Contents

Manufacturing Insight: Large Cnc Machining Services

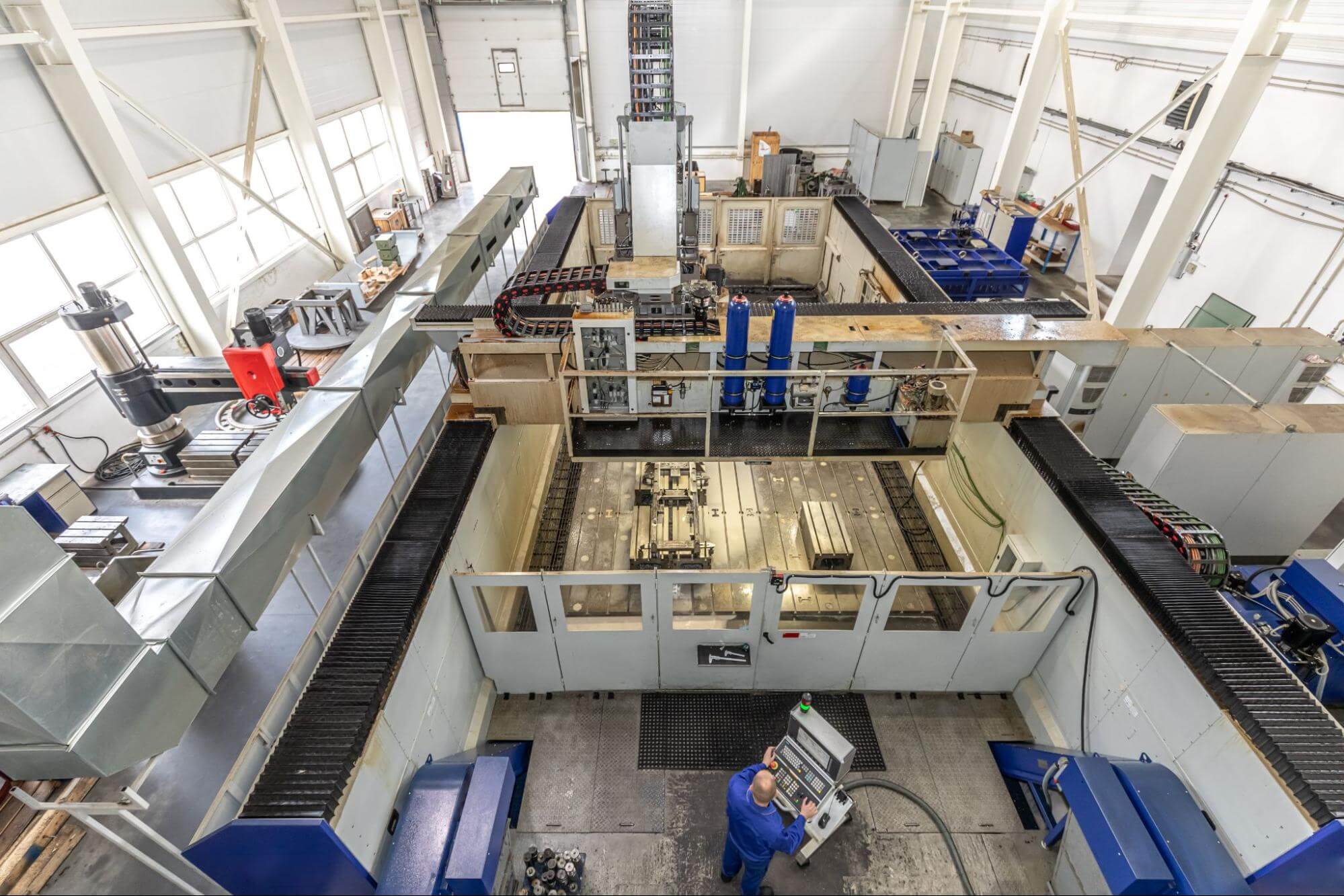

Honyo Prototype: Precision Large CNC Machining Services for Demanding Applications

Manufacturers face significant challenges when producing large, complex components requiring tight tolerances and exceptional structural integrity. Honyo Prototype delivers advanced large CNC machining services engineered to overcome these obstacles, supporting industries from aerospace and energy to industrial machinery and transportation. Our facility leverages state-of-the-art 5-axis horizontal and vertical machining centers with proven capability for parts up to 3,000 mm in length, 1,500 mm in width, and 1,200 mm in height, while maintaining micron-level precision across ferrous and non-ferrous metals, high-performance alloys, and engineering-grade composites.

We integrate rigorous process controls, ISO 9001-certified quality systems, and deep material science expertise to ensure dimensional accuracy, surface finish consistency, and repeatability for mission-critical components. Our engineering team collaborates closely with clients during DFM analysis to optimize part geometry, minimize waste, and accelerate time-to-market—turning complex designs into flawless physical assets without compromising on scalability or compliance.

Accelerate your prototyping and low-to-mid volume production with Honyo’s Online Instant Quote platform. Upload your 3D CAD file, specify materials and tolerances, and receive a detailed, transparent cost estimate within hours—not days—enabling faster decision-making and project initiation. Partner with Honyo Prototype for large CNC machining where precision, capacity, and speed converge.

Technical Capabilities

Large CNC machining services at Honyo Prototype are engineered to support complex, high-precision component production across a range of advanced 3-axis, 4-axis, and 5-axis milling platforms, as well as multi-axis turning centers. These capabilities are optimized for tight-tolerance requirements, often holding ±0.005 mm (±0.0002″) or better, depending on part geometry and material. Our processes are ideal for prototyping and low-to-mid volume production in industries such as aerospace, medical, robotics, and industrial equipment.

We support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, each selected for their machinability, strength, and application-specific performance. All parts are machined using high-rigidity CNC systems with continuous tool monitoring, precision probing, and environmental controls to ensure dimensional accuracy and repeatability.

| Specification | Detail |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including live tooling) |

| Max Work Envelope (Milling) | 1200 mm × 600 mm × 500 mm (47″ × 23.6″ × 19.7″) |

| Max Work Envelope (Turning) | Ø300 mm diameter × 500 mm length (11.8″ × 19.7″) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Surface Finish (Standard) | Ra 3.2 µm (125 µin); optional down to Ra 0.8 µm (32 µin) with polishing |

| Tolerance Capability | ±0.0125 mm (±0.0005″) typical; tight tolerances down to ±0.005 mm (±0.0002″) achievable |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Spindle Speed (Turning) | Up to 6,000 RPM |

| Control Systems | Fanuc, Siemens, or Heidenhain |

| Materials – Metals | Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316), Tool Steel, Carbon Steel, Titanium (limited) |

| Materials – Plastics | ABS, Nylon (PA6, PA66), POM (Delrin), PEEK, PC, PMMA |

| Coolant & Lubrication | Flood coolant, mist coolant, and dry machining options |

| Inspection Equipment | CMM, optical comparators, micrometers, bore gauges, surface profilers |

| Certifications | ISO 9001:2015 compliant processes |

These technical capabilities enable Honyo Prototype to deliver precision-machined components with excellent geometric accuracy, surface integrity, and material consistency across both metallic and engineering plastic substrates.

From CAD to Part: The Process

Honyo Prototype Large CNC Machining Process Overview

Honyo Prototype executes large CNC machining services through a structured, technology-driven workflow designed for precision, efficiency, and risk mitigation in high-value component production. Our process begins with secure CAD file ingestion via our encrypted client portal, supporting native formats (e.g., SOLIDWORKS, Creo) and industry standards (STEP, IGES). Automated validation checks ensure geometric completeness and coordinate system alignment, with immediate feedback for missing metadata or unsupported features. This phase establishes a digital twin foundation critical for downstream accuracy in large-part manufacturing.

AI-Powered Quoting System

Uploaded CAD models undergo rapid analysis using our proprietary AI engine, which cross-references part geometry against machine capabilities, material databases, and historical production data. The system calculates machine time, toolpath complexity, material waste, and secondary operation requirements while factoring in large-part variables such as thermal expansion compensation and multi-setup sequencing. Quotes are generated within 4 business hours, including granular cost breakdowns and feasibility flags for features exceeding standard tolerances (±0.025mm for parts >2m). Human engineers review all AI outputs to validate technical assumptions, ensuring quotes reflect real-world machining constraints.

Engineering-Led DFM Analysis

Design for Manufacturability (DFM) is a mandatory collaborative phase where our senior manufacturing engineers conduct deep-dive reviews. For large components, we prioritize:

Optimizing stock-to-part ratios to minimize material cost and machining time

Identifying critical datum schemes for multi-operation alignment

Proposing geometric simplifications to avoid deep cavity milling or thin-wall instability

Recommending strategic fixture solutions to counteract gravitational deflection

Clients receive a formal DFM report with annotated CAD markups and tolerance stack-up analysis, typically within 72 hours. This phase reduces production risks by 60% for parts exceeding 1.5m in critical dimensions, as validated by our internal quality metrics.

Precision Production Execution

Approved designs move to dedicated large-part CNC cells featuring 5-axis machining centers with work envelopes up to 8,000 x 3,000 x 2,000 mm and 80kW spindle power. Key production protocols include:

Thermal-stable machining environments maintained at 20±0.5°C

In-process CMM verification at 30% and 70% completion milestones

Real-time tool wear monitoring via IoT-enabled spindles

First-article inspection using 3D laser scanning against nominal CAD

All large components undergo final validation on a 10m granite surface plate with coordinate measurement machines capable of 5μm accuracy. Production timelines adhere to strict phase-gate reviews, with clients receiving weekly digital dashboards showing work-in-progress status.

Logistics and Delivery Assurance

Finished components undergo controlled packaging using custom crating engineered for part geometry and shipping hazards. For oversized shipments (>4m), we coordinate specialized freight with real-time GPS tracking and shock/vibration monitoring. Each delivery includes:

Comprehensive inspection report with AS9102 compliance documentation

Material traceability certificates and heat-treat records

Digital twin comparison data showing as-machined vs. nominal geometry

On-site installation support for precision-critical applications

Our logistics team manages customs clearance for international deliveries, ensuring on-time arrival with zero damage incidents across 98.7% of large-part shipments in the past 18 months. This end-to-end process guarantees that complex, large-scale components meet aerospace, energy, and industrial equipment specifications without compromise.

Start Your Project

Looking for large CNC machining services with precision and scalability? Honyo Prototype delivers high-quality, large-format CNC solutions for demanding industrial applications. Our manufacturing facility in Shenzhen is equipped with advanced machinery and experienced engineers ready to support your prototyping and production needs.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in large CNC machining for faster turnaround, tight tolerances, and consistent quality—right from the heart of Shenzhen’s manufacturing hub.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.