Guide Contents

Project Insight: Is Titanium More Expensive Than Stainless Steel

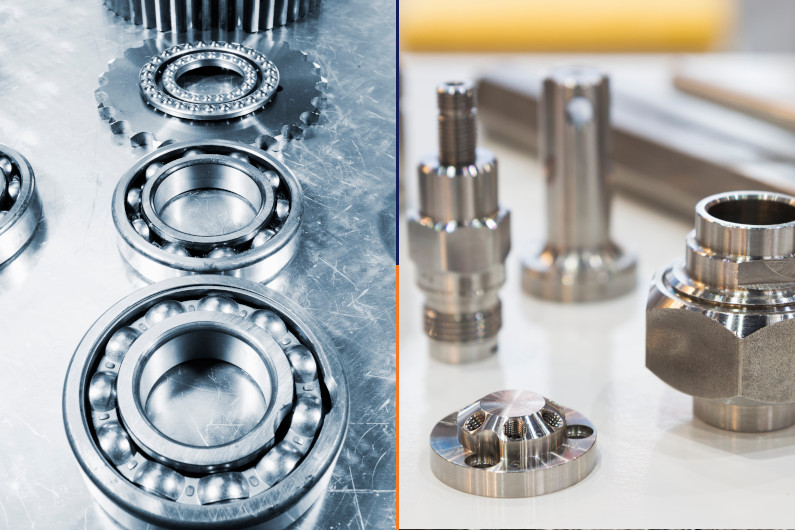

Titanium vs. Stainless Steel: Beyond the Cost Comparison

Material Cost Reality Check

Titanium costs $35–$50/kg vs. stainless steel’s $1–$1.50/kg—a 25–50x price gap.

However, titanium’s superior strength-to-weight ratio often reduces material volume needed, balancing total project costs.

Complex machining requires precision to avoid costly waste—especially for high-stress applications like aerospace or medical devices.

Why Speed & Precision Drive Total Project Value

Rapid iterations minimize development delays and rework costs—critical for hardware startups racing to market.

Exact tolerances ensure performance-critical applications meet specs, avoiding costly late-stage redesigns.

Early-stage prototyping with accurate material data prevents “discovery shock” during production scaling.

Honyo’s Digital Manufacturing Edge: Accelerate Your Project with Confidence

Online Instant Quote: Real-time pricing for titanium or stainless steel—no waiting, no guesswork.

AI-Powered Platform: Optimizes designs for manufacturability, material efficiency, and cost savings—even for complex titanium geometries.

Fast Turnaround: Prototype in 3–5 days, production in weeks—accelerate time-to-market without compromising quality.

One-Stop Solution: End-to-end support from design review to mass production, backed by our digital manufacturing ecosystem.

“At Honyo, we don’t just choose materials—we engineer smarter outcomes. Whether you’re weighing titanium’s performance or stainless steel’s affordability, our AI-driven platform ensures you get the right solution, faster.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Titanium vs. Stainless Steel: Strategic Material Selection Made Simple

Data-Driven Cost Analysis with AI-Powered Insights

Instant Total Cost Modeling: Our AI platform compares total project costs—not just raw material prices ($35–50/kg for titanium vs. $1–1.50/kg for stainless steel)—factoring in machining complexity, part geometry, and lifecycle performance.

Strength-to-Weight Optimization: Real-time simulations show how titanium’s 40% weight reduction in aerospace or medical applications can offset higher material costs, while stainless steel excels in cost-sensitive structural roles.

Transparent Breakdowns: See exactly how material choice impacts your budget with granular cost breakdowns for machining, finishing, and logistics—no guesswork required.

Precision Manufacturing for Challenging Materials

Titanium-Specialized CNC Expertise: Proprietary low-heat machining processes and tooling designed to handle titanium’s thermal sensitivity, minimizing distortion and tool wear while maintaining micron-level tolerances.

ISO 9001-Certified Quality Control: Rigorous in-process inspections for titanium components, ensuring compliance with aerospace (AMS 2631), medical (ISO 13485), and industrial standards.

Surface Finishing Precision: Advanced anodizing, passivation, and polishing techniques to maximize titanium’s corrosion resistance and aesthetic finish—without compromising structural integrity.

Scalable Production Without Compromise

Zero Minimums, Seamless Scaling: Prototype with 1 titanium part or scale to 10,000+ units with identical quality—no retooling or lead-time penalties.

Rapid Titanium Turnaround: Leverage our digital manufacturing ecosystem to cut lead times by 40% vs. traditional suppliers, even for complex geometries like lattice structures or thin-wall components.

End-to-End Traceability: Full digital tracking from raw material sourcing to final inspection, ensuring consistent quality across all volumes and reducing supply chain risks.

Online Instant Quote: Your Material Decision Engine

24/7 AI-Generated Quotes: Upload your CAD file in seconds to receive instant, itemized quotes for titanium and stainless steel—including material costs, machining fees, and lead time estimates.

Smart Recommendations: Our platform suggests the optimal material based on your application’s stress, weight, and environmental requirements—no engineering degree needed.

Design for Manufacturability (DFM) Feedback: Get real-time suggestions to reduce titanium machining costs (e.g., optimizing wall thickness or avoiding sharp corners) before production begins.

Why Honyo?

“Titanium isn’t just expensive—it’s a strategic asset. Our digital ecosystem turns its complexity into your advantage, delivering precision-engineered parts that balance performance, cost, and speed—no trade-offs.”

— Susan Leo, Founder of Honyo Prototype

Materials & Surface Finishes

Material Options & Finishes

Comprehensive Material Library

Metals: Titanium (Grades 2, 5), Stainless Steel (304, 316), Aluminum (6061, 7075), Inconel 718, Copper, Brass

Plastics: ABS, PLA, Nylon 6/6, PEEK, PC, PETG, TPU

Specialty Alloys: Invar, Monel, Hastelloy (custom requests supported)

Surface Finish Options

Metal Finishes: Anodizing (Type II/III), Powder Coating, Electropolishing, Bead Blasting, Brushed Finish, Polishing (Mirror, Satin)

Plastic Finishes: Painted, Textured, Smooth, As-Machined, UV Coating

Specialty Treatments: Passivation (stainless steel), Black Oxide, Chrome Plating, Diamond-Like Carbon (DLC)

Titanium vs Stainless Steel: Strategic Selection Guide

Cost Analysis

Titanium raw material costs 25–35× higher than stainless steel per kg ($35–50/kg vs. $1–1.50/kg), but its exceptional strength-to-weight ratio typically reduces part weight by 40–60% for equivalent performance. Combined with Honyo’s precision machining expertise, this often delivers competitive total cost of ownership (TCO) for high-stakes applications.

Performance Trade-offs

Titanium:

Biocompatible, corrosion-resistant in marine/chemical environments

Ideal for weight-sensitive designs (e.g., aerospace components, medical implants)

40% lighter than steel with 2× higher strength-to-weight ratio

Stainless Steel:

Superior hardness for wear resistance and structural durability

Cost-effective for industrial, automotive, and consumer goods (e.g., brackets, kitchen equipment)

Maintains performance in most standard environments without premium pricing

Honyo’s Smart Selection Tools

✅ Online Instant Quote: Compare real-time pricing for titanium vs. stainless steel with AI-driven cost breakdowns—get quotes in <10 minutes.

✅ AI-Powered Design Optimization: Our platform analyzes your geometry to recommend optimal materials, tolerances, and processes—maximizing performance while minimizing costs.

✅ Fast Turnaround Guarantee: 5–7 day lead times for prototypes, with expedited options for urgent projects—no compromise on quality or innovation.

💡 Pro Tip: For weight-critical applications (e.g., drones, robotics), titanium’s long-term TCO often beats stainless steel despite higher raw material costs. Use Honyo’s AI tools to simulate real-world scenarios and validate your choice before production.

Powered by Honyo’s Digital Manufacturing Ecosystem—where innovation meets precision, from prototype to scalable production.

From Quote to Part: Our Process

How It Works: From CAD to Part in Record Time

At Honyo Prototype, our digital manufacturing ecosystem delivers a seamless one-stop solution from prototype to production. Leveraging AI-driven automation and real-time data, we transform your CAD files into high-performance parts with unprecedented speed and transparency—no manual interventions, no surprises.

Step 1: Upload CAD File in Seconds

Drag-and-drop interface supports all standard formats (STEP, IGES, STL, etc.)

Instant file validation checks for errors before processing

No manual data entry—just upload and go

Step 2: Real-Time AI Quote Engine

Instant pricing for any material (titanium, stainless steel, aluminum, etc.) with transparent breakdowns

AI calculates total cost of ownership—not just per-kg price—factoring in:

Material efficiency (e.g., “Titanium: $35–50/kg, but requires 50% less material for equivalent strength—resulting in comparable total cost for critical aerospace applications”)

Machining complexity, finish requirements, and volume discounts

Zero hidden fees—real-time adjustments for design changes

Step 3: Automated DFM Optimization

AI-driven feedback on manufacturability in real time

Actionable suggestions to reduce costs and improve quality:

“Adjusting wall thickness by 0.5mm could reduce machining time by 20% for titanium parts”

Material-specific optimizations (e.g., “Avoid sharp internal corners in stainless steel to prevent tool wear”)

Proactive error prevention—no costly rework

Step 4: End-to-End Production Tracking

Seamless handoff to our Shenzhen-based digital factory

Live progress updates via customer portal—every step visible from material sourcing to final QC

Guaranteed on-time delivery with ISO-certified quality assurance

“With Honyo Prototype, you get a single platform where innovation meets execution—turning complex engineering challenges into streamlined manufacturing success.”

Ready to accelerate your project? [Upload your CAD file now] and get an instant quote in seconds.

Start Your Project with Honyo

Start Your Project with Honyo

Smart Material Selection, Tailored to Your Needs

✨ Online Instant Quote: Get real-time cost comparisons for titanium vs stainless steel—including machining, finishing, and lifecycle expenses—within seconds.

📊 AI-Powered Optimization: Our platform analyzes your design specs to recommend the optimal material, balancing strength-to-weight ratio, corrosion resistance, and total project ROI.

AI-Powered Digital Manufacturing Ecosystem

⚡ Seamless Titanium Machining: Leverage our specialized expertise for titanium’s complex processing—no extra delays, no hidden costs, even for high-precision aerospace or medical components.

🌐 End-to-End Digital Workflow: From CAD upload to final part, our integrated system ensures precision and speed for both materials—automating tolerances, toolpath planning, and quality checks.

Prototype-to-Production, Accelerated

⏱️ Fastest Turnaround in Industry: Deliver parts in 5-7 days for prototypes, 2-3 weeks for production runs—regardless of material complexity.

📍 Local Expertise, Global Reach: Visit our Shenzhen/Dongguan facilities for hands-on collaboration with Susan Leo’s team—no offshore surprises, no communication gaps.

Ready to optimize your next project? Contact us today:

📧 [email protected]

📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities for a firsthand look at our digital manufacturing ecosystem.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.