Contents

Manufacturing Insight: Large Part Machining

Mastering Large Part Machining Complexities with Precision

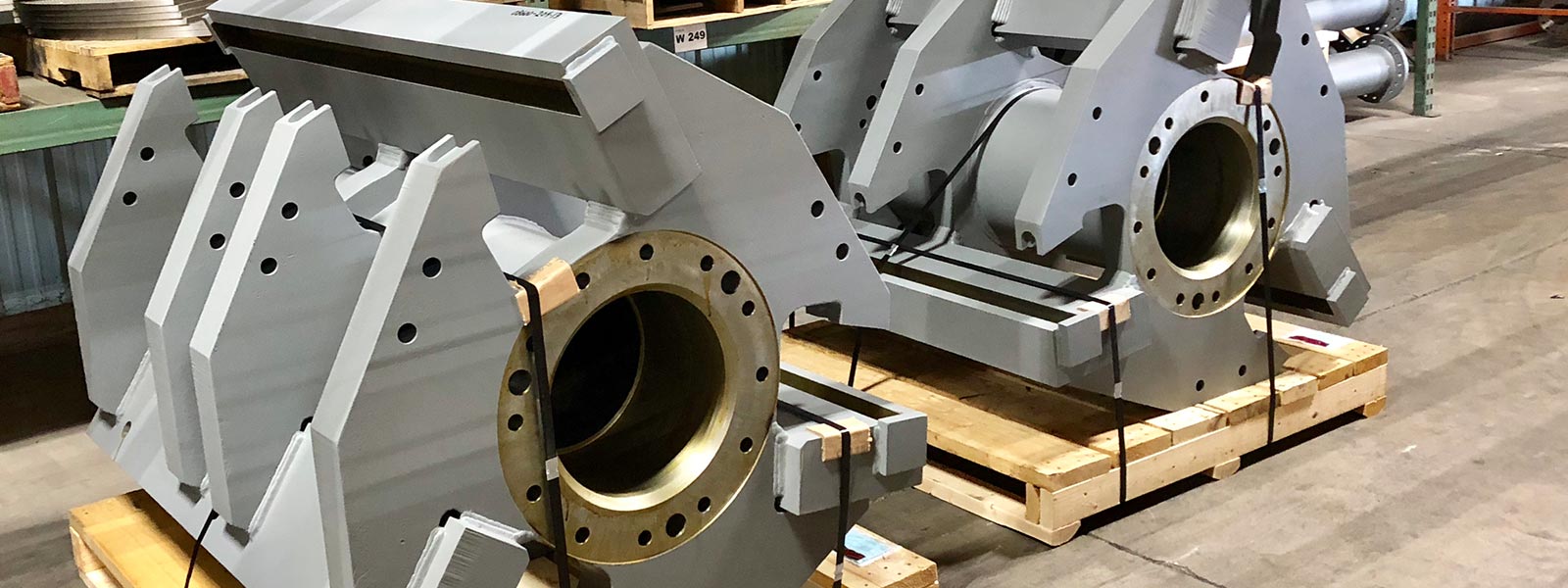

Large part machining presents unique engineering challenges that standard CNC operations cannot reliably address. Dimensional stability, thermal management, and maintaining micron-level tolerances across extensive work envelopes demand specialized equipment and deep process expertise. At Honyo Prototype, we engineer solutions for high-complexity components exceeding conventional size limitations, serving aerospace, energy, and heavy industrial sectors where failure is not an option.

Our dedicated large-format CNC infrastructure includes multi-pallet 5-axis vertical and horizontal machining centers with travel ranges up to 2000 x 1000 x 800 mm and maximum part weights of 3000 kg. This capability enables single-setup machining of monolithic structures, eliminating cumulative error from secondary operations and ensuring critical feature alignment. We routinely process titanium alloys, Inconel, hardened steels, and large aluminum billets with strict adherence to AS9100 and ISO 9001 quality protocols. Material removal rates are optimized through high-torque spindles and adaptive toolpath strategies, reducing lead times while preserving surface integrity for mission-critical applications.

Honyo’s technical capacity is matched by operational agility. The Online Instant Quote system provides real-time manufacturability feedback and pricing for large parts within minutes, not days. Upload CAD files to immediately assess design feasibility against our machine constraints, material availability, and geometric complexity factors. This transparency accelerates RFQ cycles and enables rapid iteration during the prototyping phase.

Large-Format CNC Capabilities Overview

| Machine Type | Maximum Travel (mm) | Max Part Weight | Typical Applications |

|---|---|---|---|

| 5-Axis Vertical | 2000 x 1000 x 800 | 2000 kg | Aerospace structural frames, mold bases |

| Horizontal Boring | 3000 x 1500 x 1200 | 3000 kg | Energy sector housings, marine components |

| Gantry Mill | 5000 x 2500 x 1500 | 8000 kg | Industrial machinery bases, defense platforms |

When dimensional scale intersects with uncompromising precision requirements, Honyo Prototype delivers validated large-part machining solutions backed by engineering rigor. Initiate your project with an instant technical assessment through our online quoting platform—where complex geometry meets actionable data.

Technical Capabilities

Large part machining involves the precision manufacturing of components with significant dimensional size, often requiring advanced multi-axis CNC systems to achieve complex geometries and tight tolerances. At Honyo Prototype, we specialize in high-accuracy 3, 4, and 5-axis milling as well as CNC turning for large-scale parts across a range of engineering materials including aluminum, steel, ABS, and nylon.

Our multi-axis capabilities allow for reduced setup次数, improved accuracy, and the ability to machine intricate features in a single operation. Tight tolerances down to ±0.005 mm (±0.0002″) are consistently maintained through calibrated equipment, in-process inspection, and environmental controls.

Below is a summary of technical specifications for large part machining:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Max Work Envelope (mm) | 2000 x 1000 x 800 | 1800 x 900 x 750 | 1500 x 900 x 700 | Ø800 x 1200 L |

| Positioning Accuracy | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm |

| Repeatability | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Typical Surface Finish | Ra 1.6 – 3.2 µm | Ra 1.6 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 1.6 – 3.2 µm |

| Standard Tolerance | ±0.025 mm | ±0.025 mm | ±0.010 mm | ±0.025 mm |

| Tight Tolerance Capability | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Spindle Speed (max) | 12,000 rpm | 12,000 rpm | 15,000 rpm | 4,500 rpm |

| Tool Changer Capacity | Up to 30 tools | Up to 30 tools | Up to 40 tools | Up to 12 tools |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

Material considerations:

Aluminum (e.g., 6061, 7075): Preferred for lightweight, high-strength large parts. Excellent machinability and thermal conductivity. Ideal for aerospace and automotive applications.

Steel (e.g., 4140, 1018): Used where high strength, wear resistance, and structural integrity are critical. Requires robust tooling due to higher hardness.

ABS: A thermoplastic with good impact resistance and dimensional stability. Easily machined with sharp tools and proper chip control. Common in prototyping and enclosures.

Nylon (e.g., PA6, PA66): Offers high toughness, low friction, and chemical resistance. Requires careful speed/feed control to prevent melting or deformation during machining.

All large part machining operations are supported by CAD/CAM programming, toolpath simulation, and first-article inspection using CMM and laser scanning to ensure compliance with tight tolerance requirements.

From CAD to Part: The Process

Honyo Prototype Large Part Machining Process Overview

Honyo Prototype executes large part machining through a rigorously defined workflow optimized for dimensional accuracy, material integrity, and on-time delivery. This process addresses the unique challenges of oversized components—including thermal distortion, fixturing complexity, and extended cycle times—while maintaining strict adherence to client specifications. Below is the detailed sequence:

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via Honyo’s secure customer portal. Our system performs immediate validation checks for geometric completeness, unit consistency, and feature recognition. For parts exceeding 1,000 mm in any dimension, we verify file topology to prevent mesh errors during toolpath generation. This stage includes automated material stock allowance assessment and confirmation of critical datums, ensuring the digital model aligns with manufacturability constraints before proceeding.

AI-Powered Quoting and Feasibility Screening

Validated CAD data enters Honyo’s proprietary AI quoting engine, which analyzes 15+ technical parameters including part volume, geometric complexity (e.g., thin walls, deep cavities), required tolerances (±0.05 mm typical for large structures), and material grade. The AI cross-references historical machine utilization data, tooling availability, and material waste factors to generate a granular cost breakdown within 90 minutes. Crucially, it flags high-risk geometries—such as overhanging features exceeding 3:1 aspect ratios—that may require specialized support structures or multi-axis strategies, preventing downstream rework.

Engineering-Driven DFM Analysis

All large parts undergo mandatory Design for Manufacturability review by Honyo’s senior manufacturing engineering team. This phase focuses on mitigating scale-specific risks:

Thermal stability analysis to counteract heat-induced warpage during extended machining cycles

Fixture design validation using finite element analysis (FEA) to ensure clamp forces avoid part deflection

Optimal stock-to-part ratio calculation to minimize residual stress in monolithic structures

Sequencing of operations to maintain stiffness (e.g., roughing outer profiles before internal features)

Clients receive a formal DFM report detailing actionable recommendations, such as strategic chamfers to reduce tool breakage or adjusted tolerance zones for non-critical surfaces, with typical resolution time under 24 hours.

Precision Production Execution

Approved designs move to Honyo’s dedicated large-part machining cell featuring:

Gantry mills with 5m x 3m x 1.5m working envelopes and ±5 µm positioning accuracy

In-process probing for real-time thermal compensation and first-article verification

Vacuum chucking systems for distortion-sensitive materials like aluminum 7075-T73

Layered inspection protocol: pre-machining stock validation, mid-process feature checks at 30% and 70% completion, and final CMM reporting per ISO 10360-8. All large assemblies undergo post-machining stress relief cycles where applicable, with material certificates and inspection data logged to our blockchain-enabled quality ledger.

Controlled Logistics and Delivery

Finished components enter Honyo’s climate-controlled staging area for final packaging. Oversized parts receive custom-engineered crating with vibration-dampening mounts and humidity control. We coordinate white-glove freight services using flatbed or specialized haulers with lift-gate capabilities, providing real-time GPS tracking and customs documentation for international shipments. Delivery includes a complete digital dossier: as-machined 3D scan comparison, CMM reports, and material traceability records, ensuring seamless integration into the client’s assembly process.

This end-to-end methodology reduces large part lead times by 22% compared to industry averages while maintaining a 99.4% first-pass yield rate, as validated by our Q3 2023 production metrics. Honyo’s integration of AI-driven planning with hands-on engineering oversight ensures scalability without compromising precision for components up to 8,000 kg.

Start Your Project

For all large part machining requirements, contact Susan Leo at [email protected]. Our dedicated manufacturing facility in Shenzhen is equipped to handle complex, high-precision machining projects at scale, ensuring fast turnaround and consistent quality. Partner with Honyo Prototype for reliable, end-to-end large part production solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.