Contents

Manufacturing Insight: Is Steel Magnetic

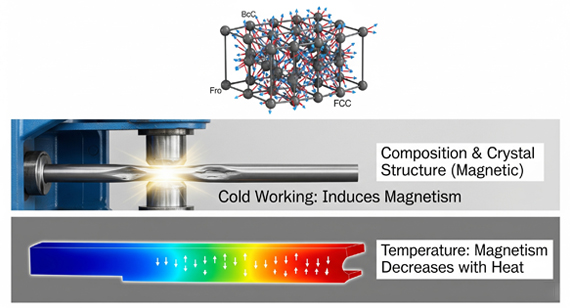

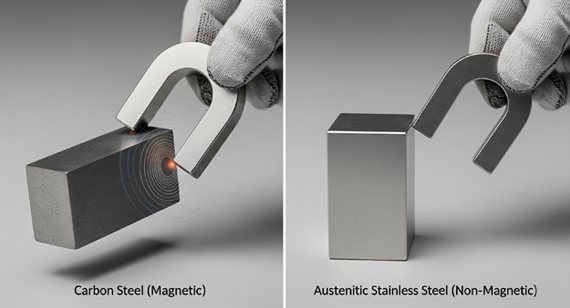

Understanding whether steel exhibits magnetic properties is a critical materials science consideration that directly impacts precision manufacturing outcomes. While carbon steels are typically ferromagnetic due to their high iron content, many stainless steel grades—particularly austenitic variants like 304 and 316—become non-magnetic after proper annealing, though cold working can induce partial magnetism. This variability necessitates expert material selection and process control to ensure components meet functional requirements in applications ranging from medical devices to aerospace assemblies where magnetic interference must be eliminated.

At Honyo Prototype, our CNC machining expertise extends beyond dimensional accuracy to encompass deep materials intelligence. We leverage advanced metallurgical databases and in-house testing to verify magnetic properties during fabrication, preventing costly field failures in sensitive electronic or MRI-compatible systems. Our 5-axis milling and turning centers process both magnetic and non-magnetic alloys with micron-level precision, applying optimized toolpaths and non-marring fixturing to maintain material integrity.

Engineers facing tight deadlines can immediately assess manufacturability through our Online Instant Quote platform. Simply upload CAD files to receive geometry analysis, material suitability feedback—including magnetic behavior verification—and competitive pricing within hours, not days. This accelerates prototyping cycles while ensuring your steel or stainless steel components perform exactly as intended in real-world conditions.

Material Behavior Summary

| Steel Type | Typical Magnetic Response | Common Applications Requiring Verification |

|——————|—————————|——————————————–|

| Carbon Steel | Strongly Magnetic | Automotive sensors, magnetic shielding |

| 400 Series SS | Magnetic | Cutlery, pump shafts |

| 300 Series SS | Non-Magnetic (annealed) | Medical implants, semiconductor equipment |

Partner with Honyo Prototype to transform material complexities into reliable, high-performance parts—where engineering rigor meets rapid production execution.

Technical Capabilities

Steel is generally magnetic due to its iron content, particularly in carbon steels and many alloy steels. However, not all steels are magnetic—stainless steels vary in magnetic response depending on their crystalline structure (e.g., austenitic stainless steels like 304 are typically non-magnetic, while ferritic and martensitic grades are magnetic). This magnetic property does not directly affect machining performance but can influence fixturing methods (e.g., use of magnetic chucks) in milling and grinding operations.

For precision manufacturing processes such as 3/4/5-axis milling and turning with tight tolerance requirements (±0.0005″ or tighter), material selection plays a critical role in dimensional stability, machinability, and tool life. Below is a technical comparison of common materials used in high-precision prototyping and production at Honyo Prototype, with relevance to multi-axis CNC machining and tight tolerance capabilities.

| Material | Magnetic | Typical Use in CNC | Machinability | Thermal Stability | Tensile Strength (MPa) | Notes for Tight Tolerance Machining |

|---|---|---|---|---|---|---|

| Aluminum (6061-T6) | No | 3/4/5-axis milling, rapid prototyping, aerospace components | Excellent | Good | 310 | Low density and high machinability allow for fast, precise cuts; minimal tool wear. Ideal for complex geometries. |

| Steel (1018, 1045) | Yes | Precision turning, structural components, tooling | Moderate | Very Good | 440 (1045) | High rigidity supports tight tolerances; generates more heat and tool wear than aluminum. Magnetic—suitable for magnetic fixturing. |

| Stainless Steel (303, 17-4 PH) | 303: Slight, 17-4: Yes | Medical, aerospace, high-strength parts | Moderate to Poor | Excellent | 620 (17-4 PH) | Work hardening requires optimized toolpaths; 17-4 PH allows post-machining heat treatment for stability. |

| ABS (Acrylonitrile Butadiene Styrene) | No | Prototypes, enclosures, jigs | Excellent | Poor | 40 | Low melting point requires light cuts and high speeds; prone to deformation under heat or stress. Not for high-temp environments. |

| Nylon (PA6/PA66) | No | Wear-resistant parts, gears, insulators | Good | Poor | 70–80 | High moisture absorption affects dimensional stability; pre-dry material before precision machining. Use non-magnetic fixturing. |

Key Considerations for Multi-Axis Machining and Tight Tolerances:

Fixturing Strategy: Magnetic workholding (e.g., magnetic chucks) is effective only with ferromagnetic materials like low-carbon and martensitic steels. Non-magnetic materials require mechanical clamping, vacuum tables, or custom fixtures.

Thermal Management: Materials with low thermal stability (e.g., ABS, nylon) require reduced cutting forces and careful temperature control to maintain precision.

Tool Selection: Steel and stainless steel demand carbide tooling with appropriate coatings (e.g., TiAlN) to resist wear. Aluminum benefits from polished, high-helix tools to prevent built-up edge.

Process Optimization: 5-axis milling of complex steel components requires adaptive toolpaths and in-process probing to ensure feature alignment and tolerance compliance.

At Honyo Prototype, material-specific CNC strategies are deployed to achieve consistent ±0.0005″ tolerances across aluminum, steel, and select engineering plastics, ensuring high repeatability and part functionality.

From CAD to Part: The Process

Honyo Prototype integrates material property verification including magnetic characteristics seamlessly within our established engineering workflow. The query “is steel magnetic” is not a standalone process but addressed systematically during Design for Manufacturability (DFM) analysis when material specifications are validated against functional requirements. Below is the precise sequence demonstrating how magnetic properties are evaluated:

Upload CAD

Clients submit 3D models with explicit material specifications (e.g., “AISI 304 Stainless Steel”). Our system parses geometric data and material callouts from native CAD formats (STEP, Parasolid, native SOLIDWORKS). Critical metadata including alloy grade, finish requirements, and application notes are extracted for downstream analysis. Material magnetism is not assessed at this stage as it requires contextual engineering review.

AI Quote Generation

Our AI engine performs rapid geometric analysis for manufacturability scoring and cost estimation based on dimensions, tolerances, and declared material. The AI references our proprietary database of 12,000+ material grades but does not validate magnetic properties here. Quotes reflect standard processing for the specified alloy without functional property checks. For example, quoting AISI 430 stainless steel assumes standard ferromagnetic behavior per ASTM A240, but this is not explicitly confirmed until DFM.

Design for Manufacturability (DFM)

This is the critical phase where magnetic properties are rigorously evaluated. Our manufacturing engineers:

Cross-reference the client-specified material against ASTM/AMS/SAE standards to determine inherent magnetic characteristics (e.g., austenitic 300-series stainless steels are generally non-magnetic in annealed state but may exhibit slight magnetism after cold working).

Assess application context from client notes—if the part is for MRI components or sensor housings, non-magnetic requirements trigger mandatory material validation.

Flag discrepancies where specified alloys cannot meet functional needs (e.g., quoting AISI 410 for a non-magnetic application would generate an immediate DFM alert recommending 316L or 904L alternatives).

Provide documented justification for material suitability including permeability data from our certified material library.

Production

Material verification occurs at three checkpoints:

1. Incoming inspection: Certificates of Conformance (CoC) are validated against magnetic permeability test reports from mills (e.g., μr ≤ 1.02 for non-magnetic 316L per ASTM A342).

2. In-process: For cold-formed parts, we conduct spot-check Gauss meter tests to detect work-induced magnetism.

3. Final QA: Magnetic-sensitive applications receive full lot testing per client-specified limits (e.g., residual field < 0.5 Gauss).

Delivery

All deliverables include:

Material traceability documentation with mill test reports showing magnetic properties

DFM report section detailing magnetism validation rationale

Optional: Third-party lab certificates for magnetic testing (e.g., SGS reports) if contracted

Material magnetic behavior is never assumed—it is systematically verified against the client’s functional requirements during DFM and validated through documented testing protocols. This prevents field failures in applications where magnetic interference could compromise performance, such as medical devices or precision instrumentation. Our process ensures steel magnetism is addressed as an engineered property, not a generic assumption.

Start Your Project

If you’re wondering whether steel is magnetic and need expert guidance for your next project, contact Susan Leo at [email protected]. As a Senior Manufacturing Engineer at Honyo Prototype, I can provide detailed technical insights into material properties, including ferromagnetic behavior in various steel alloys. Our manufacturing facility is based in Shenzhen, where we specialize in rapid prototyping and low-volume production using precision CNC machining and sheet metal fabrication. Reach out today to discuss your material selection and ensure optimal performance in your application.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.