Contents

Manufacturing Insight: Is Steel Stronger Than Titanium

Material Strength Reality Check Steel Versus Titanium in Precision Engineering

The question Is steel stronger than titanium frequently arises in component design discussions yet lacks a universal answer. Material strength depends critically on specific alloy grades heat treatment and the mechanical property in question yield strength ultimate tensile strength or fatigue resistance. For instance while certain high-strength steel alloys like 4340 can achieve ultimate tensile strengths exceeding 1800 MPa common aerospace titanium Grade 5 (Ti-6Al-4V) typically ranges between 900–1000 MPa. However titanium offers superior strength-to-weight ratio and corrosion resistance making it indispensable for weight-sensitive applications despite lower absolute strength in some comparisons.

| Material Example | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Key Application Advantage |

|---|---|---|---|

| AISI 4140 Steel (Q&T) | 655 | 1020 | High wear resistance cost efficiency |

| Ti-6Al-4V (Grade 5) | 880 | 950 | 45% lighter than steel exceptional corrosion fatigue performance |

At Honyo Prototype we engineer solutions around these nuanced material behaviors leveraging our advanced CNC machining capabilities to transform both steel and titanium into high-precision components. Our 5-axis milling turning and Swiss-type machining centers paired with rigorous in-process metrology ensure dimensional accuracy within ±0.005mm while optimizing for each material’s unique machining characteristics such as titanium’s low thermal conductivity or steel’s chip control requirements. This technical mastery prevents costly material waste and accelerates time-to-test for demanding sectors including aerospace medical devices and robotics.

When your design requires confident material selection backed by manufacturing expertise utilize Honyo’s Online Instant Quote platform. Upload your CAD file specify material requirements and receive a detailed manufacturability analysis with competitive pricing in under two hours enabling faster iteration from prototype to production.

Technical Capabilities

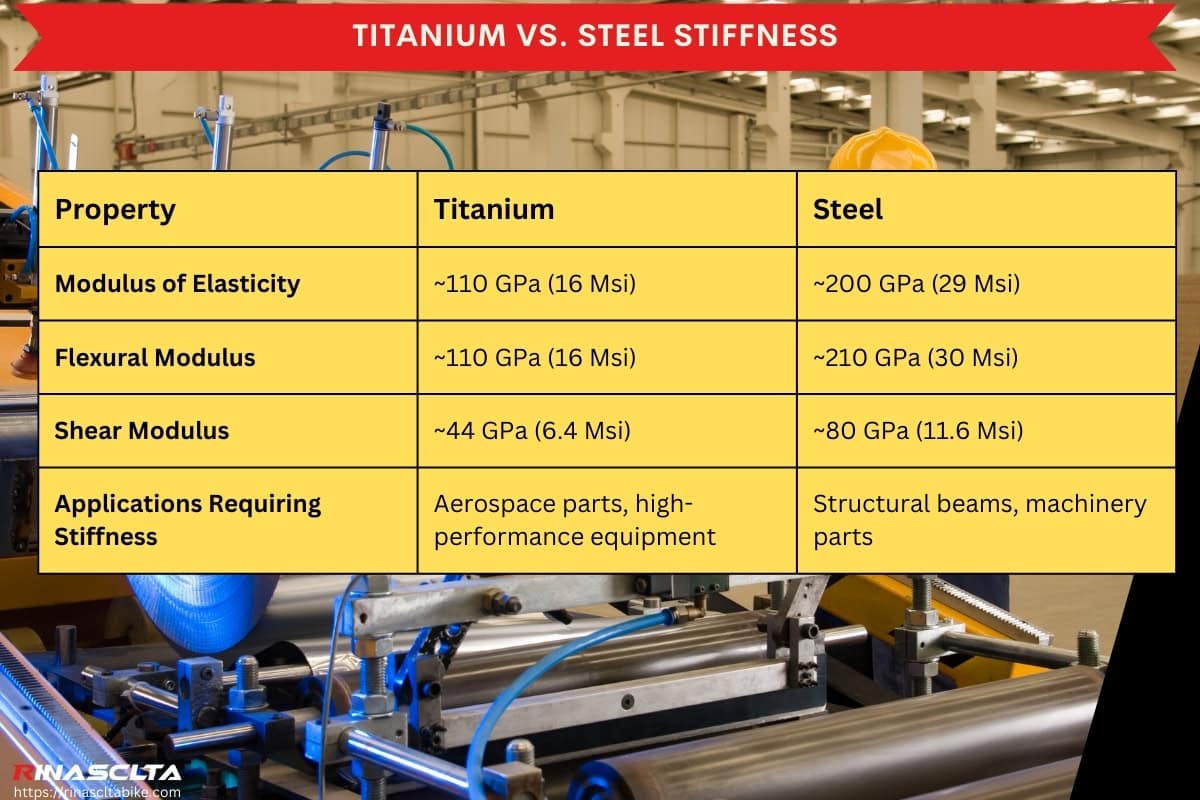

The question “is steel stronger than titanium” requires clarification in the context of material properties and machining performance, particularly for precision manufacturing processes such as 3/4/5-axis milling and turning with tight tolerance requirements. While strength is a key factor, other properties like machinability, stiffness, thermal stability, and density significantly influence material selection in high-precision CNC applications.

Strength must be evaluated in terms of yield strength and tensile strength. In general, certain grades of steel (e.g., 4140, 4340) exhibit higher tensile and yield strength than commercially pure titanium (Grade 2), but high-strength titanium alloys (e.g., Ti-6Al-4V) can match or exceed many steels while offering a superior strength-to-density ratio.

For CNC operations involving tight tolerances (±0.0005″ or better), the material’s dimensional stability, thermal expansion, and response to cutting forces are critical. Below is a comparison of key materials used in precision prototyping and production, particularly at Honyo Prototype, with relevance to multi-axis milling, turning, and tolerance control.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Modulus of Elasticity (GPa) | Density (g/cm³) | Machinability Rating | Thermal Expansion (µm/m·°C) | Typical Use in 3/4/5-Axis Machining & Tight Tolerance |

|---|---|---|---|---|---|---|---|

| Steel (4140) | 850–1000 | 655–850 | 205 | 7.85 | 65% | 11.3 | High-strength components, tooling, tight tolerance shafts; requires rigid setups and carbide tooling due to work hardening |

| Titanium (Ti-6Al-4V) | 900–950 | 830 | 114 | 4.43 | 30% | 8.6 | Aerospace, medical implants; challenging to machine due to low thermal conductivity and high chemical reactivity; needs slow speeds, high feed, and sharp tools |

| Aluminum (6061-T6) | 310 | 275 | 69 | 2.70 | 90% | 23.6 | Ideal for high-speed 5-axis milling; excellent for tight tolerance parts with complex geometry; low heat retention |

| ABS (Plastic) | 40–50 | 40 | 2.0–3.0 | 1.04 | 100% | 70–100 | Rapid prototyping, jigs, fixtures; easy to machine but prone to melting; requires sharp tools and light cuts |

| Nylon (PA6) | 70–80 | 50–60 | 2.5–3.0 | 1.13 | 85% | 80–120 | Wear-resistant parts, gears; flexible and tough; needs climb milling to avoid deformation |

Key Observations for Precision Machining:

Steel offers higher absolute strength and stiffness compared to titanium, making it suitable for applications where deflection under load must be minimized during high-precision turning or milling. However, titanium’s lower density gives it a superior strength-to-weight ratio, which is critical in aerospace and performance applications.

In 3/4/5-axis milling and tight tolerance turning, aluminum is often preferred for prototypes and housings due to its excellent machinability, dimensional stability, and ability to hold tight tolerances with minimal distortion. Steels and titanium alloys require more advanced toolpaths, tooling, and thermal management to achieve sub-0.001” tolerances consistently.

ABS and nylon, while not strong in the mechanical sense, are valuable for non-structural precision components where weight, insulation, or cost are priorities. Their low stiffness and high thermal expansion require specialized CNC strategies to maintain accuracy.

Material selection at Honyo Prototype is driven by functional requirements, environmental exposure, and manufacturability—balancing strength, precision, and production efficiency.

From CAD to Part: The Process

Honyo Prototype executes rapid manufacturing through a streamlined digital workflow optimized for precision and speed. Our process addresses client design intent including material specifications but does not provide generic material strength comparisons. When a client uploads a CAD file specifying steel or titanium components, the workflow proceeds as follows:

CAD Upload and Validation

Clients submit native or neutral CAD formats through our secure portal. Our system performs automated geometry validation including unit consistency checks and manifold verification. If the CAD file references material properties like “steel” or “titanium,” this information is captured for downstream processing but not interpreted as a standalone technical inquiry. Material selection must align with the client’s functional requirements documented in the RFQ.

AI-Powered Quoting Engine

Our machine learning algorithm analyzes the validated CAD geometry to generate instant cost and lead time estimates. The system factors in material type (e.g., 304 stainless steel vs. Ti-6Al-4V), volume, tolerances, and secondary operations. Crucially, the AI does not evaluate comparative material strengths; it processes the client-specified material as a production parameter. Quote accuracy exceeds 95% for standard geometries based on our 12-million-part production dataset.

Engineering DFM Analysis

Licensed mechanical engineers conduct formal Design for Manufacturability review within 4 business hours. For material-related considerations, we verify:

Whether the selected material meets stated mechanical requirements (e.g., yield strength ≥ 800 MPa)

Feasibility of achieving specified tolerances with the chosen material

Cost implications of material alternatives if requested by client

Example DFM feedback: “Your titanium bracket design requires 0.05mm tolerances. Switching to 17-4PH stainless steel would reduce cost by 37% while maintaining yield strength above 900 MPa for your load case.” We do not initiate unsolicited material comparisons.

Production Execution

Approved designs move to our integrated manufacturing cells. Material-specific process parameters are auto-loaded:

| Material | Primary Process | Typical Tolerance | Max Build Size |

|———-|—————-|——————-|—————|

| Steel (e.g., 316L) | CNC Milling/Laser Powder Bed | ±0.025mm | 1000 x 500 x 400mm |

| Titanium (e.g., Ti64) | Electron Beam Melting/CNC | ±0.05mm | 350 x 350 x 350mm |

All materials undergo certified testing per ISO 17638 with full traceability.

Delivery and Documentation

Completed parts ship with material certificates, CMM reports, and process validation data. For critical applications, we provide mechanical test results matching the client’s specified requirements – not generic material property tables. Lead time averages 7-12 days from CAD approval to shipment for standard prototypes.

Honyo’s workflow transforms client-specified designs into physical parts with material selection treated as a defined input parameter. We optimize manufacturability within the client’s material constraints rather than providing theoretical material comparisons. Clients requiring material selection guidance should include functional requirements in their RFQ for targeted DFM recommendations.

Start Your Project

If you’re evaluating material options for your next project and wondering, “Is steel stronger than titanium?”—the answer depends on the specific application, grade, and mechanical properties required. While certain steels exhibit higher tensile strength than titanium, titanium offers a superior strength-to-density ratio, making it ideal for weight-critical applications in aerospace, medical, and performance automotive industries.

For precise material selection and engineering support, contact Susan Leo at [email protected]. With our manufacturing facility based in Shenzhen, Honyo Prototype delivers high-precision metal fabrication, rapid prototyping, and production-grade solutions tailored to your design and performance requirements.

Let us help you choose the right material for strength, durability, and cost-efficiency.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.