Contents

Manufacturing Insight: Is Steel Magnetic Material

Understanding Steel Magnetism in Precision Manufacturing

Steel’s magnetic properties are a critical consideration in engineering design and manufacturing, varying significantly based on alloy composition and microstructure. While ferritic and martensitic stainless steels exhibit magnetic behavior due to their iron-rich crystalline structure, austenitic grades like 304 or 316 remain non-magnetic after annealing—a distinction that directly impacts applications in electronics, medical devices, and aerospace where magnetic interference must be minimized. At Honyo Prototype, we leverage this metallurgical expertise to ensure your CNC-machined components meet exact functional requirements, whether you require magnetic retention or non-magnetic stability.

Our advanced CNC machining services specialize in processing diverse steel alloys with micron-level precision, from low-carbon steels to hardened tool grades. We address material-specific challenges such as work hardening, thermal expansion, and magnetic permeability through optimized toolpaths, specialized cutting parameters, and rigorous in-process inspection. This technical mastery ensures your prototypes and low-volume production parts perform flawlessly in tolerance-critical applications.

For immediate clarity on feasibility and cost, utilize Honyo Prototype’s Online Instant Quote platform. Input your steel grade, part geometry, and tolerances to receive a detailed machining assessment and competitive pricing within minutes—accelerating your path from design validation to functional hardware.

| Material Property | Relevance to CNC Machining at Honyo Prototype |

|---|---|

| Magnetic Permeability | Guides fixturing strategy to prevent magnetic interference in sensitive assemblies |

| Alloy Composition | Determines coolant selection, spindle speed, and tool coating requirements |

| Hardness & Work Hardening | Informs step-down depth and feed rate optimization for surface integrity |

Technical Capabilities

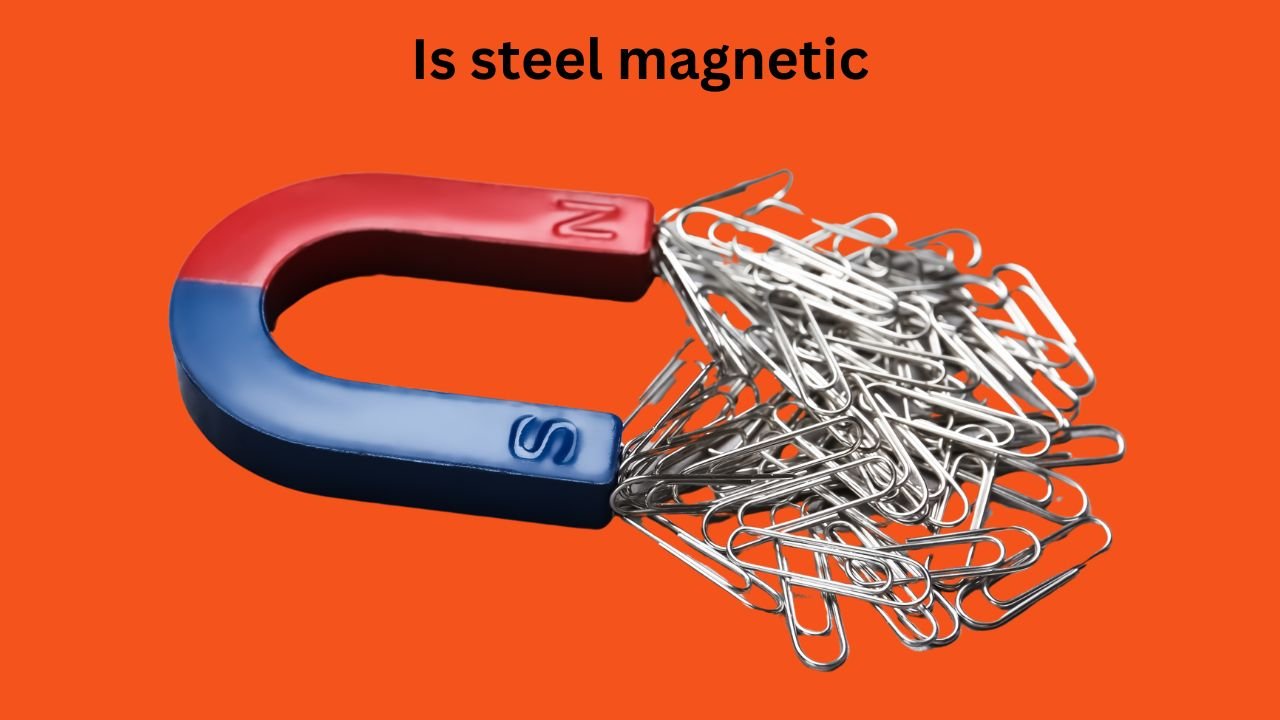

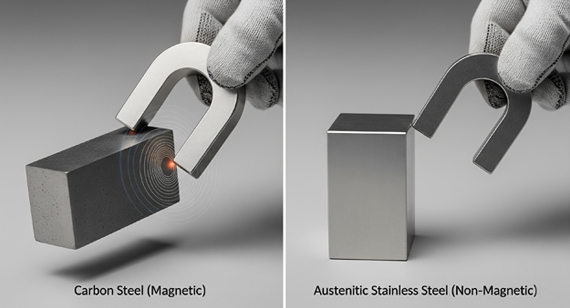

Steel is generally a magnetic material due to its iron content, particularly in carbon steel and many alloy steels. However, not all steel grades are magnetic—stainless steels such as austenitic grades (e.g., 304, 316) are typically non-magnetic or only weakly magnetic after cold working. This magnetic property does not directly affect machining performance but can influence fixturing methods (e.g., magnetic chucks) in milling and grinding operations.

The following table outlines the technical considerations for 3/4/5-axis milling and turning operations with a focus on tight tolerance capability across common materials: Aluminum, Steel, ABS, and Nylon.

| Material | Magnetic? | Machinability (Mill/Turn) | Typical Tolerance (±) | Surface Finish (Ra) | Notes for High-Precision Machining |

|---|---|---|---|---|---|

| Aluminum (e.g., 6061, 7075) | No | Excellent | 0.005 mm (0.0002″) | 0.8 – 1.6 µm | High material removal rates; ideal for complex 5-axis geometries; minimal tool wear; excellent for tight tolerance work. Requires sharp tools to avoid burring. |

| Steel (e.g., 1018, 4140) | Yes (Ferromagnetic) | Good to Moderate | 0.010 mm (0.0004″) | 1.6 – 3.2 µm | Higher cutting forces and heat generation; requires rigid setups; suitable for tight tolerance turning and milling; magnetic properties allow use of magnetic fixturing. |

| Stainless Steel (e.g., 304, 17-4 PH) | Varies (Ferritic: Yes, Austenitic: No) | Moderate (work-hardens) | 0.010 mm (0.0004″) | 1.6 – 3.2 µm | 17-4 PH is precipitation-hardened and magnetic; 304 is generally non-magnetic; requires specialized tooling and cooling for tight tolerance; prone to chatter. |

| ABS (Acrylonitrile Butadiene Styrene) | No | Very Good | 0.050 mm (0.002″) | 3.2 – 6.3 µm | Low thermal resistance; prone to melting if not cooled properly; excellent dimensional stability; suitable for prototypes; tight tolerance limited by creep and thermal expansion. |

| Nylon (Polyamide) | No | Good | 0.050 mm (0.002″) | 3.2 – 6.3 µm | Hygroscopic—absorbs moisture affecting dimensions; requires pre-drying; low friction but can deform under clamping; not ideal for ultra-tight tolerance over time. |

Application Notes:

In 3/4/5-axis milling, aluminum and steel are most commonly used for high-precision, tight-tolerance components such as aerospace and medical parts.

Steel’s magnetic nature allows for efficient workholding using magnetic vises or chucks in secondary operations, though this is less relevant in turning.

For tight tolerance turning, steel and aluminum demonstrate superior dimensional control compared to thermoplastics like ABS and Nylon.

ABS and Nylon are typically used in prototyping or non-structural applications where electrical insulation or weight reduction is critical, but they are not suitable for long-term tight tolerance due to environmental sensitivity.

At Honyo Prototype, we leverage advanced CNC platforms with thermal compensation and in-process probing to maintain tight tolerances across all compatible materials.

From CAD to Part: The Process

Honyo Prototype’s process for addressing material properties such as steel magnetism is integrated into our standard workflow but operates under a critical technical principle: magnetism is an inherent material property, not a process step we perform. Our role is to validate specifications against material science fundamentals and manufacturing realities. Below is the precise integration of magnetism verification within your stated workflow stages, reflecting our engineering rigor.

Upload CAD

During CAD file submission, clients specify material requirements (e.g., “304 Stainless Steel”). If magnetism is critical to the application (e.g., MRI components requiring non-magnetic properties), explicit notes must be included. We do not assume magnetism requirements; they must be declared in the CAD metadata or RFQ comments. Ambiguous requests like “steel” trigger automatic clarification requests before proceeding.

AI Quote

Our AI quotation engine cross-references the requested material against ASTM/ISO standards and inherent properties. For instance:

If “304 Stainless Steel” is specified, the AI flags that annealed 304 is typically non-magnetic but cold-worked sections may exhibit slight magnetism due to martensitic transformation.

If “430 Stainless Steel” is requested, the AI explicitly states it is ferritic (magnetic) in all conditions.

The quote output includes a material properties addendum detailing magnetic behavior, thermal treatment effects, and alternatives if the requested steel cannot meet non-magnetic requirements. No quotation is finalized until magnetism specifications are resolved.

DFM (Design for Manufacturability)

Our engineering team conducts a formal material validation during DFM review:

Confirms whether the selected steel grade aligns with the functional need for magnetic/non-magnetic properties.

Identifies manufacturing processes (e.g., welding, bending) that could alter magnetic response. For example, laser cutting 316L may induce localized magnetism at edges.

Recommends material substitutions if necessary (e.g., switching from 410 stainless to 316L for true non-magnetic performance).

This phase includes a signed material certification checklist where magnetic properties are explicitly verified against client requirements.

Production

Magnetism is not tested during production as it is a bulk material property defined by composition and structure. Instead:

We source steel with certified mill test reports (MTRs) confirming ASTM/EN grades.

For critical non-magnetic applications, we use only solution-annealed stainless grades (e.g., 316L per ASTM A240) and avoid cold-forming processes.

Optional third-party material verification (e.g., Gauss meter testing per ASTM A342) can be requested at client expense but is not standard practice since MTRs are definitive.

Delivery

All shipments include:

Material certification with chemical composition and mechanical properties.

Explicit statement of magnetic behavior (e.g., “Austenitic structure confirmed; non-magnetic in annealed condition per ASTM A262”).

If magnetism was a critical requirement, a signed statement from our quality team confirming compliance with the specified standard (e.g., “Meets EN 10088-1 for non-magnetic stainless steel”).

Critical Technical Note

Confusion often arises between stainless steel grades. The table below clarifies common steels and magnetic behavior:

| Steel Grade | Type | Magnetic? | Key Conditionality |

|---|---|---|---|

| 304/304L | Austenitic | Typically No | May become slightly magnetic after cold working |

| 316/316L | Austenitic | Typically No | More stable than 304; less prone to magnetic shift |

| 430 | Ferritic | Yes | Always magnetic |

| 410 | Martensitic | Yes | Always magnetic |

| 17-4 PH | Precipitation | Variable | Magnetic in H900/H1025 conditions |

Honyo does not “process” steel to alter its magnetic properties; we engineer solutions by selecting appropriate base materials and controlling manufacturing variables. Clients must define magnetic requirements upfront to avoid delays. For applications demanding absolute non-magnetic performance (e.g., medical sensors), we recommend nickel alloys like Inconel 718 and will validate this during DFM.

Start Your Project

Yes, steel is generally considered a magnetic material, particularly if it contains a high proportion of iron. Most common grades of carbon steel and low-alloy steel exhibit ferromagnetic properties, making them suitable for applications requiring magnetic response. However, certain stainless steels—such as austenitic grades (e.g., 304 and 316)—are non-magnetic due to their crystal structure.

For further technical details or project-specific material recommendations, contact Susan Leo at [email protected]. Honyo Prototype operates a precision manufacturing facility in Shenzhen, offering rapid prototyping and low-volume production services with expert material selection support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.