Contents

Manufacturing Insight: Is Titanium Or Aluminum Lighter

Material weight comparisons between titanium and aluminum frequently arise in precision engineering, yet the answer requires nuanced technical evaluation beyond simple density metrics. While aluminum alloys average 2.7 g/cm³ density versus titanium’s 4.43 g/cm³—making aluminum objectively lighter by volume—real-world component design demands analysis of strength-to-weight ratios, fatigue resistance, and application-specific performance. A titanium part may weigh more than its aluminum counterpart but achieve equivalent structural integrity at significantly reduced cross-sections, ultimately optimizing system mass in aerospace or medical applications.

At Honyo Prototype, our senior engineering team leverages decades of CNC machining expertise to navigate these critical trade-offs. We specialize in high-precision milling and turning of both materials, utilizing advanced 5-axis CNC systems to maintain tolerances down to ±0.005mm while maximizing material efficiency. Our process ensures optimal geometry for weight-critical components without compromising durability or function.

Material Property Comparison

| Property | Aluminum 6061-T6 | Titanium Grade 5 (Ti-6Al-4V) |

|——————-|——————|——————————|

| Density (g/cm³) | 2.70 | 4.43 |

| Tensile Strength | 310 MPa | 900 MPa |

| Strength-to-Weight| Moderate | Exceptional |

For engineers finalizing material selection, Honyo provides actionable insights through our Online Instant Quote platform. Upload your CAD file to receive manufacturability feedback, material recommendations, and precise cost estimates within minutes—accelerating your transition from design validation to certified production. Optimize your next lightweight component with Honyo’s integrated engineering and CNC machining services.

Technical Capabilities

When evaluating whether titanium or aluminum is lighter, the primary consideration is material density. Aluminum is significantly lighter than titanium, with a density of approximately 2.7 g/cm³ compared to titanium’s 4.5 g/cm³. This makes aluminum the preferred choice when weight reduction is critical, such as in aerospace, automotive, and portable industrial equipment. However, titanium offers a superior strength-to-density ratio and better performance at elevated temperatures, which may justify its use despite higher weight and machining complexity.

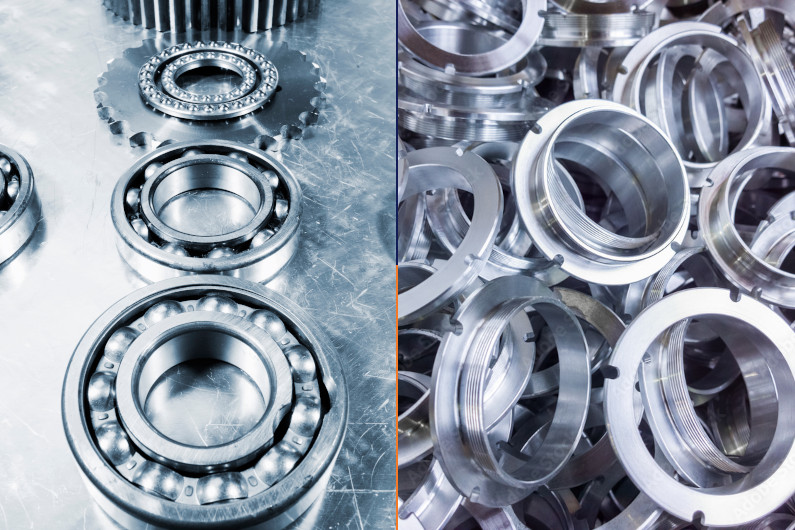

In precision manufacturing processes such as 3/4/5-axis milling and turning—especially under tight tolerance requirements (±0.005 mm to ±0.025 mm)—material selection impacts tool life, cycle time, surface finish, and overall cost. Below is a comparative technical overview of common materials used in high-precision CNC machining.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Typical Applications in Precision Machining | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|

| Aluminum (e.g., 6061, 7075) | 2.7 | 310 (6061), 570 (7075) | Excellent (Machinability ~90-100%) | Aerospace components, enclosures, heat sinks, jigs | High metal removal rates; low cutting forces; excellent for complex 5-axis contours; minimal tool wear; ideal for tight tolerance work |

| Titanium (e.g., Ti-6Al-4V) | 4.5 | 900–950 | Poor (Machinability ~20-30%) | Medical implants, aerospace structural parts, high-performance motorsports | Low thermal conductivity requires slow speeds/feeds; prone to work hardening; demands rigid setups and sharp, carbide tooling; challenging for tight tolerances due to thermal expansion |

| Steel (e.g., 4140, 17-4 PH) | 7.8–7.9 | 650–1300 | Moderate to Good | Tooling, shafts, high-strength fixtures | Higher cutting forces; more tool wear than aluminum; suitable for tight tolerances with proper setup; 5-axis applications limited by mass and rigidity |

| ABS (Acrylonitrile Butadiene Styrene) | 1.0–1.1 | 40–45 | Excellent | Prototypes, enclosures, low-stress components | Very low cutting forces; minimal heat generation; suitable for high-speed milling; requires proper fixturing due to low stiffness; tight tolerances achievable |

| Nylon (Polyamide, e.g., PA6, PA66) | 1.1–1.2 | 70–85 | Good | Insulators, wear components, gears | Prone to melting if cooling not managed; low thermal expansion; good dimensional stability; excellent for turning and light milling; tolerances depend on moisture content |

Summary for Precision Machining Applications:

Aluminum is the lightest structural metal commonly used in CNC machining and offers superior machinability, making it ideal for complex 3/4/5-axis millings and tight-tolerance turning operations. Titanium, while stronger and more temperature-resistant, is denser and far more challenging to machine, requiring specialized tooling and slower processes. For non-metallic options, ABS and nylon are even lighter than aluminum but are limited to lower-stress, non-high-temperature environments. Steel, though heavy and less favorable for weight-sensitive designs, remains essential for high-strength, wear-resistant components where mass is less critical.

From CAD to Part: The Process

Honyo Prototype applies precise material science principles within our streamlined workflow to address weight-critical design decisions such as titanium versus aluminum selection. The fundamental material property difference is non-negotiable: aluminum has a density of approximately 2.7 g/cm³ while titanium is 4.5 g/cm³, making aluminum inherently lighter by volume. Our process leverages this data to provide accurate weight projections and manufacturability insights for your specific part geometry.

Upload CAD

Upon receiving your 3D model, our system extracts geometric data including volume and surface area. Material density constants from certified industry databases are immediately referenced—not determined—since titanium and aluminum densities are fixed physical properties. This step establishes the baseline for weight calculation before any quoting begins.

AI Quote

Our AI engine calculates theoretical part weight using the CAD-derived volume and pre-validated material densities. The output clearly states:

| Material | Density (g/cm³) | Theoretical Weight |

|———-|—————–|———————|

| Aluminum | 2.70 | [Calculated Value] |

| Titanium | 4.51 | [Calculated Value] |

The quote explicitly confirms aluminum will be lighter for identical geometries while highlighting titanium’s strength-to-weight advantages where structural demands justify added mass.

DFM Analysis

Our engineering team evaluates weight implications during Design for Manufacturability review. We identify opportunities to optimize weight without compromising function:

Recommending aluminum for non-critical load paths to minimize mass

Suggesting topology-optimized structures if titanium is required for strength

Flagging unnecessary titanium use where aluminum alloys meet specifications

Calculating actual vs. theoretical weight deltas from manufacturing tolerances

Production

Machining parameters are adjusted per material: titanium requires slower feeds/speeds due to work hardening, while aluminum allows aggressive material removal. In-process inspections verify critical dimensions affecting weight. All titanium stock is certified to AMS 4928 or equivalent with traceable density documentation.

Delivery

Final parts undergo weight verification using calibrated scales. The packing slip includes as-built weight alongside theoretical values from the quote, with deviations explained (e.g., “0.8% heavier than calculated due to weld reinforcement”). Material test reports for titanium include density validation per ASTM B861.

This structured approach ensures you receive not just a part, but validated data proving why aluminum delivers lower mass for your application—unless titanium’s mechanical properties are essential. We transform material science fundamentals into actionable manufacturing intelligence for weight-sensitive projects.

Start Your Project

If you’re evaluating whether titanium or aluminum is lighter for your next project, the answer depends on material properties and application requirements. Aluminum has a lower density—approximately 2.7 g/cm³—compared to titanium’s 4.5 g/cm³, making aluminum the lighter choice by weight. However, titanium offers a superior strength-to-density ratio, which may influence design decisions where strength and durability are critical.

For prototyping or production support using either material, our engineering team at Honyo Prototype provides expert guidance in material selection, CNC machining, and rapid manufacturing. With our ISO-certified factory located in Shenzhen, we deliver high-precision metal and plastic components with fast turnaround times.

Contact Susan Leo at [email protected] for technical consultation or to request a quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.