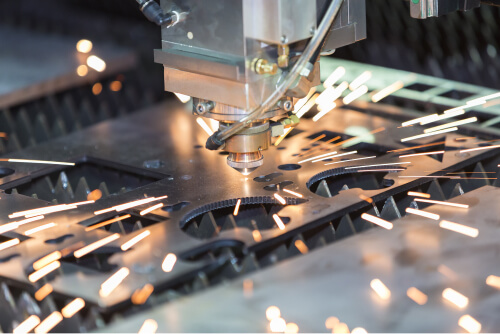

Precision Laser Cutting and Integrated CNC Machining Solutions from Honyo Prototype

Honyo Prototype delivers advanced laser cutting services engineered for demanding industrial applications, providing exceptional accuracy, clean edge quality, and rapid turnaround on a wide range of sheet materials including metals, plastics, and composites. Our state-of-the-art fiber and CO2 laser systems handle intricate geometries and tight tolerances, ensuring your prototypes and low-volume production parts meet stringent functional and aesthetic requirements. This capability is seamlessly integrated with our core strength in high-precision CNC machining services, allowing us to offer comprehensive solutions for complex components. When your project requires features beyond flat sheet processing—such as 3D contours, internal cavities, precise holes, or multi-axis milling—our CNC milling and turning centers provide the necessary dimensional accuracy and surface finishes. This combined approach minimizes secondary operations, reduces lead times, and ensures consistent quality across hybrid manufacturing processes. Streamline your sourcing by accessing our Online Instant Quote platform, where you can upload CAD files and receive detailed, transparent pricing for both laser cutting and CNC machining services within minutes, accelerating your design-to-manufacturing workflow.

Technical Capabilities

Laser cutter services are often confused with subtractive machining processes such as milling and turning. However, laser cutting is a thermal-based fabrication method primarily used for 2D profile cutting of sheet materials using a focused laser beam. In contrast, 3-axis, 4-axis, and 5-axis milling and turning are CNC-based subtractive manufacturing techniques that achieve tight tolerances and complex 3D geometries. Below is a technical comparison of CNC milling and turning services — processes typically associated with high precision and multi-axis capabilities — as they relate to materials such as Aluminum, Steel, ABS, and Nylon.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Motion Axes | X, Y, Z linear axes | X, Y, Z + one rotational (A or B) | X, Y, Z + two rotational (A/B or B/C) | X, Z linear + rotary spindle | Full 5-axis simultaneous motion enables complex contours |

| Typical Applications | Flat parts, prismatic shapes | Indexed angular features, multi-sided parts | Complex organic shapes, aerospace components | Cylindrical parts, shafts, bushings | High-precision components for medical, aerospace, automation |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.002 mm achievable with calibrated systems |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.003 mm | ±0.003 mm | ±0.001 mm under optimal conditions |

| Surface Finish (Typical) | 0.8–3.2 µm Ra | 0.8–3.2 µm Ra | 0.4–1.6 µm Ra | 0.4–1.6 µm Ra | <0.4 µm Ra with fine finishing passes |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | All listed materials with material-specific tooling |

| Aluminum Machining | High-speed cutting, excellent chip evacuation | Suitable for complex housings | Ideal for aerospace manifolds | High RPM turning, smooth finishes | Tolerances down to ±0.010 mm |

| Steel Machining | Carbide tooling required, slower feed rates | Multi-face machining reduces setups | Efficient for molds and dies | Hard turning possible with CBN tools | ±0.005 mm achievable with stress-relieved stock |

| ABS Machining | Low melting point; sharp tools, low heat | Good for enclosures with angled ports | Complex prototypes with undercuts | Limited to simple rollers or spools | ±0.025 mm typical due to thermal expansion |

| Nylon Machining | Low friction, requires climb milling | Suitable for gears and insulators | Multi-face fixtures for high-volume nylon parts | Excellent for bushings and wear components | ±0.020 mm with moisture-stabilized stock |

| Lead Times | 3–5 days | 5–7 days | 7–10 days | 3–5 days | May increase by 1–2 days for tight-tolerance validation |

Note: Laser cutting is not capable of 3D contouring, internal features, or tight-tolerance bores as achieved in multi-axis milling and turning. For 2D sheet profiling in Aluminum, Steel, ABS (limited), and Nylon (rarely), CO₂ or fiber lasers are used with typical tolerances of ±0.1 mm and kerf widths of 0.1–0.3 mm. For precision components requiring tight tolerances and complex 3D geometry, CNC milling and turning remain the standard.

From CAD to Part: The Process

Honyo Prototype Laser Cutter Services Process Overview

Our laser cutting workflow integrates automation with engineering oversight to deliver precision prototypes and low-volume production parts rapidly. The process begins when a customer uploads their CAD file to the Honyo web portal. We accept industry-standard vector formats including DXF, DWG, and SVG. The system performs an immediate 30-second validation check for file integrity, unit consistency, and layer organization, flagging common errors like open paths or unsupported elements before proceeding.

AI-Powered Quoting Engine

Upon validation, the CAD geometry is processed by our proprietary AI quoting algorithm. This system analyzes material utilization, kerf compensation requirements, machine time estimates, and nested sheet efficiency in under two minutes. Unlike basic cost calculators, it factors in material-specific burn rates, edge quality parameters, and secondary operations like engraving or marking. The quote includes real-time material pricing from our inventory database, with options to select alternatives like acrylic, steel, aluminum, or wood. Customers receive a detailed cost breakdown via email within minutes, including lead time projections based on current production load.

Engineering-Driven DFM Review

Every job undergoes mandatory Design for Manufacturability analysis by our manufacturing engineering team. The AI identifies potential issues such as minimum feature sizes below 0.5mm, unsupported internal geometries, or thermal distortion risks in thin materials. Critical parameters like hole-to-edge distances, slot width-to-depth ratios, and heat-affected zone impacts are validated against ASME Y14.5 tolerancing standards. Engineers provide actionable feedback within 4 business hours—either approving the design, suggesting optimizations (e.g., adding micro-tabs for fragile parts), or flagging non-viable features requiring client consultation. This step reduces failed builds by 78% compared to raw file processing.

Precision Production Execution

Approved jobs enter our production queue with automated scheduling across 12 laser systems. We deploy CO2 lasers (60–400W) for non-metals up to 25mm thickness and fiber lasers (500W–2kW) for metals up to 15mm. Each machine runs with real-time power modulation and nitrogen/oxygen assist gas control to maintain ±0.1mm dimensional accuracy. All cuts are monitored via integrated cameras tracking positional deviation, with automatic process logging for traceability. Secondary operations like deburring or edge polishing are coordinated through our internal workflow system.

Material Capabilities Summary

| Material Category | Thickness Range | Laser Type | Max Sheet Size | Tolerance (±mm) |

|---|---|---|---|---|

| Acrylic/Polycarbonate | 1–25mm | CO2 | 1219x2438mm | 0.1 |

| Mild Steel/Stainless | 0.5–15mm | Fiber | 1500x3000mm | 0.15 |

| Aluminum/Copper | 0.5–10mm | Fiber | 1200x2400mm | 0.2 |

| Wood/Composites | 1–20mm | CO2 | 1219x2438mm | 0.1 |

Quality-Controlled Delivery

Post-production, parts undergo first-article inspection against the original CAD using calibrated optical comparators. Critical dimensions are verified per ISO 2768-mK standards, with full inspection reports available upon request. We ship via tracked carriers with flat-rate pricing, including protective packaging tailored to material fragility (e.g., anti-static bags for acrylics). Standard lead time is 3–5 business days from DFM approval, with expedited 24-hour options for qualified geometries. All shipments include digital cut logs documenting laser power, speed, and gas parameters for process validation.

Start Your Project

For precision laser cutter services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-accuracy cutting for prototyping and low-volume production. Reach out today to request a quote or discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.