Introduction: Navigating the Global Market for laser cnc machine for wood

In the competitive landscape of woodworking, sourcing a reliable laser CNC machine for wood cutting and engraving can be a formidable challenge for international B2B buyers. With the increasing demand for precision and efficiency, businesses are seeking advanced solutions that not only enhance production capabilities but also offer versatility across various wood materials. This guide serves as a comprehensive resource, delving into the different types of laser CNC machines available in the market, their applications in diverse industries, and essential criteria for supplier vetting.

Buyers will gain insights into the cost considerations involved in acquiring a laser CNC machine, ensuring they can make informed financial decisions that align with their operational needs. Additionally, we will discuss how to evaluate machine specifications such as power capacity, cutting speed, and software compatibility, which are crucial for maximizing productivity. For B2B buyers from regions like Africa, South America, the Middle East, and Europe, including Brazil and Vietnam, this guide not only highlights the intricacies of the laser CNC market but also empowers them to navigate it confidently. By understanding the key factors influencing their purchasing decisions, businesses can enhance their woodworking processes and ultimately achieve a competitive edge in the global market.

Understanding laser cnc machine for wood Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Laser CNC Machines | High power for thick materials, versatile | Furniture making, architectural models | Pros: High cutting speed; Cons: Limited to non-metal materials. |

| Blue Laser CNC Machines | Enhanced precision and speed, lower power loss | Artisanal crafts, detailed engravings | Pros: Superior detail; Cons: Higher initial investment. |

| Fiber Laser CNC Machines | High efficiency for metal and wood, compact | Industrial manufacturing, signage | Pros: Fast processing; Cons: Less effective on thick wood. |

| Desktop Laser CNC Machines | Compact, user-friendly, affordable | Small businesses, hobbyists | Pros: Easy to use; Cons: Limited cutting capacity. |

| Hybrid Laser CNC Machines | Combines engraving and cutting capabilities | Custom product development, prototyping | Pros: Versatile applications; Cons: Complexity in operation. |

What are the key characteristics of CO2 Laser CNC Machines?

CO2 laser CNC machines are recognized for their ability to cut through thick materials, making them ideal for industries such as furniture making and architectural modeling. They utilize a high-powered laser beam, which allows for rapid cutting speeds and efficient material removal. B2B buyers should consider the machine’s power capacity and bed size to ensure it meets the specific needs of their projects. However, these machines are primarily designed for non-metal materials, which may limit their versatility in some applications.

How do Blue Laser CNC Machines enhance precision and speed?

Blue laser CNC machines represent a significant advancement in laser technology, offering enhanced precision and reduced power loss compared to traditional CO2 lasers. They are particularly well-suited for artisanal crafts and detailed engravings, enabling businesses to produce intricate designs with high accuracy. Buyers should assess the optical power and engraving capabilities, as these factors directly influence the quality of the output. While the initial investment may be higher, the benefits of superior detail and efficiency can justify the cost.

Why choose Fiber Laser CNC Machines for industrial applications?

Fiber laser CNC machines are highly efficient and suitable for both metal and wood applications, making them a popular choice in industrial manufacturing and signage production. Their compact design and fast processing capabilities allow for high-volume production runs. B2B buyers need to consider the machine’s compatibility with various materials and its cutting speed. While fiber lasers excel in speed, they may not be the best choice for thick wood cutting, requiring careful evaluation based on the specific needs of the operation.

What advantages do Desktop Laser CNC Machines offer to small businesses?

Desktop laser CNC machines are ideal for small businesses and hobbyists due to their compact size, affordability, and user-friendly operation. These machines can effectively handle a variety of engraving and cutting tasks, making them versatile for personalized products and small-scale production. Buyers should consider the machine’s cutting capacity and software compatibility to ensure it aligns with their project requirements. However, the limited cutting capacity may restrict their use for larger projects.

How can Hybrid Laser CNC Machines benefit custom product development?

Hybrid laser CNC machines combine both engraving and cutting capabilities, making them highly versatile for custom product development and prototyping. This flexibility allows businesses to adapt to various project requirements without needing multiple machines. When purchasing, B2B buyers should evaluate the complexity of operation and the machine’s adaptability to different materials. While these machines offer significant advantages in versatility, the complexity may require additional training for operators to maximize their potential.

Key Industrial Applications of laser cnc machine for wood

| Industry/Sector | Specific Application of laser cnc machine for wood | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture design and production | Enhanced precision in cutting complex shapes, reducing waste and production time | Power capacity, bed size, and software compatibility |

| Architectural Modeling | Creation of intricate architectural models and prototypes | Ability to produce detailed and accurate models for client presentations | Material compatibility and precision requirements |

| Artisanal Crafts | Personalized and bespoke wood crafts | Unique product offerings that cater to niche markets, increasing customer loyalty | Laser power for engraving, speed, and versatility |

| Signage and Branding | Custom signage production | High-quality, detailed signage that enhances brand visibility and appeal | Cutting thickness and design capabilities |

| Educational Institutions | Wood-based educational models and teaching aids | Engaging learning tools that enhance student understanding | Safety features, ease of use, and software compatibility |

How is Laser CNC Machine for Wood Used in Furniture Manufacturing?

In the furniture manufacturing sector, laser CNC machines are employed to create custom furniture designs that require intricate cuts and engravings. These machines enable manufacturers to produce complex shapes with high precision, which reduces material wastage and speeds up production timelines. For international buyers, especially from regions like Africa and South America, the focus should be on sourcing machines that offer robust power capacity and compatibility with various design software to meet diverse client demands.

What Role Does Laser CNC Machine for Wood Play in Architectural Modeling?

Laser CNC machines are invaluable in architectural modeling, allowing architects and designers to create detailed models that accurately represent their visions. The precision of laser cutting ensures that even the most intricate designs can be executed flawlessly, which is crucial for client presentations. Buyers from Europe and the Middle East should prioritize sourcing machines that can handle a variety of wood thicknesses and materials, ensuring versatility in their projects.

Why Are Laser CNC Machines Essential for Artisanal Crafts?

In the artisanal crafts industry, laser CNC machines facilitate the creation of personalized and bespoke wood crafts. These machines enable artisans to produce unique items that cater to specific customer preferences, fostering customer loyalty and repeat business. For buyers in developing markets, it’s essential to consider the engraving capabilities and speed of the machines, as these factors directly impact productivity and product quality.

How Do Laser CNC Machines Enhance Signage and Branding?

Custom signage production greatly benefits from the use of laser CNC machines, which can produce high-quality, detailed signs that enhance brand visibility. These machines allow businesses to create unique signage that stands out in competitive markets. B2B buyers should focus on sourcing machines with cutting capabilities tailored to the thickness of materials they intend to use, ensuring they can meet varying customer requirements.

What Are the Applications of Laser CNC Machines in Educational Institutions?

Educational institutions utilize laser CNC machines to create wood-based models and teaching aids that enhance student engagement and understanding. These machines allow educators to produce precise and safe learning tools that can be used in various subjects, from science to art. Buyers in this sector should prioritize machines that offer safety features and ease of use, ensuring that they can be operated effectively in educational environments.

3 Common User Pain Points for ‘laser cnc machine for wood’ & Their Solutions

Scenario 1: Precision Issues Leading to Wasted Materials

The Problem:

B2B buyers in the woodworking industry often face significant challenges related to precision when using laser CNC machines. Inaccurate cuts can lead to a high rate of wasted materials, which not only increases costs but also delays production timelines. For instance, a furniture manufacturer may find that misalignments in the laser cutting process result in unusable pieces, forcing them to start from scratch and impacting their overall efficiency. This challenge is particularly acute for businesses operating on tight margins and high competition, where every detail counts.

The Solution:

To mitigate precision issues, buyers should prioritize laser CNC machines equipped with advanced positioning systems and high-quality laser heads. When sourcing equipment, look for models that offer features like closed-loop control systems and real-time feedback mechanisms. These features enhance accuracy by continuously adjusting the laser’s position during operation. Additionally, consider investing in software that allows for precise design adjustments and real-time monitoring of cutting paths. Regular maintenance and calibration of the machine are also essential to ensure that it operates at peak performance. Establishing a routine for checking alignment and settings before each project can significantly reduce material waste.

Scenario 2: Software Compatibility and Learning Curve

The Problem:

Many B2B buyers encounter difficulties with software compatibility when integrating laser CNC machines into their existing workflows. This challenge can lead to frustration, especially when trying to merge designs from various software applications. Additionally, the learning curve associated with new software can be steep, causing delays in project initiation and productivity loss. For instance, a sign-making business might struggle to adapt its designs from traditional CAD software to the new platform required by their laser cutter, hindering their ability to fulfill customer orders promptly.

The Solution:

To address software compatibility issues, buyers should seek laser CNC machines that come with user-friendly software solutions or offer compatibility with widely used design programs. Opt for systems that support formats like DXF, SVG, and AI, which are common in the industry. Additionally, investing in training for employees can dramatically reduce the learning curve. Many manufacturers provide online tutorials, webinars, and customer support that can help users become proficient quickly. Establishing a collaborative environment where team members can share tips and best practices will enhance overall efficiency and comfort with the new technology.

Scenario 3: High Initial Investment and ROI Concerns

The Problem:

Investing in a laser CNC machine for wood can require a substantial upfront cost, which often raises concerns about return on investment (ROI) among B2B buyers. Companies may be hesitant to commit funds without a clear understanding of how quickly they can recoup their investment through increased productivity or new revenue streams. For example, a small woodworking shop might worry that the initial purchase will not be justified if they cannot significantly increase their output or access new markets with the capabilities of the machine.

The Solution:

To alleviate concerns about ROI, buyers should conduct a thorough cost-benefit analysis before making a purchase. Start by evaluating the potential increase in production efficiency and the ability to take on more complex projects that could command higher prices. Additionally, consider the machine’s versatility; for instance, a laser CNC that can cut and engrave different materials will expand the range of services offered. Buyers should also explore financing options or leasing arrangements to spread out the initial costs. Engaging with current users or case studies can provide insights into how similar businesses have successfully integrated laser CNC technology and the tangible benefits they have realized over time.

Strategic Material Selection Guide for laser cnc machine for wood

What Are the Key Materials for Laser CNC Machines Used in Woodworking?

When selecting materials for laser CNC machines designed for woodworking, it is essential to consider the properties, advantages, disadvantages, and specific international compliance requirements. Below are analyses of four common materials used in conjunction with laser CNC machines for wood applications.

1. Plywood

Key Properties: Plywood is made from thin layers of wood veneer glued together, providing a strong and lightweight material. It typically has a temperature resistance of up to 100°C and offers good dimensional stability.

Pros & Cons: Plywood is highly durable and resistant to warping, making it suitable for intricate designs. However, its cost can vary significantly based on the type of wood used, and lower-quality plywood may contain adhesives that can emit harmful fumes when cut.

Impact on Application: Plywood is compatible with various laser settings, allowing for detailed engravings and cuts. It is widely used in furniture production, signage, and decorative arts.

Considerations for International Buyers: Buyers should ensure that the plywood meets local standards such as ASTM for the United States or EN standards in Europe. Additionally, sourcing from reputable suppliers can help mitigate issues related to quality and compliance.

2. MDF (Medium Density Fiberboard)

Key Properties: MDF is made from wood fibers and resin, providing a smooth surface ideal for laser cutting and engraving. It can withstand temperatures of up to 90°C and is less prone to warping compared to solid wood.

Pros & Cons: MDF is cost-effective and offers a uniform surface for intricate designs. However, it can produce a significant amount of dust during cutting, which may require additional ventilation systems. Furthermore, it is less durable than plywood and can be susceptible to moisture damage.

Impact on Application: MDF is particularly well-suited for detailed engravings and is commonly used in cabinetry, decorative items, and prototypes.

Considerations for International Buyers: Compliance with health and safety regulations regarding formaldehyde emissions is crucial, especially in regions like Europe where strict standards (e.g., E1 or E2) are enforced.

3. Solid Wood

Key Properties: Solid wood varies widely in properties depending on the species, with temperature ratings typically exceeding 100°C. It is known for its strength and natural beauty.

Pros & Cons: Solid wood offers excellent durability and aesthetic appeal, making it ideal for high-end products. However, it is often more expensive and can be challenging to work with due to variations in grain and density.

Impact on Application: Solid wood is favored for premium furniture, artistic projects, and custom cabinetry, allowing for high-quality finishes.

Considerations for International Buyers: Buyers should be aware of the sourcing regulations and sustainability certifications (like FSC) to ensure responsible procurement, especially in regions where deforestation is a concern.

4. Acrylic

Key Properties: Acrylic is a synthetic polymer that is lightweight and transparent, with a temperature resistance of around 80°C. It is known for its clarity and ability to be easily laser cut.

Pros & Cons: Acrylic can be cut and engraved with precision, making it suitable for signage and decorative items. However, it can be more expensive than wood alternatives and may require special handling to avoid scratching.

Impact on Application: Acrylic is commonly used in displays, awards, and decorative elements due to its versatility and visual appeal.

Considerations for International Buyers: Ensure compliance with local regulations regarding plastics, and consider the environmental impact of using acrylic, as it is not biodegradable.

Summary Table

| Material | Typical Use Case for laser cnc machine for wood | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plywood | Furniture, signage, decorative arts | Durable and lightweight | Can emit harmful fumes when cut | Medium |

| MDF | Cabinetry, decorative items, prototypes | Cost-effective and uniform surface | Produces dust and moisture-sensitive | Low |

| Solid Wood | Premium furniture, artistic projects | High durability and aesthetic appeal | More expensive and variable | High |

| Acrylic | Displays, awards, decorative elements | High precision and visual appeal | More expensive and prone to scratching | Medium |

This guide provides a comprehensive overview of material selection for laser CNC machines in woodworking, tailored for international B2B buyers. Understanding these materials’ properties and implications can lead to more informed purchasing decisions and successful applications in various markets.

In-depth Look: Manufacturing Processes and Quality Assurance for laser cnc machine for wood

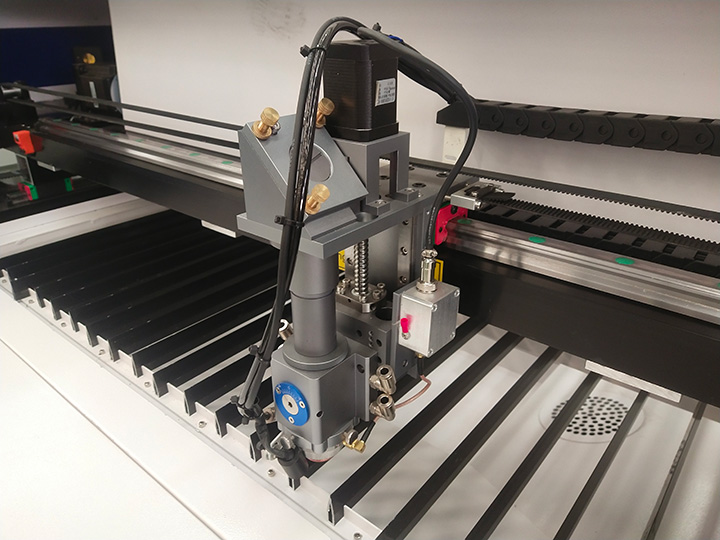

What are the Main Stages in the Manufacturing Process of Laser CNC Machines for Wood?

The manufacturing process of laser CNC machines designed for wood involves several critical stages, each ensuring the final product meets the highest standards of precision and reliability.

Material Preparation

The first stage in manufacturing laser CNC machines is material preparation. High-quality materials, such as robust metals and durable plastics, are sourced from certified suppliers. This step includes cutting raw materials into manageable sizes and performing necessary treatments, like annealing or hardening, to enhance material properties. The choice of materials directly influences the machine’s performance, durability, and overall longevity.

Forming Techniques

Once the materials are prepared, the next stage involves forming techniques. Advanced manufacturing methods such as CNC machining, laser cutting, and bending are utilized to shape components with high accuracy. For instance, laser cutting allows for intricate designs to be created in metal components, which are essential for housing and structural elements of the CNC machines. Precision in this stage is crucial, as even minor discrepancies can affect the entire machine’s operational capabilities.

Assembly Process

Following the forming stage, the assembly process begins. This involves the careful integration of various components, including the laser head, CNC control systems, and mechanical parts. Skilled technicians often use jigs and fixtures to ensure that parts fit together perfectly. During assembly, it’s common to employ automated systems for tasks that require high precision, such as aligning laser optics. The assembly stage is critical for ensuring that the machine operates smoothly and efficiently.

Finishing Touches

The final stage in the manufacturing process is finishing. This involves surface treatments such as painting, anodizing, or powder coating, which not only enhance the aesthetic appeal but also provide corrosion resistance. Additionally, rigorous cleaning processes are conducted to eliminate any contaminants that could interfere with machine performance. This stage may also include installing software and conducting initial calibrations to ensure that the machine is ready for operation.

What International Standards Should B2B Buyers Consider for Quality Assurance?

Quality assurance is an integral part of the manufacturing process for laser CNC machines, ensuring that products meet international standards and customer expectations.

Relevant International Standards

B2B buyers should be aware of several key international standards that govern the manufacturing and quality assurance processes. ISO 9001 is a widely recognized standard that focuses on quality management systems (QMS). Compliance with ISO 9001 indicates that a manufacturer has established a systematic approach to managing quality, which includes continuous improvement and customer satisfaction.

In addition to ISO 9001, other certifications such as CE marking (for compliance with European safety standards) and API (American Petroleum Institute) standards may be relevant, depending on the specific applications of the laser CNC machine. These certifications provide assurance that the products meet safety, health, and environmental protection standards.

What are the Key Quality Control Checkpoints in Laser CNC Machine Manufacturing?

Quality control checkpoints are critical in maintaining the integrity of the manufacturing process for laser CNC machines.

Incoming Quality Control (IQC)

The first checkpoint is Incoming Quality Control (IQC), where raw materials and components are inspected upon arrival at the manufacturing facility. This step ensures that all materials meet specified quality criteria before they enter the production line. Any substandard materials are either returned to the supplier or reprocessed.

In-Process Quality Control (IPQC)

In-Process Quality Control (IPQC) occurs during the manufacturing process. Regular inspections and tests are conducted at various stages of production to identify and rectify any deviations from quality standards. This could involve measuring dimensions, checking the alignment of components, and assessing the performance of machinery. The goal is to ensure that any issues are addressed promptly, minimizing waste and rework.

Final Quality Control (FQC)

The Final Quality Control (FQC) stage involves a comprehensive assessment of the completed laser CNC machine. This includes functionality tests, performance evaluations, and safety checks. Any machine that does not pass FQC is either reworked or scrapped, ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of suppliers when sourcing laser CNC machines.

Conducting Supplier Audits

One effective method is to conduct supplier audits. This process involves visiting the manufacturing facility to evaluate the quality management systems in place, the effectiveness of their processes, and compliance with international standards. During an audit, buyers can assess how well the supplier adheres to their stated quality assurance protocols.

Requesting Quality Reports

Buyers should also request quality reports from suppliers. These documents typically include information on inspection results, non-conformance reports, and corrective actions taken. Reviewing these reports can provide insights into the supplier’s commitment to quality and their ability to address issues effectively.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can further enhance confidence in supplier quality. Independent inspectors can conduct evaluations at various stages of production and provide unbiased assessments of the manufacturing processes and quality assurance practices. This is particularly beneficial for international buyers who may not have the resources to conduct on-site audits.

What are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control when sourcing laser CNC machines.

Understanding Regional Standards and Certifications

Different regions may have varying standards and certifications that impact quality assurance. Buyers should familiarize themselves with local regulations, especially when importing machinery. For example, CE marking is essential for products sold in the European market, while other regions may have their own compliance requirements.

Assessing Supply Chain Reliability

Supply chain reliability is another critical factor. Buyers should evaluate the entire supply chain, from raw material sourcing to final assembly, to ensure that quality is maintained throughout the process. Disruptions or inconsistencies in the supply chain can adversely affect the quality of the final product.

Building Strong Relationships with Suppliers

Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and standards. Regular discussions and feedback can help ensure that both parties are aligned on quality goals, ultimately leading to improved product outcomes.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing laser CNC machines for wood, ensuring they invest in reliable and high-quality equipment that meets their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘laser cnc machine for wood’

Introduction

Navigating the procurement process for a laser CNC machine tailored for wood can be complex, especially for international B2B buyers. This guide provides a practical checklist to streamline your sourcing efforts, ensuring you consider all critical aspects before making a purchase. By following these steps, you can select a machine that meets your operational needs and aligns with your business goals.

Step 1: Define Your Technical Specifications

Before exploring suppliers, clearly outline the technical requirements of the laser CNC machine you need. Consider factors such as power capacity, cutting speed, bed size, and compatibility with existing software. Understanding these specifications ensures that you choose a machine capable of handling your specific wood types and project complexities.

- Power Capacity: Higher wattage typically allows for cutting thicker materials.

- Bed Size: Ensure the machine can accommodate the largest pieces of wood you plan to work with.

Step 2: Research Available Technologies

Different laser technologies, such as CO2 and blue lasers, offer varying benefits for wood cutting and engraving. Familiarize yourself with these options to determine which technology best suits your production needs. Understanding the advantages and limitations of each technology will help you make a more informed decision.

- CO2 Lasers: Commonly used for their versatility in cutting various materials.

- Blue Lasers: Known for their superior precision and efficiency in wood processing.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reliability and reputation. Request company profiles, case studies, and references from businesses in similar sectors or regions. This step is crucial to ensuring that you partner with a supplier who can deliver quality and support.

- References: Seek feedback from previous clients to understand their experiences.

- Certifications: Verify that the supplier adheres to industry standards and regulations.

Step 4: Assess After-Sales Support and Warranty

After-sales support is vital for maintaining operational efficiency and addressing any issues that may arise post-purchase. Investigate the warranty terms and the availability of technical support from the supplier. A robust support system can save you time and money in the long run.

- Warranty Length: A longer warranty may indicate the manufacturer’s confidence in their product.

- Support Channels: Ensure that the supplier offers multiple support options, such as phone, email, or live chat.

Step 5: Compare Pricing Models

Obtain quotes from several suppliers and compare their pricing structures. Look beyond the initial purchase price to understand the total cost of ownership, which includes maintenance, operational costs, and consumables. This comprehensive view will help you budget effectively and avoid unexpected expenses.

- Hidden Costs: Inquire about shipping, installation, and training fees.

- Financing Options: Some suppliers may offer financing plans to ease the upfront investment.

Step 6: Request Demonstrations or Samples

Whenever possible, request demonstrations or samples of the laser CNC machines you are considering. This hands-on experience allows you to evaluate the machine’s performance and suitability for your specific projects. Observing the machine in action can provide valuable insights into its capabilities.

- Performance Testing: Evaluate how well the machine handles your preferred wood types.

- User Experience: Pay attention to ease of use and software compatibility during demonstrations.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier and machine, review the purchase agreement carefully. Ensure that all terms, including delivery timelines, installation procedures, and support services, are clearly outlined. A well-defined agreement protects your interests and sets clear expectations for both parties.

- Payment Terms: Clarify payment schedules and methods.

- Delivery Expectations: Confirm the timeline for delivery and installation to avoid disruptions in your operations.

By following this checklist, B2B buyers can make informed decisions when sourcing a laser CNC machine for wood, ultimately enhancing their production capabilities and business success.

Comprehensive Cost and Pricing Analysis for laser cnc machine for wood Sourcing

When sourcing laser CNC machines for wood, understanding the comprehensive cost structure and pricing dynamics is critical for international B2B buyers. Below, we explore the key components influencing costs, pricing strategies, and practical tips for effective negotiation and procurement.

What Are the Key Cost Components for Laser CNC Machines for Wood?

The overall cost of laser CNC machines encompasses several components:

-

Materials: The choice of materials for the laser machine’s construction significantly impacts the price. High-quality metals and components can enhance durability and performance but also increase the upfront cost.

-

Labor: Labor costs vary by region. In regions like Europe, labor may be more expensive compared to Africa or South America. This variance can affect the final pricing of the machine, especially if skilled labor is required for assembly and calibration.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, rent, and equipment maintenance. Suppliers with higher operational costs may pass these expenses onto buyers.

-

Tooling: The specific tools required for production, including specialized jigs and fixtures for laser CNC machines, contribute to initial setup costs. More complex machines may require advanced tooling, adding to the overall expenditure.

-

Quality Control (QC): Effective quality assurance processes ensure that the machines meet performance standards. However, rigorous QC protocols can also drive up costs, especially in manufacturers aiming for high certification standards.

-

Logistics: Transportation costs can vary widely based on distance, shipping method, and packaging requirements. International shipping, especially to regions like Africa or South America, can incur higher freight charges.

-

Margin: The supplier’s profit margin plays a crucial role in the final price. Understanding a supplier’s pricing strategy can help buyers gauge the competitiveness of quotes received.

How Do Price Influencers Affect Laser CNC Machine Costs?

Several factors can influence pricing dynamics:

-

Volume/MOQ: Bulk orders generally lead to lower per-unit costs. Establishing a minimum order quantity (MOQ) can be beneficial for negotiating better pricing.

-

Specifications and Customization: Custom features or advanced specifications can significantly increase costs. Buyers should carefully evaluate whether such features are necessary for their operations.

-

Materials and Quality Certifications: Machines built with premium materials and recognized certifications (e.g., ISO) often come with a higher price tag but provide assurance of quality and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer more consistent quality but at a premium price.

-

Incoterms: Understanding the terms of trade (Incoterms) is essential for determining responsibilities and costs associated with shipping, insurance, and customs clearance.

What Tips Can Buyers Use for Cost-Efficiency and Negotiation?

To navigate the complexities of sourcing laser CNC machines effectively, consider the following strategies:

-

Engage in Negotiation: Always negotiate prices and payment terms. Suppliers may have flexibility, especially when dealing with large orders or long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also operational costs, maintenance, and potential downtime. A lower upfront cost may lead to higher long-term expenses.

-

Understand Pricing Nuances for International Buyers: Be mindful of currency fluctuations, import duties, and taxes that can affect the final cost. Engaging local consultants or logistics experts can provide insights into hidden costs.

-

Research Market Trends: Stay informed about market trends and competitor pricing. Understanding the competitive landscape can empower buyers during negotiations.

Conclusion

Sourcing laser CNC machines for wood requires a comprehensive understanding of cost structures and pricing dynamics. By analyzing cost components, recognizing influential factors, and employing strategic negotiation tactics, international B2B buyers can make informed purchasing decisions. Always remember to consult multiple suppliers and consider the total cost of ownership to ensure a smart investment that aligns with your business objectives.

Alternatives Analysis: Comparing laser cnc machine for wood With Other Solutions

Understanding Alternative Solutions for Wood Cutting and Engraving

When considering a laser CNC machine for wood, it’s essential to explore alternative technologies that can achieve similar results. Each method has distinct advantages and limitations that can influence a B2B buyer’s decision based on their specific needs, budget, and operational requirements. Below, we compare laser CNC machines with traditional woodworking methods and CNC routers to provide a comprehensive overview.

| Comparison Aspect | Laser CNC Machine For Wood | Traditional Woodworking Methods | CNC Router |

|---|---|---|---|

| Performance | High precision and speed; intricate designs possible | Varies; may lack consistency and precision | Good precision; suitable for larger cuts |

| Cost | Higher initial investment, but potential for high ROI | Lower initial costs, but labor-intensive | Moderate cost; requires additional tooling |

| Ease of Implementation | Requires technical knowledge for setup and operation | Simple for skilled woodworkers; no tech needed | Requires CNC programming knowledge |

| Maintenance | Regular maintenance needed for laser optics | Minimal maintenance; depends on tools used | Moderate; regular bit replacement needed |

| Best Use Case | Ideal for intricate designs, fast production | Best for handmade, artisanal projects | Best for mass production and larger designs |

What Are the Pros and Cons of Traditional Woodworking Methods?

Traditional woodworking methods involve manual tools such as saws, chisels, and routers. The primary advantage of this approach is its low cost and accessibility; skilled artisans can produce high-quality work without the need for advanced technology. Moreover, the craftsmanship involved can add unique value to the finished product. However, traditional methods often lack the precision and speed of laser cutting, making them less suitable for projects requiring intricate designs or high-volume production. Additionally, manual processes are labor-intensive and may lead to inconsistencies in quality.

How Does a CNC Router Compare to a Laser CNC Machine for Wood?

CNC routers are computer-controlled cutting machines that use various types of bits to carve and shape wood. They offer good precision and are versatile, capable of handling a range of materials beyond wood. CNC routers are generally more affordable than laser CNC machines and are easier to maintain. However, they may not achieve the same level of detail in engraving or cutting thin materials, as lasers can. Additionally, CNC routers require programming knowledge and may involve longer setup times for intricate designs.

Conclusion: How to Choose the Right Solution for Your Woodworking Needs

Selecting the appropriate wood cutting solution depends on various factors such as the desired outcome, production volume, and available budget. For businesses prioritizing precision and intricate designs, a laser CNC machine is an excellent investment that can yield high returns through custom projects. On the other hand, if cost and ease of use are primary concerns, traditional woodworking methods or CNC routers may be more suitable. Assessing your operational capabilities and long-term goals will ensure you choose the solution that best aligns with your business objectives and market demands.

Essential Technical Properties and Trade Terminology for laser cnc machine for wood

When investing in a laser CNC machine for wood, understanding the essential technical properties and trade terminology is crucial for making informed decisions. This knowledge not only assists in evaluating options but also helps in negotiating and managing supplier relationships effectively.

What Are the Key Technical Properties of Laser CNC Machines for Wood?

-

Power Capacity

– The power of the laser cutter, typically measured in watts (W), directly influences its cutting speed and material thickness capabilities. Higher wattage allows for faster cutting and the ability to handle thicker materials. For example, a 45W laser cutter can efficiently cut wood up to 20mm thick, making it ideal for robust projects. Understanding power capacity helps buyers match the machine to their production needs. -

Cutting Speed

– Measured in millimeters per second (mm/s), cutting speed indicates how quickly the machine can execute cuts. A higher cutting speed is essential for maximizing productivity, especially in high-volume operations. For B2B buyers, assessing cutting speed relative to their production timelines can lead to significant cost savings and efficiency improvements. -

Bed Size

– The bed size refers to the working area of the laser cutter, which dictates the maximum dimensions of the materials that can be processed. A larger bed size accommodates bigger sheets of wood, reducing the need for multiple setups and enhancing workflow. B2B buyers should consider their project sizes and production frequency when selecting the appropriate bed size. -

Precision and Tolerance

– Precision in laser cutting is often quantified in terms of the machine’s ability to maintain tight tolerances, typically within fractions of a millimeter. This is critical for applications requiring intricate designs or components that must fit together seamlessly. Understanding precision and tolerance ensures that the chosen machine meets the specific quality standards demanded by clients. -

Software Compatibility

– The ability of the laser CNC machine to integrate with various design software is vital for seamless operation. Compatibility with popular software such as LightBurn or proprietary programs can enhance usability and efficiency. B2B buyers should evaluate software compatibility to ensure their teams can effectively design and execute projects without extensive retraining. -

Cooling System

– The cooling system of a laser CNC machine is essential for maintaining optimal operating temperatures during cutting. Efficient cooling systems prevent overheating, thus prolonging the lifespan of the laser and ensuring consistent performance. Buyers should consider the cooling technology used in the machine to avoid downtime and maintenance issues.

What Are Common Trade Terms in the Laser CNC Machine Industry?

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of laser CNC machines, understanding OEM relationships can help buyers identify the source of components and assess quality. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Understanding MOQs helps in negotiating better purchasing terms and managing stock levels. -

RFQ (Request for Quotation)

– An RFQ is a document that solicits price offers from suppliers for specific products or services. It is an essential tool for B2B buyers to compare pricing, terms, and conditions from multiple vendors. Crafting a detailed RFQ can lead to more competitive offers. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and tariffs. Familiarity with Incoterms is critical for B2B buyers to avoid misunderstandings and ensure smooth logistics. -

Lead Time

– Lead time is the period from placing an order to receiving the product. Understanding lead times is vital for project planning and inventory management, allowing buyers to align production schedules with supplier capabilities. -

Service Level Agreement (SLA)

– An SLA is a contract that outlines the expected level of service between a provider and a client. This agreement is important for B2B relationships, ensuring that performance metrics are clearly defined and adhered to, which is crucial for maintaining operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing laser CNC machines for wood, ultimately leading to more strategic sourcing and enhanced operational outcomes.

Navigating Market Dynamics and Sourcing Trends in the laser cnc machine for wood Sector

What Are the Current Market Dynamics and Key Trends in the Laser CNC Machine for Wood Sector?

The global market for laser CNC machines designed for wood processing is experiencing significant growth, driven by several key factors. Firstly, the rising demand for customized wood products across various sectors, including furniture, crafts, and interior design, has spurred innovation in laser cutting and engraving technologies. This trend is particularly evident in emerging markets such as Brazil and Vietnam, where local artisans and manufacturers are increasingly adopting laser technology to enhance precision and efficiency in production. Additionally, advancements in machine capabilities, such as improved power output and cutting speed, are making these machines more attractive to international buyers looking to optimize their operations.

Moreover, the integration of advanced software solutions is enhancing the usability of laser CNC machines, making them more accessible to businesses of all sizes. This shift towards user-friendly technology is particularly beneficial for B2B buyers in regions like Africa and the Middle East, where there is a growing interest in adopting modern manufacturing techniques. International trade dynamics are also shaping the market, with suppliers from Europe and Asia seeking to penetrate new markets by offering competitive pricing and localized support.

How Is Sustainability and Ethical Sourcing Impacting the Laser CNC Machine for Wood Market?

Sustainability is becoming an increasingly critical consideration for B2B buyers in the laser CNC machine sector. The environmental impact of wood sourcing and processing is under scrutiny, prompting companies to prioritize ethical sourcing practices. Buyers are encouraged to seek suppliers who can demonstrate adherence to sustainable forestry practices, ensuring that the wood used in their projects is sourced from responsibly managed forests.

Furthermore, the demand for “green” certifications is on the rise, as businesses aim to align their operations with global sustainability goals. Certifications such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) are becoming essential for companies looking to enhance their marketability and meet consumer expectations for environmentally friendly products. As laser CNC technology evolves, manufacturers are also exploring eco-friendly materials and processes, such as using water-based adhesives and finishes, to further reduce their ecological footprint.

What Is the Brief Evolution and History of Laser CNC Machines for Wood?

The evolution of laser CNC machines for wood can be traced back to the late 20th century when laser technology began to gain traction in industrial applications. Initially, these machines were primarily used for high-precision cutting in metal industries. However, as technology advanced and costs decreased, wood processing applications emerged, especially for engraving and intricate designs.

Over the years, the introduction of CO2 lasers revolutionized the wood cutting sector, offering superior cutting quality and speed. More recently, blue laser technology has taken the market by storm, providing even greater precision and efficiency. This evolution has enabled businesses to meet the growing demand for customization and intricate designs, making laser CNC machines an indispensable tool in modern woodworking and manufacturing industries.

In conclusion, B2B buyers in the laser CNC machine for wood sector must navigate a complex landscape characterized by technological advancements, sustainability imperatives, and evolving market dynamics to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of laser cnc machine for wood

-

How do I select the right laser CNC machine for wood cutting?

When selecting a laser CNC machine for wood cutting, consider key factors such as power capacity, bed size, cutting speed, and software compatibility. Machines with higher wattage, like the 45W blue laser heads, are ideal for cutting thicker materials, while lower wattage options are better for detailed engraving on thinner wood. Additionally, ensure that the machine is compatible with user-friendly software that can streamline your workflow. Evaluating these features against your specific project requirements will help you make an informed choice. -

What is the best laser CNC machine for wood engraving?

The best laser CNC machine for wood engraving typically combines precision, speed, and versatility. Models like the Opt Lasers XT-50, which features a 6W optical power, are excellent for detailed engravings on thin wood materials. For projects requiring more intricate designs, a machine with a high DPI (dots per inch) specification will yield superior results. Ultimately, the choice will depend on the specific applications and materials you plan to work with, so assess your needs carefully. -

What materials can I cut and engrave with a laser CNC machine?

Laser CNC machines designed for wood can also handle a variety of materials, including acrylic, leather, and certain metals, depending on the laser type and power. For wood, the machine’s settings should be adjusted according to the thickness and type of wood to achieve optimal results. Ensure to check the manufacturer’s guidelines for material compatibility to maximize the machine’s potential and avoid damage. -

How can I ensure quality and reliability when sourcing a laser CNC machine?

To ensure quality and reliability, conduct thorough research on potential suppliers, checking their certifications, customer reviews, and case studies. Request samples of their previous work or machine performance metrics. Additionally, inquire about warranty terms, after-sales support, and maintenance services. Establishing a good rapport and communication with suppliers will also help you gauge their reliability and commitment to customer satisfaction. -

What are the typical payment terms for purchasing laser CNC machines internationally?

Payment terms can vary widely by supplier and region but often include options such as upfront payment, a deposit followed by a balance upon delivery, or payment via letters of credit. It’s crucial to clarify these terms before finalizing any agreements. Additionally, consider any potential import duties, taxes, or fees that may apply when importing equipment to your country, as these can affect your overall budget. -

What is the minimum order quantity (MOQ) for laser CNC machines?

The MOQ for laser CNC machines can vary significantly based on the manufacturer and model. Some suppliers may offer machines as single units, while others might require bulk orders to meet production standards. Always confirm the MOQ with your supplier to ensure it aligns with your purchasing strategy. If you’re a small business, inquire about sample units or starter kits that may be available. -

What logistics considerations should I keep in mind when importing laser CNC machines?

When importing laser CNC machines, consider logistics factors such as shipping methods, transit times, and customs clearance processes. Choose a reliable freight forwarder experienced in handling machinery imports to navigate these complexities efficiently. Additionally, verify that your supplier provides proper documentation, such as invoices and packing lists, to facilitate smooth customs clearance. Planning for potential delays can also help minimize disruptions to your operations. -

How can I customize a laser CNC machine to meet my specific needs?

Many manufacturers offer customization options for their laser CNC machines, allowing you to tailor features such as bed size, laser power, and software compatibility to your specific requirements. Engage with the supplier to discuss your needs and explore available modifications. It’s also beneficial to inquire about any additional components or accessories that could enhance the machine’s functionality, ensuring it aligns perfectly with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Laser Cnc Machine For Wood Manufacturers & Suppliers List

1. Wattsan – Laser Machines for Cutting, Engraving, and Marking

Domain: wattsan.com

Registered: 2016 (9 years)

Introduction: Laser machines for various applications including cutting, engraving, and marking. Features include high precision, speed, and versatility. Suitable for materials like wood, acrylic, metal, and more. Available in different models with varying power outputs and working areas to meet diverse industrial needs.

2. Reddit – Laser Cutting vs CNC

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Laser cutting is generally faster for thin materials and detailed cuts, while CNC is faster for thicker materials. Laser cutting burns edges and generates smoke, while CNC leaves a clean cut edge and produces sawdust. CNC requires more setup and is noisier, while laser cutting is quieter and easier to start. Entry-level machines are limited; mid-range ($3k to $5k) is recommended for decent setups….

3. STYLECNC – CO2 Laser Engraver

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: Affordable CNC Laser Cutter Engraving Machines for Sale – STYLECNC offers a variety of CNC laser machines including CO2 Laser Cutters, Fiber Laser Cutting Machines, Hybrid Laser Cutting Systems, Laser Marking Machines, and more. Key products include: 1. STJ1390: CO2 Laser Engraver (60W-180W) priced at $3,500 – $5,500, suitable for wood, fabric, leather, glass, acrylic, paper, plastic, stone. 2. ST…

4. Woodcraft – Laser Engravers & CNC Routers

Domain: woodcraft.com

Registered: 1995 (30 years)

Introduction: This company, Woodcraft – Laser Engravers & CNC Routers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Rabbit Laser – CNC Machines for Wood

Domain: finewoodworking.com

Registered: 1998 (27 years)

Introduction: CNC laser machines for wood vary based on user needs (hobbyist or professional), application (engraving or cutting), and size requirements. Recommended brands include Rabbit Laser and Trotec for higher budgets, while Wattsan is noted for good price and quality. Important criteria for selection include power, machine size, configurations, controller, software, and post-sale support.

6. HowToMechatronics – DIY CNC Laser Engraver Machine

Domain: howtomechatronics.com

Registered: 2015 (10 years)

Introduction: DIY CNC Laser Engraver Machine

– Components: MGN15H linear rails, NEMA 17 stepper motors, GT2 pulleys, timing belts, micro limit switches, 8mm MDF board.

– Working area: 390 by 360mm.

– Electronics: Arduino UNO board with CNC shield.

– Construction method: Assembled using a drill and hand tools, no 3D printer required.

– Capabilities: Laser engraving and potential for future pen plotting; can cut …

7. FLUX – Beamo 30W Laser Cutter & Engraver

Domain: top3dshop.com

Registered: 2018 (7 years)

Introduction: {“products”:[{“name”:”FLUX Beamo 30W Laser Cutter & Engraver”,”price”:”$1,596.00″,”laser_power”:”30W”,”availability”:”In Stock”},{“name”:”xTool F1 Laser Engraver”,”price”:”$1,199.00″,”original_price”:”$1,999.00″,”availability”:”In Stock”,”working_area”:”100 x 100 mm”},{“name”:”xTool P2 55W CO2 Laser Cutter and Engraver”,”price”:”$3,699.00″,”original_price”:”$4,999.00″,”availability”:”In Stock”,”la…

Strategic Sourcing Conclusion and Outlook for laser cnc machine for wood

How Can Strategic Sourcing Enhance Your Procurement of Laser CNC Machines for Wood?

In the competitive landscape of woodworking, strategic sourcing of laser CNC machines is paramount for businesses aiming to enhance precision and efficiency. By carefully evaluating key factors such as laser power, bed size, and software compatibility, buyers can make informed decisions that align with their operational needs and growth objectives. The integration of advanced technology, like blue laser heads, not only streamlines production but also elevates the quality of craftsmanship, allowing companies to meet the increasing demand for bespoke wooden products.

International buyers from Africa, South America, the Middle East, and Europe should recognize the value of investing in high-quality laser CNC machines. These tools not only offer a significant return on investment through enhanced production capabilities but also open doors to new market opportunities by enabling the creation of custom products that resonate with consumers.

As the market for laser CNC technology continues to evolve, staying abreast of the latest innovations will be crucial. Engage with reputable suppliers and explore cutting-edge solutions to position your business for success. The future of woodworking is bright; seize the opportunity to innovate and lead in your market today.