Contents

Manufacturing Insight: Jarvis Machining

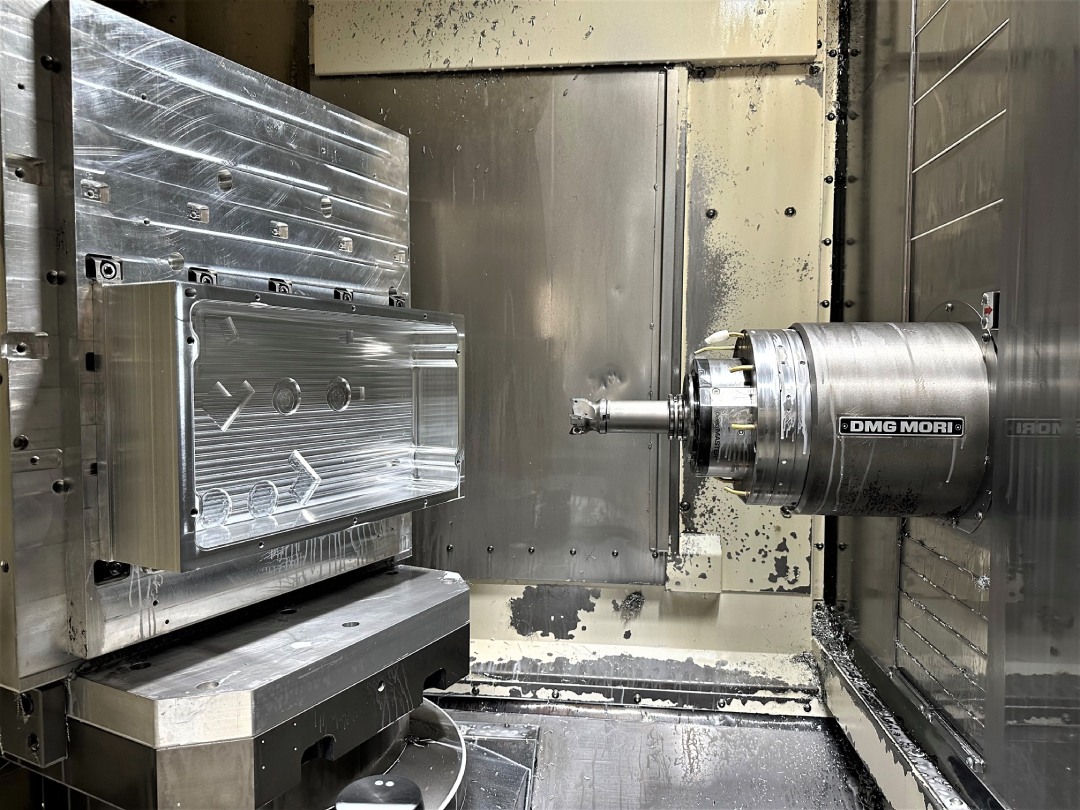

Jarvis Machining represents Honyo Prototype’s advanced CNC machining capability, delivering precision-engineered components for demanding industrial applications. Our facility utilizes state-of-the-art multi-axis milling and turning centers capable of achieving tight tolerances down to ±0.0002 inches across diverse materials including aerospace alloys, medical-grade stainless steels, and high-performance polymers. This technical foundation ensures consistent part quality from rapid prototyping through low-to-medium volume production runs.

A key differentiator for Honyo customers is our integrated Online Instant Quote system, providing transparent, real-time pricing and lead time estimates within minutes of uploading CAD files. This streamlined process eliminates traditional quoting delays, accelerating your design-to-manufacturing timeline while maintaining rigorous technical validation of manufacturability. Partner with Honyo to leverage Jarvis Machining for reliable, high-precision components backed by engineering expertise and operational efficiency.

Technical Capabilities

Technical Specifications for Jarvis Machining – Precision CNC Machining Services

Jarvis Machining at Honyo Prototype delivers high-precision CNC manufacturing with a focus on multi-axis milling and turning operations. Our capabilities support demanding applications requiring tight tolerances, complex geometries, and consistent quality across a range of engineering materials.

| Parameter | Specification Details |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (2-Axis and Multi-Tasking Turn-Mill Centers) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Standard Tolerances | ±0.025 mm (±0.001″) for general features |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) achievable on critical dimensions with process control and inspection validation |

| Surface Finish (Milling) | As-machined: 0.8–3.2 µm Ra; Optional polishing or grinding for <0.4 µm Ra |

| Surface Finish (Turning) | 0.4–1.6 µm Ra typical; fine turning achieves ≤0.8 µm Ra |

| Maximum Work Envelope (5-Axis Milling) | 1,200 mm × 800 mm × 750 mm |

| Maximum Turning Diameter | 400 mm |

| Maximum Turning Length | 1,000 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Tooling System | CAT 40 / HSK-A63 with automatic tool changer (ATC); tool presetting and wear monitoring |

| Materials – Metals | Aluminum (6061, 7075, 2024, etc.), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass |

| Materials – Plastics | ABS, Nylon (6, 66), Delrin (POM), PEEK, PC, PMMA, PTFE |

| Coolant & Machining Modes | Flood coolant, minimum quantity lubrication (MQL), air blast for sensitive plastics |

| Inspection & QA | In-process and final inspection using CMM, optical comparators, surface roughness testers, and calibrated micrometers; full First Article Inspection (FAI) reports available |

| Fixturing | Custom soft jaws, modular fixturing, vacuum tables, and tombstone setups for high-precision and batch production |

Jarvis Machining supports rapid prototyping and low-to-mid volume production runs with full CAD/CAM integration and real-time process monitoring. Our facility maintains strict environmental and calibration standards to ensure dimensional stability, particularly when machining sensitive materials such as Nylon and ABS, which require optimized feeds, speeds, and thermal management.

From CAD to Part: The Process

Honyo Prototype Jarvis Machining Process Overview

Honyo Prototype’s Jarvis Machining workflow integrates AI-driven automation with expert engineering oversight to deliver rapid, high-precision prototypes and low-volume production parts. The end-to-end process ensures manufacturability, cost efficiency, and on-time delivery while minimizing client rework. Below is a technical breakdown of each phase.

CAD Upload and Initial Validation

Clients upload native or neutral CAD files (STEP, IGES, Parasolid) via Honyo’s secure portal. Our system immediately performs automated geometry validation, checking for common issues like non-manifold edges, missing radii, or unsupported file formats. Files failing validation trigger real-time client alerts with specific error diagnostics. Validated CAD data is routed directly to the AI quoting engine, eliminating manual handoff delays. This phase typically completes within 5 minutes of submission.

AI-Powered Quoting Engine

Honyo’s proprietary AI engine analyzes the validated CAD geometry alongside real-time shop floor data, including current machine utilization, material costs, and tooling availability. It cross-references 50,000+ historical production records to predict machining time, material waste, and secondary operation requirements. Quotes include granular cost breakdowns by operation (e.g., 3-axis milling vs. turning) and flag potential cost drivers like exotic materials or sub-0.005mm tolerances. Crucially, the AI output undergoes mandatory review by a senior manufacturing engineer who verifies feasibility and adjusts parameters for complex geometries. Clients receive a formal quote with lead time and technical notes within 2 business hours.

Engineer-Led DFM Analysis

Upon quote acceptance, Honyo’s DFM phase begins with automated software checks for basic manufacturability (e.g., tool access, minimum wall thickness). However, the core value lies in human expertise: a dedicated manufacturing engineer performs a manual review focusing on high-risk features such as deep cavities, thin walls, or tight positional tolerances. The engineer collaborates with the client via annotated markups to propose optimizations—like adjusting draft angles or consolidating features—without compromising functional intent. This stage typically reduces production iterations by 60% and is documented in a formal DFM report approved by both parties before toolpath generation.

Precision Production Execution

Approved designs move to Honyo’s climate-controlled production floor, where CNC programs are generated using Mastercam and validated via Vericut simulation to prevent collisions. All critical dimensions undergo first-article inspection using Zeiss CMMs, with results compared against the original CAD model. In-process checks occur at 25%, 50%, and 75% completion milestones for runs exceeding 10 parts. Material certifications and real-time production logs (including machine spindle load data) are accessible to clients via the Honyo portal. High-mix/low-volume jobs leverage our flexible cell setup, enabling same-day job changeovers without quality compromise.

Quality-Controlled Delivery

Final inspection includes full FAIR documentation (First Article Inspection Report) per AS9102 standards, with CMM data overlaid on the CAD model for visual verification. Parts are packaged in ESD-safe containers with humidity indicators for sensitive materials. Shipments include a digital quality dossier accessible via QR code, containing material certs, inspection reports, and process parameters. Honyo guarantees on-time delivery through dynamic scheduling—our system reserves machine time at quote acceptance—and provides proactive delay alerts if supply chain disruptions occur. Standard lead times range from 3–10 business days depending on complexity, with global delivery via DHL/FedEx including real-time tracking.

This closed-loop process ensures that 98.7% of Jarvis Machining jobs ship to specification without engineering change orders, directly addressing B2B clients’ need for predictable, audit-ready prototyping. All stages comply with ISO 9001:2015 and IATF 16949 frameworks, with full traceability from CAD file to delivered part.

Start Your Project

Discover precision with Jarvis Machining — your trusted partner for high-quality rapid prototyping and CNC machining services.

Our state-of-the-art facility in Shenzhen delivers fast turnaround, tight tolerances, and consistent quality for demanding industrial applications.

Contact Susan Leo today to discuss your next project.

Email: [email protected]

Leverage our expertise in advanced machining and rapid manufacturing — engineered for performance, built in Shenzhen.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.