Introduction: Navigating the Global Market for is brass softer than copper

Navigating the complexities of material selection can be daunting for international B2B buyers, particularly when considering the question, “Is brass softer than copper?” Understanding the properties and applications of these two metals is critical for sourcing the right materials for diverse projects, whether in construction, electronics, or decorative arts. This guide offers a comprehensive overview of the differences between brass and copper, including their metallurgic properties, visual characteristics, and specific applications across various industries.

In addition to clarifying the relative softness of brass compared to copper, this resource delves into vital considerations such as supplier vetting, cost comparisons, and the nuances of alloy compositions. By providing actionable insights tailored to the needs of buyers from Africa, South America, the Middle East, and Europe—regions characterized by unique market dynamics—this guide empowers decision-makers to make informed purchasing choices. Whether you are in Saudi Arabia seeking high-quality plumbing materials or in Vietnam evaluating decorative applications, understanding these metals will enhance your sourcing strategy and ensure you achieve the best value for your investments.

Understanding is brass softer than copper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

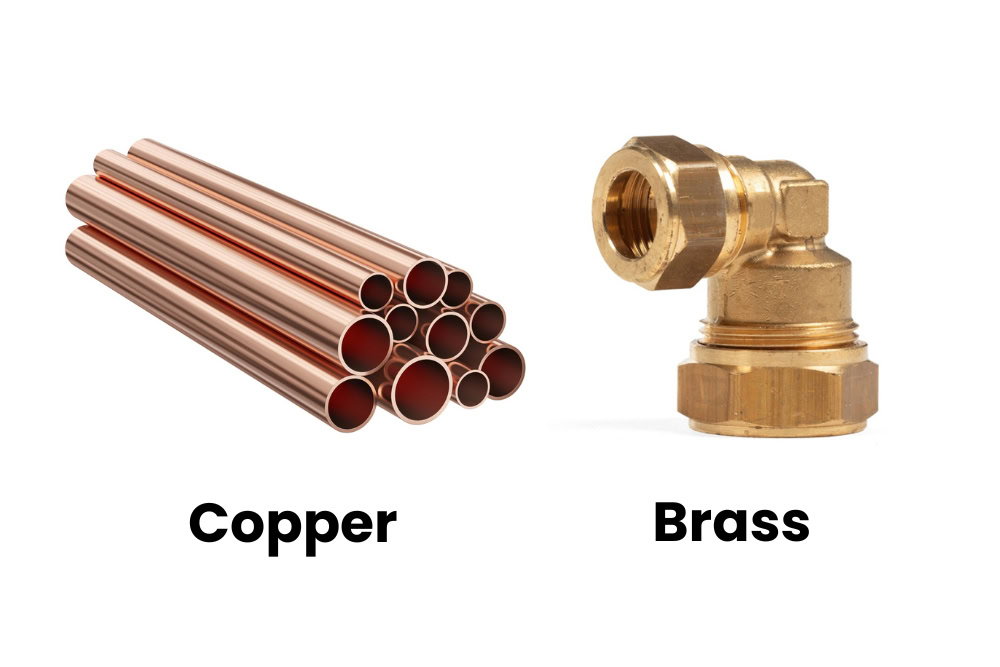

| Copper | Pure metal, reddish-brown color, high electrical conductivity | Electrical wiring, plumbing, roofing, electronics | Pros: Excellent conductivity, corrosion-resistant. Cons: Softer, more expensive than brass. |

| Brass (Standard) | Alloy of copper and zinc, gold-like appearance, moderate hardness | Decorative items, plumbing fittings, musical instruments | Pros: Attractive finish, good corrosion resistance. Cons: Less conductive than copper, can crack under stress. |

| Brass (High-Zinc) | Increased zinc content, higher strength and hardness | Industrial applications, automotive parts, machinery | Pros: Greater strength, improved wear resistance. Cons: Reduced electrical conductivity, more expensive than standard brass. |

| Brass (Leaded) | Contains lead for enhanced machinability | Precision machining, valve components, fasteners | Pros: Easy to machine, good surface finish. Cons: Not suitable for food applications due to lead content. |

| Brass (Manganese) | Incorporates manganese for enhanced corrosion resistance | Marine applications, plumbing fixtures, electrical components | Pros: Excellent corrosion resistance, strong mechanical properties. Cons: Higher cost, limited availability. |

What are the Characteristics of Copper for B2B Buyers?

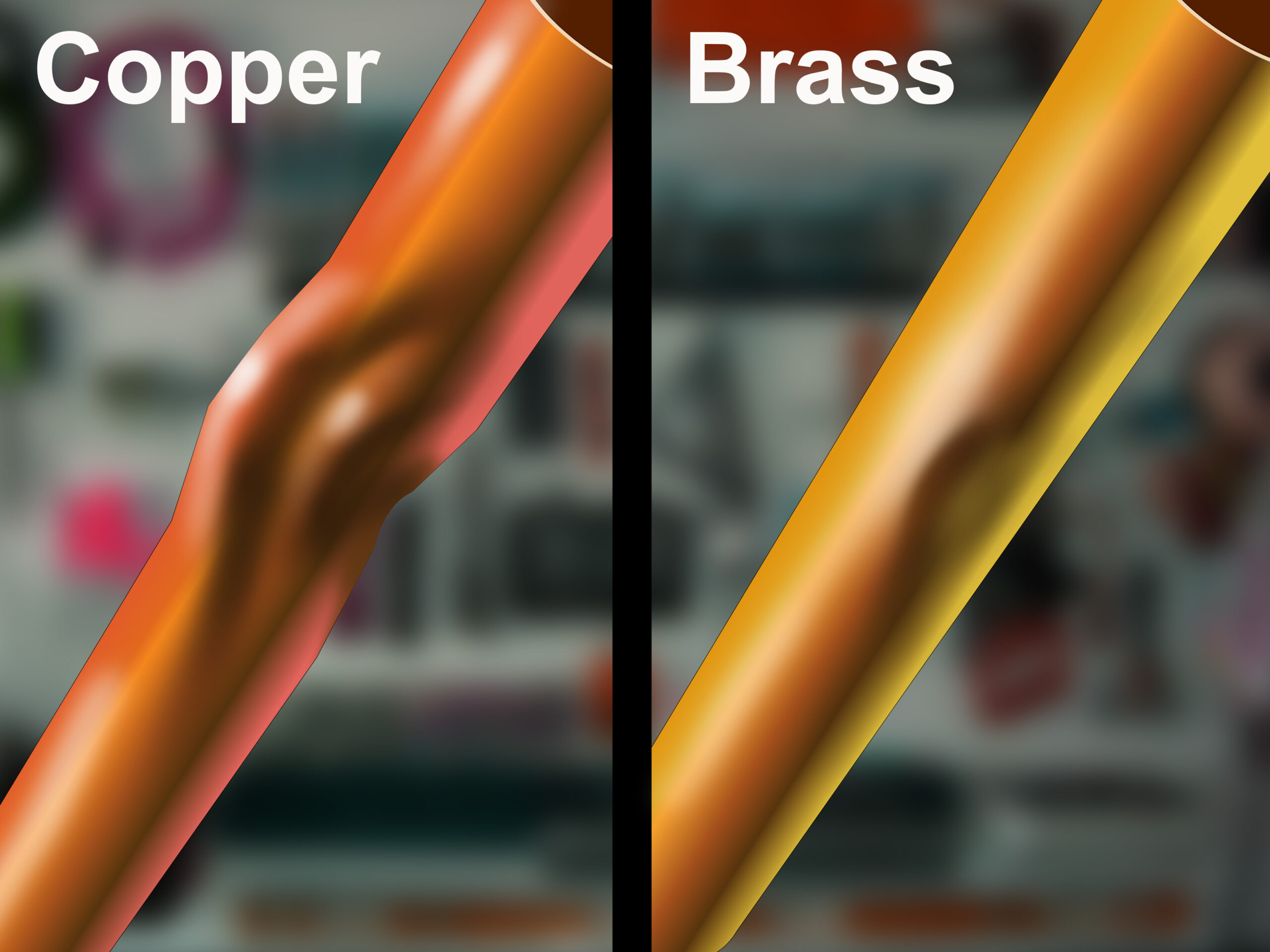

Copper is a naturally occurring metal known for its exceptional electrical conductivity and malleability. It features a reddish-brown hue and is highly resistant to corrosion, making it ideal for applications in electrical wiring, plumbing, and roofing. B2B buyers should consider copper for projects that require high conductivity and durability. However, its softness can limit its use in high-stress applications, and its higher price point compared to brass can affect budget considerations.

How Does Standard Brass Differ from Copper?

Standard brass is an alloy primarily composed of copper and zinc, giving it a gold-like appearance and moderate hardness. It is widely used in decorative items, plumbing fittings, and musical instruments due to its aesthetic appeal and good corrosion resistance. B2B buyers should assess the balance between cost and desired properties; while brass offers a visually appealing option, it has lower electrical conductivity compared to copper and may crack under significant stress.

What Advantages Does High-Zinc Brass Offer?

High-zinc brass features increased zinc content, enhancing its strength and hardness. This variant is commonly employed in industrial applications, automotive parts, and machinery, where durability is paramount. B2B buyers should consider high-zinc brass for projects requiring robust materials that can withstand wear and tear. However, it is essential to note that while it offers improved strength, it sacrifices some electrical conductivity compared to copper and standard brass.

Why Choose Leaded Brass for Precision Applications?

Leaded brass contains added lead to enhance its machinability, making it a preferred choice for precision machining and components like valves and fasteners. It provides a smooth surface finish and is easier to work with, which can reduce manufacturing costs. However, B2B buyers must be cautious as leaded brass is unsuitable for food-related applications due to potential health risks. The benefits of ease of machining need to be weighed against safety regulations.

What are the Benefits of Manganese Brass?

Brass that incorporates manganese offers superior corrosion resistance and strong mechanical properties, making it suitable for marine applications and plumbing fixtures. This variant is particularly valuable in environments where exposure to moisture and corrosive elements is prevalent. B2B buyers should consider manganese brass for projects that demand longevity and reliability in challenging conditions, although its higher cost and limited availability may be factors to evaluate in the purchasing decision.

Key Industrial Applications of is brass softer than copper

| Industry/Sector | Specific Application of is brass softer than copper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Engineering | Electrical connectors and terminals | High conductivity and corrosion resistance | Ensure compliance with international standards and certifications. |

| Plumbing and HVAC | Fittings and valves for plumbing systems | Excellent durability and resistance to corrosion | Consider local regulations and availability of specific brass grades. |

| Automotive | Engine components and fittings | Enhanced strength and lower weight | Focus on sourcing materials that meet automotive industry specifications. |

| Musical Instruments | Wind instruments and components | Superior acoustic properties and malleability | Verify the alloy composition for optimal sound quality and durability. |

| Decorative Hardware | Door handles, knobs, and fixtures | Aesthetic appeal and antimicrobial properties | Assess the finish quality and design compatibility with existing products. |

What Are the Key Industrial Applications of Brass Being Softer Than Copper?

Brass’s relative softness compared to copper makes it a preferred choice in various electrical applications, particularly for connectors and terminals. The softer nature allows for easier machining and forming, which is crucial when creating intricate designs that require precise fitting. Additionally, the corrosion resistance of brass enhances the longevity of electrical components, making them reliable for international buyers who often face diverse environmental conditions.

In plumbing and HVAC sectors, brass fittings and valves leverage their softer properties to create tight seals, preventing leaks. This softness allows for easier installation and adjustments, which is vital for projects in regions with fluctuating temperatures and humidity levels, such as parts of Africa and the Middle East. Buyers should ensure that the brass grades sourced comply with local plumbing standards to guarantee performance and safety.

The automotive industry benefits from brass’s characteristics in engine components and fittings. The alloy’s softer nature contributes to weight reduction while maintaining strength, crucial for improving fuel efficiency. International buyers should prioritize sourcing materials that meet specific automotive standards, as this ensures compatibility with various vehicle designs and enhances overall performance.

In the realm of musical instruments, particularly wind instruments, brass’s softer quality allows for detailed craftsmanship and better acoustic properties. The malleability of brass facilitates the creation of complex shapes that contribute to sound quality. Manufacturers must confirm the alloy composition to ensure optimal performance, especially for international markets where musical standards may vary.

Lastly, in decorative hardware, the aesthetic appeal of brass combined with its antimicrobial properties makes it an excellent choice for door handles and fixtures. Its softness allows for intricate designs that enhance visual appeal while providing practical benefits. Buyers should evaluate the finish quality and design compatibility with existing hardware to ensure a cohesive look in their projects.

3 Common User Pain Points for ‘is brass softer than copper’ & Their Solutions

Scenario 1: Understanding Material Hardness for Manufacturing Processes

The Problem: A manufacturer in South America is faced with a dilemma regarding the selection of materials for a new product line that requires both durability and aesthetic appeal. The team is debating whether to use brass or copper, given their differing properties. The primary concern is that brass, while it may be visually appealing, is often perceived as softer than copper, which could impact the product’s longevity and performance under stress. This misunderstanding can lead to production delays and increased costs if the wrong material is selected.

The Solution: To address this challenge, it is crucial for the manufacturer to conduct a thorough analysis of the mechanical properties of both metals. They should consult with material experts and refer to detailed specifications on the hardness, tensile strength, and corrosion resistance of various brass and copper alloys. It is advisable to create prototypes using both materials and conduct stress tests to evaluate their performance in real-world conditions. By documenting these findings, the manufacturer can make an informed decision based on empirical data, ensuring that the selected material meets both aesthetic and functional requirements.

Scenario 2: Misconceptions About Corrosion Resistance in Different Environments

The Problem: An industrial buyer from the Middle East is tasked with sourcing materials for a coastal construction project. The buyer is unsure whether brass or copper will offer better performance against corrosion due to the high salinity of the environment. There is a common misconception that brass is softer and thus more susceptible to corrosion, leading to potential project delays and budget overruns if the wrong material is chosen.

The Solution: To mitigate this risk, the buyer should leverage industry knowledge regarding the corrosion resistance of both metals. It is essential to recognize that while copper is a pure metal, brass’s alloy composition can actually enhance its corrosion resistance, particularly in marine environments. The buyer should seek brass alloys that contain higher levels of manganese or silicon, which are known to improve corrosion resistance. Additionally, consulting with suppliers who specialize in marine-grade metals can provide insights into the best options for the project. Implementing a rigorous selection process that includes testing samples in simulated environmental conditions will help ensure that the chosen material stands up to the specific challenges of the coastal application.

Scenario 3: Cost Implications of Material Choices in Project Budgets

The Problem: A procurement manager in Europe is evaluating options for a new line of plumbing fixtures. The team is considering using either brass or copper based on budget constraints. While brass is generally less expensive, the perception that copper is a more durable material leads to hesitation in making a decision. The potential for increased long-term costs due to maintenance and replacement could affect the overall project budget.

The Solution: The procurement manager should perform a total cost of ownership analysis that goes beyond initial purchase prices. This analysis should consider factors such as the longevity of each material, maintenance costs, and the potential for product failure over time. By engaging with suppliers who can provide life cycle assessments for both brass and copper fixtures, the manager can quantify the long-term value of each option. Additionally, exploring bulk purchasing agreements or long-term contracts with suppliers can yield cost savings on high-quality brass or copper, making it feasible to choose the material that best meets performance requirements without compromising the budget.

Strategic Material Selection Guide for is brass softer than copper

What Are the Key Properties of Brass and Copper in B2B Applications?

When evaluating whether brass is softer than copper, it’s essential to consider the metallurgical properties of both materials. Copper is a pure metal known for its excellent electrical conductivity, malleability, and corrosion resistance. It has a melting point of approximately 1,084°C, making it suitable for high-temperature applications. Brass, on the other hand, is an alloy primarily composed of copper and zinc. Its properties can vary significantly based on the zinc content and any additional alloying elements, which can enhance characteristics like strength and corrosion resistance. Generally, brass is considered harder than copper, which impacts its applications across various industries.

What Are the Pros and Cons of Using Brass vs. Copper?

Copper

Pros:

– Exceptional electrical and thermal conductivity, making it ideal for electrical components and wiring.

– High resistance to corrosion, ensuring longevity in various environments.

– Antimicrobial properties, beneficial for applications in healthcare and food industries.

Cons:

– Higher cost compared to brass, which may be a concern for budget-sensitive projects.

– Softer nature can lead to wear and deformation under heavy stress, limiting its use in high-load applications.

Brass

Pros:

– Greater hardness and strength compared to copper, making it suitable for mechanical components and fixtures.

– Excellent corrosion resistance, particularly in marine environments when alloyed with higher zinc content.

– Versatile in manufacturing due to its machinability and ability to be cast into complex shapes.

Cons:

– Lower electrical conductivity than copper, which may limit its use in certain electrical applications.

– Can be more brittle under stress, especially if the zinc content is high, leading to cracking.

How Do Material Properties Impact Application Suitability?

The choice between brass and copper significantly affects the performance of the final product. For example, copper is preferred in electrical applications due to its superior conductivity, while brass is often chosen for plumbing fixtures and decorative items due to its aesthetic appeal and durability. Additionally, brass’s ability to resist corrosion makes it a popular choice in environments exposed to moisture, such as marine applications. Understanding the specific media compatibility is crucial; for instance, while copper is excellent for water systems, brass may be more suitable for applications involving acids or other corrosive substances.

What Should International B2B Buyers Consider When Selecting Brass or Copper?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, compliance with local standards is paramount. Familiarity with standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards) can influence material selection. Additionally, buyers should consider the availability of materials in their region, as well as logistical factors like shipping costs and tariffs. Preferences may also vary by region; for example, buyers in Europe may prioritize sustainability and recyclability, while those in the Middle East might focus on durability in high-temperature environments.

| Material | Typical Use Case for is brass softer than copper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring and components | Superior electrical conductivity | Higher cost and softer nature | High |

| Brass | Plumbing fixtures and decorative items | Greater hardness and corrosion resistance | Lower electrical conductivity and potential brittleness | Medium |

| Copper Alloy (with tin) | Marine applications | Enhanced corrosion resistance | Can be more expensive than standard brass | High |

| Brass Alloy (with aluminum) | Aerospace components | Lightweight and strong | May have lower thermal conductivity | Medium |

This strategic material selection guide provides a comprehensive overview of the differences between brass and copper, highlighting the importance of understanding their properties, advantages, and limitations. By considering these factors, international B2B buyers can make informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for is brass softer than copper

What Are the Key Stages in the Manufacturing Process of Brass and Copper?

Understanding the manufacturing processes for brass and copper is crucial for B2B buyers who need high-quality materials for various applications. The production of these metals involves several stages, including material preparation, forming, assembly, and finishing.

Material Preparation: What Does It Involve?

The first step in manufacturing brass or copper involves material preparation, which includes selecting and sourcing high-grade raw materials. For brass, this means acquiring copper and zinc in specific proportions, depending on the desired alloy characteristics. In contrast, copper is sourced directly in its raw form.

Once the materials are acquired, they undergo purification processes to remove impurities that could compromise quality. This step is vital for ensuring that the final product meets industry standards, particularly for applications requiring high conductivity or corrosion resistance.

How Are Brass and Copper Formed?

After material preparation, the next stage is forming, where the raw materials are shaped into usable forms. Common techniques include extrusion, rolling, and forging.

-

Extrusion: This method involves forcing heated metal through a die to create long shapes like rods or tubes. It is ideal for producing uniform cross-sections.

-

Rolling: In this technique, large slabs of metal are passed through rollers to achieve thinner sheets. This is particularly useful for applications requiring flat metal components.

-

Forging: This process involves shaping metal using compressive forces, which enhances its strength. Brass is often forged into components like fittings and valves.

Each of these techniques has its own set of advantages, allowing manufacturers to tailor the properties of the finished product to meet specific needs.

What Does the Assembly Stage Entail?

In the assembly phase, different components made from brass or copper are put together to form finished products. This stage may involve soldering, welding, or mechanical fastening, depending on the requirements of the application.

For instance, in the plumbing industry, copper pipes are often joined using soldering techniques that ensure a watertight seal. In contrast, brass components might be assembled using mechanical fasteners for enhanced durability.

What Are the Finishing Techniques Used in Brass and Copper Manufacturing?

Finishing is the final stage in the manufacturing process, where the appearance and surface properties of the product are enhanced. Common techniques include:

-

Polishing: This improves the aesthetic appeal and can also enhance corrosion resistance.

-

Coating: Applying protective coatings can further increase durability and resistance to environmental factors.

-

Heat Treatment: This process alters the physical properties of the metal, improving its strength and ductility.

Finishing techniques vary based on the intended use of the product. For example, decorative items may undergo more extensive polishing than industrial components.

What Quality Assurance Measures Are Essential for Brass and Copper Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for brass and copper, ensuring that products meet both international standards and customer specifications.

Which International Standards Should Be Considered?

B2B buyers should be familiar with several international quality standards, including:

-

ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate consistent quality in their products.

-

CE Marking: Particularly relevant in Europe, this marking indicates that a product meets EU safety, health, and environmental protection requirements.

-

API Standards: For industries like oil and gas, adherence to American Petroleum Institute (API) standards ensures that materials can withstand the rigors of harsh environments.

These certifications help buyers assess the reliability and quality of suppliers.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are critical for ensuring product integrity. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor processes and product quality, allowing for immediate corrections if necessary.

-

Final Quality Control (FQC): Once production is complete, finished products undergo rigorous testing to verify they meet all specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is crucial. Here are some actionable strategies:

-

Conduct Audits: Regular audits of suppliers can reveal the effectiveness of their quality control measures. Buyers should consider both on-site inspections and third-party audits.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including test results and compliance with relevant standards.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s quality control practices.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control:

-

Cultural Differences: Understanding local manufacturing practices and quality expectations can help in establishing effective communication with suppliers.

-

Regulatory Compliance: Different regions may have specific regulatory requirements that impact product quality. Buyers should ensure that suppliers are compliant with local laws and international standards.

-

Logistics and Supply Chain: The complexities of international shipping can affect product quality. Buyers should work closely with suppliers to ensure that products are handled properly during transit.

By understanding the manufacturing processes and quality assurance measures for brass and copper, B2B buyers can make informed decisions that align with their specific needs and industry standards. This knowledge not only aids in supplier selection but also enhances overall supply chain efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘is brass softer than copper’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in understanding the differences between brass and copper, specifically addressing the question of whether brass is softer than copper. By following this checklist, you can make informed decisions when procuring materials that meet your project requirements, ensuring the right choice for your applications.

Step 1: Define Your Technical Specifications

Before sourcing materials, clearly outline your project requirements. This includes understanding the specific properties needed, such as hardness, electrical conductivity, corrosion resistance, and thermal stability. Knowing these parameters helps narrow down your material choices, ensuring you select the right type of brass or copper for your needs.

Step 2: Research Material Properties

Understanding the metallurgic properties of brass and copper is critical. Brass, being an alloy primarily of copper and zinc, generally exhibits greater hardness and strength compared to pure copper. Familiarize yourself with the specific grades and types of brass, as variations in zinc content can significantly affect mechanical properties.

Step 3: Compare Cost Implications

Evaluate the pricing of both materials as part of your procurement strategy. Generally, brass is more affordable than copper due to its composite nature, but consider the long-term costs associated with durability and maintenance. Assess the total cost of ownership to determine which material provides the best value for your application.

Step 4: Verify Supplier Certifications

When selecting suppliers, it’s essential to ensure they hold relevant certifications. Look for ISO certifications or quality assurance standards that indicate compliance with international manufacturing protocols. This step is crucial for maintaining quality control and ensuring that the materials meet your specifications.

Step 5: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to assess their credibility. Request detailed company profiles, case studies, and references from other clients within your industry or region. A robust supplier with a proven track record can significantly reduce risks associated with sourcing.

Step 6: Assess Delivery and Logistics Capabilities

Confirm that your chosen supplier can meet your logistical needs, including timely delivery and shipping options. Understanding their supply chain capabilities is vital, especially for international buyers, as delays can impact project timelines. Evaluate their inventory management practices to ensure they can fulfill your order efficiently.

Step 7: Establish Post-Purchase Support

Finally, inquire about the support services offered by the supplier after the purchase. This includes warranty options, technical support, and return policies. A reliable supplier should provide assistance in case of defects or issues, ensuring a smooth experience and fostering a long-term partnership.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing brass and copper materials, ensuring they select the right metal for their specific applications.

Comprehensive Cost and Pricing Analysis for is brass softer than copper Sourcing

In the competitive landscape of sourcing brass and copper materials, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers. The comparison between these two metals not only hinges on their physical properties but also on a myriad of cost components that influence procurement decisions.

What Are the Key Cost Components in Sourcing Brass and Copper?

When assessing the costs involved in sourcing brass and copper, several components come into play:

-

Materials: The base price of brass is generally lower than copper, with high-quality copper costing up to £6.50 per kilogram compared to brass at around £4. This discrepancy stems from copper’s broader applications in industries like electrical and plumbing, which drives its demand and price.

-

Labor: Labor costs can vary significantly based on the region and the complexity of the manufacturing processes involved. For example, regions with skilled labor might command higher wages, influencing the overall cost of production.

-

Manufacturing Overhead: This includes the costs associated with factory operations, utilities, and equipment maintenance. Brass, being an alloy, may require different processing techniques compared to pure copper, which can affect overhead costs.

-

Tooling: The need for specialized tooling can add to the cost, particularly when producing custom or complex parts. Brass often requires different tooling compared to copper due to its unique properties, which can impact the overall cost structure.

-

Quality Control (QC): Ensuring the quality of materials is critical, especially for applications in industries like aerospace and medical. The costs associated with QC processes can vary based on the supplier’s standards and certifications.

-

Logistics: Transportation and shipping costs are significant, especially for international buyers. Incoterms can affect logistics pricing, determining whether costs are borne by the seller or the buyer.

-

Margin: Supplier margins can vary based on market conditions, competition, and the supplier’s operational efficiency. Understanding these margins can aid in effective negotiation.

How Do Price Influencers Affect Brass and Copper Sourcing?

Several factors can influence the pricing of brass and copper:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger volumes often lead to bulk discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Customized orders tailored to specific applications can lead to higher prices due to the additional processing and material costs involved.

-

Materials and Quality Certifications: The quality of the raw materials and the presence of certifications (such as ISO standards) can influence costs. High-quality materials may command higher prices but can offer better durability and performance.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge a premium for their services, but they often offer better quality assurance.

-

Incoterms: Understanding the agreed terms of shipping can help buyers manage logistics costs effectively. Common Incoterms like FOB (Free On Board) or CIF (Cost Insurance Freight) can influence final pricing.

What Are the Best Negotiation Tips for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for effective negotiation:

-

Research Market Prices: Understand the prevailing market rates for brass and copper to ensure you are negotiating from an informed position.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also factors like maintenance, lifespan, and potential resale value to determine the true cost of the materials.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits in terms of pricing flexibility.

-

Leverage Volume: If feasible, consolidate orders to meet minimum volume requirements and negotiate bulk pricing.

-

Be Aware of Pricing Nuances: Understand that prices may fluctuate based on market demand, geopolitical factors, and currency exchange rates, especially when sourcing internationally.

Disclaimer on Indicative Prices

The prices mentioned are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Buyers should conduct thorough research and engage in direct discussions with suppliers to obtain the most accurate and current pricing.

Alternatives Analysis: Comparing is brass softer than copper With Other Solutions

Exploring Alternatives to “Is Brass Softer Than Copper”

In the quest to determine whether brass is softer than copper, it is essential to consider various alternatives that can fulfill similar applications. While the comparison between brass and copper is crucial, other materials and technologies may offer beneficial properties for specific projects. This analysis will help B2B buyers make informed decisions by evaluating the performance, cost, ease of implementation, maintenance, and best use cases of each alternative.

| Comparison Aspect | Is Brass Softer Than Copper | Alternative 1: Aluminum | Alternative 2: Stainless Steel |

|---|---|---|---|

| Performance | Softer and more malleable | Lightweight, good strength-to-weight ratio | High strength, excellent corrosion resistance |

| Cost | Moderate cost | Generally cheaper | Higher cost due to alloying elements |

| Ease of Implementation | Relatively easy to work with | Easy to fabricate and weld | More challenging to machine |

| Maintenance | Requires polishing to maintain appearance | Low maintenance, resistant to corrosion | Requires regular maintenance to avoid rust |

| Best Use Case | Decorative items, musical instruments | Aerospace, automotive components | Industrial applications, kitchenware |

In-Depth Analysis of Alternatives

Alternative 1: Aluminum

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio. It is often more cost-effective than brass and is easier to fabricate and weld, making it suitable for various applications, particularly in the aerospace and automotive industries. However, while aluminum is resistant to corrosion, it lacks the aesthetic appeal of brass, which can be an essential factor for decorative applications. Additionally, aluminum is not as malleable as brass, limiting its use in applications requiring intricate shapes.

Alternative 2: Stainless Steel

Stainless steel is renowned for its high strength and exceptional corrosion resistance. It is ideal for industrial applications where durability is paramount, such as in kitchenware and medical instruments. However, stainless steel tends to be more expensive than brass, and its machining can be more challenging, which may increase production costs. Maintenance is required to prevent rust, especially in environments with high humidity. While stainless steel may not offer the same aesthetic qualities as brass, its performance in demanding environments makes it a preferred choice for many B2B applications.

Conclusion: Choosing the Right Material for Your Needs

When evaluating whether brass is softer than copper or considering alternatives like aluminum and stainless steel, B2B buyers should focus on the specific requirements of their projects. Factors such as performance, cost, ease of implementation, and maintenance needs will play a critical role in the decision-making process. By aligning the material’s properties with the intended application, buyers can ensure optimal results and long-term satisfaction with their chosen solution. This thoughtful approach not only enhances project outcomes but also supports cost efficiency and sustainability in production.

Essential Technical Properties and Trade Terminology for is brass softer than copper

What Are the Key Technical Properties of Brass and Copper?

When evaluating whether brass is softer than copper, it’s essential to understand the technical properties that define these materials. This knowledge helps B2B buyers make informed decisions based on their specific applications.

Material Composition and Grades

Brass is an alloy primarily composed of copper and zinc, with the proportions varying to achieve desired characteristics. Common grades include C260 (cartridge brass), C270 (yellow brass), and C360 (free-cutting brass). Understanding material grades is crucial for B2B buyers, as they dictate the mechanical properties, corrosion resistance, and machinability of the alloy. Selecting the correct grade can enhance product performance and longevity.

Hardness and Strength

Brass is generally harder than copper due to the presence of zinc and other alloying elements. The hardness is typically measured using the Rockwell or Brinell scales. This property is vital for applications requiring durability, such as fittings, fasteners, and decorative items. A higher hardness level also translates to better wear resistance, which can be a deciding factor in selecting materials for heavy-duty applications.

Electrical Conductivity

Copper boasts superior electrical conductivity compared to brass, making it the preferred choice for electrical applications. Brass, while conductive, offers some resistance due to its alloy composition. For businesses in sectors like telecommunications or electronics, this distinction is critical. The choice between the two materials can impact the efficiency and safety of electrical systems.

Corrosion Resistance

Brass generally exhibits better corrosion resistance than copper, especially in marine environments. The addition of zinc enhances brass’s ability to withstand oxidation and other forms of degradation. For industries such as plumbing or marine construction, this property can significantly influence maintenance costs and the lifespan of products.

Thermal Conductivity

Copper also has a higher thermal conductivity than brass, which is vital in applications involving heat transfer, such as heat exchangers and cooling systems. Buyers in industries that require efficient heat dissipation must consider this factor when choosing between the two materials.

What Are Common Trade Terminology and Jargon in the Brass and Copper Industry?

Understanding industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, knowing whether a supplier is an OEM can help in assessing the quality and reliability of the products they offer.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand pricing structures and inventory management, as it affects overall procurement strategies.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific goods or services. It is an essential step in the procurement process, allowing buyers to compare offers and negotiate better terms.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers mitigate risks and understand their obligations in international transactions.

Tolerance

Tolerance refers to the allowable variation in the dimensions of a manufactured part. Understanding tolerance is critical for buyers in industries where precision is essential, such as aerospace or automotive manufacturing.

Lead Time

Lead time is the period between the initiation of an order and its completion. Knowing lead times is vital for supply chain planning and inventory management, allowing buyers to align their operations with supplier capabilities.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding their material choices and procurement strategies, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the is brass softer than copper Sector

Market Overview & Key Trends: What Are the Current Dynamics in Brass and Copper Sourcing?

The global metals market is experiencing significant shifts, influenced by economic recovery post-pandemic, technological advancements, and evolving supply chain dynamics. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate their sourcing strategies, they must consider the unique properties of brass and copper. Brass, being an alloy of copper and zinc, is generally softer than pure copper, which impacts its applications across various industries.

Emerging trends in sourcing emphasize the importance of adaptability and resilience. Buyers are increasingly leveraging digital procurement platforms to streamline sourcing processes, enabling access to a broader range of suppliers. In addition, the rise of Industry 4.0 technologies—such as IoT and AI—facilitates better inventory management and predictive analytics, allowing businesses to respond swiftly to market changes.

In terms of market dynamics, the demand for copper remains robust due to its superior electrical conductivity, making it essential in industries like telecommunications and electrical manufacturing. Conversely, brass is gaining traction in decorative applications and plumbing, where its aesthetic appeal and corrosion resistance are prized. B2B buyers should remain vigilant about fluctuating commodity prices, which can impact sourcing decisions and operational costs.

Sustainability & Ethical Sourcing in B2B: How Does Environmental Impact Influence Brass and Copper Procurement?

The sustainability narrative is reshaping B2B procurement strategies, making it imperative for buyers to prioritize ethical sourcing. The environmental impact of metal extraction and processing is significant; thus, companies are increasingly scrutinizing their supply chains. For brass and copper, this involves assessing the carbon footprint associated with mining and refining processes.

Sourcing ‘green’ materials is becoming a key differentiator in the marketplace. Buyers should seek suppliers who are certified in sustainable practices, such as ISO 14001, which denotes effective environmental management systems. Furthermore, opting for recycled brass or copper can significantly reduce environmental impact, as recycling uses less energy compared to primary production.

Ethical sourcing also extends to labor practices. Ensuring that suppliers adhere to fair labor standards is crucial, particularly in regions where mining is prevalent. This not only safeguards the reputation of B2B companies but also aligns with the growing consumer demand for ethically sourced products. By prioritizing sustainability and ethical sourcing, companies can enhance their brand value while contributing positively to global environmental goals.

Brief Evolution/History: How Have Brass and Copper Evolved in B2B Applications?

The use of brass and copper dates back thousands of years, with both metals playing pivotal roles in the development of human civilization. Copper was one of the first metals to be used by mankind, known for its malleability and conductivity. Over time, the discovery of alloys led to the creation of brass, combining copper with zinc to enhance its properties.

Historically, brass became prominent during the Industrial Revolution, where its strength and resistance to corrosion made it a preferred material in machinery, plumbing, and decorative arts. Today, both metals have diversified applications, adapting to modern technological needs while maintaining their fundamental properties. As industries continue to evolve, understanding the historical context of these materials can provide valuable insights into their current applications and market potential.

Frequently Asked Questions (FAQs) for B2B Buyers of is brass softer than copper

-

1. How do I determine whether brass or copper is better for my application?

To determine whether brass or copper is better for your application, consider the specific requirements such as strength, corrosion resistance, and electrical conductivity. Brass, being an alloy of copper and zinc, is generally harder and more durable than pure copper. If your project requires high electrical conductivity, copper is the superior choice. Conversely, if you need a material that is aesthetically pleasing and resistant to corrosion, brass may be more suitable. Assess your project’s environmental conditions and stress factors to make an informed decision. -

2. Is brass softer than copper, and how does that affect my project?

Yes, brass is generally softer than copper. This softness can affect your project in terms of machining and fabrication. While brass is easier to shape and mold, it may not withstand high-stress applications as well as copper, which has better tensile strength. If your project involves heavy wear or structural integrity, consider the mechanical properties of both metals and choose accordingly. Understanding the specific grades and compositions can also help you select the right material for your needs. -

3. What are the key differences in corrosion resistance between brass and copper?

Brass typically offers better corrosion resistance than copper due to the addition of zinc and other alloying elements. This makes brass suitable for applications exposed to moisture or corrosive environments. However, copper has inherent antimicrobial properties, which can be advantageous in medical or high-touch applications. When selecting materials, consider the specific environmental conditions and potential exposure to corrosive substances to ensure longevity and performance. -

4. How can I ensure the quality of brass or copper when sourcing internationally?

To ensure the quality of brass or copper when sourcing internationally, vet suppliers thoroughly by checking their certifications, production processes, and customer reviews. Request samples to evaluate the material properties before making bulk purchases. Additionally, inquire about quality assurance protocols, such as testing for chemical composition and mechanical properties, to ensure compliance with industry standards. Building a strong relationship with reliable suppliers can also facilitate better quality control. -

5. What customization options are available for brass and copper products?

Customization options for brass and copper products can vary by supplier. Many manufacturers offer services such as specific alloy compositions, surface treatments, and fabrication processes like cutting, bending, or machining to meet your project’s unique specifications. Discuss your requirements upfront and ask for detailed capabilities from potential suppliers. This ensures that you receive materials that not only meet your technical needs but also fit your design specifications. -

6. What are the minimum order quantities (MOQ) for brass and copper?

Minimum order quantities (MOQ) for brass and copper can differ significantly based on the supplier and the specific product. Typically, MOQs can range from a few kilograms to several tons. It’s essential to clarify these terms before committing to a supplier to avoid any unexpected costs. If your project requires smaller quantities, look for suppliers that cater to custom or small-batch orders, especially those experienced in international trade. -

7. What payment terms should I expect when sourcing brass or copper internationally?

Payment terms for sourcing brass or copper internationally can vary widely. Common terms include upfront deposits (typically 30% to 50%) with the balance due upon delivery or after inspection. Some suppliers may offer net payment terms, allowing you to pay within a specified period after receiving the goods. It’s crucial to negotiate terms that align with your cash flow and financial management practices. Always confirm payment methods accepted by suppliers, including wire transfers, credit cards, or letters of credit. -

8. What logistics considerations should I be aware of when importing brass or copper?

When importing brass or copper, consider logistics factors such as shipping costs, lead times, and customs regulations. Ensure that your supplier is familiar with international shipping and can provide necessary documentation like bills of lading and certificates of origin. Research tariffs and duties that may apply to your shipment to avoid unexpected expenses. Collaborating with a reliable freight forwarder can also help streamline the import process and ensure timely delivery of your materials.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Is Brass Softer Than Copper Manufacturers & Suppliers List

1. Reddit – Copper vs. Brass Malleability Discussion

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the malleability of copper compared to brass. A co-worker claims that brass is softer and easier to shape than pure copper, which is often used for musical instruments. The malleability of brass can be modified by adjusting the ratio of copper and zinc. The conversation also touches on the strength of alloys compared to pure metals, with the assertion that alloys are…

2. JingSourcing – Brass vs Copper for Jewelry

Domain: jingsourcing.com

Registered: 2015 (10 years)

Introduction: Brass vs Copper: Color, Price, Hardness | Which is Right for Jewelry? 1. Copper: – Characteristics: Soft, ductile, malleable, reddish-orange color, excellent conductor of electricity. – Uses: Tools, weapons, wiring, construction. 2. Brass: – Composition: Copper alloy with zinc, may contain tin, iron, lead, aluminum, silicon, manganese. – Characteristics: Ductility and strength vary with zinc conte…

3. Mig Welding – Soft Jaws

Domain: mig-welding.co.uk

Registered: 2005 (20 years)

Introduction: This company, Mig Welding – Soft Jaws, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Sivana Spirit – Copper & Brass Essentials

Domain: sivanaspirit.com

Registered: 2004 (21 years)

Introduction: Copper is a soft metal known for its malleability, conductivity, and corrosion resistance, with a reddish-orange color. Brass is an alloy of copper and zinc, typically containing around 70% copper and 30% zinc, and has a yellow color. Copper is denser and heavier than brass, and it has superior electrical and thermal conductivity, making it ideal for electrical wiring and plumbing. Brass is durabl…

5. Prashaant Steel – Brass and Copper Alloys

Domain: prashaantsteel.com

Registered: 2015 (10 years)

Introduction: Brass is a copper alloy containing zinc and other metals like tin, iron, aluminum, lead, silicon, and manganese, contributing to its ductility and strength. Copper is a pure element classified as a transition metal with high electrical conductivity. Key differences include:

1. **Element Composition**: Brass is a copper-zinc alloy; Copper is a pure metal.

2. **Corrosion Resistance**: Brass is mor…

6. Aixi Hardware – Key Metals Overview

Domain: aixihardware.com

Registered: 2019 (6 years)

Introduction: Overview of Brass, Bronze, and Copper:

– Copper: Pure, non-ferrous transition metal.

– Brass: Alloy of copper and zinc (60-90% Cu, 10-40% Zn), strong and malleable.

– Bronze: Alloy of copper and tin (88-95% Cu, 5-12% Sn), durable and robust.

Differences:

– Composition: Brass (Cu + Zn), Bronze (Cu + Sn), Copper (pure).

– Color: Brass (Golden/Yellow), Bronze (Earth-Brown), Copper (Reddish-Bro…

7. Fine Metal – Brass Alloys

Domain: finemetal.ro

Introduction: Brass is an alloy primarily composed of copper and zinc, engineered to be stronger than pure copper due to the addition of zinc. Brass offers improved corrosion resistance and machinability, making it versatile for various applications. The strength of brass can vary significantly depending on the zinc content, with higher zinc content resulting in enhanced strength and hardness. Brass tensile str…

8. Hmaking – Brass and Bronze Alloys

Domain: hmaking.com

Registered: 2021 (4 years)

Introduction: Brass: An alloy of copper (Cu) and zinc (Zn), typically in a 60% to 40% ratio, used for its electrical and thermal conductivity, corrosion resistance, and machinability. Applications include jewelry making and sculpting. Bronze: An alloy of copper and tin (Sn), usually containing about 12% tin, mixed with other elements like aluminum and silicon for enhanced durability and machinability. Applicati…

Strategic Sourcing Conclusion and Outlook for is brass softer than copper

In evaluating whether brass is softer than copper, it is crucial for international B2B buyers to consider the unique properties and applications of each metal. While brass, an alloy of copper and zinc, exhibits greater hardness and durability, copper retains its status as a highly malleable and conductive material. These distinctions are vital for making informed decisions in strategic sourcing, particularly for industries that demand specific metallurgic properties for applications ranging from plumbing to electronics.

Understanding the cost implications is also essential, as brass typically presents a more affordable option compared to copper, making it an attractive choice for budget-conscious projects without compromising on quality. As you navigate procurement decisions, prioritize suppliers who offer a diverse range of high-quality materials, ensuring compatibility with your project requirements.

Looking ahead, the demand for both copper and brass will likely continue to grow across various sectors, particularly in emerging markets in Africa, South America, and the Middle East. By leveraging strategic sourcing and fostering supplier relationships, you can position your business to capitalize on market opportunities. Engage with trusted suppliers to optimize your material choices, ensuring your projects are both cost-effective and aligned with industry standards.