Guide Contents

Project Insight: Is Titanium Better Than Aluminum

Titanium vs Aluminum: Choosing the Right Material for Your Project

It’s Not About “Better”—It’s About Right Fit

In product development, material selection isn’t about superiority—it’s about matching performance, cost, and timeline to your specific use case. Here’s how Honyo’s digital ecosystem helps you navigate the trade-offs:

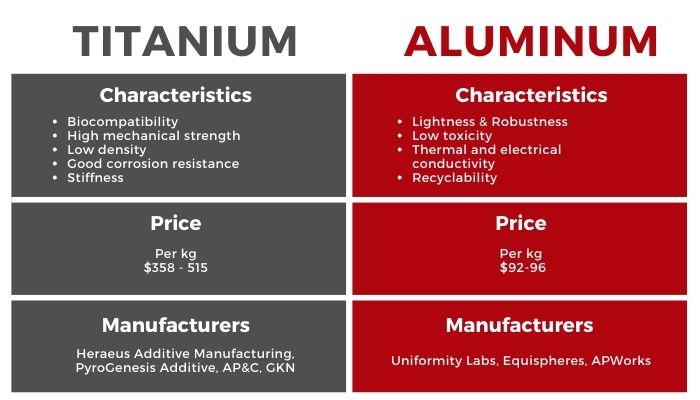

Material Cost & Budget Optimization: Aluminum’s affordability (~$2/kg) accelerates cost-effective prototyping, while titanium’s premium (~$20/kg) delivers mission-critical strength for aerospace or medical applications. Honyo’s instant quoting tool enables real-time cost comparisons to align material choice with project budgets.

Machinability & Production Speed: Aluminum’s softer structure allows 30-50% faster CNC machining than titanium, slashing prototyping cycles. Titanium’s high strength requires precision tooling, but Honyo’s AI-optimized toolpaths minimize cycle times without compromising tolerances.

Strength-to-Weight Balance: Titanium offers 2x the strength of aluminum at 60% higher density—ideal for weight-sensitive designs. Aluminum excels in general-purpose applications where cost and ease of fabrication dominate. Our digital platform analyzes your design requirements to recommend the optimal material for performance and efficiency.

Speed & Precision: The Honyo Advantage

When innovation moves at the speed of iteration, your manufacturing partner must accelerate decision-making and execution. Honyo’s digital manufacturing ecosystem delivers:

Online Instant Quote: Get real-time pricing for aluminum or titanium parts within seconds—no manual quotes, no delays. Our platform instantly calculates costs based on geometry, material, and volume.

AI-Powered Material Selection: Our smart algorithm analyzes your design specs to recommend the optimal material (aluminum or titanium) based on performance needs, budget, and timeline constraints.

Fast Turnaround: Leverage our integrated digital manufacturing ecosystem to cut lead times by 30%—whether machining aluminum for rapid iterations or titanium for high-performance end-use parts.

Why Honyo is Your Strategic Manufacturing Partner

One-Stop Solution: From prototype to production, we handle material selection, machining, and finishing seamlessly—no juggling multiple vendors. Just a single point of contact for end-to-end manufacturing.

Scalable Expertise: Switching from aluminum prototypes to titanium production? Our system adapts instantly, ensuring consistency and quality across all stages.

Founder’s Vision: Susan Leo, Founder of Honyo Prototype, emphasizes: “At Honyo, we don’t just manufacture—we engineer solutions. Our digital ecosystem empowers innovators to choose the right material, at the right speed, for the right cost.”

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Titanium & Aluminum Projects

AI-Powered Material Selection & Instant Cost Transparency

Real-time online quotes with transparent pricing for titanium vs. aluminum (including 7075, 6061, and aerospace-grade alloys), based on your CAD files and volume requirements.

AI-driven analysis optimizes material choice by balancing strength-to-weight ratio, corrosion resistance, thermal properties, and total project cost—no guesswork, just data-driven decisions.

Zero hidden fees: View exact costs for machining, finishing, and shipping before committing—perfect for budget-conscious startups and procurement teams.

Scalable Production from Prototype to Volume

Seamlessly scale from 1 prototype to 10,000+ units using our fully integrated digital manufacturing ecosystem—no retooling or delays during volume transitions.

ISO 9001-certified quality control ensures consistency across all batches, whether machining titanium for medical implants or aluminum for consumer electronics.

Fast turnaround: 3-day prototype delivery, 2–3 weeks for production runs—accelerating your time-to-market without compromising precision.

Precision Machining for Demanding Applications

Titanium-specific expertise: Advanced CNC tooling and cooling systems to manage heat sensitivity, ensuring dimensional accuracy for aerospace and defense components.

Aluminum optimization: Process enhancements reduce cycle times by 25% for alloys like 7075, while maintaining tight tolerances (±0.001″) for high-stress applications.

Real-time production monitoring via our digital platform—automated quality checks at every stage guarantee defect-free parts, every time.

End-to-End Support with Expedited Options

Dedicated engineering team provides material-specific advice: Titanium for extreme environments (e.g., marine or high-temp aerospace), aluminum for lightweight consumer goods.

One-stop solution: From DFM (Design for Manufacturability) optimization to post-processing (anodizing, powder coating, passivation)—all under one roof.

48-hour rush prototyping for critical deadlines—delivering speed without sacrificing quality, so you stay ahead of market demands.

💡 Why choose Honyo?

We don’t just make parts—we solve your material dilemma with AI-driven insights, scalable precision, and unmatched speed. Whether you need titanium’s strength for mission-critical applications or aluminum’s cost-efficiency for high-volume runs, our digital ecosystem turns complexity into clarity. Get your instant quote today—prototype to production, simplified.

Materials & Surface Finishes

Material Options & Finishes

Comprehensive Material Portfolio

Metals:

Aluminum alloys (6061, 7075, 2024)

Titanium alloys (Grade 2, Grade 5 / Ti-6Al-4V)

Stainless steel (304, 316)

Steel (1018, 4140)

Brass

Plastics:

ABS, Nylon, POM (Acetal), PC (Polycarbonate), PEEK, PETG

Surface Finish Capabilities

Anodizing: Standard for aluminum (color options: clear, black, blue); titanium anodizing for custom hues (e.g., aerospace-grade aesthetics)

Powder Coating: Durable, corrosion-resistant finish for high-wear applications

Polishing: Mirror or matte finishes for optical clarity or tactile appeal

Bead Blasting: Uniform texture for improved adhesion and visual consistency

Passivation: For stainless steel to enhance corrosion resistance

Electroplating: Nickel, zinc, or chrome plating for specialized conductivity or wear resistance

Titanium vs Aluminum: Strategic Material Selection

When choosing between titanium and aluminum, prioritize these engineering-driven factors:

Cost Efficiency

Aluminum costs ~$2/kg vs. titanium’s ~$20/kg—a 10x difference. For high-volume production or budget-sensitive projects (e.g., consumer electronics housings), aluminum delivers unmatched ROI without compromising core functionality.

Strength-to-Weight Ratio

Titanium’s strength-to-weight ratio is ~60% higher than aluminum. Critical for aerospace components, medical implants, or high-stress structural parts where weight savings justify the premium. Aluminum suffices for general-purpose brackets or non-critical load-bearing applications.

Corrosion Resistance

Both resist corrosion, but titanium excels in marine, chemical, or high-temperature environments without additional treatment. Aluminum requires anodizing for comparable performance in harsh conditions.

Machinability & Lead Time

Aluminum machines 2–3x faster than titanium due to lower tool wear and higher cutting speeds. Titanium demands specialized coolant, slower feeds, and precision tooling—increasing costs. Honyo’s AI-optimized CNC ecosystem minimizes these gaps, ensuring titanium parts ship as fast as aluminum—often within 3–5 days.

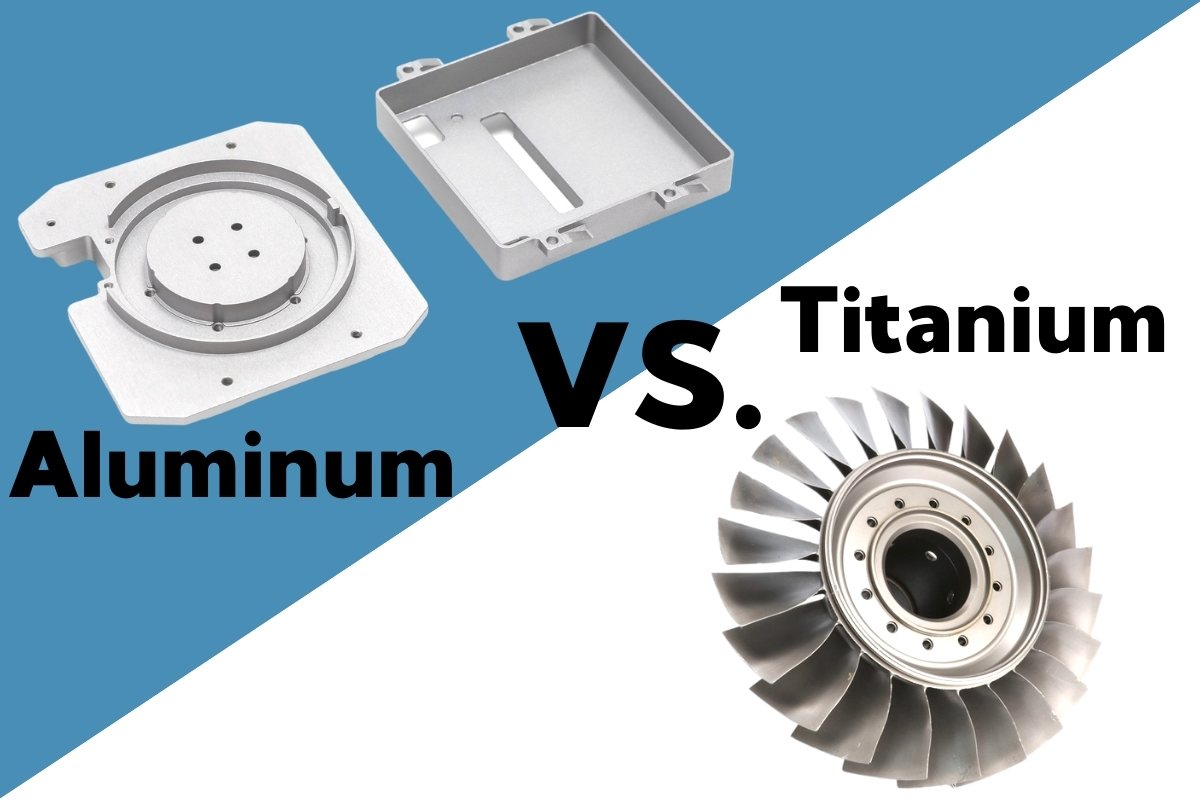

Application-Specific Use Cases

✅ Choose Aluminum:

Prototyping, automotive brackets, drone frames, or consumer tech enclosures

Projects requiring rapid iteration or cost-sensitive scaling

✅ Choose Titanium:

Medical implants, rocket components, or high-performance racing parts

Environments demanding extreme durability (e.g., saltwater exposure, 500°C+ temperatures)

Why Honyo Prototype?

Instant Online Quotes: Compare titanium vs aluminum costs, lead times, and tolerances in real-time via our AI-powered platform—no manual quotes, no delays.

Smart Material Recommendations: Upload your CAD file, and our system auto-suggests the optimal material balancing performance, cost, and manufacturability.

Fast Turnaround: From prototype to production, we deliver precision parts in 3–10 days—even for complex titanium geometries—thanks to our integrated digital manufacturing ecosystem.

“At Honyo, we don’t just choose materials—we engineer solutions. Whether you need aluminum’s affordability or titanium’s performance, our platform turns uncertainty into actionable insights.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, our digital manufacturing ecosystem transforms your design into reality—faster, smarter, and transparently. Here’s how:

Upload CAD File – Instant Design Validation

Submit your 3D model (STEP, STL, IGES) in seconds—our AI instantly checks for manufacturability, material suitability, and potential design flaws.

Get immediate feedback on whether titanium’s strength-to-weight ratio or aluminum’s cost-efficiency best suits your application—no manual review delays.

AI-Powered Instant Quote – Transparent Pricing in Real-Time

Receive a dynamic quote within 60 seconds, with side-by-side comparisons for aluminum ($2/kg) vs. titanium ($20/kg) and other materials.

See exact pricing breakdowns: material costs, machining time, and total part price—no hidden fees, no guesswork.

DFM Analysis – Expert Insights, Automated

Our platform analyzes titanium-specific challenges (e.g., thermal management during CNC) versus aluminum’s machinability advantages.

Receive actionable optimization tips to reduce costs while maintaining performance—whether you prioritize weight savings or budget constraints.

Production & Delivery – Speed Without Compromise

Leverage our integrated digital ecosystem for seamless production: from CNC machining to additive manufacturing, optimized for your material choice.

Track progress in real-time—prototypes delivered in 3–5 days, production runs scaled effortlessly with zero bottlenecks.

Honyo Prototype: Your end-to-end partner for precision manufacturing—from concept to delivery, faster than ever.

Start Your Project with Honyo

Start Your Project with Honyo – Precision Material Selection, Zero Compromise

Why Honyo is Your Smart Partner for Material Decisions

Online Instant Quote: Get real-time pricing for titanium or aluminum parts in seconds—no waiting, just accurate, tailored cost estimates.

AI-Powered Platform: Our smart system analyzes your design specs to recommend the optimal material based on performance, cost, and manufacturability—eliminating guesswork.

Fast Turnaround: From quote to production in 48 hours. Our digital manufacturing ecosystem ensures seamless scaling from prototype to volume with zero quality gaps.

Ready to Build Smarter?

Susan Leo and our expert team are ready to help. Contact us today:

Email: [email protected]

Phone: +86 139 2843 8620

Visit: Shenzhen/Dongguan facilities to experience our digital manufacturing ecosystem firsthand

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.