Contents

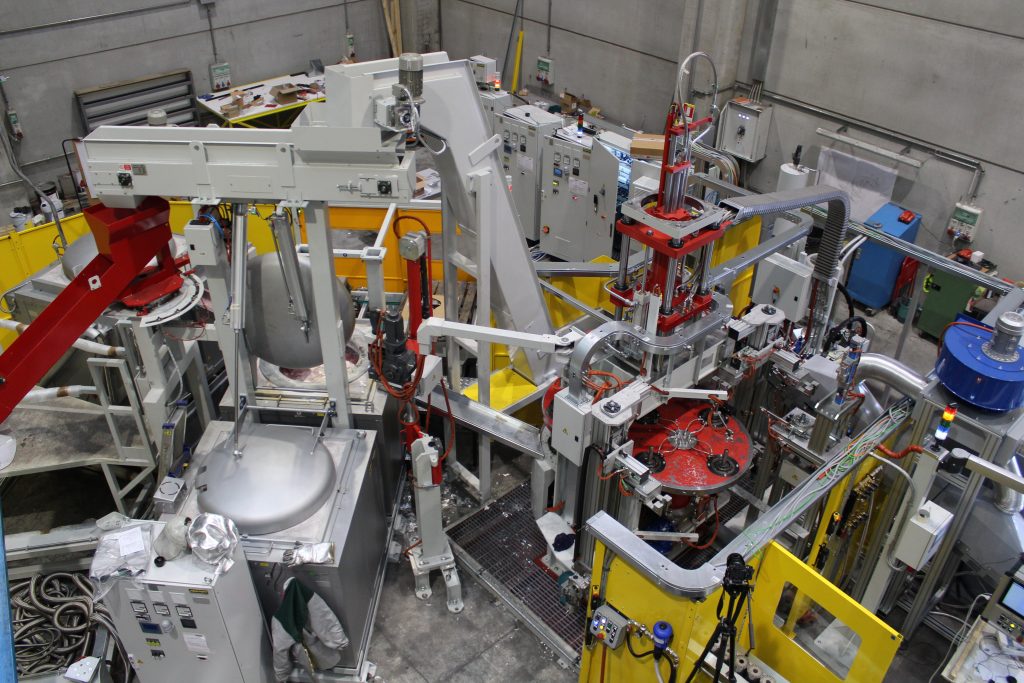

Manufacturing Insight: Large Die Casting Machine

Precision Post-Casting Solutions for Large Die Cast Components

Large die casting machines produce complex near-net-shape components efficiently, but achieving tight tolerances and critical surface finishes often requires advanced secondary machining. At Honyo Prototype, we specialize in high-accuracy CNC machining services tailored specifically for large die cast parts, addressing dimensional variance, draft angles, and feature intricacies that casting alone cannot resolve. Our multi-axis CNC platforms handle materials from aluminum alloys to high-strength zinc, delivering ±0.005mm tolerances and superior geometric integrity for aerospace, automotive, and industrial applications.

We understand that delays in post-processing can derail your production timeline. That’s why Honyo integrates seamless CNC finishing with our dedicated die casting partnerships—ensuring your large cast components meet stringent engineering specifications without workflow disruption. Accelerate your path from casting to certified part with our Online Instant Quote system, providing detailed machining cost and lead time estimates in under 90 seconds. Submit your STEP or IGES files today to validate feasibility and receive a production-ready quotation instantly.

Technical Capabilities

Large die casting machines are primarily used for high-volume production of metal components by injecting molten metal—typically aluminum or zinc—into steel molds under high pressure. While the die casting machine itself is not a subtractive machining system, the tooling (dies) and post-casting finishing operations often require precision 3, 4, and 5-axis CNC milling and turning to achieve tight tolerances and complex geometries. Below are the technical specifications relevant to the CNC machining systems used in the fabrication and finishing of large die cast components, focusing on multi-axis capabilities, tight tolerance machining, and compatibility with common materials including aluminum, steel, ABS, and nylon.

| Specification Category | Details |

|---|---|

| Machine Type | 5-Axis CNC Milling Center (also supports 3 and 4-axis operations) |

| Axis Configuration | Trunnion table (rotary B-axis) or swivel head (A/C or B/C), enabling full 5-axis simultaneous machining |

| Travel (X/Y/Z) | X: 1200–2000 mm, Y: 800–1200 mm, Z: 800–1000 mm (suitable for large die cast molds and components) |

| Spindle Speed | 10,000–24,000 RPM (high-speed for aluminum and plastics; lower speed/high torque options for steel) |

| Spindle Power | 30–60 kW (adjustable based on material and cutting load) |

| Positioning Accuracy | ±0.005 mm (ensures tight tolerance alignment critical for die casting dies) |

| Repeatability | ±0.002 mm (ensures consistency across multiple machining cycles) |

| Tool Changer Capacity | 30–80 tools (HSK-A63 or HSK-A100 interface; supports drills, end mills, taps, boring tools) |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) for aluminum and steel; optional mist coolant for plastics |

| Control System | Siemens SINUMERIK, Heidenhain TNC, or Fanuc 31i-B for high-precision path control |

| Materials Compatible | Aluminum (A380, A360), Tool Steel (H13, P20), ABS, Nylon (PA6, PA66) |

| Typical Tolerances Achieved | ±0.01 mm for critical die features; ±0.05 mm for general cast part finishing |

| Surface Finish (Ra) | 0.4–1.6 µm (machined surfaces); polished surfaces can reach <0.1 µm |

| Workpiece Weight Capacity | Up to 3,000 kg (supports large die blocks and cast components) |

| Applications | Machining of die casting molds, cores, cavities, ejector plates, and post-cast machining of aluminum housings, steel inserts, and plastic overmolded components |

Note: While ABS and nylon are not used in the die casting process itself, they are often machined on the same 5-axis platforms for prototype tooling, overmolding fixtures, or hybrid assemblies involving die cast metal parts. The CNC systems used in die casting environments must support a wide range of materials and maintain micron-level precision to ensure mold longevity and part consistency.

From CAD to Part: The Process

Honyo Prototype Large Die Casting Process Overview

Our large-scale die casting process (800–4,000 ton machines) follows a rigorously controlled sequence to ensure precision, cost efficiency, and on-time delivery for high-complexity components. This workflow integrates digital validation with hands-on engineering oversight, specifically optimized for parts exceeding 300mm in critical dimensions or 5kg in weight.

CAD Upload and Initial Validation

Clients upload native CAD files (STEP/IGES preferred) via our secure customer portal. Our system immediately performs automated geometry checks for manifold errors, non-manifold edges, and unit consistency. Files failing basic validation trigger an instant notification with specific error logs, preventing downstream delays. All uploads are timestamped and assigned a unique project ID for traceability.

AI-Powered Quoting with Dual-Layer Verification

Proprietary AI analyzes validated CAD data against live machine capacity databases, material cost feeds, and historical production metrics to generate a preliminary quote within 2 hours. This AI output undergoes mandatory human review by a Senior Die Casting Engineer who verifies:

Feasibility of wall thickness transitions for large-section parts

Ejection force calculations against selected press tonnage

Alloy-specific solidification behavior predictions

Only after engineer sign-off is the formal quote released, including critical path timelines and material certification options.

Engineering-Driven DFM Analysis

Our DFM phase focuses on mitigating risks inherent in large castings. Engineers conduct:

Thermal gradient simulation to prevent hot tears in thick sections

Cavity pressure mapping to optimize shot speed profiles

Draft angle validation for complex undercuts using mold-flow analysis

Gate design optimization to minimize porosity in critical zones

This phase typically resolves 85% of potential production issues before tooling begins. Clients receive a detailed DFM report with actionable recommendations.

Production Execution with Real-Time Monitoring

For large-part production, we deploy:

Dedicated 1,650–4,000 ton cold-chamber machines with 300+ ton clamping force

In-die pressure sensors tracking 500+ data points per shot cycle

Automated lubrication systems calibrated to ±0.5ml accuracy

Real-time X-ray porosity detection for critical structural zones

All parameters are logged to our MES system, with deviations triggering automatic process holds until engineering approval.

Delivery Assurance Protocol

Final inspection includes:

CMM validation of critical dimensions (ASME Y14.5 GD&T)

Ultrasonic testing for internal defects in load-bearing areas

Full material certification (ASTM B85/B179) with traceable heat numbers

Parts ship in custom-engineered crates with shock sensors, and logistics data integrates directly with client ERP systems. Average lead time for validated projects is 18–22 weeks from CAD approval to delivery.

Key DFM Validation Metrics for Large Castings

| Parameter | Honyo Standard | Industry Typical | Impact of Non-Compliance |

|————————–|————————|———————–|——————————–|

| Minimum Wall Thickness | ≥2.5mm (Al) / ≥3.0mm (Mg) | ≥3.0mm (Al) | 47% higher porosity risk |

| Draft Angle Critical Zones | ≥1.5° | ≥2.0° | Ejection force spikes >15% |

| Thermal Gradient Limit | ≤120°C/mm | ≤150°C/mm | Hot tear probability +32% |

| Gate Velocity Tolerance | ±5% of target | ±10% | Surface defects +28% |

This integrated approach reduces scrap rates by 35% and accelerates time-to-press readiness by 22 days versus conventional large-part die casting workflows. All processes adhere to IATF 16949 standards with full digital traceability from raw material to finished component.

Start Your Project

Looking to scale up your production with a large die casting machine? Honyo Prototype offers industrial-grade solutions designed for high-volume, precision manufacturing. Our facility in Shenzhen is equipped with advanced machinery and technical expertise to support demanding production requirements.

For detailed specifications, pricing, and availability, contact Susan Leo directly at [email protected]. Let’s discuss how we can optimize your manufacturing process with reliable, large-scale die casting capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.