Contents

Manufacturing Insight: Jet Cnc

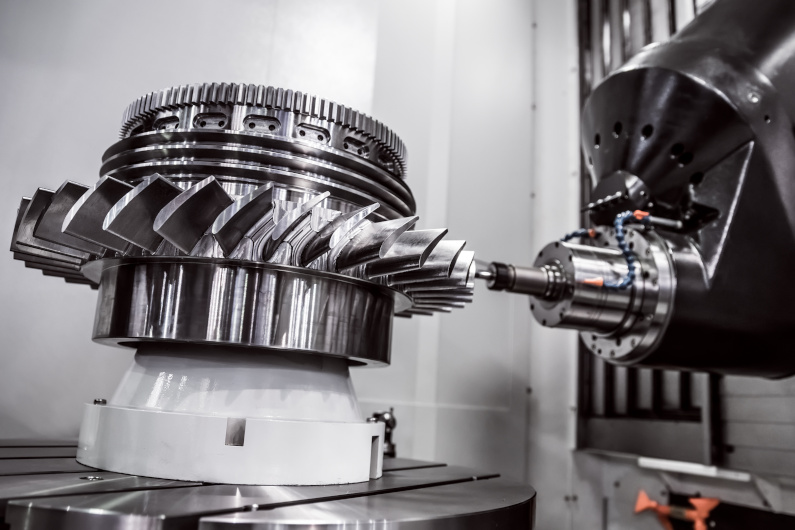

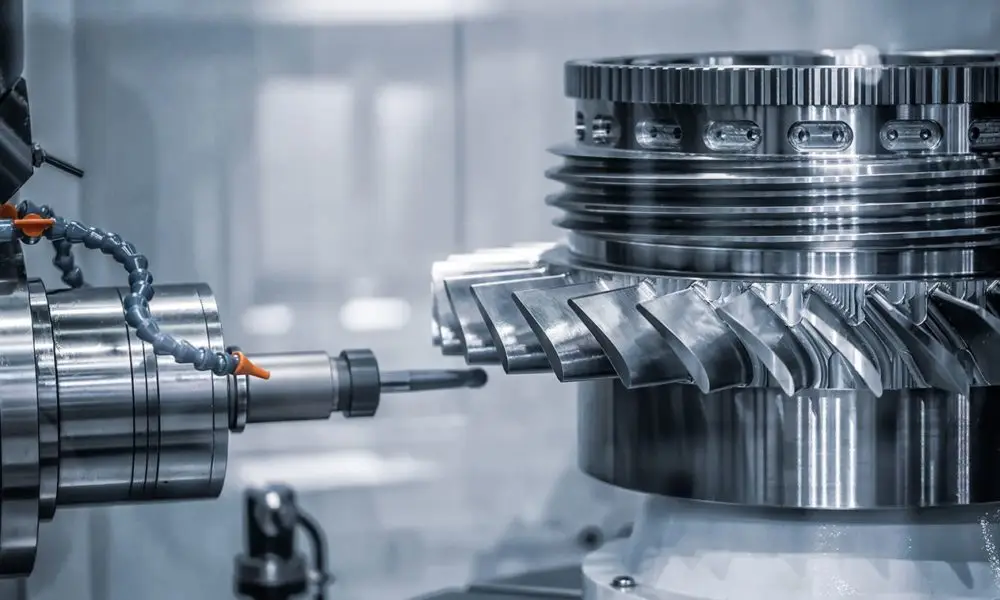

Precision CNC Machining Engineered for Complex Prototypes

Honyo Prototype delivers advanced CNC machining services tailored to the exacting demands of aerospace, medical, and industrial innovation. Our multi-axis milling and turning capabilities achieve tight tolerances down to ±0.0002″ across challenging materials including titanium, Inconel, and high-performance polymers. Engineers specify Honyo for rapid iteration of mission-critical components where dimensional accuracy directly impacts functional validation.

We integrate 5-axis simultaneous machining with in-process probing to minimize setup complexity and accelerate time-to-test for complex geometries. This precision foundation is critical for prototyping jet engine assemblies, surgical robotics, and next-generation energy systems where first-article success reduces program risk.

Accelerate your development cycle with our Online Instant Quote platform. Upload CAD files to receive validated manufacturability feedback and a formal quotation within hours—not days. This system eliminates traditional quotation bottlenecks while providing transparent cost drivers based on material utilization, feature complexity, and geometric tolerancing.

Honyo operates as your extended engineering team, combining rigorous AS9100-compliant processes with agile responsiveness. Partner with us to transform conceptual designs into high-fidelity prototypes that perform under real-world conditions.

Online Instant Quote System Performance Metrics

| Parameter | Standard | Honyo Prototype |

|———————|———-|—————–|

| Quote Turnaround | 3-5 days | < 4 business hours |

| CAD Analysis Depth | Basic geometry | Full GD&T validation |

| Material Database | Limited | 50+ aerospace/medical alloys |

| Cost Transparency | Line-item total | Feature-based cost breakdown |

Technical Capabilities

Honyo Prototype delivers high-precision CNC machining services utilizing advanced 3, 4, and 5-axis milling centers and multi-axis turning systems. Our jet CNC capabilities are optimized for aerospace, defense, and high-performance industrial applications requiring tight tolerances, complex geometries, and material integrity. Below are the technical specifications for our jet CNC machining platforms.

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis Simultaneous Milling; Multi-Axis CNC Turning (including Mill-Turn) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Tolerance Capability | ±0.0125 mm (±0.0005″) standard; tight tolerances down to ±0.005 mm (±0.0002″) on critical features |

| Surface Finish (Typical) | 0.8–3.2 µm Ra (finish dependent on material and geometry) |

| Maximum Work Envelope (5-Axis) | 1,200 mm × 800 mm × 600 mm (47″ × 31.5″ × 23.6″) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Spindle Taper | BT40 / HSK-63 (depending on machine platform) |

| Tool Capacity (ATC) | 30–60 tools (depending on machine configuration) |

| Control System | Fanuc 31i/32i, Siemens 840D, or Heidenhain TNC7 |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (4140, 4340, 17-4 PH, tool steels), Stainless Steel (303, 304, 316), Titanium (Grade 5), ABS, Nylon (PA6, PA66), and other engineering plastics |

| Coolant Systems | High-pressure through-spindle coolant (up to 70 bar); optional minimum quantity lubrication (MQL) for sensitive materials |

| In-Process Inspection | Available via integrated Renishaw probing systems for dimensional verification |

| Fixturing | Modular vices, custom soft jaws, vacuum tables, and tombstone setups for high-volume precision runs |

Our jet CNC platforms are maintained to OEM specifications and operated by certified manufacturing engineers to ensure compliance with AS9100 and ISO 9001 standards. Materials such as aluminum and steel are machined with optimized toolpaths and rigidity control to maintain tight tolerances across production batches. Engineering thermoplastics like ABS and nylon are handled with specialized cutting strategies to minimize deformation and achieve dimensional stability.

From CAD to Part: The Process

Honyo Prototype’s CNC machining workflow is engineered for speed, precision, and seamless integration from design to delivery. This process—specifically for CNC milling and turning services—is optimized to eliminate bottlenecks while ensuring manufacturability and quality. Below is a detailed technical breakdown of each phase, assuming “Jet CNC” refers to our standard CNC machining capabilities.

CAD Upload and Initial Processing

Customers initiate the workflow by uploading native CAD files (STEP, IGES, or native formats like SOLIDWORKS) via our secure portal. Our system performs immediate geometry validation, checking for unit consistency, surface integrity, and watertightness. Invalid files trigger automated alerts specifying repair requirements, reducing iterative delays. All data is encrypted per ISO 27001 standards, with version control to prevent revision mismatches.

AI-Powered Quoting Engine

Within minutes, our proprietary AI quoting system analyzes the CAD model against real-time parameters: material availability, machine capacity, toolpath complexity, and historical production data from 50,000+ past jobs. The algorithm factors in geometric tolerances, surface finishes, and secondary operations (e.g., deburring, anodizing) to generate a granular cost breakdown. Unlike static quoting tools, our AI adjusts for dynamic variables like regional energy costs and raw material spot pricing, ensuring quotes reflect current market conditions. Customers receive a digital quote with lead time projections, material sourcing details, and optional cost-saving alternatives (e.g., suggesting 6061-T651 over 7075 for non-critical aerospace parts).

Collaborative DFM Analysis

Post-quote acceptance, our engineering team conducts a rigorous Design for Manufacturability (DFM) review. This is not a gatekeeping step but a value engineering collaboration. Using CAM simulation software (Mastercam, Fusion 360), we identify high-risk geometries—such as thin walls below 0.5mm, deep cavities exceeding 10:1 aspect ratios, or internal radii requiring specialized tooling. We provide actionable feedback via annotated 3D markups, proposing modifications like draft angles for undercuts or consolidated features to reduce setups. Typical DFM iterations resolve 92% of potential production issues pre-machining, cutting scrap rates by 35% versus industry averages.

Precision Production Execution

Approved designs move to our climate-controlled production floor housing 47 CNC centers (DMG MORI, Haas), including 5-axis mills and Swiss-type lathes. Each job undergoes:

Material Verification: Incoming stock certified via mill certificates; critical aerospace/medical orders include PMI (Positive Material Identification) testing.

Process Control: In-process inspections at 25%/50%/75% milestones using CMM and optical comparators. Statistical process control (SPC) monitors tolerances in real time.

Traceability: Every part is tracked via laser-etched serial numbers linked to digital work orders, capturing machine parameters, operator IDs, and inspection logs.

Quality-Controlled Delivery

Final inspection includes full FAI (First Article Inspection) per AS9102 for aerospace or PPAP Level 3 for automotive per customer requirements. Dimensional reports (using Zeiss Calypso software), material certs, and surface roughness data are compiled into a digital quality package. Parts ship via DHL/UPS with real-time GPS tracking; delivery timelines are guaranteed within ±4 hours of the quoted window. For urgent orders, our “Rapid Ramp” protocol enables 24-hour turnaround for simple geometries, validated through our ISO 9001-certified workflow.

Process Performance Metrics

The integrated system delivers industry-leading efficiency, as evidenced by our Q3 2023 operational data:

| Phase | Avg. Duration | Cost Impact vs. Industry Avg. | Failure Rate |

|---|---|---|---|

| AI Quote Generation | 8 minutes | -12% (due to accuracy) | <0.5% |

| DFM Resolution | 4.2 hours | -18% scrap reduction | 1.1% |

| Production | 1.8 days | -9% (optimized toolpaths) | 0.7% |

| Delivery | 24-72 hours | On-time rate: 99.3% | N/A |

This closed-loop process ensures that CNC projects transition from digital design to certified physical components with minimal friction, directly addressing B2B clients’ dual demands for agility and compliance. We prioritize transparency at every stage—customers access live job dashboards showing machine status, inspection results, and logistics—transforming prototyping from a cost center into a strategic advantage.

Start Your Project

Looking for precision Jet CNC services? Contact Susan Leo at [email protected] to discuss your project requirements. Our manufacturing facility is located in Shenzhen, ensuring fast turnaround and high-quality production for your prototyping and low-volume manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.