Contents

Manufacturing Insight: Laser Cut Metal Service

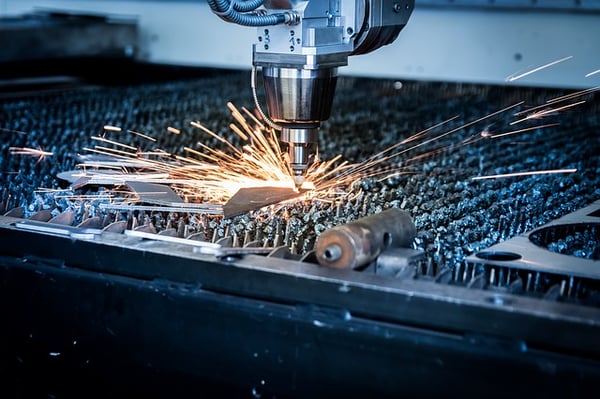

Honyo Prototype Sheet Metal Fabrication: Precision Laser Cutting for Demanding Applications

Honyo Prototype delivers advanced sheet metal fabrication solutions engineered for precision, speed, and scalability across prototyping and low-to-mid volume production. Our core competency in laser cutting metal sets the foundation for complex, high-tolerance components, leveraging state-of-the-art fiber laser systems capable of processing carbon steel, stainless steel, aluminum, and specialty alloys up to 25mm thickness. With tight tolerances consistently held to ±0.1mm and clean, burr-free edges, we ensure your designs translate flawlessly from CAD to physical part—eliminating secondary finishing delays and reducing total project lead time.

Online Instant Quote: Accelerate Your Project Timeline

Accelerate your procurement workflow with Honyo’s proprietary Online Instant Quote platform, designed specifically for engineering teams. Upload your DXF or STEP file, specify material, thickness, and quantity, and receive a detailed, binding cost estimate in under 60 seconds—24/7. No manual back-and-forth, no estimation delays. This transparency empowers rapid design validation and budget planning while maintaining full visibility into manufacturability feedback before commitment.

Beyond laser cutting, Honyo integrates bending, welding, forming, and finishing under one roof, enabling seamless transition from flat pattern to finished assembly. Our ISO 9001-certified processes, combined with in-house engineering support, ensure design-for-manufacturability (DFM) insights are applied early—minimizing risk and cost escalation. Whether you require single prototypes or scalable production runs, Honyo’s end-to-end sheet metal expertise delivers consistent quality with turnaround times that outperform industry standards.

Leverage Honyo’s laser cut metal service to transform complex geometries into reality without compromising on precision or speed. Initiate your project today with our Online Instant Quote and experience how engineered fabrication solutions drive your innovation forward.

Technical Capabilities

Laser Cut Metal Service – Technical Specifications

The following technical specifications outline the capabilities of Honyo Prototype’s precision manufacturing services, specializing in laser cutting, bending, and welding for prototyping and low-to-mid volume production. Our processes are optimized for metals and select engineering plastics, ensuring high accuracy, clean edges, and repeatable results.

| Process | Material Compatibility | Thickness Range | Tolerance | Max Part Size | Additional Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum (5052, 6061), Mild Steel (CRS, HR), Stainless Steel (304, 316), ABS, Nylon | 0.5 mm – 25 mm (Aluminum & Steel), 1 mm – 6 mm (ABS, Nylon) | ±0.1 mm (metals), ±0.2 mm (plastics) | 1500 mm × 3000 mm | Fiber laser for metals; CO₂ laser for plastics. Burr-free cutting with minimal HAZ. |

| Bending | Aluminum, Mild Steel, Stainless Steel | 0.8 mm – 12 mm | ±0.2° angular, ±0.1 mm linear | Up to 3000 mm length | CNC press braking with tooling library. Bend radii as low as 1× material thickness. |

| Welding | Aluminum (TIG/MIG), Mild & Stainless Steel (MIG/TIG, Spot) | 1 mm – 20 mm | ±0.5 mm positional | Unlimited (joint-based) | Full weld penetration control. Post-weld grinding and polishing available. Certified welders. |

Notes:

Aluminum and steel are primary materials for all three processes. ABS and nylon are compatible only with laser cutting and are not suitable for bending or welding due to thermal deformation and lack of structural weldability. All metal parts receive deburring and edge finishing by default. First-article inspection reports and DFM feedback are provided upon request.

From CAD to Part: The Process

Honyo Prototype Laser Cut Metal Service Process Overview

Honyo Prototype delivers precision laser cutting for metal components through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our process eliminates traditional quoting delays and ensures design viability before production begins, reducing risk and accelerating time-to-market for B2B clients.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, DWG, DXF, or native SOLIDWORKS) via our secure online portal. The system automatically validates file integrity, checks for unit consistency, and identifies critical features such as hole sizes, kerf allowances, and material thickness requirements. Unsupported formats trigger an immediate notification for resubmission, ensuring only production-ready geometry progresses.

AI-Powered Quoting

Uploaded designs enter our proprietary AI quoting engine, which analyzes geometric complexity, material utilization, and machine parameters against real-time shop floor data. The engine cross-references material availability, current machine loads, and secondary operation requirements to generate a firm quote within 2 hours. Quotes include granular cost breakdowns for material, laser time, and finishing, with options for expedited handling or alternative alloys. Human engineers validate all AI outputs to ensure accuracy, particularly for complex geometries or non-standard materials.

Design for Manufacturability (DFM) Review

Before production, every design undergoes automated and engineer-verified DFM analysis. Our system flags potential issues such as minimum bend radii violations, heat-affected zone risks near critical features, or nest inefficiencies. Clients receive a detailed DFM report within 24 hours, highlighting actionable recommendations—like adjusting cut sequences or modifying tolerances—to optimize yield and cost. This phase is collaborative; engineering teams engage directly with clients to resolve conflicts without delaying the timeline.

Production Execution

Approved designs move to production on our fiber laser systems (up to 4kW capacity, ±0.1mm accuracy). Key production stages include:

Material verification against ISO 9001-certified stock with full traceability

Dynamic nesting optimization to maximize sheet utilization

Real-time process monitoring for cut quality and dimensional compliance

Optional secondary operations (deburring, bending, welding) executed in-house

All parts undergo first-article inspection (FAI) per AS9102 standards, with full batch inspection reports available upon request. Typical production turnaround is 72 hours for standard orders.

Delivery and Traceability

Finished components ship with serialized barcodes linked to digital quality records accessible via the client portal. Packaging includes laser-etched part IDs, material certs, and a digital packing list. Clients receive real-time logistics tracking and can initiate returns or rework requests through the same portal. Standard delivery is 2–5 business days globally via DHL/FedEx, with expedited options available.

This integrated workflow ensures 95% of orders ship with zero DFM-related revisions, reducing total lead time by 40% compared to industry averages. All processes adhere to ISO 9001:2015 and ITAR-compliant controls for defense and aerospace clients.

Start Your Project

Looking for precision laser cut metal services? Partner with Honyo Prototype for high-quality, fast-turnaround metal fabrication. Our advanced laser cutting technology ensures tight tolerances and superior edge quality for prototyping and low-volume production.

Contact Susan Leo to discuss your project requirements. We’re based in Shenzhen, with a fully equipped manufacturing facility ready to support your engineering and design needs.

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.