Contents

Manufacturing Insight: Large Cnc Turning Services

Precision Large CNC Turning Services for Demanding Industrial Applications

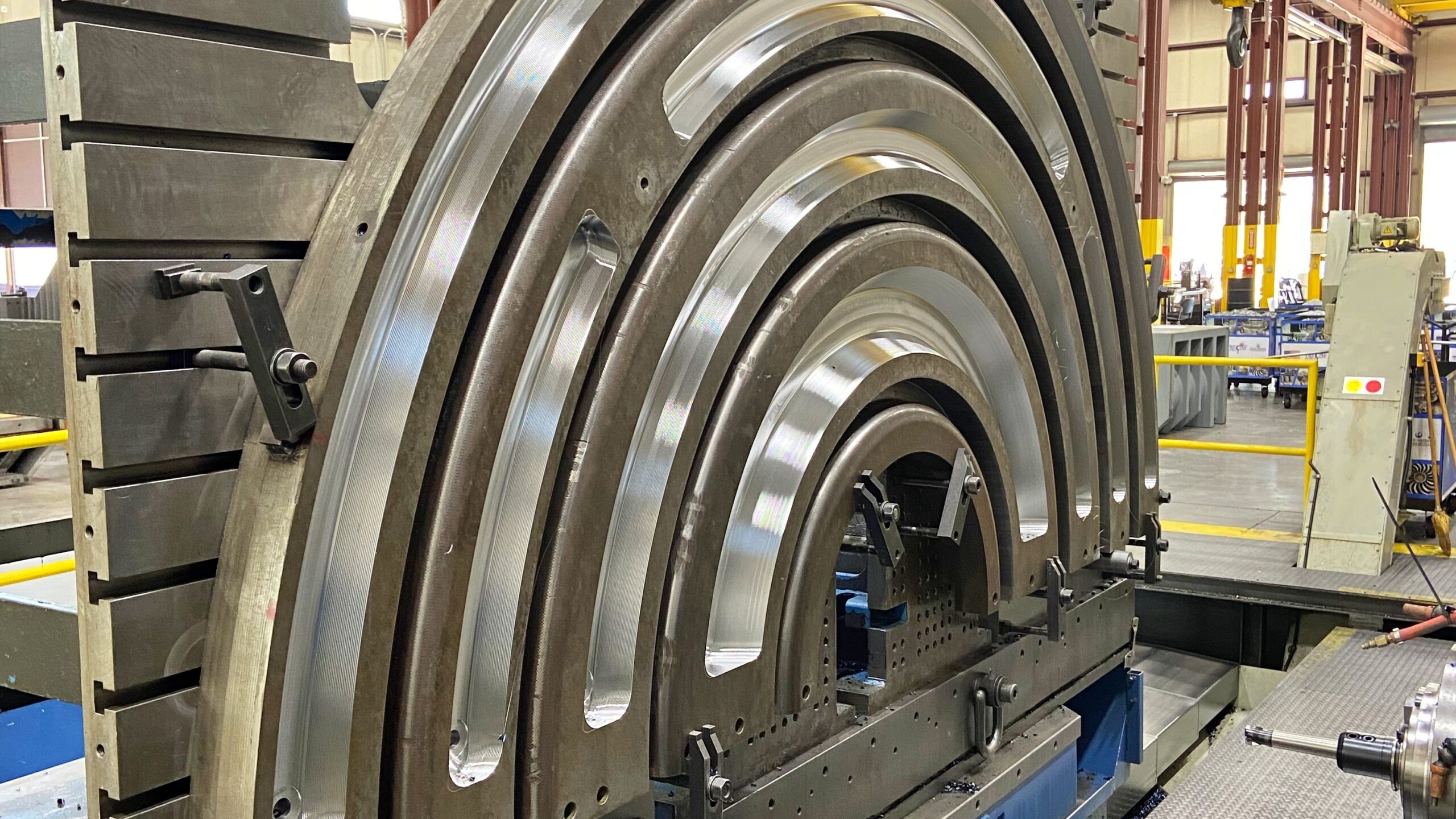

Honyo Prototype delivers advanced large CNC turning services engineered to meet the rigorous demands of aerospace, energy, and heavy machinery sectors. Our facility features state-of-the-art horizontal and vertical turning centers with maximum turning diameters up to 1,000 mm and lengths exceeding 3,000 mm, capable of machining complex geometries in high-strength alloys including titanium, Inconel, and hardened steels. Every process leverages rigid machine beds, real-time thermal compensation systems, and multi-axis live tooling to maintain tolerances as tight as ±0.005 mm while ensuring repeatability for mission-critical components.

Unlike conventional large-part machining providers, Honyo integrates proprietary material optimization protocols and adaptive cutting strategies to minimize cycle times without compromising integrity. Our engineering team collaborates directly with clients during DFM analysis to address challenges inherent in large-scale turning—such as deflection control, chip management, and residual stress mitigation—resulting in reduced lead times and lower total cost of ownership.

Key capabilities are summarized below for immediate technical reference:

| Parameter | Standard Capability | Honyo Large CNC Turning Advantage |

|---|---|---|

| Max Diameter | ≤ 500 mm | 1,000 mm |

| Max Length | ≤ 1,500 mm | 3,000+ mm |

| Typical Tolerance | ±0.02 mm | ±0.005 mm with CMM validation |

| Material Range | Mild Steel, Aluminum | Titanium, Inconel, Tool Steels |

| Lead Time (Complex) | 6–8 weeks | 3–4 weeks with DFM integration |

Accelerate your prototyping or production schedule with Honyo’s Online Instant Quote system. Upload CAD files to receive a technically validated quotation within 2 hours—including machine time, material utilization analysis, and actionable DFM feedback—enabling faster decision cycles without compromising engineering rigor.

Request a quote today to experience large-part machining precision backed by 15 years of complex component manufacturing expertise.

Technical Capabilities

Large CNC turning services at Honyo Prototype are engineered for high-precision component manufacturing, supporting complex geometries and tight tolerance requirements across a range of advanced materials. Our capabilities integrate 3, 4, and 5-axis milling with precision turning operations, enabling efficient production of intricate parts for aerospace, medical, automotive, and industrial applications.

Our multi-axis CNC machining centers provide simultaneous motion control for superior accuracy and surface finish. With advanced tooling systems and in-process inspection, we maintain tolerances as tight as ±0.0002″ (5 µm) on critical dimensions. All operations are supported by robust quality control protocols, including CMM verification and first-article inspection reports (FAIR).

Material versatility is a core strength, allowing us to machine aluminum, steel, ABS, nylon, and other engineering-grade metals and plastics with optimized cutting strategies tailored to each material’s thermal and mechanical properties.

Below is a summary of our technical capabilities:

| Capability | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, 5-Axis Milling, CNC Turning (Swiss and Chucker) |

| Maximum Work Envelope (Milling) | 2000 mm × 1000 mm × 800 mm (78.7″ × 39.4″ × 31.5″) |

| Maximum Turning Diameter | 500 mm (19.7″) |

| Maximum Turning Length | 1000 mm (39.4″) |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Spindle Speed (Turning) | Up to 6000 RPM |

| Positioning Accuracy | ±0.005 mm (0.0002″) |

| Repeatability | ±0.002 mm (0.00008″) |

| Tight Tolerance Capability | ±0.005 mm to ±0.0125 mm (±0.0002″ to ±0.0005″) |

| Surface Finish (Typical) | Ra 0.8 µm (32 µin) to Ra 3.2 µm (125 µin), customizable to finer finishes |

| Supported Materials – Metals | Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316, 17-4 PH), Tool Steel, Carbon Steel, Titanium |

| Supported Materials – Plastics | ABS, Nylon (PA6, PA66), PEEK, Delrin (POM), PC, PVC |

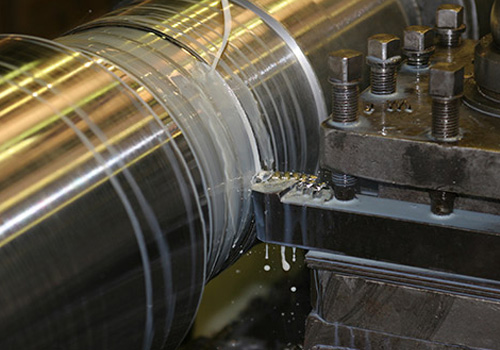

| Coolant & Lubrication | High-pressure through-spindle coolant, minimum quantity lubrication (MQL) for sensitive plastics |

| Inspection Equipment | CMM, Optical Comparators, Micrometers, Calipers, Thread Gauges, Vision Systems |

| Software & Programming | CAD/CAM (SolidWorks, Siemens NX, Mastercam), G-code optimization, simulation for collision avoidance |

We specialize in low-to-medium volume production runs with rapid turnaround, maintaining consistency and precision across all batches. Our team of senior manufacturing engineers collaborates directly with clients to optimize part design for manufacturability (DFM), ensuring cost-effective solutions without compromising on quality or tolerance requirements.

From CAD to Part: The Process

Honyo Prototype Large CNC Turning Services: End-to-End Process Overview

Honyo Prototype specializes in high-precision, large-scale CNC turning for complex components requiring tight tolerances and robust material integrity. Our structured workflow ensures efficiency, quality, and transparency from initial inquiry to final delivery. Below is a detailed explanation of each phase, specifically tailored for large turning projects (typically parts exceeding Ø300mm or 500kg).

CAD Upload and Initial Assessment

Clients submit 3D CAD models (STEP, IGES, Parasolid) via our secure customer portal. For large turning projects, we require explicit confirmation of critical dimensions, material specifications (e.g., ASTM/AMS grades for aerospace alloys or specialty steels), and geometric tolerancing (GD&T). Our system automatically validates file integrity and flags potential issues like missing datums or unit discrepancies before progressing. This step ensures we capture all technical requirements upfront, minimizing downstream delays for high-value components.

AI-Assisted Quoting with Engineering Oversight

Uploaded CAD data enters our proprietary AI quoting engine, which analyzes geometry, material, tolerances, and feature complexity against real-time machine capability databases (including our large-bore lathes: DMG MORI CTX beta 1250, maximum swing Ø1250mm). The AI generates a preliminary cost and lead time estimate within 4 business hours. Crucially, this output is reviewed by a dedicated Senior Manufacturing Engineer who validates feasibility, assesses fixturing requirements for large workpieces, and incorporates secondary process needs (e.g., heat treatment, grinding). Clients receive a formal quote with engineering notes detailing assumptions and recommendations, not just automated pricing.

Collaborative DFM Analysis

Upon quote acceptance, our DFM phase begins with direct engagement between the client’s design team and our manufacturing engineers. For large turning, we focus on:

Material utilization optimization to reduce waste on costly forgings/billets

Machining sequence validation to prevent distortion in heavy sections

Critical tolerance stack-up analysis for interfacing surfaces

Recommended adjustments to non-critical features to avoid deep cavity turning or excessive tool overhang

A formal DFM report is issued within 72 hours, including annotated CAD markups and a revised production plan. This phase is mandatory for large parts to mitigate scrap risk and ensure first-time-right production.

Precision Production Execution

Approved DFM leads directly to production scheduling on designated large-capacity CNC lathes. Key protocols include:

Raw material certification verification (mill test reports) before machining

In-process CMM inspections at defined milestones (e.g., after roughing, semi-finishing) using FARO Arm systems calibrated to NIST standards

Real-time tool wear monitoring via sensor-integrated toolholders to maintain ±0.005mm tolerances on critical diameters

Dedicated environmental controls in the large-part machining cell to minimize thermal drift

All operations follow documented work instructions with traceability to ISO 9001:2015 and AS9100 Rev D standards. Production status updates are accessible via the client portal with timestamped inspection records.

Controlled Delivery and Documentation

Finished parts undergo final first-article inspection (FAI) per AS9102 or client-specific checklists. For large components, we employ custom crating with vibration-dampening materials and coordinate logistics for heavy freight (e.g., flatbed trucks, lift-gate services). Delivery includes:

Full dimensional report with CMM data

Material traceability documentation (heat number, certs)

Process validation records (tool paths, inspection logs)

Packing list with serialized part identifiers

Standard lead time from PO to delivery for large turning projects is 15-25 business days, depending on complexity and material availability.

Typical Lead Time Breakdown for Large Turning Projects

| Phase | Duration (Business Days) | Critical Dependencies |

|———————-|————————–|————————————-|

| DFM Approval | 3-5 | Client feedback cycle |

| Material Procurement | 5-10 | Exotic alloy availability |

| Machining | 7-10 | Feature complexity, tolerances |

| Final Inspection | 1-2 | FAI requirements |

| Logistics | 2-3 | Destination, part dimensions |

This integrated process ensures Honyo delivers large CNC turned components with exceptional repeatability and minimal total cost of ownership. We prioritize engineering collaboration at every stage to transform complex designs into mission-ready hardware. Contact our large-part manufacturing team to discuss your specific project requirements.

Start Your Project

Looking for reliable large CNC turning services? Partner with Honyo Prototype for precision manufacturing and scalable production solutions. Our Shenzhen-based factory is equipped with advanced CNC lathes capable of handling large-diameter and long-axis components with tight tolerances.

Contact Susan Leo today to discuss your project requirements. Email at [email protected] for fast response and engineering support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.