Introduction: Navigating the Global Market for is bronze and brass the same thing

Navigating the global market for materials can be a daunting task, especially when it comes to distinguishing between bronze and brass, two commonly confused copper alloys. Understanding whether bronze and brass are the same thing is crucial for B2B buyers looking to make informed sourcing decisions for their projects. This comprehensive guide delves into the unique properties, compositions, and applications of both metals, helping you differentiate between them effectively.

From exploring the various types of bronze and brass to examining their specific industrial applications, this guide covers all the essentials. We will also provide insights into supplier vetting processes, cost considerations, and the implications of each material choice on your projects. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—making the right material choice can significantly impact project outcomes and profitability.

By arming you with detailed knowledge about bronze and brass, this guide empowers you to navigate the complexities of material selection confidently. Whether you are in manufacturing, construction, or electronics, understanding these alloys will enable you to optimize your purchasing strategy and ensure the success of your business ventures in a competitive global market.

Understanding is bronze and brass the same thing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brass | Copper-zinc alloy, high malleability, lower melting point | Plumbing, electrical fittings, decorative items | Pros: Easy to machine; good corrosion resistance. Cons: Less corrosion-resistant than bronze. |

| Bronze | Copper-tin alloy (often with aluminum or phosphorus), higher hardness | Marine applications, sculptures, electrical connectors | Pros: Excellent corrosion resistance; durable. Cons: More brittle than brass, harder to work with. |

| Phosphor Bronze | Contains copper, tin, and phosphorus; enhanced hardness and low friction | Electrical components, bushings, marine fittings | Pros: High wear resistance; excellent conductivity. Cons: More expensive due to complex composition. |

| Red Brass | High copper content (85%+), lower zinc content | Plumbing fixtures, musical instruments | Pros: Excellent corrosion resistance; good for casting. Cons: Limited strength compared to other brass types. |

| Aluminum Bronze | Copper-aluminum alloy; superior corrosion resistance | Aerospace, marine, and chemical processing | Pros: Exceptional strength; resistant to seawater. Cons: Higher cost; more challenging to machine. |

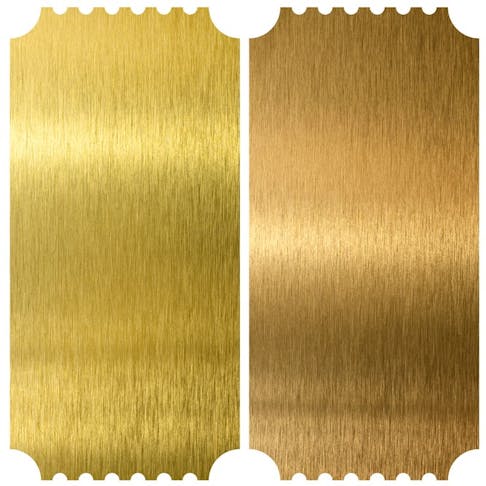

What Are the Key Characteristics of Brass for B2B Buyers?

Brass is primarily composed of copper and zinc, making it highly malleable and easy to shape. This property is particularly advantageous for manufacturers needing to create intricate designs or components. Its lower melting point (around 900 degrees Celsius) allows for efficient casting and machining processes. Common applications include plumbing fittings, electrical connectors, and decorative items, where both form and function are crucial. Buyers should consider the specific zinc content, as it significantly influences the alloy’s strength and ductility.

How Does Bronze Differ from Brass in Application Suitability?

Bronze is characterized by its copper-tin alloy composition, often enhanced with additional elements like aluminum or phosphorus. This results in a material that is harder and exhibits superior corrosion resistance, especially in marine environments. Its applications range from ship fittings to artistic sculptures. However, bronze is generally more brittle than brass, which can pose challenges in machining. B2B buyers should assess the intended application carefully, as bronze is ideal for high-stress environments but may require more complex fabrication techniques.

What Makes Phosphor Bronze a Unique Option for Buyers?

Phosphor bronze combines copper with tin and a small amount of phosphorus, resulting in a material that exhibits high strength and excellent wear resistance. It is particularly effective in applications where low friction is essential, such as bushings and electrical connectors. The enhanced hardness makes phosphor bronze suitable for high-performance environments, although it tends to be more expensive due to its complex composition. Buyers should weigh the cost against the long-term benefits of durability and performance, especially in demanding applications.

Why Consider Red Brass for Plumbing and Musical Instruments?

Red brass, with a high copper content of over 85%, is known for its excellent corrosion resistance and workability. It is commonly used in plumbing fixtures and musical instruments due to its aesthetic appeal and durability. While it offers good casting capabilities, its strength may not match that of other brass types. B2B buyers should consider the specific requirements of their applications, as red brass is particularly beneficial in environments where corrosion resistance is a priority.

What Are the Advantages of Aluminum Bronze for Specialized Industries?

Aluminum bronze is a copper-aluminum alloy recognized for its exceptional strength and corrosion resistance, especially in seawater. This makes it a preferred choice for applications in aerospace, marine, and chemical processing industries. However, the higher cost and machining difficulty may deter some buyers. It is crucial for businesses to evaluate the long-term performance benefits against the initial investment, especially for components exposed to harsh environments.

Key Industrial Applications of is bronze and brass the same thing

| Industry/Sector | Specific Application of is bronze and brass the same thing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Engineering | Use of bronze for ship fittings and propellers | High corrosion resistance in saltwater environments | Ensure compliance with maritime standards and regulations |

| Electronics | Brass and bronze components in electrical connectors | Excellent conductivity and durability | Look for suppliers with certifications for electrical applications |

| Plumbing | Brass for plumbing fixtures and pipes | Corrosion resistance and longevity | Verify the alloy composition for specific plumbing standards |

| Musical Instruments | Brass and bronze in instrument manufacturing | Superior acoustics and aesthetic appeal | Source from manufacturers with expertise in musical applications |

| Decorative Arts | Bronze for sculptures and decorative items | Unique aesthetic qualities and historical significance | Consider sourcing from artisans or suppliers specializing in art-grade materials |

How is Bronze Used in Marine Engineering Applications?

In the marine engineering sector, bronze is predominantly used for ship fittings and propellers due to its exceptional resistance to corrosion from saltwater. This characteristic ensures longevity and reduces maintenance costs for vessels operating in harsh marine environments. For international B2B buyers, particularly from coastal regions in Africa, South America, and the Middle East, it’s crucial to source bronze that meets specific maritime standards to ensure compliance and reliability. Buyers should consider suppliers who provide detailed material certifications and can guarantee the alloy’s performance under marine conditions.

What Role Does Brass Play in Electronics?

Brass and bronze are essential in the electronics industry, particularly for electrical connectors, where their excellent conductivity and durability are vital. Brass, with its higher ductility, is often preferred for components requiring precise machining. For international buyers, especially those in Europe and the Middle East, sourcing brass that meets international electrical standards is critical. Buyers should prioritize suppliers who provide clear documentation regarding the alloy’s conductivity and resistance to wear, ensuring the components perform reliably over time.

Why is Brass Preferred in Plumbing?

Brass is widely utilized in plumbing fixtures and pipes due to its corrosion resistance and durability, making it ideal for water supply systems. The longevity of brass components leads to reduced maintenance costs, appealing to businesses focused on long-term investments. International B2B buyers, particularly from regions with varying water quality, should ensure that the brass alloy meets local plumbing standards. It is essential to verify that suppliers can provide detailed specifications of the alloy composition to ensure compliance with safety regulations.

How is Brass and Bronze Used in Musical Instrument Manufacturing?

In the musical instrument industry, both brass and bronze are favored for their unique acoustic properties and aesthetic appeal. Brass is often used in wind instruments, while bronze is preferred for percussion instruments due to its ability to produce rich tones. For international buyers, particularly from regions with a strong musical heritage, sourcing high-quality materials from reputable manufacturers is vital. Buyers should seek suppliers who specialize in musical-grade alloys, ensuring that the materials will enhance the sound quality and durability of the instruments.

What is the Importance of Bronze in Decorative Arts?

Bronze is a popular choice in the decorative arts for sculptures and ornamental items, valued for its unique aesthetic qualities and historical significance. The material’s ability to withstand the elements while maintaining its appearance makes it ideal for both indoor and outdoor artworks. For B2B buyers in the art sector, sourcing bronze from specialized suppliers ensures access to high-quality materials that meet artistic standards. Buyers should focus on suppliers who can provide information on the alloy’s composition and provenance, ensuring the authenticity and value of the decorative pieces.

3 Common User Pain Points for ‘is bronze and brass the same thing’ & Their Solutions

Scenario 1: Misidentifying Materials in Critical Projects

The Problem: A procurement officer at a manufacturing plant in South America is tasked with sourcing metal alloys for a new line of marine equipment. Due to the interchangeable use of terms like bronze and brass, the officer mistakenly orders brass instead of bronze, leading to equipment that is not suited for saltwater environments. This misstep results in significant project delays, increased costs for reordering, and potential damage to the company’s reputation.

The Solution: To prevent such costly errors, it is crucial for B2B buyers to clearly understand the properties and applications of bronze and brass before making procurement decisions. Buyers should invest in comprehensive training sessions for their procurement teams on material specifications. Establishing a standardized checklist that includes the intended application, environmental conditions, and mechanical properties can help ensure the correct material is selected. Furthermore, collaborating with suppliers who provide detailed product specifications and comparative analyses can enhance material understanding. Keeping a physical sample of both materials on hand can also aid in quick visual identification and verification before finalizing orders.

Scenario 2: Miscommunication with Suppliers

The Problem: A design engineer in Germany is developing a new line of decorative fixtures and needs to communicate specific requirements to a supplier. However, due to the confusion surrounding the terms bronze and brass, the supplier delivers brass, which is less suitable for the aesthetic and durability requirements of the project. The designer faces pushback from stakeholders who are unhappy with the quality of the delivered product, complicating the project timeline.

The Solution: To mitigate miscommunication, it is essential for B2B buyers to establish clear and precise documentation when communicating with suppliers. This includes detailed descriptions of material requirements, such as the specific alloy composition, desired properties (like corrosion resistance and appearance), and intended applications. Utilizing standardized terminology and including visual aids, such as charts comparing the two materials, can further clarify expectations. Regular meetings with suppliers to discuss project specifications and requirements can also foster a collaborative relationship, ensuring that both parties are on the same page regarding material choices.

Scenario 3: Challenges in Product Development and Testing

The Problem: An electronics manufacturer in the Middle East is developing a new line of connectors that require excellent conductivity and corrosion resistance. The R&D team initially uses brass, believing it to be equivalent to bronze, only to discover that the product fails during testing due to inadequate performance in corrosive environments. This oversight leads to wasted resources and delays in product launch, putting the company at a competitive disadvantage.

The Solution: To address such challenges, B2B buyers should implement a robust testing and validation process that factors in the specific properties of materials used in product development. Conducting thorough research and development phases that include material testing can reveal the strengths and weaknesses of each alloy under real-world conditions. Establishing partnerships with testing laboratories that specialize in metal alloys can provide valuable insights into the performance characteristics of both bronze and brass. Furthermore, creating a knowledge-sharing platform within the organization to document findings and best practices can ensure that future projects benefit from past experiences, leading to improved material selection and product quality.

Strategic Material Selection Guide for is bronze and brass the same thing

What Are the Key Properties of Brass and Bronze in B2B Applications?

Brass and bronze, while often confused, have distinct properties that affect their performance in various applications. Understanding these properties is crucial for B2B buyers to make informed decisions.

Brass: Key Properties and Applications

Brass is primarily composed of copper and zinc, with variations in the proportion of these metals affecting its characteristics. It typically has a lower melting point of around 900 degrees Celsius, making it easier to work with during manufacturing processes. Brass exhibits excellent corrosion resistance, particularly against moisture and acids, making it suitable for plumbing and electrical applications. Its malleability allows for intricate designs, which is beneficial for decorative items.

Pros & Cons:

– Pros: High ductility, good machinability, and corrosion resistance.

– Cons: Lower hardness compared to bronze, which may limit its use in high-stress environments.

Brass is widely used in plumbing fittings, musical instruments, and decorative hardware. Its compatibility with various media, including water and air, makes it a versatile choice for many applications.

Bronze: Key Properties and Applications

Bronze, on the other hand, is an alloy primarily made of copper and tin. It has a higher melting point of approximately 950 degrees Celsius, which can complicate manufacturing but also enhances its durability. Bronze is known for its exceptional corrosion resistance, particularly in marine environments, making it ideal for ship components and fittings. Its hardness and low friction properties also make it suitable for bearings and bushings.

Pros & Cons:

– Pros: Superior corrosion resistance, higher hardness, and low friction.

– Cons: More brittle than brass, which can lead to cracking under stress.

Bronze is often used in marine applications, sculptures, and electrical connectors. Its ability to withstand harsh environments, particularly saltwater, makes it a preferred choice for maritime industries.

Considerations for International B2B Buyers

When sourcing brass and bronze materials, international buyers must consider various factors, including compliance with local standards such as ASTM, DIN, and JIS. In regions like Africa, South America, the Middle East, and Europe, understanding local regulations regarding material properties and environmental impacts is essential. Additionally, buyers should be aware of the availability of specific alloys and their cost implications, as these can vary significantly by region.

Summary Table of Material Comparisons

| Material | Typical Use Case for is bronze and brass the same thing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Plumbing fittings, musical instruments | Excellent machinability and ductility | Lower hardness limits high-stress applications | Medium |

| Bronze | Marine fittings, electrical connectors | Superior corrosion resistance and hardness | More brittle, prone to cracking under stress | High |

| Phosphor Bronze | Electrical applications, bushings | High strength and wear resistance | Limited decorative appeal compared to brass | Medium |

| Leaded Bronze | High-performance bearings, gears | Excellent machinability and wear resistance | Lead content may raise health concerns | High |

This analysis provides a comprehensive understanding of the differences between brass and bronze, equipping B2B buyers with the necessary insights to select the appropriate material for their applications.

In-depth Look: Manufacturing Processes and Quality Assurance for is bronze and brass the same thing

What Are the Typical Manufacturing Processes for Bronze and Brass?

Understanding the manufacturing processes for bronze and brass is essential for B2B buyers looking to procure these materials. Both alloys undergo a series of stages from material preparation to finishing. Here’s a detailed breakdown of each stage.

Material Preparation: What Materials Are Used?

The first step in manufacturing bronze and brass involves selecting the right raw materials. Bronze typically consists of copper and tin, while brass is primarily made of copper and zinc. Quality assurance begins at this stage, as the purity and proportion of the metals can significantly affect the final product’s properties. Suppliers often source copper from reputable mines, and the tin or zinc must meet international standards for purity.

Forming: How Are Bronze and Brass Shaped?

Once the materials are prepared, the next step is forming. This can be accomplished through various techniques, such as:

- Casting: Molten metal is poured into molds to create specific shapes. This method is often used for larger components like marine fittings made of bronze.

- Extrusion: This involves forcing the metal through a die to create long shapes, such as rods or tubes. Brass is commonly extruded for plumbing applications.

- Rolling: Sheets of metal are produced by passing the material through rollers. This is particularly useful for creating thin sheets of brass for decorative applications.

Each technique requires skilled operators and precise machinery to ensure that the dimensions and surface finish meet the required specifications.

Assembly: What Are the Assembly Techniques for Bronze and Brass Products?

In many cases, bronze and brass components are assembled into final products. This may involve soldering, welding, or mechanical fastening. For instance, in plumbing applications, brass fittings are often threaded to ensure a secure connection. Quality control during assembly is crucial, as any defects can lead to product failure.

What Quality Assurance Standards Are Relevant for Bronze and Brass Manufacturing?

Quality assurance is a critical aspect of the manufacturing process for both bronze and brass. B2B buyers should be familiar with international standards and industry-specific certifications that ensure the quality of these materials.

What International Standards Should B2B Buyers Consider?

One of the most recognized quality management systems is ISO 9001, which provides a framework for consistent quality across manufacturing processes. Suppliers adhering to ISO 9001 standards demonstrate their commitment to quality management, which is crucial for B2B buyers.

In addition to ISO 9001, other industry-specific certifications may apply, such as:

- CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For suppliers dealing in oil and gas applications, adherence to American Petroleum Institute (API) standards is vital for ensuring the reliability of components.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that the final products meet the specified standards. B2B buyers should be aware of these checkpoints to better understand a supplier’s QC process.

What QC Checkpoints Should Be Included?

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring that the copper, tin, or zinc meets specified standards is crucial at this stage.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections help identify defects early. Techniques such as visual inspections, dimensional checks, and non-destructive testing are employed to monitor quality.

-

Final Quality Control (FQC): Once production is complete, the final products undergo rigorous testing. This may include tensile strength tests, corrosion resistance tests, and surface finish evaluations to ensure compliance with international standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should adopt proactive measures to verify the quality control processes of their suppliers. Here are some effective strategies:

What Auditing Practices Should Be Followed?

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and QC practices. During these audits, buyers can assess the adherence to international standards like ISO 9001 and review documentation.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline testing methods, results, and compliance with industry standards. Buyers should review these reports to ensure that they align with their requirements.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality practices. This is particularly valuable for international buyers who may not be able to conduct audits personally.

What QC and Certification Nuances Exist for International Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, it is essential to understand regional differences in quality assurance practices.

How Do Regional Differences Impact Quality Assurance?

-

Local Standards: While international standards like ISO 9001 are widely recognized, local certifications may also play a role. Buyers should familiarize themselves with any regional quality standards that may affect the procurement process.

-

Cultural Considerations: Understanding the cultural context of a supplier’s operations can provide insights into their commitment to quality. For instance, some regions may place a higher emphasis on craftsmanship, which can impact the quality of the final product.

-

Logistical Challenges: International shipping can introduce risks related to damage or quality degradation. Buyers should consider specifying quality control measures that include packaging and handling standards.

Conclusion

The manufacturing processes and quality assurance practices for bronze and brass are multifaceted and require careful consideration by B2B buyers. By understanding the various stages of production, the relevant quality standards, and the QC checkpoints, buyers can make informed decisions when selecting suppliers. Verifying a supplier’s quality control through audits, reports, and third-party inspections will further enhance the reliability of their procurement choices, ensuring that the materials meet the high standards required for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘is bronze and brass the same thing’

Introduction

Navigating the complexities of sourcing metals like bronze and brass can significantly impact your projects and operations. This guide provides a step-by-step checklist to help international B2B buyers understand the differences between these two copper alloys and make informed procurement decisions. By following these steps, you will ensure that you select the right material for your specific applications.

Step 1: Identify Your Application Needs

Understanding the specific requirements of your project is crucial. Different applications may require unique properties such as corrosion resistance, strength, or malleability. For instance, if you are working on marine applications, bronze’s superior resistance to saltwater corrosion would be more suitable than brass.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications for your materials. This includes desired properties such as tensile strength, melting point, and electrical conductivity. By detailing these specifications, you can better communicate your needs to suppliers, ensuring they provide the right alloy composition that aligns with your project requirements.

Step 3: Evaluate Potential Suppliers

Before making a purchase, vet potential suppliers thoroughly. Request detailed company profiles, product catalogs, and case studies that showcase their expertise in supplying brass and bronze. Look for references from other buyers in similar industries or regions to validate the supplier’s credibility and reliability.

Step 4: Request Material Samples

Always request samples of both bronze and brass to assess their physical properties and appearance. This step allows you to evaluate the alloy’s suitability for your application firsthand. Pay attention to factors like color, finish, and malleability during your evaluation.

Step 5: Verify Compliance with Standards

Ensure that the materials you are considering comply with relevant international standards and certifications. This may include ISO certifications or compliance with ASTM standards. Compliance not only guarantees quality but also ensures that the materials are suitable for your intended application and are safe to use.

Step 6: Analyze Cost Implications

Conduct a thorough cost analysis for both bronze and brass, taking into account not just the purchase price but also factors such as processing and long-term maintenance costs. Understanding the total cost of ownership will help you make a more informed decision and potentially identify which alloy provides the best value for your project.

Step 7: Establish a Clear Procurement Process

Define a clear procurement process that includes timelines, payment terms, and delivery expectations. Establishing a structured approach helps to avoid miscommunication and ensures that both you and your supplier are aligned on expectations. This clarity can improve supplier relationships and reduce the risk of delays or issues during the procurement process.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing bronze and brass, ensuring they select the most appropriate material for their specific needs.

Comprehensive Cost and Pricing Analysis for is bronze and brass the same thing Sourcing

Understanding the cost structure and pricing nuances for sourcing bronze and brass is essential for B2B buyers navigating the international market. This analysis breaks down the cost components, price influencers, and offers actionable tips for buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing Bronze and Brass?

When sourcing bronze and brass, several cost components contribute to the overall pricing structure:

-

Materials: The primary cost driver is the raw materials used to create these alloys. Bronze generally consists of copper and tin, while brass is made from copper and zinc. The market prices for these base metals can fluctuate significantly, impacting overall costs.

-

Labor: The labor cost is influenced by the complexity of the manufacturing process. For example, producing intricate designs in brass may require skilled artisans, thereby increasing labor costs.

-

Manufacturing Overhead: This encompasses costs associated with production facilities, utilities, and equipment maintenance. Higher operational costs in certain regions can lead to increased pricing.

-

Tooling: Initial investment in tooling can be substantial, especially for custom orders. The need for specialized molds or dies can drive up the cost for both bronze and brass.

-

Quality Control (QC): Ensuring quality standards is crucial, particularly in industries requiring certifications. Rigorous QC processes may add to production costs.

-

Logistics: Transportation and shipping costs vary based on the distance, mode of transport, and Incoterms. This is particularly relevant for international buyers who need to consider import duties and tariffs.

-

Margin: Suppliers will factor in their desired profit margin, which can vary widely based on market competition and demand.

What Influences the Price of Bronze and Brass?

Several factors influence the pricing of bronze and brass beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs. Buyers should consider negotiating MOQs to achieve better pricing.

-

Specifications and Customization: Custom specifications can significantly impact pricing. Unique compositions or sizes may require additional processing and materials, leading to higher costs.

-

Materials and Quality/Certifications: The quality of materials used and any required certifications (e.g., ISO, ASTM) can affect pricing. Higher quality often comes with a premium.

-

Supplier Factors: The reputation and reliability of the supplier can also influence price. Established suppliers may charge more due to their proven track record and service quality.

-

Incoterms: The chosen Incoterms can affect the total landed cost. Buyers should understand their responsibilities and potential liabilities in the shipping process.

What Are Essential Buyer Tips for Cost-Efficiency?

For B2B buyers, particularly in diverse regions, several strategies can enhance cost-efficiency when sourcing bronze and brass:

-

Negotiate Effectively: Building relationships with suppliers can lead to better pricing. Don’t hesitate to negotiate terms, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, durability, and potential replacement costs. This is particularly relevant for applications where longevity is critical.

-

Understand Pricing Nuances in International Markets: Be aware of regional market conditions that may affect pricing. For example, local demand in Africa or Europe can create price fluctuations that differ from other regions.

-

Stay Informed on Market Trends: Regularly monitoring metal prices and industry trends can provide leverage in negotiations and help forecast future costs.

-

Evaluate Supplier Certifications: Ensure that suppliers have the necessary certifications to meet your quality and compliance requirements. This can prevent costly issues down the line.

Disclaimer on Indicative Prices

Prices for bronze and brass are subject to change based on market conditions, raw material availability, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their needs.

Alternatives Analysis: Comparing is bronze and brass the same thing With Other Solutions

Understanding Alternative Solutions to Bronze and Brass

In the quest for effective materials in manufacturing and construction, understanding the nuances of different metals is crucial. While bronze and brass are often compared due to their copper-based compositions, alternatives exist that may better suit specific applications. This section explores how the decision to choose between bronze and brass measures up against other viable solutions, providing actionable insights for B2B buyers.

| Comparison Aspect | Is Bronze And Brass The Same Thing | Alternative 1: Stainless Steel | Alternative 2: Aluminum Alloy |

|---|---|---|---|

| Performance | Varies by alloy; good corrosion resistance | Excellent corrosion resistance; high strength | Lightweight; good corrosion resistance but lower strength |

| Cost | Moderate, varies by alloy | Generally higher initial cost | Lower cost, especially for large volumes |

| Ease of Implementation | Moderate; requires specific machining | Easier to work with in large sheets | Highly machinable; easy to form |

| Maintenance | Low; durable in various environments | Low; resistant to rust and staining | Moderate; can corrode in certain environments |

| Best Use Case | Art, marine applications, plumbing | Industrial, food processing, and medical | Aerospace, automotive, and lightweight structures |

Exploring Alternatives: Stainless Steel

Stainless steel is a robust alternative to bronze and brass, offering exceptional corrosion resistance and strength. Its composition typically includes iron, chromium, and nickel, making it less prone to rust and staining. This makes stainless steel particularly suitable for industrial and medical applications where hygiene and durability are paramount. However, the initial cost can be higher than that of brass and bronze, which might be a consideration for budget-conscious buyers. Furthermore, while stainless steel is relatively easy to work with, it requires specialized tools for machining.

Understanding Aluminum Alloy as an Alternative

Aluminum alloys present another compelling alternative to bronze and brass. Known for their lightweight properties, aluminum alloys are favored in aerospace and automotive applications where reducing weight is crucial. They also provide good corrosion resistance, although they may not match the strength of bronze or brass in high-stress scenarios. One significant advantage is their lower cost, especially for large production runs, making them an attractive option for manufacturers. However, aluminum alloys may require more maintenance in certain environments, particularly when exposed to saltwater or acidic conditions.

Conclusion: Making the Right Choice for Your B2B Needs

When determining the best metal for a specific application, B2B buyers should carefully consider the unique properties of bronze and brass alongside viable alternatives like stainless steel and aluminum alloys. Each material has distinct advantages and disadvantages that can impact performance, cost, and application suitability. Assessing these factors in relation to the specific requirements of your project will guide you in making an informed decision that balances functionality with budgetary constraints. Whether you prioritize corrosion resistance, weight, or cost, understanding these alternatives will empower you to select the most effective solution for your business needs.

Essential Technical Properties and Trade Terminology for is bronze and brass the same thing

What Are the Key Technical Properties of Bronze and Brass for B2B Buyers?

Understanding the technical properties of bronze and brass is essential for B2B buyers to make informed purchasing decisions. Here are several critical specifications:

1. Material Composition

- Definition: The specific metals and their percentages that constitute the alloy.

- Importance: Different compositions yield varying properties. For instance, brass is primarily composed of copper and zinc, while bronze consists of copper and tin. Buyers should know the composition to select the right material for specific applications, such as plumbing or marine environments.

2. Corrosion Resistance

- Definition: The ability of a material to withstand degradation due to environmental factors.

- Importance: Corrosion resistance is crucial for materials used in harsh environments. Bronze offers superior resistance to saltwater corrosion, making it ideal for marine applications, while brass is suitable for plumbing due to its moisture resistance. This property directly influences the longevity and durability of the components.

3. Malleability and Ductility

- Definition: Malleability refers to the ability of a material to be shaped without breaking, while ductility is its ability to stretch.

- Importance: Brass is more malleable and ductile compared to bronze, making it easier to work with for intricate designs. This property is particularly beneficial for decorative applications and manufacturing processes where complex shapes are required.

4. Melting Point

- Definition: The temperature at which a material changes from solid to liquid.

- Importance: The melting points of bronze (950°C) and brass (900°C) determine the temperatures at which these materials can be processed. Understanding these values helps manufacturers plan their production processes and avoid issues related to material deformation or failure.

5. Thermal and Electrical Conductivity

- Definition: The ability of a material to conduct heat or electricity.

- Importance: Brass is known for its excellent electrical conductivity, making it a preferred choice in electrical applications, while bronze is used in situations where low friction and wear resistance are needed. B2B buyers should match these properties to their application requirements.

6. Hardness

- Definition: A measure of a material’s resistance to deformation.

- Importance: Bronze is generally harder than brass, which can be advantageous in applications like bearings and bushings that require wear resistance. Understanding hardness helps in selecting materials for specific operational environments.

What Are Common Trade Terms Related to Bronze and Brass?

Familiarizing yourself with key trade terminology is essential for navigating procurement processes effectively. Here are several terms relevant to the industry:

1. OEM (Original Equipment Manufacturer)

- Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

- Importance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure that they are sourcing materials that meet specific standards and specifications.

2. MOQ (Minimum Order Quantity)

- Definition: The smallest quantity of a product that a supplier is willing to sell.

- Importance: Knowing the MOQ helps businesses manage inventory and budget constraints. It can also impact pricing negotiations, as larger orders may lead to discounts.

3. RFQ (Request for Quotation)

- Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

- Importance: An RFQ is essential for comparing offers from different suppliers, ensuring that buyers can make cost-effective decisions based on detailed quotes.

4. Incoterms (International Commercial Terms)

- Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

- Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk transfer, and cost allocation, which are crucial for international transactions.

5. Lead Time

- Definition: The time it takes from placing an order to receiving the product.

- Importance: Understanding lead times is critical for planning production schedules and managing inventory. It allows businesses to align their procurement strategies with operational needs.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategy and ensure that they select the appropriate materials for their specific applications, ultimately leading to more successful projects and partnerships.

Navigating Market Dynamics and Sourcing Trends in the is bronze and brass the same thing Sector

What Are the Current Market Dynamics for Bronze and Brass?

The global market for bronze and brass continues to evolve, influenced by various factors including technological advancements and changing consumer preferences. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate these dynamics, understanding the key drivers is essential. One significant trend is the increasing demand for high-performance materials in industries such as construction, automotive, and electronics. The rise of electric vehicles and renewable energy technologies has spurred the need for materials with superior conductivity and corrosion resistance, making bronze and brass highly sought after.

Moreover, digital transformation in supply chain management is changing the way companies source materials. E-commerce platforms and B2B marketplaces are making it easier for buyers to access diverse suppliers and compare prices. This trend is particularly beneficial for buyers in emerging markets, where traditional sourcing methods may have been limited. Additionally, the push towards customization and rapid prototyping is prompting manufacturers to seek versatile materials like brass and bronze that can be tailored for specific applications.

How Is Sustainability Shaping the Sourcing of Bronze and Brass?

Sustainability is a growing concern in the procurement of materials, with buyers increasingly prioritizing ethical sourcing practices. The environmental impact of metal production, particularly regarding mining and processing, has led to heightened scrutiny from consumers and regulatory bodies alike. For B2B buyers, this means that selecting suppliers who adhere to sustainable practices is not just a trend but a necessity.

Ethical supply chains and certifications, such as ISO 14001 for environmental management, are becoming critical factors in the decision-making process. Buyers are encouraged to seek suppliers who can demonstrate responsible sourcing of copper, zinc, and tin, the primary components of bronze and brass. Additionally, the recycling of these metals plays a significant role in reducing the environmental footprint of production. By opting for recycled materials, businesses can minimize waste and energy consumption, aligning with global sustainability goals.

How Has the History of Bronze and Brass Influenced Their Current Use?

The historical significance of bronze and brass cannot be overstated. Bronze, dating back to around 3500 BCE, was one of the first alloys used by humans, heralding the Bronze Age and revolutionizing tool and weapon manufacturing. Brass followed much later, emerging around 500 BCE, primarily due to the need for a more malleable and workable alloy.

This long-standing history has shaped the applications of these materials today. Bronze is often used in marine environments due to its resistance to corrosion, while brass has found its niche in decorative applications and plumbing due to its malleability and ductility. Understanding this evolution can help B2B buyers appreciate the unique properties of each alloy, ensuring informed decisions based on their specific application needs.

In summary, as international B2B buyers navigate the market for bronze and brass, they must stay attuned to emerging trends, prioritize sustainability, and recognize the historical context that informs current applications. These insights will not only enhance their sourcing strategies but also align their business practices with modern demands for ethical and responsible procurement.

Frequently Asked Questions (FAQs) for B2B Buyers of is bronze and brass the same thing

-

How do I determine whether to use bronze or brass for my project?

When deciding between bronze and brass, consider the specific application requirements. Bronze, with its higher resistance to corrosion and wear, is ideal for marine applications, sculptures, and electrical components. Brass, being more malleable and easier to machine, is better suited for decorative items, plumbing, and electrical fittings. Conduct a thorough analysis of environmental conditions and mechanical stresses your product will face to make an informed choice. -

What are the key differences between bronze and brass in terms of composition and properties?

Bronze is primarily an alloy of copper and tin, often containing other elements like aluminum or phosphorus, leading to greater hardness and corrosion resistance. In contrast, brass is mainly composed of copper and zinc, offering better ductility and malleability. This composition affects their melting points—bronze melts at around 950 degrees Celsius while brass melts at approximately 900 degrees Celsius—impacting their usability in various applications. -

What industries commonly use bronze and brass, and for what applications?

Bronze is frequently used in marine applications due to its corrosion resistance to saltwater, as well as in artistic sculptures and electrical connectors. Brass, with its aesthetic appeal and workability, is popular in plumbing fittings, musical instruments, and decorative hardware. Identifying the primary industry and application for your project can guide you in selecting the appropriate alloy. -

What factors should I consider when sourcing bronze or brass from international suppliers?

When sourcing from international suppliers, evaluate their certifications, quality assurance processes, and compliance with international standards. Request samples to assess material quality and conduct due diligence on supplier reliability. Additionally, consider their ability to meet your specific requirements for customization, minimum order quantities (MOQ), and lead times to ensure a smooth procurement process. -

How can I customize bronze or brass products for my specific needs?

Customization options for bronze and brass products often include altering dimensions, finishes, and alloy compositions. Communicate your specific requirements clearly to potential suppliers, and inquire about their capabilities for producing custom orders. It’s essential to discuss tolerances and any special treatments, such as coatings or heat treatments, to ensure the final product meets your expectations. -

What are the typical payment terms and options when sourcing bronze or brass internationally?

Payment terms can vary widely depending on the supplier and the relationship established. Common practices include upfront deposits followed by balance payments upon shipment or delivery. Options such as letters of credit, bank transfers, and payment through escrow services are also prevalent. Always negotiate payment terms that align with your cash flow needs and ensure they are documented in the purchase agreement. -

How can I ensure quality assurance (QA) in my bronze or brass procurement?

To guarantee quality assurance, establish clear specifications and standards for the materials you require. Request certification documents from suppliers that validate the chemical composition and mechanical properties of the alloys. Implement an inspection protocol for incoming shipments, including visual inspections and material testing, to confirm compliance with your quality standards before final acceptance. -

What logistical considerations should I keep in mind when importing bronze or brass?

Logistical considerations include shipping methods, customs clearance, and potential tariffs or import duties. Determine the most efficient shipping options based on delivery timelines and costs, and ensure that your suppliers are familiar with the documentation required for smooth customs processing. Additionally, factor in lead times for production and shipping to avoid delays that could affect your project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Is Bronze And Brass The Same Thing Manufacturers & Suppliers List

1. Rotax Metals – Brass and Bronze Alloys

Domain: rotaxmetals.net

Registered: 2003 (22 years)

Introduction: Brass and bronze are both alloys of copper but differ in composition: brass is made of copper and zinc, while bronze is made of copper and tin. Brass has a bright gold, copper, or silver color, while bronze has a reddish-brown or reddish-gold color that oxidizes to dark brown or green. Brass is more malleable than bronze, making it less likely to break when worked. Both alloys are effective conduc…

2. The Craftsman Blog – Brass and Bronze Alloys

Domain: thecraftsmanblog.com

Registered: 2012 (13 years)

Introduction: Brass and bronze are two common copper-based alloys with distinct differences.

**Bronze:**

– Composition: Primarily 88% copper and 12% tin, can include other metals like arsenic, phosphorous, aluminum, manganese, silicone, and nickel.

– Color: Deep red or bright brownish.

– Properties: Highly resistant to corrosion, low melting point (~950 °C), easy machinability, does not produce sparks when…

3. Saxon – Bronze Saxophones

Domain: saxontheweb.net

Registered: 2001 (24 years)

Introduction: Bronze saxophones are typically made of 93% Copper, 5% Zinc, and 2% Tin. They are generally considered to be sturdier and more rigid than brass saxophones, which are made with zinc instead of tin. The weight of bronze saxophones is often greater; for example, the Bauhaus Walstein “Original” tenor weighs 3.65kg compared to 2kg for their brass T-M2L tenor. Some players believe that bronze can produc…

4. WaykenRM – Metal Solutions

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: Brass, bronze, and copper are metallic materials known for high electric/thermal conductivity, corrosion resistance, and thermal resistance. They are used in various industries including electronics, artwork, architecture, and machinery. Key differences include: 1. Element Composition: Copper is a natural metal; brass is an alloy of copper and zinc; bronze is an alloy of copper and tin. 2. Corrosi…

5. Metal Supermarkets – Copper & Brass

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Copper: Pure elemental metal with reddish-brown hue; excellent thermal and electrical conductivity; used in electrical wiring and electronics; antimicrobial properties; available in various grades including oxygen-free copper for high conductivity applications. Brass: Alloy of copper and zinc; brighter yellowish appearance; enhanced strength and malleability; used in decorative arts, plumbing fixt…

Strategic Sourcing Conclusion and Outlook for is bronze and brass the same thing

In summary, understanding the distinctions between bronze and brass is crucial for international B2B buyers seeking to optimize their sourcing strategies. Both materials offer unique properties that cater to diverse applications, from decorative uses to highly specialized industrial components. Brass, with its malleability and corrosion resistance, is ideal for plumbing and decorative items, while bronze excels in environments requiring superior strength and resistance to saltwater corrosion.

Strategic sourcing of these materials not only enhances product quality but also fosters long-term supplier relationships, ensuring consistent supply and competitive pricing. As markets evolve, leveraging the unique characteristics of each alloy can lead to innovative applications and improved operational efficiency.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should consider the specific requirements of their projects when selecting between bronze and brass. Engaging with knowledgeable suppliers who can provide tailored solutions will be essential in navigating the complexities of the global metals market. By prioritizing informed sourcing decisions, businesses can position themselves for success in an increasingly competitive landscape.