Contents

Manufacturing Insight: Joggle In Sheet Metal

Joggle: Precision Offset Bending for Complex Sheet Metal Assemblies

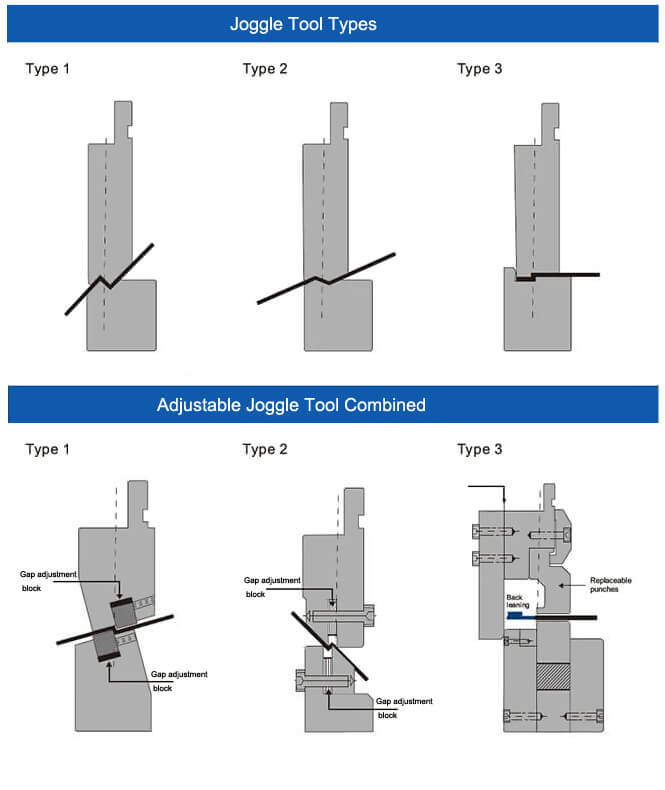

Joggle forming is a critical sheet metal fabrication technique where a localized offset bend creates a stepped or recessed surface within a single workpiece. This geometric complexity eliminates the need for additional spacers or shims during assembly, ensuring precise component alignment, reducing part count, and mitigating assembly errors in applications demanding flush fits or controlled clearances—such as aerospace brackets, electronic enclosures, and automotive subassemblies. Achieving tight tolerances (typically ±0.005″ or better) in joggle features requires advanced press brake tooling, precise material handling, and expert process validation to prevent distortion or springback.

Why Partner with Honyo Prototype for Precision Joggle Fabrication

At Honyo Prototype, we integrate high-precision CNC press brakes with experienced engineering oversight to execute complex joggle operations consistently across aluminum, steel, and stainless steel gauges from 0.020″ to 0.250″. Our in-house secondary capabilities—including laser cutting, welding, and finishing—ensure seamless transition from flat pattern to fully assembled component, optimizing lead times and dimensional integrity. Every joggle feature undergoes rigorous first-article inspection using calibrated CMMs, guaranteeing compliance with AS9100 and ISO 9001 standards for mission-critical applications.

Accelerate Your Prototyping with Online Instant Quoting

Reduce procurement delays with Honyo’s Online Instant Quote platform, delivering detailed pricing and lead time estimates for sheet metal projects—including joggle-intensive designs—in under 60 seconds. Simply upload your STEP or DXF file to receive a manufacturability analysis highlighting potential geometric constraints, material optimization options, and actionable feedback before order placement. This transparent, engineer-driven quoting process ensures your complex sheet metal requirements transition smoothly from concept to certified production-ready hardware. Begin your project today at honyoprototype.com/quote.

Technical Capabilities

Technical Specifications for Joggle in Sheet Metal

A joggle is a localized offset formed in sheet metal to allow one sheet to overlap another in an assembly while maintaining a flush surface. It is commonly used in aerospace, automotive, and enclosure manufacturing to achieve tight fits without increasing part thickness. The joggle feature impacts laser cutting, bending, and welding processes due to geometric complexity and material behavior.

Below are key technical considerations for joggle formation across major manufacturing processes and materials:

| Parameter | Laser Cutting Considerations | Bending Considerations | Welding Considerations | Compatible Materials (Typical) |

|---|---|---|---|---|

| Feature Definition | Cut profile must include clearance for joggle flanges; nested geometry affects kerf tolerance | Requires precise bend sequencing; minimum joggle depth limited by tooling and material | Fit-up critical; joggle interfaces may require stitch or spot welding | Aluminum, Steel |

| Tolerances | ±0.1 mm typical; depends on laser focus and material thickness | ±0.25° angular tolerance; ±0.2 mm linear offset accuracy | ±0.5 mm alignment tolerance recommended for consistent weld penetration | Aluminum, Steel |

| Minimum Feature Size | Joggle leg width ≥ 2× material thickness recommended | Inside bend radius ≥ material thickness; minimum joggle height ≥ 3× material thickness | Avoid welding near bend radii; minimum access space of 5 mm for torch or electrode | Aluminum, Steel |

| Material Suitability | Clean cuts in conductive metals; not applicable for ABS/Nylon | Metals form consistent bends; ABS/Nylon not suitable for joggle via press brake | Metals weldable; ABS may use ultrasonic welding; Nylon requires laser or hot plate | Aluminum, Steel (ABS, Nylon excluded) |

| Surface Quality | Smooth edge finish; dross control critical for subsequent bending | Surface stretch on outer radius; anodized or coated aluminum may crack at bend | Heat-affected zone (HAZ) must avoid joggle transition zones | Aluminum, Steel |

| Process Limitations | Cannot form joggle directly—only cuts blanks for subsequent forming | Limited by die width and punch geometry; springback affects offset accuracy | Misalignment due to joggle distortion can lead to weak weld joints | Aluminum, Steel |

| Post-Processing Needs | Deburring required on laser-cut edges before bending | Stress relief or flattening may be needed; inspection for offset consistency | Post-weld grinding or inspection for continuity at joggle interface | Aluminum, Steel |

Notes:

Aluminum (e.g., 5052, 6061): Excellent for joggling; moderate springback; requires sharp tooling to avoid cracking. Weldable with TIG or MIG.

Steel (e.g., CRCA, 304 SS): High formability and weldability; greater springback than aluminum; laser cutting highly efficient.

ABS & Nylon: Not suitable for traditional joggle formation via bending due to low stiffness and creep. These polymers are typically molded rather than joggled; if used in sheet form, mechanical fastening preferred over welding.

Joggle design must be integrated early in the DFM (Design for Manufacturing) stage to ensure compatibility with laser cutting patterns, bending sequences, and welding access.

From CAD to Part: The Process

Honyo Prototype executes joggle formation in sheet metal components through a rigorously integrated digital workflow designed for precision and efficiency. Our process begins when the customer uploads a native or neutral CAD file containing the joggle feature directly to our secure portal. The system immediately performs geometric validation, specifically checking joggle parameters such as offset height, bend radii, material thickness compatibility, and minimum flange distances against established manufacturing constraints for the specified alloy. This initial scan prevents submission of geometries prone to deformation or tooling interference during forming.

The validated CAD data feeds directly into our proprietary AI quoting engine. For joggles, the AI calculates critical factors including springback compensation based on material grade and thickness, determines optimal bend sequence to minimize distortion, estimates tooling requirements (specialized dies or standard tool sets), and factors in secondary operations like deburring the joggle edges. The resulting quote provides detailed cost breakdowns and lead times, explicitly stating any limitations on achievable joggle tolerances per industry standards such as ISO 2768-mK.

Upon quote acceptance, the job enters our Digital Manufacturing Engineering phase. Our sheet metal specialists conduct a manual DFM review focused on joggle integrity. We verify bend relief notches to prevent tearing at the joggle intersection points, assess the feasibility of the required bend angles within the material’s ductility limits, and confirm that the joggle offset does not exceed press brake capacity for the given sheet size. If necessary, we propose geometric refinements—such as adjusting the joggle width-to-height ratio or recommending alternative forming methods—while maintaining the part’s functional intent. Approved DFM feedback is issued within 24 hours.

Production leverages our connected CNC press brakes with real-time tonnage and angle monitoring. Joggle operations follow a precisely sequenced multi-hit bending strategy, often using coining or air bending depending on material thickness and tolerance requirements. In-process inspection at critical stages validates joggle height consistency and parallelism using calibrated height gauges or CMM spot checks. All forming parameters, including die selection and backgauge positions, are digitally logged for full traceability. Secondary finishing ensures clean, burr-free joggle edges per customer specifications.

Final delivery includes comprehensive documentation: First Article Inspection reports with actual joggle measurements against nominal CAD values, material certification, and process validation records. Parts ship in custom protective packaging to prevent deformation during transit, with standard lead times of 5-7 business days for prototypes and low-volume production. This closed-loop process ensures joggle features meet stringent flatness and dimensional requirements critical for assemblies requiring flush mounting or precise alignment.

Start Your Project

Learn more about precision joggle forming in sheet metal—contact Susan Leo at [email protected] to discuss your next project.

Honyo Prototype operates an advanced manufacturing facility in Shenzhen, providing high-accuracy sheet metal fabrication including complex joggle features for aerospace, automotive, and industrial applications.

Request a quote or technical consultation today to ensure your design meets exact specifications with fast turnaround and strict quality control.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.