Introduction: Navigating the Global Market for laser cnc precio

In the rapidly evolving landscape of manufacturing, sourcing reliable and cost-effective laser CNC machines can be a daunting task for international B2B buyers. The challenge lies not only in understanding the diverse range of products available but also in navigating the myriad factors that influence laser CNC pricing. This comprehensive guide on “laser CNC precio” addresses these complexities, equipping buyers with the knowledge needed to make informed purchasing decisions.

Covering various types of laser CNC machines, their applications across industries, and essential insights into supplier vetting, this resource serves as a crucial tool for businesses in Africa, South America, the Middle East, and Europe, including regions like Vietnam and Nigeria. Buyers will find actionable insights on price comparisons, ensuring they understand the value proposition of different options available in the market.

Furthermore, this guide delves into critical aspects such as warranty considerations, after-sales support, and potential financing options, all of which are vital for establishing long-term supplier relationships. By empowering businesses with the right information, this guide not only simplifies the purchasing process but also enhances operational efficiency, ultimately leading to better investment decisions in laser CNC technology.

Understanding laser cnc precio Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Laser CNC Machines | Utilizes CO2 gas for cutting and engraving, effective on non-metals | Woodworking, signage, and textile industries | Pros: Versatile, excellent for organic materials. Cons: Limited metal cutting capabilities. |

| Fiber Laser CNC Machines | Employs fiber optics to generate laser, ideal for metals | Metal fabrication, automotive, aerospace | Pros: High precision, fast cutting speeds. Cons: Higher initial investment. |

| Hybrid Laser CNC Systems | Combines CO2 and fiber laser technologies | Multi-material processing | Pros: Flexibility in material types. Cons: Complexity in operation and maintenance. |

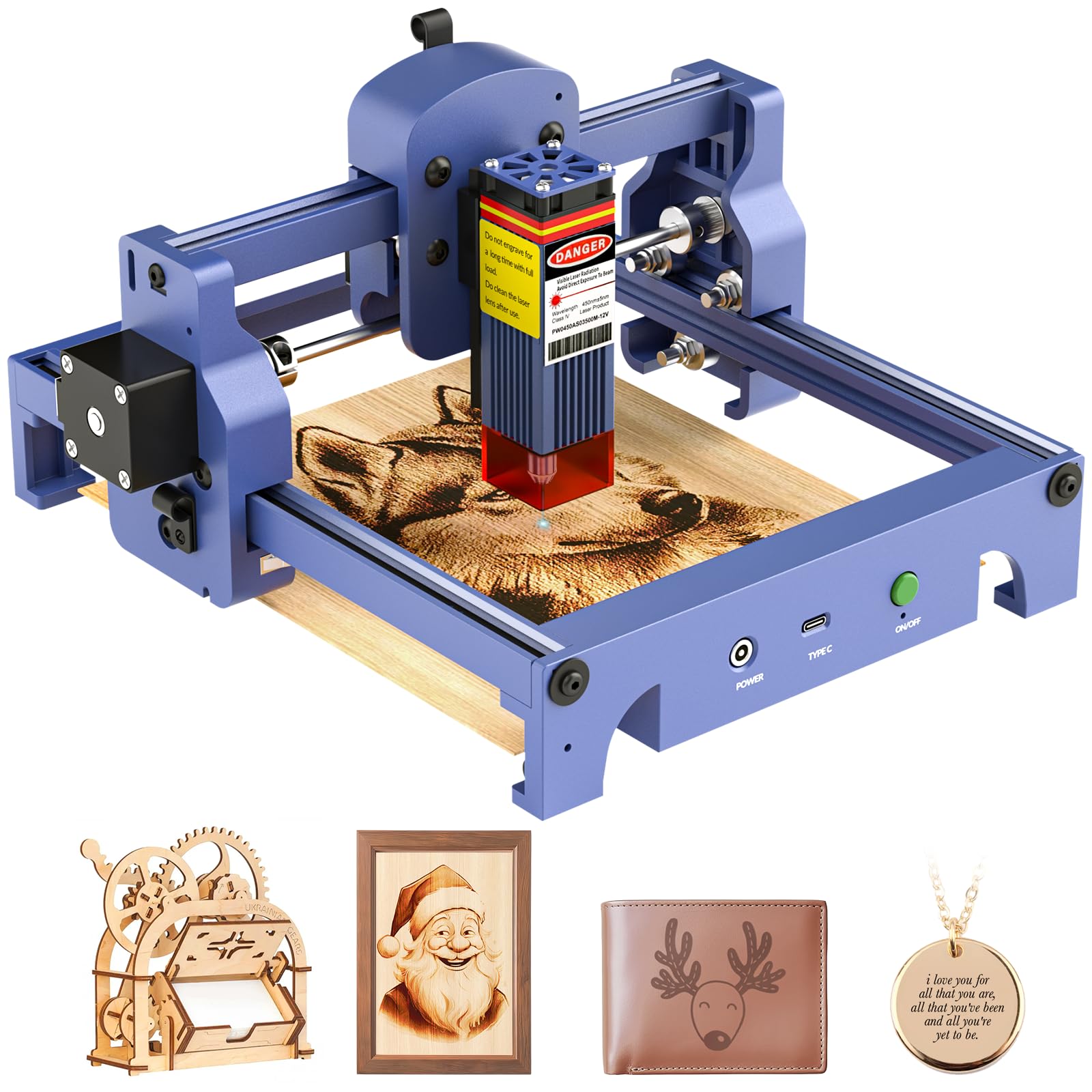

| Desktop Laser CNC Engravers | Compact, user-friendly, suitable for small-scale operations | Prototyping, crafts, and small businesses | Pros: Affordable, easy to operate. Cons: Limited cutting depth and speed. |

| Industrial Laser Cutting Systems | Large-scale, high-power machines for mass production | Manufacturing, heavy industry | Pros: High throughput, robust construction. Cons: Requires significant floor space. |

What Are the Characteristics of CO2 Laser CNC Machines?

CO2 laser CNC machines are primarily designed for cutting and engraving non-metal materials such as wood, acrylic, and textiles. They utilize a gas laser, which produces a high-quality beam suitable for intricate designs. These machines are widely used in woodworking and signage industries due to their versatility and efficiency. B2B buyers should consider factors such as the machine’s power, bed size, and software compatibility when purchasing.

How Do Fiber Laser CNC Machines Stand Out?

Fiber laser CNC machines are specifically engineered for metal cutting, utilizing fiber optics to create a focused beam. This technology allows for high-speed cutting with exceptional precision, making it ideal for applications in metal fabrication and industries like automotive and aerospace. Buyers should evaluate the wattage, cutting thickness, and material compatibility to ensure they select a machine that meets their production needs.

What Advantages Do Hybrid Laser CNC Systems Offer?

Hybrid laser CNC systems combine both CO2 and fiber laser technologies, providing the flexibility to work with a variety of materials, including both metals and non-metals. This versatility makes them suitable for businesses that require multi-material processing. When considering a hybrid system, B2B buyers should assess the machine’s operational complexity and maintenance requirements, as these can impact overall productivity.

Why Choose Desktop Laser CNC Engravers for Small Businesses?

Desktop laser CNC engravers are compact and user-friendly, making them ideal for small-scale operations and startups. They are particularly effective for prototyping and craft applications, where space and budget constraints are a concern. Buyers should focus on the engraving area, software ease of use, and support services when selecting a desktop model to ensure it aligns with their business objectives.

What Should B2B Buyers Know About Industrial Laser Cutting Systems?

Industrial laser cutting systems are built for high-volume production, capable of handling large sheets of material with robust performance. These machines are essential in heavy industries, where precision and speed are critical. B2B buyers must consider the machine’s size, power requirements, and integration capabilities with existing manufacturing processes to ensure optimal operation within their facilities.

Key Industrial Applications of laser cnc precio

| Industry/Sector | Specific Application of laser cnc precio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision Metal Cutting | High accuracy and reduced waste in production | Supplier reliability, machine compatibility, and maintenance support |

| Automotive | Custom Part Fabrication | Fast prototyping and reduced lead times | Material compatibility, after-sales service, and warranty options |

| Aerospace | Component Engraving and Marking | Enhanced traceability and compliance with regulations | Quality certifications, precision capabilities, and international shipping options |

| Electronics | PCB Prototyping and Etching | Efficient design iterations and cost savings | Technology updates, local support, and compatibility with existing systems |

| Arts and Crafts | Decorative Laser Engraving and Cutting | Unique product offerings and enhanced customer engagement | Design flexibility, material choices, and artistic capabilities |

How is ‘laser cnc precio’ Utilized in Manufacturing?

In the manufacturing sector, laser CNC machines are pivotal for precision metal cutting. These machines enable businesses to achieve high levels of accuracy while minimizing material waste. This capability not only streamlines production but also significantly reduces costs. For international buyers, especially in regions like Africa and South America, sourcing machines that offer reliable support and compatibility with local materials is crucial. Additionally, understanding the machine’s maintenance requirements can prevent costly downtimes.

What Role Does ‘laser cnc precio’ Play in Automotive Custom Part Fabrication?

The automotive industry benefits greatly from laser CNC technology, particularly for custom part fabrication. With the ability to quickly prototype and produce components, manufacturers can significantly reduce lead times and respond faster to market demands. Buyers should consider the machine’s adaptability to various materials, as well as the supplier’s capability to provide ongoing support and warranty services. This is especially important for businesses in the Middle East and Europe, where regulatory standards for automotive parts are stringent.

How is ‘laser cnc precio’ Enhancing Aerospace Component Engraving?

In aerospace, laser CNC machines are used for engraving and marking components, which is essential for traceability and regulatory compliance. The precision offered by these machines ensures that markings are clear and durable, which is critical in meeting industry standards. Buyers from Europe and other regions should prioritize suppliers that have quality certifications and can demonstrate precision capabilities. Furthermore, understanding the logistics of international shipping and customs can help streamline the procurement process.

What Benefits Does ‘laser cnc precio’ Offer for Electronics PCB Prototyping?

In the electronics sector, laser CNC technology is extensively used for PCB prototyping and etching. This application allows for rapid design iterations, enabling companies to bring products to market faster while saving costs on material and labor. For international B2B buyers, especially those in emerging markets, sourcing machines that offer local support and technology updates is vital. Additionally, ensuring compatibility with existing production systems can facilitate smoother integration into operations.

How is ‘laser cnc precio’ Transforming the Arts and Crafts Sector?

Laser CNC machines are revolutionizing the arts and crafts industry by providing unique decorative engraving and cutting capabilities. This technology allows artisans to create intricate designs and personalized products, enhancing customer engagement and satisfaction. For B2B buyers, particularly in regions like Africa and South America, it is essential to consider the design flexibility of the machine and the variety of materials it can handle. Establishing relationships with suppliers that offer comprehensive training and design resources can further empower creators in this sector.

3 Common User Pain Points for ‘laser cnc precio’ & Their Solutions

Scenario 1: Navigating High Initial Investment Costs for Laser CNC Machines

The Problem: One of the primary challenges that B2B buyers face when considering laser CNC machines is the high initial investment required. Companies in regions such as Africa and South America may struggle with budget constraints, especially if they are small or medium enterprises. This can lead to reluctance in making a purchase, as they fear overextending their financial resources. Additionally, fluctuating currency values can complicate pricing, making it difficult for buyers to assess whether they are getting a fair deal.

The Solution: To address the issue of high costs, buyers should conduct a thorough market analysis to identify various suppliers and their pricing structures. It’s advisable to request quotes from multiple vendors, ensuring to factor in shipping, taxes, and potential import duties. Buyers can also explore financing options such as installment payment plans or leasing arrangements, which can alleviate the burden of upfront costs. Furthermore, engaging with local distributors may yield better pricing or additional support services that can enhance the value of the investment. Prioritizing suppliers that offer warranties and customer support can ensure long-term reliability and reduce future expenses.

Scenario 2: Understanding the Complexity of Laser CNC Specifications

The Problem: B2B buyers often find themselves overwhelmed by the technical specifications associated with laser CNC machines. With various options available—ranging from different wattages to cutting speeds and materials compatibility—buyers may struggle to determine which machine best suits their operational needs. This complexity can lead to misinformed decisions, resulting in purchasing equipment that does not meet their requirements or is underutilized.

The Solution: To mitigate this issue, buyers should invest time in understanding the specific needs of their operations. This involves conducting a needs assessment that considers the types of materials they will be working with, the desired precision, and the production volume. Consulting with industry experts or suppliers can provide valuable insights into which specifications are essential for their applications. Additionally, attending trade shows or workshops can offer practical demonstrations of equipment in action, helping buyers to make informed decisions. Using a checklist of required specifications can streamline the selection process and ensure that the chosen laser CNC machine aligns with their operational goals.

Scenario 3: Ensuring Adequate Training and Support for New Equipment

The Problem: After investing in a laser CNC machine, many companies face challenges related to inadequate training and support for their staff. In regions with limited access to technical resources, it can be difficult for employees to operate new machinery effectively. This can lead to reduced productivity, increased error rates, and potential safety hazards, ultimately impacting the company’s bottom line.

The Solution: To overcome these challenges, buyers should prioritize suppliers that provide comprehensive training programs as part of their sales package. This can include on-site training sessions, access to online tutorials, and detailed user manuals. Additionally, establishing a relationship with the supplier for ongoing technical support is crucial. Companies should also consider appointing a dedicated staff member as a ‘machine champion’ who can lead training efforts and troubleshoot issues. Investing in regular refresher courses can further enhance employee skills and ensure the equipment is utilized to its full potential, leading to greater efficiency and safety in operations.

Strategic Material Selection Guide for laser cnc precio

What Are the Key Properties of Common Materials Used in Laser CNC Applications?

When selecting materials for laser CNC applications, understanding the properties of each material is crucial for optimizing performance and ensuring compatibility with various manufacturing processes. Below, we analyze four common materials used in laser CNC operations: wood, acrylic, metal, and composite materials.

Wood: Versatile and Cost-Effective

Wood is a widely used material in laser CNC applications, particularly for engraving and cutting. Its key properties include a low density, good workability, and a natural aesthetic appeal. Wood is generally resistant to temperature fluctuations but can be susceptible to moisture and pests.

Pros: Wood is relatively inexpensive and easy to source, making it an excellent choice for small businesses and startups. It can be finished in various ways, allowing for customization in end products.

Cons: The primary limitation of wood is its variability in quality and density, which can affect cutting precision. Additionally, certain wood types may produce harmful fumes when cut, necessitating proper ventilation.

Impact on Application: Wood is compatible with a range of laser settings, making it suitable for intricate designs and detailed engravings.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the importation of wood products, especially concerning pest control and sustainability certifications.

Acrylic: Durable and Aesthetic

Acrylic, also known as PMMA (polymethyl methacrylate), is a popular choice for laser cutting and engraving due to its clarity and durability. It has excellent weather resistance and can withstand a wide range of temperatures.

Pros: Acrylic is lightweight, shatter-resistant, and available in various colors and finishes, making it suitable for diverse applications from signage to decorative items.

Cons: While acrylic is durable, it can be more expensive than wood and may require specific laser settings to avoid melting or charring.

Impact on Application: Acrylic’s optical clarity allows for unique visual effects in products, enhancing their market appeal.

Considerations for International Buyers: Compliance with local standards for plastic materials, such as ASTM or ISO, is essential. Buyers should also consider the availability of acrylic in their region to ensure consistent supply.

Metal: Strength and Precision

Metals such as stainless steel, aluminum, and brass are increasingly used in laser CNC applications for their strength and durability. These materials typically have high melting points and excellent corrosion resistance.

Pros: Metal components provide superior strength and durability, making them ideal for industrial applications. They can also be finished in various ways, including anodizing and powder coating.

Cons: The cost of metal materials is generally higher than wood or acrylic, and the manufacturing process can be more complex, requiring specialized equipment and expertise.

Impact on Application: Metals are suitable for high-precision applications, including automotive and aerospace components, where durability is paramount.

Considerations for International Buyers: Buyers should be aware of international standards for metal quality and certification, such as ASTM and DIN, to ensure compliance and quality assurance.

Composite Materials: Innovative and Versatile

Composite materials, which combine two or more constituent materials, are increasingly popular in laser CNC applications. These materials can be engineered to exhibit specific properties, such as enhanced strength or reduced weight.

Pros: Composites offer flexibility in design and can be tailored to meet specific performance requirements, making them suitable for a wide range of applications.

Cons: The complexity of composite materials can lead to higher costs and manufacturing challenges, particularly in ensuring uniformity in production.

Impact on Application: Composites can be used in industries ranging from aerospace to consumer goods, providing innovative solutions that traditional materials may not offer.

Considerations for International Buyers: Understanding the specific standards applicable to composite materials, such as JIS or ISO, is critical for ensuring compliance and quality.

Summary Table of Material Selection for Laser CNC Applications

| Material | Typical Use Case for laser cnc precio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Engraving, decorative items | Cost-effective and easy to work with | Variability in quality | Low |

| Acrylic | Signage, displays | Durable and available in various colors | Higher cost than wood | Medium |

| Metal | Industrial components, precision parts | Superior strength and durability | Higher manufacturing complexity | High |

| Composite | Aerospace, automotive applications | Tailored properties for specific needs | Higher costs and production challenges | High |

This guide provides actionable insights for B2B buyers, enabling informed decisions regarding material selection for laser CNC applications. Understanding the properties, advantages, and limitations of each material will help businesses optimize their production processes while ensuring compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for laser cnc precio

What Are the Main Stages of Manufacturing Laser CNC Machines?

The manufacturing process for laser CNC machines involves several critical stages, each designed to ensure precision and quality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting high-quality raw materials, typically metals such as aluminum or steel, and plastics for various components. The materials are sourced from reputable suppliers and undergo initial inspections to ensure they meet specified standards. Advanced technologies like laser cutting may be used to create precise shapes and sizes from the raw materials.

-

Forming: This stage includes techniques such as machining, bending, and welding. CNC machining is widely used to shape components with high accuracy. Forming processes are guided by computer-aided design (CAD) files, ensuring that every piece aligns with the design specifications. Automated tools, including laser cutters and plasma cutters, are often employed to enhance precision and reduce waste.

-

Assembly: After forming, components are assembled into the final product. This may involve soldering electronic parts, connecting optical fibers, and integrating control systems. Skilled technicians typically handle this process to ensure that all parts fit together correctly and function as intended. Automated assembly lines may also be utilized to enhance efficiency.

-

Finishing: The final stage includes surface treatment processes such as anodizing, powder coating, or painting to enhance durability and aesthetics. Quality checks are performed throughout the finishing process to ensure that the final appearance meets the expected standards. This stage may also include the installation of safety features and compliance with regulatory standards.

How Is Quality Assurance Implemented in Laser CNC Manufacturing?

Quality assurance (QA) is a vital aspect of manufacturing laser CNC machines, ensuring that products meet international standards and client expectations. The QA process involves several key components:

-

International and Industry-Specific Standards: Adhering to quality standards such as ISO 9001 is essential for manufacturers. This standard emphasizes a systematic approach to management processes, ensuring consistency in quality. For laser CNC machines, compliance with CE marking and other relevant certifications is also crucial, particularly for equipment sold in Europe. These certifications demonstrate that products meet safety and environmental requirements.

-

Quality Control Checkpoints: Effective QA includes multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for early detection of defects.

– Final Quality Control (FQC): Once the product is assembled, it undergoes thorough testing to ensure it meets design specifications and quality standards. -

Common Testing Methods: Various testing methods are employed to verify the functionality and safety of laser CNC machines. These include:

– Functional Testing: Ensures that all components operate correctly under normal conditions.

– Performance Testing: Assesses the machine’s capabilities, such as cutting speed and precision.

– Safety Testing: Evaluates compliance with safety regulations to protect users during operation.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure that their suppliers maintain high-quality standards. Here are several strategies for verifying supplier QC:

-

Supplier Audits: Conducting audits at the supplier’s manufacturing facility can provide firsthand insight into their quality control processes. This includes evaluating their adherence to standards like ISO 9001 and reviewing their documentation practices.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures in place. This may include data on defect rates, corrective actions taken, and results from various testing methods.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control. These services can conduct tests and inspections that align with international standards, offering additional assurance to buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, face unique challenges when it comes to quality control:

-

Cultural Differences: Understanding cultural attitudes towards quality can influence supplier relationships. Buyers should consider local practices and how they align with international standards.

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should be aware of local laws and standards to ensure that their products meet compliance in their target markets.

-

Logistics and Communication: Time zone differences and language barriers can complicate communication regarding quality issues. Establishing clear lines of communication and utilizing technology for real-time updates can mitigate these challenges.

-

Documentation: Maintaining comprehensive documentation throughout the supply chain is crucial for international transactions. Buyers should ensure that suppliers provide all necessary certifications and quality assurance documentation to facilitate smooth customs processes and compliance checks.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for laser CNC machines is essential for B2B buyers. By familiarizing themselves with these stages, implementing effective verification strategies, and being aware of international nuances, buyers can make informed decisions and build successful partnerships with their suppliers. This proactive approach to quality assurance not only enhances product reliability but also strengthens the overall business relationship.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘laser cnc precio’

When sourcing a laser CNC machine, especially for international B2B transactions, it’s vital to follow a structured approach to ensure you make informed decisions. This guide provides a step-by-step checklist to assist you in navigating the complexities of procurement, from defining your requirements to evaluating potential suppliers.

Step 1: Define Your Technical Specifications

Clearly outline your technical needs before engaging with suppliers. Consider the materials you will be working with, the thickness of the materials, and the precision required for your projects. Additionally, determine the power of the laser (e.g., 40W, 80W) and the size of the work area. Having precise specifications will help you communicate effectively with potential suppliers and streamline the selection process.

Step 2: Research Market Prices

Conduct thorough research on the market prices for the laser CNC machines that meet your specifications. This includes looking at various suppliers across different regions to understand pricing variations. Pay attention to additional costs such as shipping, taxes, and tariffs, as these can significantly impact the total price. Understanding the price range will also help you identify competitive offers and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Check for supplier certifications and standards compliance (e.g., ISO, CE) to ensure quality and reliability. Engaging with suppliers who have a solid reputation can mitigate risks associated with international procurement.

Step 4: Assess Warranty and After-Sales Support

Review the warranty terms and after-sales support offered by potential suppliers. A robust warranty can protect your investment in case of defects or performance issues. Additionally, inquire about the availability of technical support, spare parts, and maintenance services. Reliable after-sales support is essential, especially if you are operating in a region where immediate assistance may not be readily available.

Step 5: Request Samples and Demonstrations

Where possible, request samples or demonstrations of the laser CNC machines. This allows you to assess the machine’s capabilities and performance firsthand. Pay attention to the quality of cuts and engravings, as well as the machine’s ease of use. If a supplier cannot provide samples, consider visiting their facility or attending trade shows to see the machines in action.

Step 6: Negotiate Payment Terms

Establish favorable payment terms that align with your financial capabilities. Discuss options such as installment payments, letters of credit, or escrow services to protect your investment. Be clear about your payment expectations and ensure that both parties understand the terms to avoid misunderstandings later in the process.

Step 7: Finalize the Contract

Once you have selected a supplier, it’s time to finalize the contract. Ensure that all terms, including delivery timelines, payment schedules, warranty details, and specifications, are clearly documented. Review the contract carefully and consider legal counsel if necessary to protect your interests. A well-defined contract can prevent disputes and ensure a smoother transaction.

By following this checklist, you will be better equipped to make informed decisions when sourcing laser CNC machines, ultimately leading to successful procurement and operational efficiency.

Comprehensive Cost and Pricing Analysis for laser cnc precio Sourcing

What Are the Key Cost Components for Laser CNC Pricing?

Understanding the cost structure for laser CNC machines is crucial for B2B buyers looking to optimize their procurement strategies. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals and specialized components can elevate the price, while standard materials may reduce costs. Buyers should consider sourcing locally to mitigate material costs and lead times.

-

Labor: Skilled labor is essential for manufacturing laser CNC machines. Labor costs can vary widely based on geographic location and labor market conditions. In regions with a higher cost of living, such as parts of Europe, buyers may face increased manufacturing costs.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Overhead costs can be optimized by selecting suppliers with efficient production processes and facilities.

-

Tooling: Custom tooling can be a significant upfront investment. However, it is necessary for producing specialized parts. Buyers should assess whether their production requirements justify the investment in custom tooling.

-

Quality Control (QC): Ensuring that machines meet quality standards can incur additional costs. Investing in robust QC processes can lead to long-term savings by reducing defects and warranty claims.

-

Logistics: Shipping and handling costs can vary based on the distance between the supplier and buyer, as well as the chosen shipping method. Understanding Incoterms is essential for calculating total shipping costs.

-

Margin: Suppliers typically include a profit margin, which can vary based on their market position and the competitive landscape. Buyers should be aware of industry standards to negotiate effectively.

How Do Price Influencers Affect Laser CNC Machine Costs?

Several factors influence pricing in the laser CNC market, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to significant discounts. Buyers should negotiate MOQs that align with their production schedules to maximize savings.

-

Specifications and Customization: Customized machines tailored to specific applications can command higher prices. Buyers need to assess whether these custom features will deliver sufficient value to justify the investment.

-

Materials and Quality Certifications: The quality of materials used, alongside any industry certifications, can influence price. Machines with higher-grade components or certifications (like ISO) may be priced higher but offer better reliability and performance.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven track record and customer service.

-

Incoterms: Understanding the logistics and responsibilities associated with different Incoterms can impact overall costs. Buyers should clarify whether the quoted price includes shipping, insurance, and duties.

What Are the Best Buyer Tips for Cost-Efficiency in Laser CNC Sourcing?

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing and terms. Consider leveraging competitive quotes from multiple suppliers to strengthen your negotiating position.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price to consider ongoing operational costs, maintenance, and potential downtime. A more expensive machine may offer lower long-term costs through greater efficiency and reliability.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local market conditions, tariffs, and shipping costs. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Consider Payment Terms: Suppliers may offer favorable payment terms, such as installment plans or deferred payments, which can alleviate cash flow pressures.

-

Stay Informed About Market Trends: Keeping abreast of technological advancements and market shifts can help buyers make informed decisions and anticipate price changes.

Conclusion

Navigating the complexities of laser CNC pricing requires a comprehensive understanding of cost components, price influencers, and effective procurement strategies. By leveraging this knowledge, B2B buyers can enhance their sourcing decisions, ultimately leading to improved operational efficiency and cost savings. Please note that the prices indicated in various sources are for reference and may vary based on market conditions and specific supplier arrangements.

Alternatives Analysis: Comparing laser cnc precio With Other Solutions

Exploring Alternatives to Laser CNC Technology

In the realm of precision manufacturing, the choice of technology can greatly influence productivity and cost-effectiveness. While laser CNC systems are renowned for their accuracy and versatility, it is essential for businesses to consider alternative solutions that may better suit their specific needs and budget. This analysis compares laser CNC technology with two viable alternatives: traditional CNC routers and plasma cutting systems.

| Comparison Aspect | Laser CNC Precio | Traditional CNC Router | Plasma Cutting System |

|---|---|---|---|

| Performance | High precision; ideal for detailed engraving and cutting of various materials | Good precision; better for larger cuts in wood and softer materials | Excellent for cutting thick metals; less precise than laser |

| Cost | Higher initial investment; ongoing costs for laser maintenance | Moderate initial cost; lower maintenance | Lower initial investment; consumable costs can add up |

| Ease of Implementation | Requires skilled operators; setup can be complex | Generally user-friendly; easier for operators to learn | Simple setup; may require more safety training |

| Maintenance | Regular maintenance needed for laser optics and alignment | Lower maintenance; routine checks sufficient | Requires regular replacement of consumables; some maintenance |

| Best Use Case | Ideal for detailed designs, engraving, and cutting thin materials | Best for woodworking, sign-making, and basic machining | Excellent for heavy-duty metal fabrication and industrial applications |

What are the Pros and Cons of Traditional CNC Routers?

Traditional CNC routers offer a balanced approach to precision machining. They excel in woodworking and softer materials, making them suitable for furniture production, cabinetry, and signage. One of the main advantages is their ease of use; operators can quickly learn to program and operate these machines, reducing training time and costs. However, traditional routers do not provide the same level of precision as laser CNC systems, particularly for intricate designs or cutting very thin materials. Additionally, they may struggle with harder materials, limiting their versatility compared to laser technology.

How Does Plasma Cutting Compare as an Alternative?

Plasma cutting systems are an effective solution for businesses that require the ability to cut through thick metals quickly and efficiently. They have a lower initial investment compared to laser CNC systems, making them attractive for companies with tighter budgets. Plasma cutters are also relatively easy to set up and operate, requiring less specialized training than laser systems. However, the trade-off is in precision; plasma cutting may not achieve the fine detail that laser technology can offer. Moreover, the operating costs can escalate due to the need for consumables like electrodes and nozzles, which require frequent replacement.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right manufacturing technology depends on several factors, including the materials being processed, the required precision, and the available budget. Businesses that prioritize intricate designs and detailed work may find laser CNC systems to be the best fit, despite the higher costs. In contrast, companies focused on larger-scale production of wood or softer materials might benefit from traditional CNC routers. For those involved in heavy metal fabrication, plasma cutting systems present a viable and cost-effective option. Ultimately, a thorough assessment of production needs, budget constraints, and operational capabilities will guide B2B buyers in making an informed decision that aligns with their strategic goals.

Essential Technical Properties and Trade Terminology for laser cnc precio

What Are the Key Technical Properties of Laser CNC Machines?

When evaluating laser CNC machines for purchase, several technical properties are crucial for B2B buyers to understand. These specifications determine the machine’s capabilities, efficiency, and suitability for various applications.

-

Power Rating (Wattage)

– The power rating, typically measured in watts (W), indicates the laser’s cutting and engraving capabilities. Higher wattage allows for cutting through thicker materials and achieving faster processing speeds. For B2B buyers, understanding the power requirements helps in selecting a machine that meets their production needs without compromising quality. -

Cutting Area

– This refers to the maximum dimensions of materials that the laser CNC can accommodate, often expressed in millimeters or inches (e.g., 1220mm x 2440mm). A larger cutting area is essential for businesses that work with larger sheets of material or need to process multiple items simultaneously, enhancing operational efficiency. -

Material Compatibility

– Different laser CNC machines are designed to work with various materials, including wood, acrylic, metal, and glass. Knowing the material compatibility is vital for B2B buyers as it affects the machine’s versatility and the range of products they can manufacture, impacting overall business growth. -

Precision and Tolerance

– Precision refers to the accuracy with which the laser can cut or engrave materials, often measured in microns. Tolerance indicates the acceptable deviation from a specified dimension. High precision and tight tolerances are critical for industries requiring intricate designs and detailed work, such as electronics and aerospace. -

Cooling System

– Laser machines often use air or water cooling systems to maintain optimal operating temperatures. A robust cooling system enhances machine longevity and performance, particularly in high-demand environments. Buyers should consider the cooling method as it affects maintenance requirements and overall operational costs. -

Software Compatibility

– The software used to control the laser CNC machine can greatly influence its functionality. Compatibility with popular design software (like AutoCAD or CorelDRAW) is essential for seamless workflow integration. Understanding software capabilities allows businesses to optimize their design processes and enhance productivity.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in the B2B space. Here are some key terms relevant to laser CNC transactions:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of laser CNC machines, understanding OEM relationships can help buyers assess product quality and support, ensuring they choose reliable suppliers. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers, especially when planning inventory and budgeting, as it can significantly impact purchasing decisions and supply chain management. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for specific products or services. B2B buyers should utilize RFQs to gather pricing, terms, and conditions from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage shipping risks and costs effectively. -

Lead Time

– Lead time refers to the time taken from placing an order to its delivery. B2B buyers must consider lead times when planning production schedules and managing inventory, as longer lead times can affect overall business operations and customer satisfaction. -

After-Sales Support

– This term encompasses the services provided by the supplier after the purchase, including installation, maintenance, and technical support. Strong after-sales support is crucial for ensuring the longevity and reliability of laser CNC machines, making it an important factor for B2B buyers during the procurement process.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing laser CNC machines, ensuring they choose the right equipment for their specific needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the laser cnc precio Sector

What Are the Current Market Dynamics and Key Trends in the Laser CNC Precio Sector?

The laser CNC price sector is experiencing a significant transformation driven by technological advancements and evolving market demands. Globally, the push for automation in manufacturing processes is a primary driver, enabling companies to enhance precision, reduce labor costs, and improve production efficiency. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking affordable yet advanced laser CNC solutions to compete in a global market. The demand for versatility is also rising, with buyers looking for machines that can perform multiple tasks, such as cutting, engraving, and 3D printing, in one integrated system.

Emerging trends include the adoption of compact and portable laser CNC machines, which cater to small and medium-sized enterprises (SMEs) that lack extensive manufacturing floors. Moreover, the rise of e-commerce platforms has made it easier for international buyers to source equipment directly, often resulting in cost savings and broader options. Another noteworthy trend is the integration of IoT technology, allowing for remote monitoring and predictive maintenance, which enhances operational uptime and reduces unexpected breakdowns.

How Are Sustainability and Ethical Sourcing Influencing the Laser CNC Precio Market?

Sustainability has become a crucial consideration for B2B buyers in the laser CNC price sector. Companies are increasingly aware of the environmental impact associated with manufacturing processes and are seeking suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials, energy-efficient machinery, and responsible waste management practices.

The importance of ethical supply chains cannot be overstated; buyers are now more inclined to partner with manufacturers who can demonstrate compliance with international labor standards and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming prerequisites for suppliers targeting international markets. Furthermore, there is a growing demand for ‘green’ materials that are sourced responsibly, which aligns with the values of consumers who prioritize sustainability.

What Is the Brief Evolution of Laser CNC Technology?

The evolution of laser CNC technology dates back to the 1960s when laser cutting was first developed for industrial applications. Initially, the technology was expensive and limited to large manufacturers. However, advancements in laser technology and decreasing costs have democratized access, allowing SMEs to invest in laser CNC machines. Over the decades, the integration of computer numerical control (CNC) has further enhanced precision and efficiency, making laser CNC machines indispensable in various sectors, including automotive, aerospace, and textiles. As the technology continues to evolve, its applications are expanding, paving the way for innovative solutions that cater to the diverse needs of global B2B buyers.

In summary, understanding these market dynamics and trends is essential for B2B buyers in the laser CNC price sector. By leveraging technological advancements and prioritizing sustainability, they can position themselves competitively in an increasingly complex global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of laser cnc precio

-

How do I determine the right laser CNC machine for my business needs?

To select the appropriate laser CNC machine, assess your specific application requirements, such as the materials you will be processing (wood, metal, acrylic, etc.), the thickness of these materials, and the desired precision. Additionally, consider the production volume and whether you need features like rotary attachments for cylindrical objects. Research different models and their specifications, and consult with suppliers who can provide insights based on your industry needs. -

What factors influence the price of laser CNC machines?

The price of laser CNC machines is influenced by various factors including the machine’s power (measured in watts), size, brand reputation, and additional features such as advanced software capabilities or safety enhancements. Machines with higher power ratings typically command higher prices due to their ability to cut through thicker materials. Furthermore, the inclusion of warranties and after-sales support can also impact pricing. -

What are the common payment terms for purchasing laser CNC machines internationally?

Payment terms can vary significantly among suppliers. Common terms include payment in advance, a deposit followed by balance on delivery, or net payment after delivery. It’s essential to clarify these terms before finalizing a purchase. Some suppliers may also offer financing options or installment plans, which can ease cash flow constraints for businesses. Always ensure that terms are documented in the purchase agreement. -

What should I look for in a supplier when sourcing laser CNC machines?

When vetting suppliers, consider their industry experience, reputation, and customer reviews. Ensure they provide detailed product specifications and are transparent about warranty and support services. Ask for references from other B2B clients and evaluate their responsiveness to inquiries. Additionally, check if they comply with international standards and certifications, which can indicate quality and reliability. -

Can I customize my laser CNC machine to fit specific production needs?

Yes, many suppliers offer customization options for laser CNC machines, allowing you to tailor features such as size, laser power, and software capabilities. Customization can also include additional attachments for specialized applications. Discuss your requirements with potential suppliers to see how they can accommodate your needs and what the implications are for pricing and lead times. -

What are the minimum order quantities (MOQ) for laser CNC machines?

Minimum order quantities can differ based on the supplier and the type of machine. Some manufacturers may allow orders for single units, while others may have higher MOQs, especially if they offer discounts for bulk purchases. It’s advisable to inquire about MOQs during your initial discussions with suppliers, particularly if you are considering future expansions or additional equipment. -

What quality assurance (QA) measures should be in place for laser CNC machines?

Effective quality assurance measures include rigorous testing during the manufacturing process and before shipment. Suppliers should provide certification documents that demonstrate compliance with international quality standards such as ISO 9001. Additionally, inquire about the availability of post-purchase support, including maintenance services and spare parts, to ensure long-term operational reliability. -

How does logistics affect the procurement of laser CNC machines internationally?

Logistics play a crucial role in the procurement process, influencing delivery times and costs. Factors such as the shipping method (air, sea, or land), customs clearance, and local regulations can affect overall timelines. It’s essential to work with suppliers who have experience in international shipping and can provide transparent information about logistics and potential delays, ensuring that your production schedule remains on track.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Laser Cnc Precio Manufacturers & Suppliers List

1. eBay – 40W Laser Module Head for CNC 3018Pro

Domain: pr.ebay.com

Registered: 1995 (30 years)

Introduction: This company, eBay – 40W Laser Module Head for CNC 3018Pro, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Snapmaker – Artisan 3-in-1 3D Printer

Domain: shop.snapmaker.com

Registered: 2014 (11 years)

Introduction: Snapmaker Artisan 3-in-1 3D Printer: Premium dual extrusion 3D printing, 40W laser engraving, and 200W CNC carving capabilities. Snapmaker 2.0: World’s best-selling 3-in-1 3D printer. Snapmaker Ray: 40W laser cutter with Class 1 safety. Filament options include SnapSpeed PLA, Matte PLA, Basic PLA, PETG, ABS, PVA, TPU, Wood PLA, Glow-in-the-dark PLA, and Black Nylon. Modules available: 40W Laser Mo…

3. TodoCortes – Grabadora Láser de Fibra 50W

Domain: todocortes.cl

Introduction: MAQUINAS LASER CNC – TodoCortes.cl

1. GRABADORA LÁSER DE FIBRA POTENCIA 30W PARA METALES

– Precio: $3.290.000 (IVA incluido, original $3.690.000)

– Estado: Agotado

2. GRABADORA LÁSER DE FIBRA POTENCIA 50W PARA METALES

– Precio: $3.990.000 (IVA incluido)

3. MAQUINA DE CORTE Y GRABADO LÁSER CNC 300X200MM 40W Y BASE CON RUEDAS

– Precio: $889.990 (IVA incluido)

4. MAQUINA DE CORTE Y GR…

4. OMTech – Laser Engraving & Cutting Machines

Domain: bo.ebay.com

Registered: 1995 (30 years)

Introduction: Cortador Láser CNC Power Material 50 W, Menos de 1000 W, Metal, Madera, Aluminio, Acero, Plástico, Acrílico, Brass. Vendedores destacados: OMTech AF2028-60 60W 20″ x 28″ CO2 Laser Engraving Cutting Machine, OMTech K40 Pro 8″x12″ Laser Engraving Machine, OMTech ZF2028-60E 60W CO2 Laser Engraver Cutter. Precios: Bs. 23.82 a Bs. 28,392.50. Tipos de materiales: Acero, Acrílico, Aluminio, Goma, Madera,…

5. Sideco – Cortadora Láser Metal SIF-S1530A

Domain: sideco.com.mx

Registered: 2014 (11 years)

Introduction: {“Cortadora_Laser_Metal”: {“precio_lista”: “$1,330,661.77 MXN”, “modelos”: [{“nombre”: “SIF-S1530A”, “precio”: “$1,330,661.77”, “peso_neto”: “4 T”, “velocidad_movimiento”: “120,000 mm/min”, “aceleracion_maxima”: “1.2 G”, “area_util_trabajo”: “3,080 x 1,530 mm”}, {“nombre”: “SIF-S1530B”, “precio”: “$1,973,479.59”, “peso_neto”: “7 T”, “velocidad_movimiento”: “120,000 mm/min”, “aceleracion_maxima”: “…

6. Stanser – CNC Machinery

Domain: stanser.com

Registered: 2013 (12 years)

Introduction: Stanser offers a range of CNC machinery including: CNC Router, Laser CO2, Plasma, and Fiber Laser cutting machines. Key products include: CNC Router models (SR1325, SR1325-PLUS, SR1325-PRO, SR1325-TITAN 2H, SR6090, OKC1325 PRO, SR1325-ATC PRO4, SR1325-ATC PRO8), CNC Plasma models (SR1530P, SR1530P-R with Hypertherm Powermax 45A – 125A), Fiber Laser models (SR1390LF, SR3015LF for SMEs, SR3015LF-PLU…

7. Tecnomaquinaria – Cortadora Láser CNC

Domain: tecnomaquinaria.com

Registered: 2011 (14 years)

Introduction: Cortadora láser CNC: Dispositivo de manufactura asistido por computadora que utiliza un láser de alta potencia para cortar y grabar materiales. Tipos de láser: láser de fibra (eficiente para metales, mayor costo, larga vida útil) y láser de CO2 (versátil, más económico, adecuado para cuero, madera, metacrilato). Ventajas: precisión y calidad del corte, versatilidad de materiales (papel, cartón, ca…

Strategic Sourcing Conclusion and Outlook for laser cnc precio

In navigating the competitive landscape of laser CNC pricing, international B2B buyers must prioritize strategic sourcing to maximize value. Understanding market dynamics, including price fluctuations and technological advancements, empowers businesses to negotiate better deals and select the most suitable machinery for their operational needs. By leveraging insights from multiple suppliers, buyers can identify high-quality products that align with their budget and production requirements.

Moreover, considering factors such as warranty, after-sales support, and shipping costs is crucial in evaluating total cost of ownership. As the demand for laser CNC technology continues to rise across sectors, particularly in regions like Africa, South America, the Middle East, and Europe, establishing reliable supplier relationships will be pivotal for sustained growth.

Looking ahead, businesses are encouraged to stay informed about emerging trends and innovations in laser CNC machinery. Engaging with suppliers who offer comprehensive solutions and support can lead to enhanced productivity and competitive advantage. Make your move today—invest in strategic sourcing to ensure your business remains at the forefront of the laser CNC market.