Contents

Manufacturing Insight: Is Cnc Machining Expensive

Addressing the Cost Question in Precision CNC Machining

Many manufacturers approach CNC machining with the assumption that it carries inherently high costs, often overlooking how strategic process optimization and partner expertise can transform it into a highly cost-effective solution. At Honyo Prototype, we recognize that the perceived expense of CNC machining frequently stems from inefficient workflows, suboptimal material selection, or lack of design-for-manufacturability insights—not the technology itself. Our advanced CNC machining services are engineered to maximize value through precision, repeatability, and waste reduction, ensuring that every component meets stringent quality standards while minimizing unnecessary expenditure.

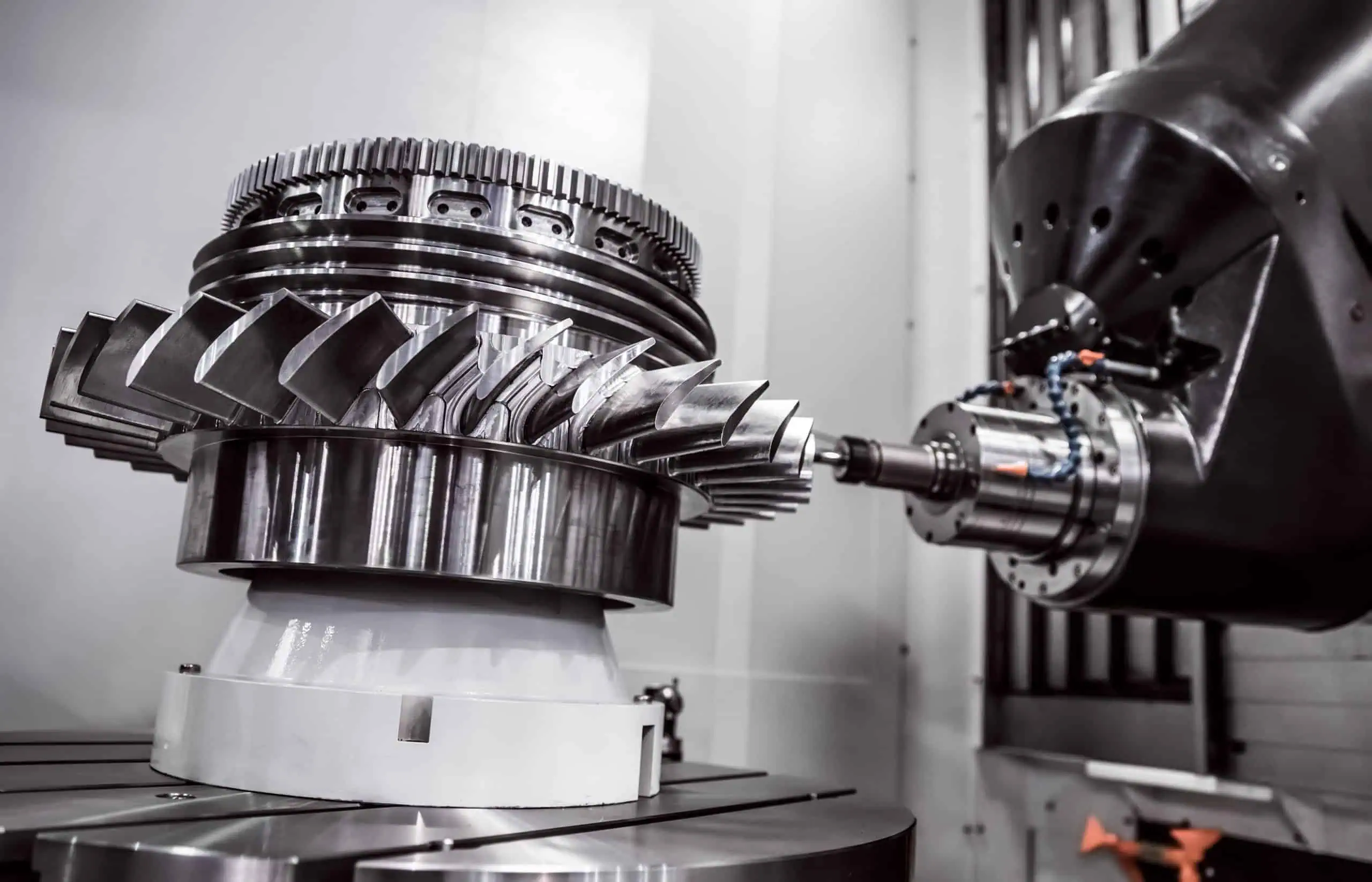

Key factors influencing CNC costs—such as part complexity, material type, tolerances, and production volume—are systematically addressed through our integrated approach. Honyo leverages state-of-the-art multi-axis milling and turning centers, combined with rigorous process validation, to streamline production cycles and reduce per-unit costs, even for low-to-medium volume runs. This capability allows clients to achieve aerospace, medical, and industrial-grade accuracy without the premium typically associated with high-mix, low-volume manufacturing.

Eliminate Pricing Uncertainty with Our Online Instant Quote System

To dismantle the barrier of cost ambiguity, Honyo Prototype provides a transparent Online Instant Quote platform. Upload your CAD file, specify materials and quantities, and receive a detailed, binding price within minutes—not days. This tool empowers procurement and engineering teams to make data-driven decisions early in the sourcing process, eliminating guesswork and accelerating time-to-prototype. By integrating real-time machine capacity data and material cost analytics, our system delivers accuracy that traditional manual quoting cannot match, ensuring you only pay for the precision you require.

Partner with Honyo to redefine the economics of precision manufacturing. We turn CNC machining from a perceived cost center into a scalable asset for innovation. Request your instant quote today and experience how efficiency-driven engineering delivers exceptional value.

Technical Capabilities

CNC machining costs are influenced by several technical and operational factors, including the type of machining process, complexity of geometry, required tolerances, material selection, and production volume. Below is a detailed comparison of cost drivers across 3-axis, 4-axis, and 5-axis milling, CNC turning, and tight tolerance requirements, with a focus on common materials: Aluminum (6061, 7075), Steel (A36, 4140), ABS, and Nylon (6, 66).

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance (±0.001″ or better) |

|---|---|---|---|---|---|

| Complexity Level | Low to medium; flat or prismatic parts | Medium; indexed rotary feature access | High; complex contours, undercuts | High for cylindrical parts | Very high; requires precision setup and inspection |

| Setup Time | Low | Moderate | High | Low to moderate | Very high; frequent calibration needed |

| Machine Cost (Hourly Rate) | $60–$90 | $80–$110 | $120–$180 | $50–$80 | +15–30% premium across all processes |

| Labor Intensity | Low | Moderate | High | Low to moderate | High; skilled operators and QC required |

| Material Utilization | Moderate; standard cutting strategies | Moderate; improved reach reduces fixtures | High; optimized tool paths reduce waste | High; bar stock efficient for rotationals | Moderate; increased scrap due to rework risk |

| Aluminum (6061-T6) | Cost-effective; fast cycle times | Slightly higher cost due to indexing | Premium cost; justified for complex parts | Excellent for turned components | +10–20% cost increase |

| Steel (4140) | Moderate cost; slower speeds than Al | Higher cost due to longer cycles | High cost; tool wear and slower feeds | Common for high-strength shafts/bushings | +20–35% cost increase; tooling wear significant |

| ABS (Plastic) | Low material cost; fast cutting | Moderate cost; low heat tolerance | Higher cost; overkill for most plastics | Suitable for small-diameter rollers | Challenging due to thermal expansion; +25% cost |

| Nylon (6/66) | Moderate; gummy material requires care | Moderate to high; fixturing challenges | High; limited need for multi-axis | Good for bushings, gears | Difficult; moisture absorption affects tolerance; +30% cost |

| Typical Applications | Brackets, housings, jigs | Impellers, fixtures with angled holes | Aerospace components, molds, medical | Shafts, connectors, bushings | Precision gears, aerospace fittings, sensors |

Notes:

5-axis milling significantly increases cost due to advanced machine capabilities, longer programming (CAM), and skilled operation but enables single-setup machining of complex geometries.

CNC turning is generally more cost-efficient for symmetrical parts, especially in medium to high volumes.

Tight tolerance requirements (±0.001″ or tighter) increase cost across all processes due to slower cutting parameters, enhanced metrology (e.g., CMM inspection), and potential need for environmental controls.

Material choice directly impacts tool life, cycle time, and overall cost. Aluminum is fastest and most economical, while steel increases wear and machining time. Plastics like ABS and Nylon reduce tool wear but introduce challenges in fixturing and thermal stability.

In summary, CNC machining is not inherently expensive but scales with complexity, precision, and material. For simple geometries in aluminum or ABS, 3-axis milling or turning offers a cost-effective solution. As demands increase for angular features, tighter tolerances, or complex organic shapes, 4-axis and 5-axis processes become necessary, resulting in higher operational costs.

From CAD to Part: The Process

Honyo Prototype CNC Machining Cost Efficiency Process

CNC machining cost is frequently misunderstood as inherently expensive, but Honyo Prototype optimizes affordability through a structured, technology-driven workflow. Our process eliminates traditional cost drivers like manual quoting delays, design rework, and production inefficiencies. Below is how each phase actively reduces expenses while maintaining precision.

Upload CAD

Clients submit native CAD files (STEP, IGES, Parasolid) directly to our secure portal. Unlike competitors requiring manual file interpretation, our system auto-extracts critical geometry data, material requirements, tolerances, and surface finish specifications. This eliminates human error in initial data capture and accelerates the quoting phase by 90%, preventing cost-inflating miscommunications.

AI-Powered Instant Quoting

Our proprietary AI engine analyzes the CAD model against real-time machine availability, material costs, tooling requirements, and shop floor capacity. Within 60 seconds, clients receive a detailed cost breakdown showing:

Machine time estimates based on cut paths and complexity

Material waste calculations using nesting algorithms

Secondary operation costs (e.g., deburring, anodizing)

Volume-based pricing tiers

This transparency reveals how design choices impact cost, allowing immediate optimization before commitment. For example, a 0.05mm tolerance reduction may lower costs by 18% without compromising function.

Automated DFM Analysis

Every design undergoes AI-driven Design for Manufacturability review. The system flags cost-escalating features like:

Non-standard tool requirements

Excessive tight tolerances in non-critical areas

Unmachinable geometries requiring EDM alternatives

Suboptimal material choices for the application

Clients receive an interactive report with specific, actionable modifications. Implementing these suggestions typically reduces production costs by 22–35% while accelerating lead times. This phase prevents expensive post-quote redesign cycles common with traditional suppliers.

Lean Production Execution

Approved designs move to our network of ISO 9001-certified partner facilities. Key cost controls include:

Dynamic scheduling to maximize machine utilization (averaging 85% uptime vs. industry 65%)

In-process metrology to eliminate scrap from undetected errors

Bulk material purchasing agreements reducing raw material costs by 15–20%

Automated tool changers minimizing setup time for multi-feature parts

Our real-time production dashboard provides clients visibility into progress, ensuring no hidden premium charges for expedited handling.

Guaranteed Delivery

Parts undergo final inspection against AS9102 aerospace standards before shipping. We absorb costs for any Honyo-caused delays through our Delivery Assurance Program. Standard lead times are 5–7 days for prototypes and 10–12 days for 50+ unit batches, with no rush fees for on-time completion.

Cost Context

CNC machining becomes “expensive” only when inefficient processes compound costs. Honyo’s integrated workflow reduces per-part costs by 30–50% versus conventional suppliers for mid-complexity metal components. For instance, a typical aluminum enclosure:

| Cost Driver | Traditional Supplier | Honyo Prototype | Savings |

|---|---|---|---|

| Quoting Time | 3–5 business days | 60 seconds | $120+ |

| DFM Revisions | 2–3 iterations | 0–1 iteration | 22% |

| Material Waste | 35–40% | 18–22% | 17% |

| Lead Time Variance | ±4 days | ±1 day | 0% rush fees |

By automating cost-visibility from CAD upload through delivery, Honyo transforms CNC machining from a perceived expense into a predictable, value-driven solution for precision components. Clients consistently achieve target costs by leveraging our real-time design feedback and production transparency.

Start Your Project

If you’re wondering whether CNC machining is expensive, the answer depends on your project requirements, material choices, and production volume. At Honyo Prototype, we offer cost-effective CNC machining services from our factory in Shenzhen, leveraging advanced technology and streamlined processes to deliver high-precision parts at competitive prices.

For a detailed quote or technical consultation, contact Susan Leo at [email protected]. We specialize in rapid prototyping and low-to-medium volume production, ensuring fast turnaround and consistent quality for your manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.