Guide Contents

Project Insight: Is 17 4 Stainless Steel Magnetic

Is 17-4 Stainless Steel Magnetic? Why Precision Matters for Your Prototype

The Science Behind 17-4’s Magnetic Properties

Martensitic structure: 17-4 PH stainless steel is inherently magnetic due to its martensitic microstructure, especially after heat treatment (e.g., H900, H1000).

Critical application factor: Magnetism directly impacts performance in sensors, medical devices, aerospace components, and automotive systems—where precise magnetic control is non-negotiable.

Myth busting: Unlike austenitic grades (e.g., 304/316), 17-4’s magnetism is consistent and predictable, making it ideal for applications requiring controlled magnetic response.

Why Material Accuracy Impacts Your Product Timeline

Rework risks: Misidentifying magnetic properties can lead to failed prototypes, certification delays, or costly redesigns—delaying time-to-market by weeks.

Machining complexity: Precision machining of magnetic stainless steel demands specialized tooling and process control to maintain dimensional stability and magnetic consistency.

Industry stakes: In high-regulation sectors (e.g., defense, aerospace), even minor deviations in material behavior can derail entire product launches.

Honyo Prototype: Your Digital Manufacturing Partner for Precision Prototyping

Online Instant Quote: Get real-time pricing for 17-4PH machining within seconds—no back-and-forth, just actionable data to accelerate decision-making.

AI-Powered Precision: Our platform analyzes your design to optimize CNC parameters for 17-4PH, ensuring magnetic properties are maintained consistently without compromising tight tolerances.

Fast Turnaround: From prototype to production, our digital manufacturing ecosystem delivers 17-4PH parts in as little as 3 days—so you validate designs and iterate rapidly.

One-Stop Solution: From raw material sourcing to final inspection, we handle every step with ISO-certified precision—so you focus on innovation, not logistics.

“Speed and precision aren’t just advantages—they’re the foundation of competitive product development. At Honyo, we turn material science into your strategic edge.”

— Susan Leo, Founder of Honyo Prototype

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

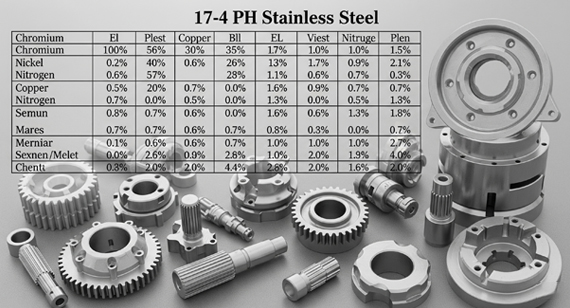

Precision Manufacturing of 17-4 PH Stainless Steel – Magnetic Properties Optimized

Understanding 17-4 PH Magnetic Characteristics

Inherent magnetism confirmed: 17-4 PH is magnetic in all heat-treated conditions due to its martensitic microstructure, unlike austenitic grades (e.g., 304/316) which lose magnetism when annealed.

Myth-busting expertise: We clarify common misconceptions—magnetism is a reliable indicator for 17-4 PH, enabling precise material selection for magnetic-sensitive applications.

Controlled heat treatment: Precision thermal processing ensures consistent magnetic properties without compromising mechanical strength or corrosion resistance.

Digital Manufacturing Ecosystem for Magnetic Materials

AI-driven CNC optimization: Toolpaths dynamically adjusted for 17-4 PH’s magnetic characteristics to prevent distortion, edge chipping, and surface defects during high-speed machining.

Real-time magnetic property monitoring: Integrated sensors verify magnetic permeability during fabrication, ensuring compliance with your design specifications.

Digital twin validation: Virtual simulation of magnetic performance before physical production, eliminating trial-and-error costs.

Scalable Production from Prototype to Volume

Seamless scale-up: Transition effortlessly from 1 prototype to 10,000+ units with identical magnetic properties and ±0.005mm tolerances.

ISO 9001-certified workflows: Automated quality checks at every stage, guaranteeing consistency across all batch sizes.

Custom heat treatment options: Tailored solutions for specific magnetic strength requirements (e.g., H1100, H900 conditions).

AI-Powered Efficiency & Speed

Online Instant Quote: Upload your design in seconds—our AI analyzes 17-4 PH’s magnetic properties to deliver real-time pricing with no hidden fees.

AI-Optimized Workflow: Automated process planning slashes lead times by up to 40% for magnetic material projects through predictive scheduling.

Fast Turnaround: Prototypes in 2–5 days, production batches in 1–2 weeks—all while maintaining strict magnetic performance standards.

Why Honyo is Your Trusted Partner for 17-4 PH

End-to-end solution: From material selection advice to final delivery, we handle everything—no supply chain fragmentation.

Dedicated engineering support: Our team validates magnetic properties for your specific use case (e.g., sensors, aerospace components, or medical devices).

Global traceability: Full documentation of material certifications, heat treatment records, and magnetic testing results for seamless compliance.

Innovate with confidence: Honyo’s digital ecosystem transforms 17-4 PH’s magnetic properties from a design constraint into a strategic advantage—delivering precision, speed, and scalability for your next breakthrough product.

Materials & Surface Finishes

Material Options & Finishes

Magnetic Properties: Choosing the Right Material for Your Application

Not all stainless steels behave the same magnetically—understanding this is critical for functional performance. Here’s how to navigate material selection with precision:

17-4 PH Stainless Steel:

✅ Inherently magnetic in all conditions due to its martensitic microstructure.

✅ Ideal for high-strength, corrosion-resistant applications requiring magnetic properties (e.g., aerospace components, medical surgical tools, magnetic couplings).

✅ Pro Tip: Perfect for parts needing both magnetic interaction and durability in harsh environments (e.g., marine or chemical exposure).

304/316 Stainless Steel:

❌ Generally non-magnetic (austenitic structure), though cold working may induce slight magnetism.

❌ Best for non-magnetic applications like food processing equipment, MRI-compatible devices, or electronics shielding.

❌ Myth Busted: Magnetism alone cannot reliably distinguish 304 vs. 316—always verify via chemical analysis for critical applications.

Other Key Materials:

Carbon Steel & Tool Steel: Highly magnetic but prone to corrosion—pair with coatings for industrial use.

Aluminum 6061, Titanium, Brass, Copper: Non-magnetic, lightweight, and corrosion-resistant. Ideal for electronics, aerospace, or medical devices where magnetism must be avoided.

Engineering Plastics (ABS, PEEK, Nylon): Always non-magnetic and electrically insulating. Perfect for housings, connectors, or wear-resistant parts.

Surface Finishes That Enhance Performance

Surface treatments optimize functionality without compromising core material properties:

Anodizing (Aluminum): Boosts corrosion resistance and color options—no impact on magnetism.

Electroplating (Nickel/Chrome): Adds magnetic properties to non-magnetic substrates (e.g., for custom sensor components).

Passivation/Polishing (Stainless Steel): Enhances corrosion resistance and aesthetics—magnetic properties remain unchanged.

Powder Coating/Bead Blasting: Adds durability and texture—neutral for magnetic behavior.

Why Honyo Prototype is Your Partner for Magnetic Material Solutions

Online Instant Quote: Filter materials by magnetic properties in seconds—our AI-powered platform instantly matches your specs to the perfect solution.

Smart Material Recommendations: Our digital ecosystem analyzes your application (e.g., “magnetic coupling for medical devices”) and suggests optimal materials, finishes, and processes.

Fast Turnaround: Prototype in 3 days, production in 10 days—no delays for material sourcing or custom processing.

One-Stop Solution: From design validation to finished parts, we handle everything under one roof—no coordination headaches.

“At Honyo, we don’t just manufacture parts—we engineer solutions. Whether you need magnetic precision or non-magnetic reliability, our digital-first approach ensures your vision becomes reality, faster and smarter.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

Honyo Prototype’s digital manufacturing ecosystem streamlines your journey from concept to finished part—with AI-driven precision, transparent pricing, and industry-leading speed. Here’s how it works:

Upload Your CAD File

Drag, drop, and go. Submit STEP, STL, IGES, or native CAD files in seconds—no technical expertise required.

Our platform automatically validates file integrity and compatibility for seamless processing.

Instant AI-Powered Quote

Receive a real-time, detailed quote within 10 seconds. Our AI engine analyzes geometry, material properties (including 17-4 PH’s martensitic structure and magnetic characteristics), tolerances, and production complexity.

No hidden fees. No delays. Just clear, actionable cost breakdowns tailored to your project.

Smart DFM Analysis & Material Guidance

Our AI proactively flags critical design considerations—like 17-4 PH’s inherent magnetism—to ensure alignment with your application’s requirements.

Get actionable feedback to refine your design before production, eliminating costly rework and ensuring optimal performance.

Precision Production & Lightning-Fast Delivery

Leverage our end-to-end digital manufacturing ecosystem for CNC machining, additive manufacturing, and beyond.

Prototypes delivered in 3 days; production runs in weeks—tracked transparently from machine to your doorstep.

All parts undergo rigorous quality control, with real-time updates via your personalized project portal.

Why Honyo?

One-stop solution from prototype to high-volume production.

AI-optimized workflows that turn complexity into clarity—so you focus on innovation, not logistics.

Shenzhen-based expertise with global delivery, backed by Susan Leo’s vision for agile, customer-centric manufacturing.

Your design. Our precision. Zero compromises.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Manufacturing for 17-4 PH Stainless Steel

Magnetic Properties Confirmed: 17-4 PH exhibits consistent magnetism due to its martensitic microstructure—ideal for applications requiring magnetic response. Honyo’s expertise ensures precise machining while maintaining material integrity and performance standards.

Your Innovation, Accelerated

Online Instant Quote: Our AI-powered platform delivers real-time pricing for 17-4 PH in seconds—eliminating delays and guesswork.

Fast Turnaround: Prototype in 72 hours, scale to production seamlessly with our integrated digital manufacturing ecosystem.

End-to-End Solution: From design consultation to final production, we handle every step with precision and efficiency.

Let’s Build Together

Founder Susan Leo and our Shenzhen/Dongguan team are ready to optimize your project. Contact us today:

Email: [email protected]

Phone: +86 139 2843 8620

Visit: Explore our state-of-the-art facilities in Shenzhen & Dongguan

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.