Introduction: Navigating the Global Market for laser cutter for hire

In the ever-evolving landscape of manufacturing and design, sourcing a reliable laser cutter for hire presents both opportunities and challenges for international B2B buyers. As businesses strive to enhance their production capabilities while minimizing costs, the demand for flexible laser cutting solutions has surged. This guide aims to equip decision-makers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—with the knowledge needed to navigate this global market effectively.

Understanding the various types of laser cutting services available, their applications across different industries, and the intricacies of supplier vetting is crucial for making informed purchasing decisions. This comprehensive resource delves into essential factors such as cost structures, turnaround times, and material compatibility, offering actionable insights that empower businesses to select the right laser cutting partner. By addressing common pain points, such as quality assurance and logistical considerations, this guide helps buyers streamline their procurement process and mitigate risks associated with outsourcing.

Ultimately, whether you are a small startup or an established enterprise, leveraging the insights provided here will enable you to harness the full potential of laser cutting technology, driving innovation and efficiency in your operations.

Understanding laser cutter for hire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DIY Laser Cutter Rental | Self-service access; hourly rental; hands-on operation. | Prototyping; small batch production. | Pros: Cost-effective; creative control. Cons: Requires technical knowledge; potential for errors. |

| Custom Laser Cutting Service | Professional operation; tailored designs; material versatility. | Signage; custom products; industrial parts. | Pros: High precision; expert support. Cons: Higher cost; longer turnaround times. |

| Mobile Laser Cutting Service | On-site service; flexibility; transportable equipment. | Events; construction; remote projects. | Pros: Convenience; immediate service. Cons: Limited material options; potential logistical challenges. |

| Laser Cutter Subscription | Membership-based access; regular training and updates. | Ongoing projects; startups; design firms. | Pros: Cost predictability; continuous support. Cons: Commitment; may not suit one-time projects. |

| Laser Cutting Marketplace | Platform for connecting with freelancers; project-based. | Small businesses; artists; hobbyists. | Pros: Diverse options; competitive pricing. Cons: Quality varies; less control over the process. |

What is a DIY Laser Cutter Rental and How Can It Benefit Businesses?

DIY laser cutter rentals provide businesses with the flexibility to operate laser cutting machines on an hourly basis. This self-service model allows companies to prototype or produce small batches without the overhead costs associated with hiring external services. However, it requires a certain level of technical proficiency and familiarity with design software, which may pose a challenge for some users. Buyers should consider their team’s skill level and the complexity of their projects when opting for this service.

How Do Custom Laser Cutting Services Cater to B2B Needs?

Custom laser cutting services are ideal for businesses requiring precision and tailored solutions for their projects. These services typically involve professional operators who can handle a wide range of materials, including wood, acrylic, and metal. They are particularly useful for creating signage, custom products, and industrial components. While they offer high-quality results and expert support, businesses should be aware of potentially higher costs and longer turnaround times compared to DIY options.

What Advantages Do Mobile Laser Cutting Services Offer?

Mobile laser cutting services bring the equipment directly to the job site, offering unparalleled convenience for projects that require immediate attention or are located in remote areas. This flexibility makes them suitable for events or construction projects where timely execution is critical. However, buyers should consider the limitations in material options and the potential logistical challenges that may arise with transporting equipment.

Why Consider a Laser Cutter Subscription for Ongoing Projects?

Laser cutter subscriptions provide businesses with ongoing access to laser cutting technology and support. This model is particularly beneficial for startups or design firms that have continuous project needs, offering cost predictability and regular training. Buyers should weigh the commitment required against the potential savings and support, especially if they anticipate fluctuating project demands.

How Does a Laser Cutting Marketplace Function for B2B Buyers?

Laser cutting marketplaces connect businesses with freelance laser cutting experts, allowing for a diverse range of options tailored to specific project needs. This platform is particularly advantageous for small businesses, artists, and hobbyists seeking competitive pricing and unique designs. However, buyers must navigate the variability in quality and the potential lack of control over the cutting process, making it essential to vet freelancers carefully.

Key Industrial Applications of laser cutter for hire

| Industry/Sector | Specific Application of laser cutter for hire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Parts Production | High precision and reduced waste in material usage | Material compatibility, turnaround times, and costs |

| Signage & Branding | Custom Signage Creation | Enhanced visibility and brand recognition | Design specifications, material choices, and local regulations |

| Aerospace & Automotive | Prototype Development | Rapid prototyping and testing of designs | Tolerance requirements, material types, and safety standards |

| Fashion & Jewelry | Unique Accessory Design | Ability to create intricate designs and personalization | Material sourcing, design file preparation, and lead times |

| Education & Research | Educational Tools and Models | Hands-on learning experience and enhanced engagement | Availability of support, training for users, and material availability |

How is Laser Cutting Used in Manufacturing and What Problems Does It Solve?

In the manufacturing sector, laser cutters for hire are utilized for producing custom parts with high precision. This technology enables businesses to create intricate designs while minimizing waste material. For international buyers, especially in regions like Africa and South America, sourcing laser cutting services means ensuring compatibility with various materials and understanding local regulations regarding manufacturing standards. Quick turnaround times are crucial, particularly when scaling production to meet market demands.

What Role Does Laser Cutting Play in Signage & Branding?

Laser cutting is essential in the signage and branding industry for creating custom signage that enhances visibility and brand recognition. Businesses can leverage this technology to produce everything from indoor signs to large outdoor displays. Buyers must consider design specifications and the types of materials used, as local regulations often dictate signage requirements. For international buyers, understanding these regulations can facilitate smoother project execution and compliance with local standards.

How Does Laser Cutting Aid in Aerospace & Automotive Prototype Development?

In the aerospace and automotive industries, laser cutters are invaluable for rapid prototype development. They allow for quick iterations and testing of designs, which is critical in these highly regulated sectors. Buyers need to focus on tolerance requirements and the types of materials suitable for their prototypes. Additionally, adhering to safety standards is paramount, especially when working with international suppliers who may have different compliance levels.

What Are the Benefits of Laser Cutting in Fashion & Jewelry Design?

The fashion and jewelry sectors benefit significantly from laser cutting technology, which enables designers to create unique and personalized pieces with intricate details. By hiring laser cutting services, designers can bring their creative visions to life without the need for expensive machinery. For international buyers, sourcing materials that are compatible with laser cutting is essential, as is ensuring that design files are prepared correctly to avoid delays in production.

How is Laser Cutting Enhancing Education & Research?

In educational settings, laser cutting technology is employed to create tools and models that enhance learning experiences. This hands-on approach promotes engagement and helps students visualize complex concepts. Institutions looking to hire laser cutting services should consider the availability of technical support and training for users. Moreover, ensuring that the right materials are available for educational projects can significantly enhance the effectiveness of learning outcomes.

3 Common User Pain Points for ‘laser cutter for hire’ & Their Solutions

Scenario 1: Difficulty Finding a Reliable Service Provider

The Problem: B2B buyers often struggle to find a reputable laser cutting service that meets their specific needs. With numerous options available, the risk of selecting a provider that lacks the necessary expertise or fails to deliver quality work is significant. This can lead to costly delays and unsatisfactory results, especially for businesses in fast-paced environments where time and precision are critical.

The Solution: To mitigate this risk, buyers should prioritize due diligence when sourcing a laser cutter for hire. Start by seeking recommendations from industry peers or online forums specific to your sector. Look for reviews and testimonials on platforms like Fiverr or specialized service directories. Once you have a shortlist, request samples of previous work and check their portfolio for projects similar to yours. Finally, engage in direct communication with potential providers to assess their responsiveness and customer service, ensuring they understand your requirements thoroughly. This proactive approach will help you select a reliable partner who can deliver high-quality results.

Scenario 2: Challenges with Design Specifications and Compatibility

The Problem: A common pain point for B2B buyers is the complexity of preparing designs that are compatible with laser cutting technology. Many buyers may not be familiar with the specific file formats or design requirements needed to ensure their projects are executed correctly. Miscommunication regarding design specifications can lead to wasted materials and increased costs, undermining the project’s overall feasibility.

The Solution: To navigate this challenge, businesses should invest time in understanding the design requirements for laser cutting. Start by familiarizing yourself with the types of files accepted by laser cutting services, such as vector formats (e.g., SVG, AI). Many services offer design guidelines on their websites, so be sure to consult these resources. If your in-house design capabilities are limited, consider hiring a freelance designer experienced in creating laser-ready files. Providing clear instructions and examples can help ensure your designs are not only compatible but optimized for the laser cutting process, reducing the likelihood of errors and material wastage.

Scenario 3: Concerns Over Cost and Budget Management

The Problem: Budget constraints can pose a significant challenge for businesses looking to hire laser cutting services. The costs associated with laser cutting can vary widely depending on the complexity of the design, the materials used, and the turnaround time required. Without a clear understanding of these costs, buyers may find themselves exceeding their budgets or facing unexpected expenses.

The Solution: To manage costs effectively, it’s essential to obtain detailed quotes from multiple service providers before making a decision. When requesting quotes, provide specific information about your project, including material types, dimensions, and desired quantities. This will enable providers to give accurate estimates. Additionally, inquire about any bulk pricing options or discounts for larger orders. Establishing a transparent communication channel with your chosen provider can also facilitate ongoing discussions about costs, allowing for adjustments and negotiations as needed. By being proactive about budgeting and seeking clarity on costs upfront, businesses can better align their laser cutting projects with their financial resources, ensuring they remain within budget while achieving high-quality results.

Strategic Material Selection Guide for laser cutter for hire

What Are the Key Properties of Common Materials for Laser Cutting?

When considering materials for laser cutting services, it’s essential to understand their properties, advantages, and limitations. This knowledge helps B2B buyers make informed decisions that align with their project requirements and operational capabilities.

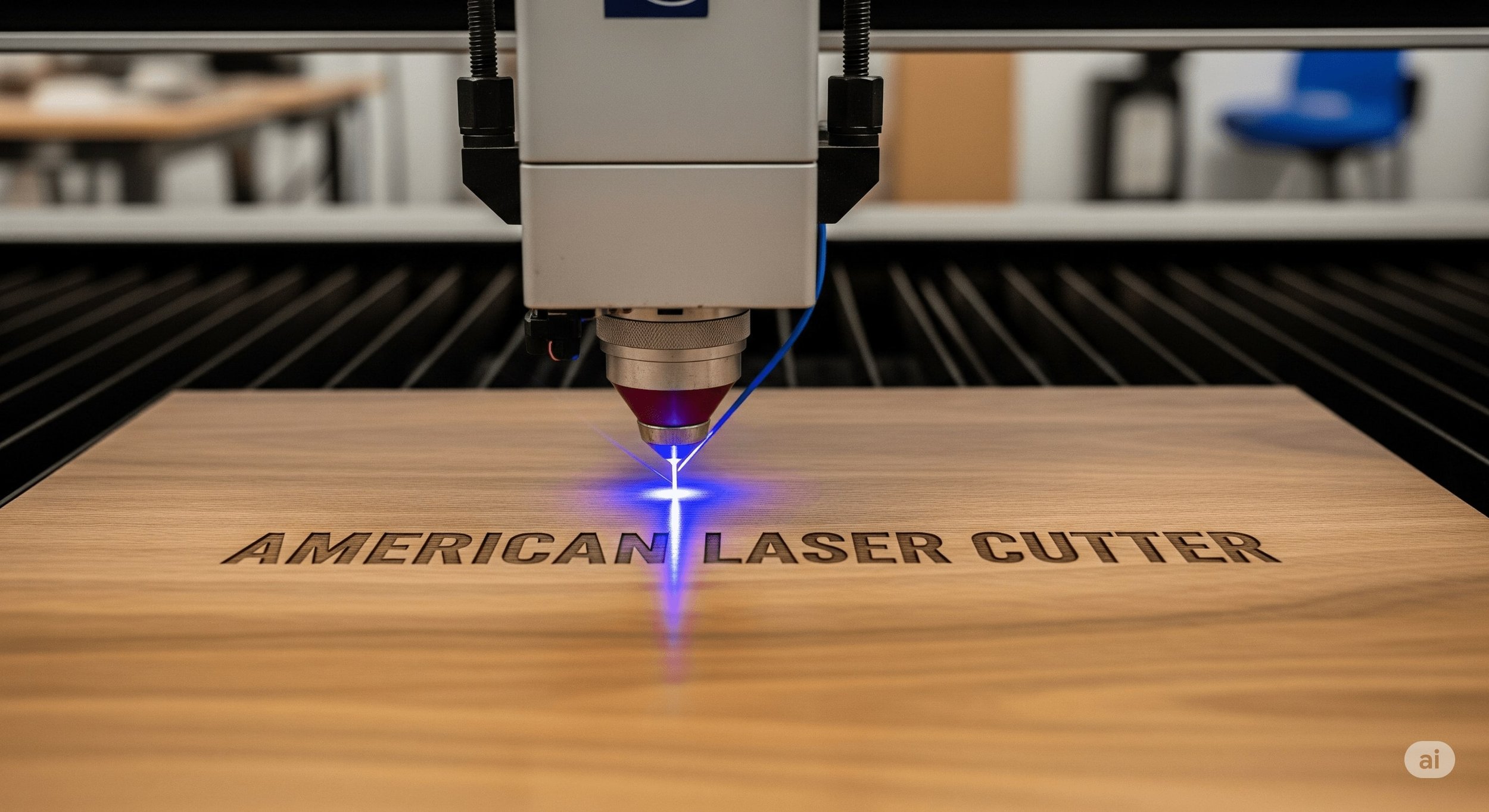

Wood: A Versatile Material for Laser Cutting

Wood is one of the most commonly used materials in laser cutting due to its natural aesthetic and ease of manipulation. Key properties include its availability in various densities and grain patterns, which can influence the final product’s appearance. Wood is generally not resistant to moisture and can warp or swell if not treated properly.

Pros: Wood is relatively inexpensive and easy to cut, making it suitable for prototypes and custom designs. It also offers a warm, organic look that is appealing in signage and decorative items.

Cons: Variability in grain and density can lead to inconsistent cuts. Additionally, untreated wood can be susceptible to environmental factors, which may limit its application in outdoor settings.

Impact on Application: Wood is compatible with a range of laser cutting applications, from signage to intricate designs for crafts. However, the choice of wood type can significantly affect the engraving quality and durability.

Considerations for International Buyers: Compliance with local standards for sourcing timber (e.g., FSC certification) is crucial, particularly in regions like Europe where sustainability is prioritized. Buyers from Africa and South America should be aware of local wood types and their availability.

Acrylic: A Durable and Aesthetic Option

Acrylic, often used as a glass substitute, is a popular choice for laser cutting due to its clarity and durability. It has excellent weather resistance and can withstand varying temperatures, making it suitable for both indoor and outdoor applications.

Pros: Acrylic is lightweight, shatter-resistant, and available in various colors and finishes. It can be easily engraved, providing a high-quality aesthetic for signage and displays.

Cons: While acrylic is durable, it can be more expensive than wood. It is also prone to scratching and can emit toxic fumes when cut, necessitating proper ventilation during the cutting process.

Impact on Application: Acrylic is ideal for signage, displays, and decorative items. Its versatility allows for intricate designs, but care must be taken to avoid damage during handling.

Considerations for International Buyers: Buyers should ensure compliance with safety standards related to fumes and waste disposal, especially in regions with strict environmental regulations. Understanding local preferences for colors and finishes can also enhance product appeal.

Metal: Precision and Strength in Laser Cutting

Metals such as stainless steel, aluminum, and brass are increasingly popular in laser cutting due to their strength and durability. Key properties include high-temperature resistance and corrosion resistance, making them suitable for a wide range of applications.

Pros: Metal offers longevity and structural integrity, making it ideal for industrial applications, signage, and custom parts. Laser cutting allows for precise designs that are difficult to achieve with traditional methods.

Cons: Metal is generally more expensive than wood and acrylic, and the cutting process can require more time and energy. Additionally, thicker materials may necessitate specialized equipment.

Impact on Application: Metal is commonly used in construction, automotive, and manufacturing industries. The choice of metal can affect the cutting speed and quality of the final product.

Considerations for International Buyers: Understanding local standards for metal quality (e.g., ASTM for the U.S. or DIN for Europe) is crucial. Buyers should also consider the availability of specific metals in their region, as this can impact lead times and costs.

Paper and Cardboard: Cost-Effective and Customizable

Paper and cardboard are often used for prototypes, packaging, and decorative items. They are lightweight and easy to cut, making them ideal for quick projects.

Pros: These materials are inexpensive and widely available, allowing for rapid prototyping and customization. They also produce minimal waste during cutting.

Cons: Paper and cardboard are not durable and can be easily damaged by moisture or physical stress. Their applications are generally limited to short-term use.

Impact on Application: Ideal for packaging, crafts, and temporary displays, paper and cardboard allow for creative designs but may not be suitable for long-lasting products.

Considerations for International Buyers: Buyers should be aware of local recycling and waste disposal regulations, as well as preferences for sustainable materials. Understanding the local market for packaging solutions can also be beneficial.

Summary Table of Material Selection for Laser Cutting

| Material | Typical Use Case for laser cutter for hire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Signage, crafts, decorative items | Cost-effective and easy to cut | Susceptible to environmental factors | Low |

| Acrylic | Signage, displays, decorative items | Durable and aesthetically pleasing | Prone to scratching and toxic fumes | Medium |

| Metal | Industrial parts, signage, construction | Strong and long-lasting | Higher cost and cutting complexity | High |

| Paper/Cardboard | Prototypes, packaging, crafts | Inexpensive and customizable | Not durable and easily damaged | Low |

This guide provides a comprehensive overview of materials commonly used in laser cutting, assisting B2B buyers in making informed decisions that align with their project needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for laser cutter for hire

What Are the Key Stages in the Manufacturing Process of Laser Cutters for Hire?

The manufacturing process of laser cutters involves several crucial stages, each designed to ensure precision and quality. Understanding these stages helps B2B buyers identify reliable suppliers capable of meeting their specific needs.

1. Material Preparation: How Is Material Selected and Processed?

Material preparation is the first critical step in the manufacturing process. Suppliers typically offer a range of materials, including wood, acrylic, metal, and fabric. The selection depends on the intended applications, such as signage, prototypes, or custom designs.

Once materials are chosen, they undergo a rigorous preparation process that includes cutting to size, cleaning, and sometimes pre-treatment to ensure optimal performance during laser cutting. The aim is to ensure that the materials are free from impurities or contaminants that could affect the cutting quality.

2. Forming: What Techniques Are Employed to Achieve Precision?

The forming stage involves the actual laser cutting process, where high-powered lasers are utilized to cut or engrave the prepared materials. This stage is defined by precision; laser cutters can create intricate designs that would be challenging to achieve through traditional cutting methods.

Key techniques include vector cutting, where the laser follows a predefined path, and engraving, where the laser alters the surface of the material to create designs. The ability to adjust laser settings for power, speed, and focus allows for customization across various materials, enhancing versatility for clients.

3. Assembly: How Are Components Brought Together?

If the laser cutter is part of a more extensive system or requires assembly after manufacturing, the assembly stage comes into play. This involves fitting together various components, including the laser module, motion control systems, and cooling units, which are essential for optimal functionality.

Skilled technicians ensure that all parts are correctly aligned and securely fastened, minimizing the risk of malfunctions during operation. This stage often includes initial functionality testing to ensure that all components work harmoniously.

4. Finishing: What Quality Enhancements Are Applied Post-Cutting?

Finishing processes are crucial for enhancing the aesthetic and functional aspects of laser-cut products. This may include sanding, coating, or applying protective finishes to ensure durability and improve the product’s overall appearance.

These finishing touches can significantly impact the final product’s marketability, especially in industries where visual appeal is paramount, such as signage and custom gifts.

What International Standards and Quality Assurance Measures Should B2B Buyers Consider?

Quality assurance in the manufacturing of laser cutters is essential for ensuring that products meet international safety and performance standards. For B2B buyers, understanding these standards can help in assessing the credibility of suppliers.

International Standards: Which Certifications Should Be Prioritized?

ISO 9001 is one of the most recognized international standards for quality management systems. Suppliers who hold this certification demonstrate their commitment to maintaining quality across all manufacturing processes.

Additionally, CE marking is vital for products sold in the European market, indicating compliance with EU safety and health regulations. For specific industries, other certifications like API (American Petroleum Institute) may be necessary, particularly if the laser cutters will be used in sectors like oil and gas.

Quality Control Checkpoints: What Are the Key QC Stages?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials before they enter the production line, ensuring they meet predefined specifications.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor processes, allowing for immediate corrections if deviations from quality standards occur.

-

Final Quality Control (FQC): After production, a thorough inspection ensures that the finished products meet all specifications and are free from defects before shipping.

What Common Testing Methods Are Utilized in Quality Assurance?

Testing methods are critical for validating the performance and safety of laser cutters. Common methods include:

-

Performance Testing: Evaluating cutting speed, precision, and finish quality to ensure the laser cutter operates within the expected parameters.

-

Safety Testing: Ensuring compliance with electrical and safety standards, particularly in equipment that will be used in commercial settings.

-

Durability Testing: Assessing how well the equipment withstands prolonged use, which is vital for buyers considering long-term investments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should actively engage in verifying the quality control practices of potential suppliers. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insights into the QC processes and the overall production environment.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their QC processes, including any certifications and results from previous inspections.

-

Third-Party Inspections: Utilizing third-party inspection services can add an extra layer of assurance, particularly for international transactions where buyers may not have direct access to supplier facilities.

What Quality Control Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of the following nuances in quality control:

-

Regulatory Compliance: Different regions may have specific regulations and compliance requirements that suppliers must adhere to, impacting the quality assurance processes.

-

Cultural Differences: Variations in business practices and communication styles can affect the reliability of supplier relationships. Establishing clear expectations and regular communication is crucial.

-

Logistics and Shipping Considerations: Quality control does not end at manufacturing; ensuring that products are transported safely and arrive in good condition is equally important. Buyers should inquire about packaging and handling practices.

By understanding these elements of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing laser cutters for hire, ensuring they select suppliers that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘laser cutter for hire’

When seeking to hire a laser cutter for your business needs, it’s essential to approach the process systematically. This checklist serves as a practical guide to help you navigate through the complexities of sourcing a reliable laser cutting service, ensuring you make informed decisions that align with your project requirements.

Step 1: Define Your Project Requirements

Before reaching out to potential suppliers, clearly outline your project specifications. Consider the materials you plan to use, the complexity of the designs, and the volume of work needed.

– Material Types: Identify whether you need cutting services for wood, acrylic, metal, or other materials.

– Design Complexity: Evaluate if your designs require intricate cuts or simple shapes, as this will affect the equipment and expertise required.

Step 2: Research Available Services

Explore various laser cutting service providers to understand the offerings available in the market. Look for companies that specialize in the materials and processes you need.

– Local vs. International Suppliers: Depending on your location, you might want to prioritize local suppliers to reduce shipping costs and time.

– Service Versatility: Check if they offer additional services like engraving or prototyping, which may be beneficial for your project.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Experience and Expertise: Look for suppliers with a proven track record in laser cutting for your specific applications.

– Customer Reviews: Analyze feedback and testimonials to gauge their reliability and quality of service.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request comprehensive quotes that detail pricing, turnaround times, and any additional fees.

– Breakdown of Costs: Ensure that quotes include costs for materials, labor, and any design services.

– Turnaround Time: Clarify production timelines to ensure they align with your project deadlines.

Step 5: Assess Quality Assurance Practices

Inquire about the quality control measures that suppliers have in place to ensure precision and consistency in their work.

– Certifications: Check if they hold relevant industry certifications that validate their quality standards.

– Sample Work: Request samples of their previous work to assess the quality of cuts and finishes.

Step 6: Verify Communication and Support

Effective communication is vital for a successful partnership. Ensure the supplier is responsive and open to collaboration throughout the project.

– Customer Support: Assess their willingness to provide ongoing support and address any issues that may arise.

– Design Assistance: Determine if they offer design services or guidance to optimize your laser-ready files.

Step 7: Confirm Logistics and Delivery Options

Finally, discuss logistics, including shipping options, delivery timelines, and any potential costs associated with these services.

– Shipping Methods: Evaluate whether they offer expedited shipping for urgent projects.

– Packaging Standards: Ensure that your products will be packaged appropriately to prevent damage during transit.

By following these steps, B2B buyers can effectively source a laser cutter for hire that meets their specific needs, ensuring a successful project outcome.

Comprehensive Cost and Pricing Analysis for laser cutter for hire Sourcing

What Are the Key Cost Components for Hiring Laser Cutting Services?

When sourcing laser cutting services, understanding the cost structure is crucial for effective budgeting and negotiation. The main components that contribute to the overall cost include:

-

Materials: The choice of materials significantly impacts pricing. Common materials used in laser cutting include wood, acrylic, metal, and paper. Each material has different cost implications based on availability and processing requirements. For instance, metals tend to be more expensive than acrylics due to the intricacies involved in cutting and engraving.

-

Labor: Skilled labor is essential for operating laser cutting machines effectively. Labor costs can vary based on geographic location, expertise, and the complexity of the project. In regions like Africa and South America, where labor costs may be lower, businesses can benefit from competitive pricing.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as facility maintenance, utilities, and equipment depreciation. These costs are typically factored into the overall pricing model offered by service providers.

-

Tooling: Depending on the project, specific tooling may be required to achieve precise cuts and engravings. Tooling costs can vary based on the complexity of the designs and the materials used.

-

Quality Control (QC): Ensuring high-quality output often involves additional QC processes, which can add to the overall cost. Services that offer certifications or guarantees for quality may charge a premium.

-

Logistics: The transportation of materials to and from the service provider can incur additional costs, particularly for international shipments. These costs can vary based on the distance and method of shipping.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin can vary based on market competition and the specific service offerings.

What Influences Pricing in Laser Cutting Services?

Several factors can influence the pricing of laser cutting services, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher volume orders often lead to reduced per-unit costs. Establishing a relationship with suppliers may also provide leverage for better pricing on larger orders.

-

Specifications and Customization: The complexity of the designs and specifications can drive costs up. Highly customized projects may require additional resources, thus increasing the overall price.

-

Materials: As previously mentioned, the choice of materials significantly affects pricing. Unique or hard-to-source materials can lead to higher costs.

-

Quality and Certifications: Suppliers offering high-quality products with certifications may charge more. Buyers should assess whether the additional cost aligns with their quality requirements.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers may offer higher prices due to their reliability and service quality.

-

Incoterms: Understanding shipping terms can help mitigate unexpected costs. Incoterms dictate who bears the costs and risks at various points in the shipping process, affecting the overall pricing structure.

What Tips Can Help Buyers Negotiate Better Pricing for Laser Cutting Services?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Always engage in negotiations to find the best price. Suppliers may have room to adjust their margins, especially for long-term contracts or bulk orders.

-

Consider Total Cost of Ownership: Evaluate the total cost, including logistics, QC, and potential rework costs. Sometimes, a lower upfront price may lead to higher overall expenses if quality is compromised.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, sourcing from suppliers in emerging markets may offer competitive pricing compared to established markets.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Trust and reliability can often result in more favorable terms.

-

Explore Local Options: Local sourcing can reduce logistics costs and lead to faster turnaround times. It may also facilitate better communication and collaboration on projects.

Disclaimer on Indicative Prices

Pricing for laser cutting services can vary widely based on numerous factors, including material costs, project specifications, and supplier location. It is essential for buyers to obtain detailed quotes tailored to their specific needs to ensure accurate budgeting.

Alternatives Analysis: Comparing laser cutter for hire With Other Solutions

Exploring Alternatives to Laser Cutter for Hire

When considering options for precision cutting in manufacturing and design, B2B buyers often evaluate various methods that can achieve similar outcomes as hiring a laser cutter. This analysis focuses on comparing the ‘laser cutter for hire’ service with two viable alternatives: DIY Laser Cutting and Outsourcing to a Custom Cutting Service. Each option presents unique advantages and challenges that can significantly impact operational efficiency and cost-effectiveness.

| Comparison Aspect | Laser Cutter For Hire | DIY Laser Cutting | Outsourcing to Custom Cutting Service |

|---|---|---|---|

| Performance | High precision and quality | Varies based on user skill | Consistent quality with professional expertise |

| Cost | Moderate to high (per project) | Lower for small projects | Higher upfront but may offer bulk discounts |

| Ease of Implementation | Simple; involves sending designs | Requires technical knowledge | Straightforward; provide designs and receive products |

| Maintenance | No maintenance required | User responsible for upkeep | No maintenance; handled by service provider |

| Best Use Case | Custom projects with specific needs | Small-scale projects and prototyping | Large orders or complex designs needing expert handling |

What Are the Pros and Cons of DIY Laser Cutting?

DIY laser cutting allows businesses to rent equipment and perform their own cutting tasks. This method can lead to significant cost savings, especially for smaller projects where outsourcing could be too expensive. It also provides complete creative control over the project. However, this approach requires a certain level of technical expertise and familiarity with design software, which may not be feasible for all companies. Additionally, the quality of the final product can vary significantly depending on the user’s skills and the equipment’s capabilities.

What Benefits Does Outsourcing to a Custom Cutting Service Offer?

Outsourcing to a custom cutting service is ideal for businesses looking for high-quality, consistent results without the hassle of managing equipment. These services often employ skilled professionals who can handle complex designs and large orders efficiently. While the cost may be higher than hiring a laser cutter for a single project, many companies find that the benefits of professional expertise and reliability justify the expense, especially for bulk orders. The downside includes less control over the production process and potential delays in turnaround time.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right cutting solution depends on the specific needs of your business. For companies focused on small-scale projects or seeking to prototype ideas, DIY laser cutting can be a cost-effective and engaging option. Conversely, for those requiring high precision and consistency in larger orders, outsourcing to a custom cutting service may be the most efficient choice. Laser cutter for hire services strike a balance between these two approaches, offering professional results without the need for ownership or maintenance of equipment. Assessing factors such as project size, budget, and required expertise will guide B2B buyers in making the best decision tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for laser cutter for hire

What are the Essential Technical Properties of a Laser Cutter for Hire?

When considering a laser cutter for hire, understanding the critical technical specifications can significantly impact your project’s success. Here are some essential properties to consider:

-

Material Compatibility

– Laser cutters can work with various materials, including wood, acrylic, metal, paper, and fabric. Knowing the compatible materials helps businesses select the right service for their specific needs. For instance, if your project requires intricate designs on metal, ensure the service can handle metal cutting. -

Cutting Thickness

– This specification indicates the maximum thickness of material the laser cutter can effectively cut. Different laser cutters have varying capabilities, typically ranging from 1/8 inch to over 1 inch for industrial machines. Understanding this helps businesses gauge whether the service meets their project requirements without compromising quality. -

Tolerance Levels

– Tolerance refers to the precision of the cut. A typical tolerance range for laser cutting is ±0.005 inches, which is crucial for applications requiring high precision, such as in manufacturing components or intricate designs. Businesses must ensure that the service can meet their tolerance needs to maintain product integrity. -

Engraving Depth

– The ability to engrave materials to specific depths adds value, especially for applications like signage or custom gifts. Knowing the maximum engraving depth allows buyers to design products that utilize this feature effectively, ensuring aesthetic and functional outcomes. -

Speed Settings

– Speed indicates how quickly the laser cutter can process the material, often measured in inches per minute (IPM). A faster speed can lead to increased productivity, but it’s essential to balance speed with quality. For larger projects, a service offering adjustable speed settings can optimize performance based on material type and intricacy. -

Laser Type

– Different types of lasers (e.g., CO2, fiber) have unique benefits. CO2 lasers are ideal for cutting non-metal materials, while fiber lasers excel at cutting metals. Understanding the laser type helps businesses select a service that aligns with their material requirements.

What are Common Trade Terms in the Laser Cutting Industry?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In laser cutting, an OEM might provide the laser cutting machines used by service providers. Understanding OEM relationships can help businesses assess the quality and reliability of the services offered. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest order that a supplier is willing to accept. Knowing the MOQ for laser cutting services helps businesses plan their projects and budgets accordingly, especially for bulk orders. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a price quote for specific services or materials. It’s an essential step in the procurement process for laser cutting services, allowing businesses to compare costs and terms effectively. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for businesses importing laser-cut products, as they dictate shipping responsibilities, costs, and risks. -

Prototyping

– This term refers to the process of creating an initial model of a product to test concepts and functionalities. In laser cutting, rapid prototyping allows businesses to quickly produce and refine designs before full-scale production. -

Vector File

– A vector file is a type of graphic file that uses mathematical equations to represent images, allowing for scalable designs without losing quality. For laser cutting, providing vector files is crucial for achieving precision cuts and engravings. Understanding this term ensures that businesses provide the correct file formats for their projects.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when hiring laser cutting services, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the laser cutter for hire Sector

What Are the Current Market Dynamics and Key Trends in the Laser Cutter for Hire Sector?

The laser cutter for hire market is witnessing significant growth driven by technological advancements and a surge in demand across various industries, including manufacturing, architecture, and design. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly turning to laser cutting services for their efficiency and precision. The rise of e-commerce and the digitalization of supply chains are also facilitating easier access to these services, allowing buyers to source customized solutions tailored to their specific needs.

Key trends shaping this market include the increasing popularity of DIY laser cutting services, where businesses can rent equipment and manage projects in-house. This trend is particularly appealing to startups and small enterprises that seek cost-effective solutions without the overhead of purchasing machinery. Additionally, the integration of advanced software solutions for design and project management is enhancing operational efficiencies, enabling quicker turnaround times for projects.

Moreover, sustainability is becoming a critical factor in the sourcing decisions of B2B buyers. As environmental concerns grow, companies are looking for suppliers that align with their sustainability goals, focusing on services that utilize eco-friendly materials and practices. These market dynamics create a robust environment for innovation and collaboration, positioning laser cutter hire services as a key enabler of business growth and adaptability in various sectors.

How Does Sustainability and Ethical Sourcing Impact the Laser Cutter for Hire Sector?

Sustainability is now at the forefront of the laser cutter for hire sector, with environmental impact becoming a significant consideration for B2B buyers. As industries face increasing pressure to reduce their carbon footprint, many are seeking suppliers that prioritize sustainable practices. This includes using materials that are recyclable, biodegradable, or sourced from responsibly managed forests.

Ethical sourcing is equally important; businesses are increasingly scrutinizing their supply chains to ensure fair labor practices and minimal environmental degradation. Certifications such as Forest Stewardship Council (FSC) for wood products or ISO certifications for sustainable practices can enhance credibility and appeal to environmentally conscious buyers.

In addition to ethical considerations, the use of “green” materials is gaining traction. Laser cutting processes that minimize waste and energy consumption are particularly attractive to companies looking to enhance their sustainability profiles. By choosing a laser cutter for hire that emphasizes eco-friendly practices, businesses can not only meet regulatory demands but also appeal to a growing base of environmentally aware consumers.

What Is the Brief Evolution and History of Laser Cutting in the B2B Context?

Laser cutting technology has evolved significantly since its inception in the 1960s. Initially developed for industrial applications, it has transformed into a versatile tool used across various sectors, including automotive, aerospace, and arts and crafts. The introduction of computer numerical control (CNC) systems in the 1980s revolutionized the industry, allowing for greater precision and efficiency.

In recent years, the democratization of laser cutting technology has made it accessible to a broader range of businesses. The rise of laser cutter hire services has particularly empowered small to medium enterprises (SMEs) and startups to leverage advanced cutting techniques without the financial burden of equipment ownership. This shift has contributed to the growth of innovative products and services, enabling companies to prototype and produce custom solutions rapidly.

As the market continues to evolve, the focus on sustainability, customization, and technological integration will likely drive further advancements in the laser cutter for hire sector, positioning it as a crucial component of modern manufacturing and design processes.

Frequently Asked Questions (FAQs) for B2B Buyers of laser cutter for hire

-

How do I ensure the quality of laser cutting services from international suppliers?

To ensure quality when sourcing laser cutting services from international suppliers, request samples of their previous work, preferably with your specific materials and designs. Evaluate their machinery and technology to ensure they meet industry standards. Additionally, verify certifications and client testimonials. Establish clear quality assurance protocols, such as detailed specifications and acceptable tolerance levels, to ensure the final product meets your expectations. -

What should I consider when choosing a laser cutter for hire?

When choosing a laser cutter for hire, consider the machine’s capabilities, including material compatibility and thickness limits. Assess the supplier’s experience and reputation in the industry, as well as their turnaround times. Additionally, inquire about customization options, minimum order quantities (MOQs), and any additional services offered, such as design assistance or material sourcing. Understanding the total cost, including shipping and handling, is crucial for budget planning. -

What is the typical lead time for laser cutting services?

Lead times for laser cutting services can vary significantly based on the supplier and the complexity of the project. Generally, expect a turnaround time of 3-10 business days after finalizing your design and payment. For larger or more complex orders, it may take longer. Always confirm lead times upfront and factor in additional time for international shipping when planning your project timeline. -

How can I customize my laser cutting project to meet specific needs?

Customizing your laser cutting project involves providing detailed specifications regarding dimensions, materials, and design. Use vector files in formats like SVG or AI to ensure precision in cutting and engraving. Communicate any specific aesthetic or functional requirements to the supplier. Many providers also offer design services to assist in creating laser-ready files, which can enhance the final output’s quality. -

What are the payment terms typically associated with laser cutting services?

Payment terms for laser cutting services can vary by supplier. Common arrangements include upfront payments, deposits, or payment upon completion. Always clarify the payment structure before proceeding, including accepted payment methods (e.g., credit cards, bank transfers) and any potential additional fees for international transactions. Negotiating favorable terms can help manage cash flow effectively. -

What logistics should I consider when hiring a laser cutter internationally?

When hiring a laser cutter internationally, consider shipping logistics, including costs, customs clearance, and delivery times. Research import regulations in your country to avoid delays. It’s also wise to confirm whether the supplier provides packaging and shipping services or if you need to arrange these separately. Establishing a reliable logistics partner can streamline the process and ensure timely delivery of your finished products. -

How do I vet potential laser cutting suppliers?

Vetting potential laser cutting suppliers involves researching their background, including years of experience and industry reputation. Request references from previous clients and review their portfolio for quality and diversity of work. Assess their communication responsiveness and willingness to accommodate your specific needs. Additionally, consider visiting their facility if possible, or arranging a video call to discuss your project in detail. -

What are the advantages of hiring a local laser cutter versus an international one?

Hiring a local laser cutter offers several advantages, such as reduced shipping costs, faster turnaround times, and easier communication. Local suppliers may also be more familiar with regional materials and regulations, which can streamline the project. Conversely, international suppliers may provide access to advanced technology or specialized services not available locally. Assess your specific project needs and budget to determine the best option for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Laser Cutter For Hire Manufacturers & Suppliers List

1. NY Laser Cut – Laser Cutting & CNC Milling Services

Domain: nyclasercut.com

Registered: 2011 (14 years)

Introduction: NY Laser Cut offers professional laser cutting services with a large format of 4’x8′ and precision up to 0.001″ tolerance. They serve the creative industry, including retail, art, design, and fashion, with over ten years of experience. Additionally, they provide CNC milling services using a 5’x10′ machine with 3-axis capabilities, capable of cutting materials up to 4″ thick and achieving fine deta…

2. Woodland Manufacturing – Custom Laser Cutting Services

Domain: woodlandmanufacturing.com

Registered: 2001 (24 years)

Introduction: Woodland Manufacturing offers custom laser cutting services for various materials including wood, acrylic, and mylar. The laser cutting service provides precise cuts and engraving features, leaving a burned edge on wood that artists appreciate. Customers can submit their specifications, including size, lettering, art, colors, and finish, to receive a quote within 2 business days. The service is su…

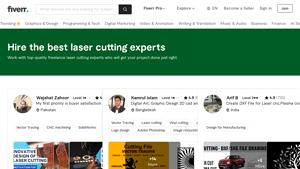

3. Fiverr – Top Freelance Laser Cutting Experts

Domain: fiverr.com

Registered: 2009 (16 years)

Introduction: 12 Best freelance laser cutting experts for hire in July 2025. Work with top-quality freelance laser cutting experts who will get your project done just right. Key experts include: W Wajahat Zahoor (Level 1, 4.9 rating, 221 reviews), K Kamrul Islam (Level 1, 4.9 rating, 601 reviews), A Arif B (Level 2, 4.9 rating, 720 reviews), A Mohssine El (Level 2, 4.9 rating, 1,162 reviews), M Max (Fiverr’s Ch…

4. Etsy – Custom Laser Cutting Services

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Custom Laser Cutting services available on Etsy, including options for custom jewelry, gift baskets, stationery, art prints, and clothing. Prices range from $1.41 to $100. Services offered include laser cutting and engraving on materials such as wood, acrylic, paper, card, stainless steel, brass, and aluminum. Some listings offer free shipping. Custom orders are available for personalized designs.

5. American Laser Company – Hourly Laser Cutter Rental

Domain: americanlaserco.com

Registered: 2015 (10 years)

Introduction: Hourly laser cutter rental service offered by American Laser Company. The service includes access to high-quality laser cutting equipment for various projects. Customers can rent the laser cutter on an hourly basis, allowing for flexibility and cost-effectiveness. The rental service is suitable for both individuals and businesses looking to complete specific tasks without the need for long-term in…

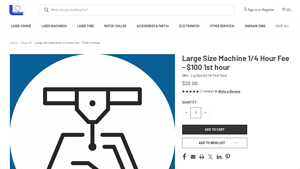

6. LightObject – Large Size Machine Rental

Domain: lightobject.com

Registered: 2004 (21 years)

Introduction: Large Size Machine 1/4 Hour Fee – $100 for the 1st hour. Machine size: 900mm x 600mm. Set up fee: $25 (to be added on top of production time per customer per visit). Assistance fee: $35/hr. SKU: Lrg Size Qtr Hr First Hour.

7. Yelp – Best Laser Cutting Services in New York

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Laser Cutting Services in New York, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for laser cutter for hire

In the dynamic landscape of laser cutting services, strategic sourcing offers businesses an invaluable opportunity to enhance their operational efficiency and product quality. By leveraging rental options, companies can access advanced technology without the hefty capital investment associated with purchasing equipment. This flexibility enables organizations to scale their production capabilities and customize projects according to specific client needs, particularly in regions like Africa, South America, the Middle East, and Europe.

Moreover, the rise of DIY laser cutting services empowers businesses to take control of their creative processes, fostering innovation and rapid prototyping. As the global market continues to evolve, the demand for precision and customization will only intensify.

For international B2B buyers, the time to act is now. Engaging with reputable laser cutter rental services can unlock new avenues for growth and creativity. Explore partnerships that align with your strategic goals, and consider how these services can enhance your product offerings and operational agility. Embrace the future of manufacturing by integrating laser cutting into your business model, and position yourself at the forefront of your industry.