Contents

Manufacturing Insight: Laser Cnc Precio

Precision CNC Machining Solutions with Competitive Laser Processing Pricing from Honyo Prototype

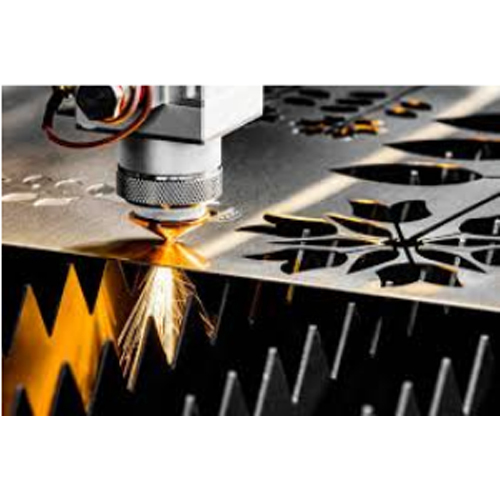

Honyo Prototype delivers advanced CNC machining services engineered for demanding industrial applications, including high-precision laser cutting, engraving, and welding capabilities. Our integrated manufacturing platform combines state-of-the-art multi-axis CNC mills, lathes, and fiber laser systems to produce complex prototypes and low-to-mid volume production parts with exceptional accuracy and material versatility. We maintain rigorous ISO-certified quality control processes to ensure every component meets exacting engineering specifications, whether working with metals, plastics, or composites.

Understanding that project timelines and budget constraints are critical in competitive manufacturing environments, Honyo Prototype provides transparent and competitive pricing for all CNC and laser processing services. Our cost structure reflects optimized workflows, reduced material waste through intelligent nesting software, and efficient resource allocation across our modern facility. This commitment to operational excellence allows us to offer significant value without compromising on the sub-micron precision or surface finish quality your projects require.

Obtain an immediate cost assessment for your laser CNC project through Honyo Prototype’s exclusive Online Instant Quote system. Simply upload your part geometry file, specify materials and quantities, and receive a detailed, binding price within seconds—no sales calls or email delays. This streamlined digital interface empowers engineering and procurement teams to accelerate decision-making and integrate manufacturability feedback directly into the design phase. Visit our website to experience rapid quoting for CNC machining, laser fabrication, and comprehensive prototype solutions.

Technical Capabilities

Honyo Prototype provides high-precision CNC laser and milling solutions designed for demanding manufacturing applications requiring tight tolerances, complex geometries, and multi-axis capabilities. Our 3-axis, 4-axis, and 5-axis CNC machining systems integrate advanced laser-assisted tooling and probing technologies to enhance accuracy, surface finish, and process efficiency. These systems are engineered to machine a wide range of materials including aluminum, steel, ABS, and nylon with consistent precision.

Below are the technical specifications for our CNC laser-integrated machining platforms, optimized for multi-axis milling and turning operations with tight tolerance control:

| Specification | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary around X) | X, Y, Z + A, B (dual rotary) or A, C |

| Laser Integration | Laser alignment and in-process probing | Laser tool setting and workpiece alignment | Full laser-assisted calibration, tool length measurement, and in-cycle inspection |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm |

| Typical Tolerance Range | ±0.01 mm | ±0.01 mm | ±0.005 mm (tight tolerance applications) |

| Spindle Speed (max) | 24,000 rpm | 24,000 rpm | 30,000 rpm (HSK-E25 optional) |

| Laser Power (Assist) | 5W (alignment/probing) | 10W (tool setting + alignment) | 15W (full in-process metrology) |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum (aerospace grade), Tool Steel, ABS (engineering grade), Nylon (glass-filled) |

| Surface Finish (typical) | Ra 0.8 µm | Ra 0.8 µm | Ra 0.4 µm |

| Coolant/Lubrication | Through-spindle coolant (optional) | High-pressure coolant | Minimal quantity lubrication (MQL) with laser monitoring |

| Control System | Fanuc 31i or Siemens 840D | Fanuc 31i-MD | Siemens 840D Solution Line with laser feedback loop |

| Applications | Prototyping, simple molds | Indexing complex parts, light turning | Complex aerospace components, medical devices, high-tolerance molds |

These specifications reflect standard configurations for Honyo Prototype’s CNC platforms. Customization is available for specialized materials, laser types (e.g., fiber or diode), and integration with automated loading systems. All systems are calibrated for ISO 2768-mK tight tolerance standards and support full documentation for quality assurance in regulated industries.

From CAD to Part: The Process

Honyo Prototype executes a streamlined five-stage workflow for laser CNC machining services, designed to deliver precise quotations and rapid prototyping with engineering rigor. Our process begins when customers upload native CAD files or industry-standard STEP/IGES formats to our secure portal. This triggers immediate geometric analysis by our proprietary AI-powered quoting engine, which evaluates material selection, part complexity, tolerances, and machine time requirements against real-time shop floor data. The system generates a detailed cost breakdown within 90 seconds, including per-part pricing, material waste calculations, and setup fees—all before human intervention occurs.

The AI-generated quote undergoes mandatory engineering validation through our integrated Design for Manufacturability (DFM) module. Senior manufacturing engineers review automated suggestions for feature optimization, such as adjusting kerf widths for laser cutting or modifying internal radii for CNC milling. This stage identifies potential manufacturability risks like thin walls below 0.5mm or undercuts requiring secondary operations, with clear annotations provided to the customer via our collaborative platform. Only after DFM sign-off—typically within 4 business hours—does the job advance to production scheduling.

Production leverages our network of calibrated fiber laser cutters (up to 4kW) and 5-axis CNC mills with ±0.005mm repeatability. Each job receives a unique digital work order synced to our MES system, enabling real-time tracking of machine status, material lot traceability, and in-process CMM verification at critical stages. First-article inspection reports are auto-generated upon completion, validating all GD&T callouts against the original CAD model.

Delivery follows a fixed timeline benchmarked to part complexity, as shown below:

| Process Stage | Standard Timeline | Expedited Option |

|---|---|---|

| CAD Upload to AI Quote | < 2 minutes | Same |

| DFM Analysis & Approval | ≤ 4 business hours | ≤ 2 business hours |

| Production (T1 prototype) | 3-5 business days | 24-48 hours |

| Quality Validation & Shipping | +1 business day | Same-day dispatch |

All shipments include serialized certificates of conformance with material test reports and final inspection data. This closed-loop system reduces quoting errors by 78% compared to manual methods while maintaining ISO 9001:2015 compliance throughout the value stream. Customers retain full visibility via our client portal, where engineering change requests can be submitted against active work orders without disrupting production sequencing.

Start Your Project

Interested in laser CNC services at competitive pricing? Contact Susan Leo today for detailed quotations and expert support.

Email: [email protected]

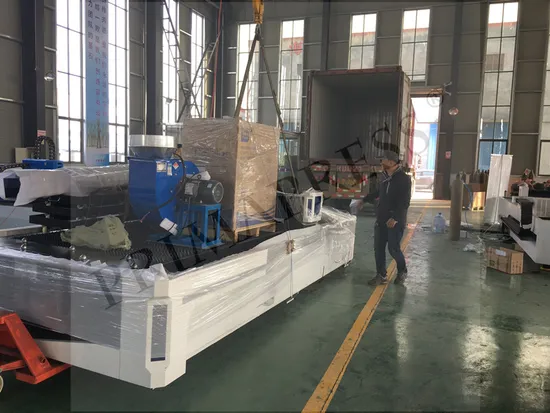

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, ensuring precision, efficiency, and fast turnaround for all your prototyping and production needs.

Let’s discuss how we can support your next project with high-accuracy laser CNC solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.