Contents

Manufacturing Insight: Is 17 4 Stainless Steel Magnetic

Understanding Magnetic Properties in 17-4 PH Stainless Steel for Precision Applications

A frequent technical inquiry concerns the magnetic characteristics of 17-4 precipitation hardening (PH) stainless steel. In its annealed condition, 17-4 PH exhibits minimal magnetism due to its predominantly austenitic structure, registering magnetic permeability values near 1.0. However, following specific heat treatments like the H900 or H1025 aging processes, the material transforms partially to martensite, resulting in slight but measurable magnetic response. This property shift is critical for applications requiring non-magnetic performance in sensors, marine hardware, or medical devices, where unintended magnetism could compromise function.

Material behavior under processing directly impacts part performance, underscoring the need for expert manufacturing control. At Honyo Prototype, our CNC machining services specialize in managing 17-4 PH stainless steel with precision, ensuring dimensional accuracy and material integrity are maintained throughout production. Our protocols account for heat treatment effects on magnetic properties, surface finish, and mechanical strength, delivering components that meet stringent aerospace, defense, and industrial specifications.

For projects requiring certified 17-4 PH machining, leverage our Online Instant Quote system to receive detailed pricing and lead time estimates within hours—not days. Simply upload your CAD file to initiate a seamless transition from design to high-fidelity prototype or production run.

| Condition | Magnetic Permeability (Relative) | Typical Application Context |

|---|---|---|

| Annealed | ~1.0 (Non-magnetic) | Base material prior to aging |

| H900 Aged | 20–50 μ (Slightly magnetic) | High-strength structural components |

| H1150 Overaged | <5 μ (Near non-magnetic) | Corrosion-critical environments |

Partner with Honyo to navigate material complexities with engineering rigor, backed by ISO-certified processes and rapid-turnaround CNC capabilities. Start your project today using our Online Instant Quote for immediate, transparent project assessment.

Technical Capabilities

Technical Overview: Magnetic Properties and Machinability of 17-4 PH Stainless Steel

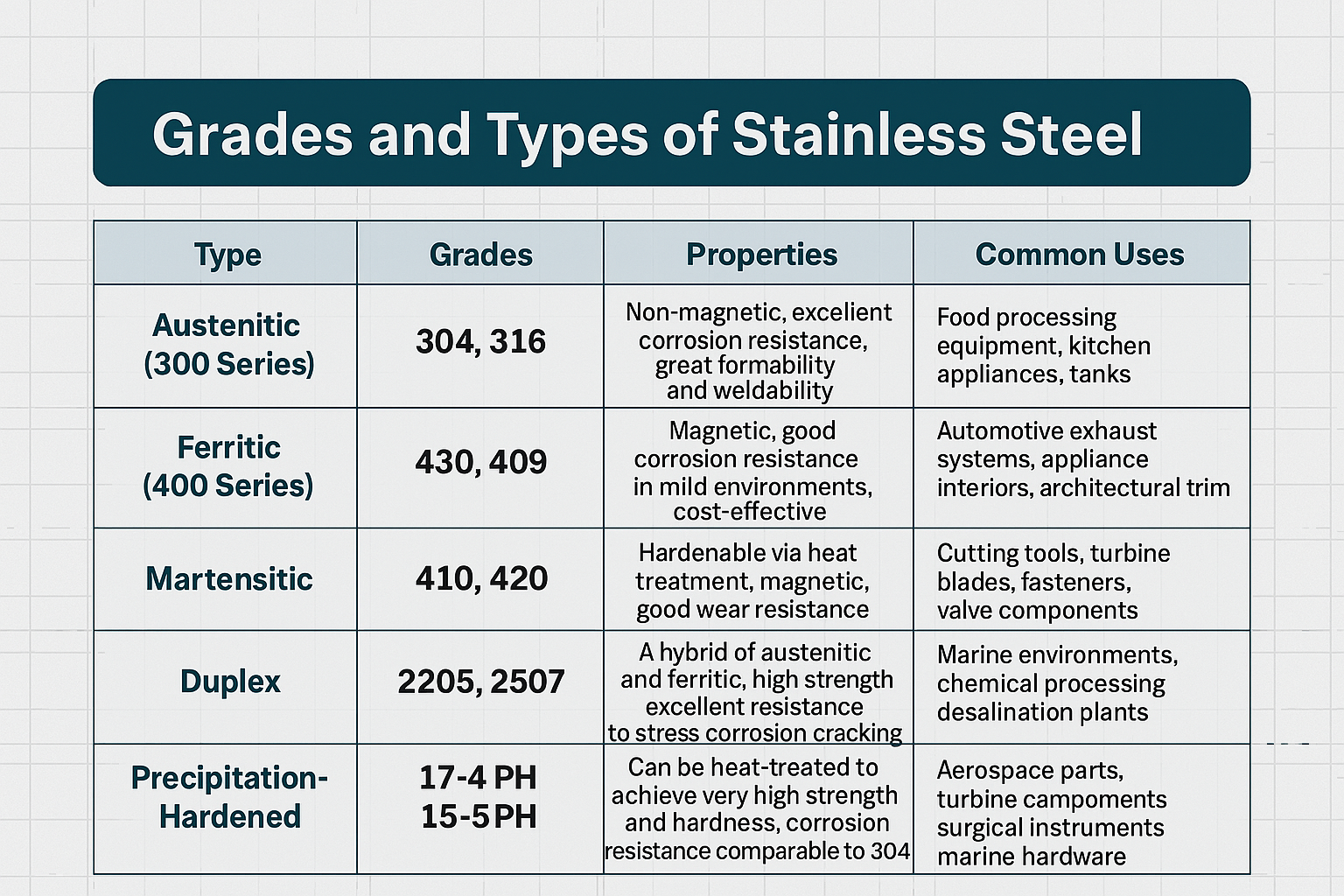

17-4 PH (Precipitation Hardening) stainless steel is a chromium-copper alloy known for its high strength, excellent corrosion resistance, and good machinability. It is mildly magnetic due to its martensitic structure, particularly after heat treatment. This distinguishes it from austenitic stainless steels (e.g., 304, 316), which are typically non-magnetic.

In precision manufacturing environments involving 3-axis, 4-axis, and 5-axis milling and turning operations, 17-4 PH is commonly selected for tight-tolerance components in aerospace, medical, and defense applications. Its ability to maintain dimensional stability during and after machining makes it well-suited for complex geometries and high-precision parts.

The table below outlines key technical characteristics of 17-4 PH stainless steel in comparison with other commonly machined materials such as Aluminum (6061-T6), Carbon Steel (1018), ABS, and Nylon (PA6), focusing on magnetic response, machinability, and suitability for tight-tolerance CNC operations.

| Material | Magnetic? | Typical Hardness (HB) | Machinability Rating (%) | Common CNC Processes | Tight Tolerance Capability (±) | Notes |

|---|---|---|---|---|---|---|

| 17-4 PH Stainless Steel | Yes (mild to moderate) | 330–380 (H900 condition) | 55–60 | 3/4/5-axis milling, turning | ±0.0005″ (12.7 µm) | Requires rigid setup; prone to work hardening; use sharp carbide tools |

| Aluminum 6061-T6 | No | 95 | 90 | 3/4/5-axis milling, turning | ±0.0005″ (12.7 µm) | High material removal rates; low cutting forces; ideal for complex 5-axis contours |

| Carbon Steel 1018 | Yes (strong) | 130 | 70 | Turning, 3-axis milling | ±0.001″ (25.4 µm) | Good for turned parts; requires coolant to manage heat and chip control |

| ABS (Thermoplastic) | No | 80–100 (Rockwell R) | 80–85 | 3/4-axis milling | ±0.005″ (127 µm) | Low melting point; minimal tool wear; fixturing critical due to flexibility |

| Nylon (PA6) | No | 85–95 (Rockwell R) | 75–80 | 3/4-axis milling, turning | ±0.005″ (127 µm) | Hygroscopic; prone to dimensional shift; sharp tools and light cuts required |

Machining Considerations for 17-4 PH Stainless Steel

For high-precision 3-axis, 4-axis, and 5-axis milling and turning of 17-4 PH stainless steel, the following best practices are recommended:

Use of high-performance carbide end mills with positive rake geometry to reduce cutting forces and prevent work hardening.

Peck drilling and controlled depth of cut to manage heat buildup.

CNC lathes with live tooling and C-axis control for complex turned-milled features.

Thermal stability in machine environment to maintain tight tolerances (±0.0005″ or better).

Stress-relieved or over-aged (Condition H1150) material preferred for minimizing distortion during final machining.

While aluminum offers superior machinability and is ideal for rapid prototyping and lightweight components, 17-4 PH stainless steel is selected when high strength, corrosion resistance, and moderate magnetic response are required. ABS and nylon are non-metallic alternatives suited for non-structural, low-friction, or insulating components but lack the dimensional precision and thermal stability of metals.

In summary, 17-4 PH stainless steel is a magnetic, high-strength alloy well adapted to tight-tolerance CNC machining across multi-axis platforms, especially when performance under load and in harsh environments is critical.

From CAD to Part: The Process

Honyo Prototype provides precise technical validation for material properties like magnetism in 17-4 stainless steel throughout our end-to-end manufacturing workflow. Below is a detailed explanation of how we address the magnetic characteristics of 17-4 PH (Precipitation Hardening) stainless steel within each phase of our standard process.

Material Science Context

17-4 stainless steel exhibits conditional magnetism dependent on its heat treatment condition. In the solution-annealed (Condition A) state, it is primarily austenitic and non-magnetic. However, after precipitation hardening (e.g., H900, H1025, or H1150 treatments), it transforms to a martensitic structure, becoming ferromagnetic. This property is critical for applications requiring magnetic compatibility or avoidance. Honyo explicitly validates this during DFM analysis based on the client-specified heat treatment.

Process Integration

Upon CAD file upload, our AI quoting engine cross-references material specifications against Honyo’s internal material property database. For 17-4 stainless steel, the system flags magnetic behavior as a variable requiring client confirmation of the required heat treatment condition. If the CAD file lacks heat treatment details, the quote includes a conditional note requesting specification of the aging condition (e.g., H900 for high strength/magnetism vs. H1150 for reduced magnetism).

During DFM analysis, our engineering team rigorously assesses the magnetic implications. We verify whether the design’s functional requirements align with the magnetic properties of the selected 17-4 condition. For instance, if the part must be non-magnetic (e.g., for MRI components), we recommend H1150 treatment or alternative materials like 316L, documenting this in the DFM report. Production planning incorporates magnetic testing protocols only if magnetism is critical to the application per client requirements.

Heat Treatment Impact on Magnetism

The table below summarizes key conditions for 17-4 stainless steel relevant to magnetic properties:

| Heat Treatment Condition | Typical Yield Strength (MPa) | Magnetic Permeability (μ) | Ferromagnetic Behavior |

|---|---|---|---|

| Condition A (Solution Annealed) | 1,000 | ~1.01–1.05 | Non-magnetic |

| H900 | 1,310 | 35–40 | Strongly magnetic |

| H1150 | 930 | 1.02–1.08 | Minimally magnetic |

In production, we strictly adhere to the specified heat treatment schedule. For magnetic-sensitive applications, we perform post-aging permeability testing per ASTM A342 using a fluxmeter, with results included in the material certification package. Final delivery includes traceable documentation confirming the achieved magnetic properties, ensuring compliance with the client’s functional requirements. Clients must specify the required 17-4 condition during CAD submission to avoid delays; otherwise, Honyo defaults to H900 and explicitly states its magnetic characteristics in the quotation.

Start Your Project

Is 17-4 Stainless Steel Magnetic? Find Out from the Experts at Honyo Prototype

17-4 stainless steel is a precipitation-hardening alloy known for its high strength, excellent corrosion resistance, and mechanical properties. One frequently asked question is whether it is magnetic. The answer depends on the heat treatment and microstructure—typically, 17-4 stainless steel is magnetic due to its martensitic structure, especially in H900, H1025, and other common conditions.

For technical confirmation and material certification, consult our engineering team at Honyo Prototype. We manufacture precision components in Shenzhen and regularly work with 17-4 PH stainless steel for aerospace, medical, and industrial applications.

Contact Susan Leo for material specifications, testing data, or custom prototyping support.

Email: [email protected]

Factory Location: Shenzhen, China

Get accurate answers and reliable manufacturing—partner with Honyo Prototype for your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.