Contents

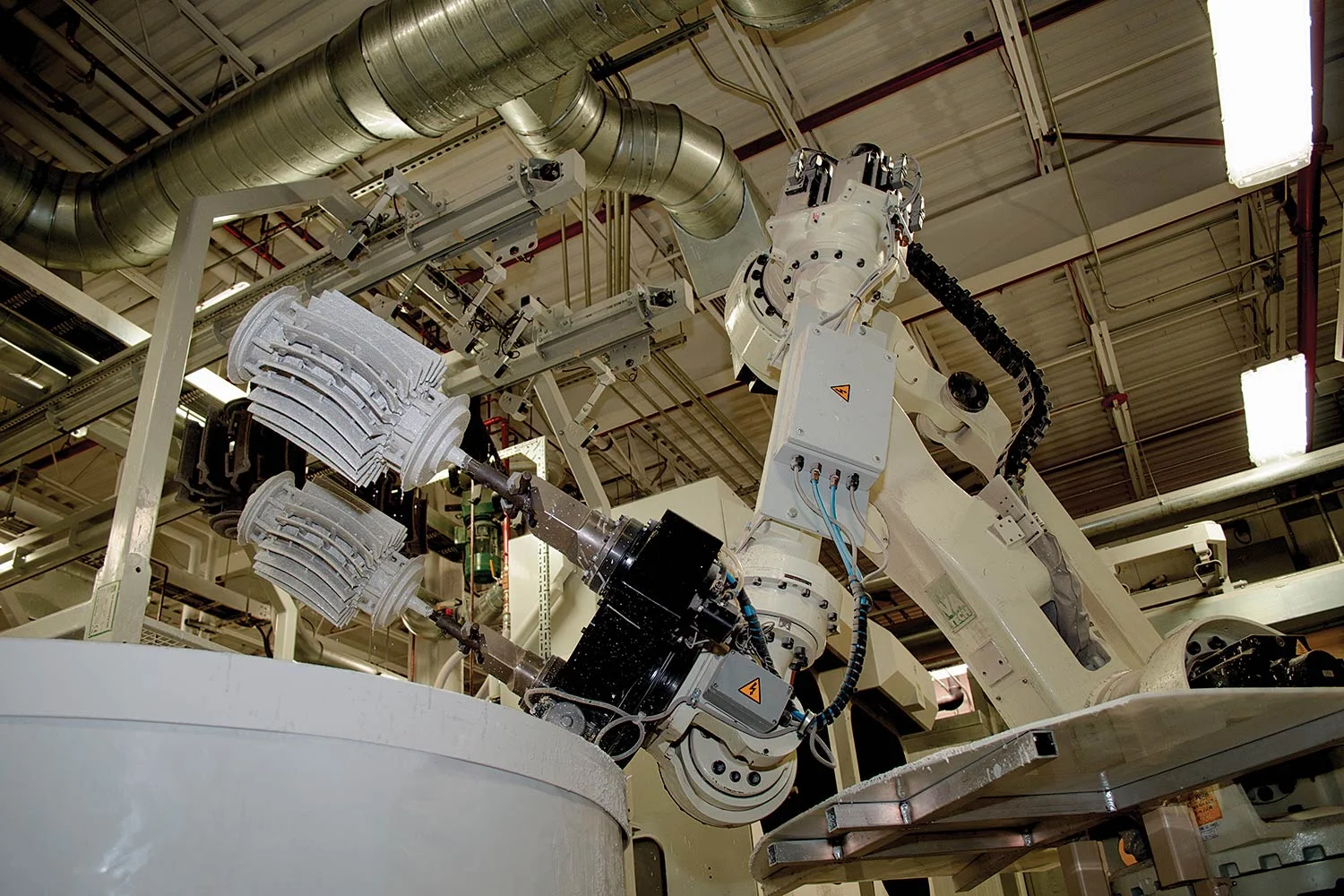

Manufacturing Insight: Investment Casting Machine

Honyo Prototype delivers integrated manufacturing solutions where investment casting meets precision CNC finishing to achieve uncompromising part quality. Investment casting excels at producing complex near-net-shape metal components across aerospace, medical, and industrial applications, yet critical dimensions, tight tolerances, and refined surface finishes frequently require post-cast machining. Our vertically integrated facility eliminates supply chain delays and quality inconsistencies by pairing advanced investment casting capabilities with proprietary CNC Machining Services. This synergy ensures geometric complexity from the casting process is perfected through high-accuracy milling, turning, and multi-axis operations, maintaining strict dimensional control down to ±0.0002 inches while adhering to AS9100 and ISO 13485 standards.

Engineers and procurement teams benefit from seamless transition between casting and machining stages under one quality management system, reducing lead times by up to 30% compared to outsourced finishing. For rapid project validation, utilize Honyo’s Online Instant Quote platform to receive detailed manufacturability feedback and competitive pricing within hours—simply upload CAD files to initiate the process. This integrated approach guarantees investment cast parts meet exact functional requirements without secondary vendor dependencies.

Technical Capabilities

The term “investment casting machine” typically refers to equipment used in the investment (or lost-wax) casting process, which involves creating precision metal parts through wax pattern production, ceramic shell building, and high-temperature casting. However, investment casting itself does not involve milling or turning operations. Instead, post-cast machining—such as 3-, 4-, or 5-axis CNC milling and turning—is performed on cast components to achieve tight tolerances and fine surface finishes.

Below is a technical specification table for a high-precision CNC machining center commonly used for post-processing investment cast parts, with capabilities in multi-axis milling, turning, and tight-tolerance machining for materials including Aluminum, Steel, ABS, and Nylon.

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis CNC Milling and Turning Center (Multi-Tasking Machining Center) |

| Axis Configuration | X, Y, Z linear axes with A (rotary) and C (spindle rotary) axes for full 5-axis simultaneous machining; optional Y-axis turning attachment |

| Spindle Speed | Up to 24,000 RPM (high-speed for Aluminum and plastics); lower torque variants available for Steel |

| Spindle Power | 30–50 kW (adjustable based on material: high for steel, moderate for aluminum and plastics) |

| Positioning Accuracy | ±0.002 mm (±0.00008″) |

| Repeatability | ±0.001 mm (±0.00004″) |

| Tool Changer Capacity | 30–80 tools (automatic tool changer with ATC) |

| Tool-to-Tool Change Time | < 2 seconds |

| Work Envelope (X×Y×Z) | 760 × 610 × 510 mm (30″ × 24″ × 20″) |

| Maximum Workpiece Weight | 1,000 kg (2,200 lbs) |

| Rapid Traverse Rate | 60 m/min (2,360 in/min) |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar), optional mist coolant for plastics |

| Probing System | On-machine touch probe for in-process inspection and tool setting |

| Materials Compatible | Aluminum alloys (e.g., 6061, 7075), Stainless and Tool Steels (e.g., 17-4 PH, 4140), Engineering Plastics (ABS, Nylon, PEEK) |

| Typical Surface Finish | Ra 0.8 μm (32 μin) achievable; down to Ra 0.4 μm with fine finishing |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005″) for general features; down to ±0.005 mm (±0.0002″) with precision setups and thermal compensation |

| Thermal Compensation | Active spindle and structural thermal control systems |

| Automation Ready | Compatible with robotic pallet changers and FMS (Flexible Manufacturing Systems) |

This type of CNC machining center is ideal for finishing investment-cast components requiring high dimensional accuracy, complex geometries, and excellent surface integrity. It supports hybrid operations—combining milling and turning in one setup—reducing part handling and improving repeatability, especially critical when working with tight-tolerance aerospace, medical, or automotive components.

From CAD to Part: The Process

Honyo Prototype employs a streamlined digital workflow for investment casting projects that integrates advanced technology with precision manufacturing to ensure rapid, high-quality prototype and low-volume production. Our process begins with secure CAD file upload through the Honyo Customer Portal where proprietary validation algorithms perform initial geometry and file integrity checks. This step confirms compliance with standard casting parameters and identifies obvious file errors before proceeding.

The validated CAD model then enters our AI-powered quoting engine which analyzes over 200 manufacturability indicators including wall thickness distribution, feature complexity, and draft requirements. Unlike conventional quoting systems this artificial intelligence correlates geometric data with real-time machine capacity, material costs, and historical production metrics to generate accurate cost and lead time estimates within 90 minutes while flagging potential high-risk design elements.

Following client acceptance of the quote our engineering team conducts a formal Design for Manufacturability review focusing on investment casting specific considerations. This critical phase involves collaborative analysis of gating system optimization, shrinkage compensation, and ceramic shell build strategy with direct communication to the client regarding any necessary design refinements. Typical DFM outcomes include recommended modifications to minimize secondary operations while maintaining functional requirements.

Production commences with rapid pattern production using our in-house stereolithography systems to create precise wax patterns. These patterns undergo sequential ceramic shell coating through automated dipping stations with controlled slurry application and stucco application cycles. The completed shells proceed to our induction melting furnaces where aerospace-grade alloys are poured under vacuum or controlled atmosphere conditions before controlled cooling and shell removal.

Final processing includes precision cutoff, weld repair if necessary, and comprehensive dimensional validation against the original CAD model using coordinate measuring machines. Every shipment includes full material certification, first article inspection reports, and process documentation with standard lead times of 12-18 days from approved DFM to delivery for most prototype quantities. Our integrated quality management system tracks all process parameters ensuring traceability from digital design to physical component.

Key production metrics for standard investment casting projects

| Parameter | Prototype Range | Low Volume Production | Quality Standard |

|———–|—————–|————————|——————|

| Lead Time | 12-18 days | 18-25 days | AS9100 Rev D compliant |

| Dimensional Accuracy | ±0.005 in/in | ±0.003 in/in | Per ISO 2768-mK |

| Surface Finish | 125-250 μin Ra | 63-125 μin Ra | Measured per ASTM B46 |

| Material Options | 30+ alloys including IN718, Ti-6Al-4V, 17-4PH | Full production alloy range | Certified mill test reports |

This closed-loop process eliminates traditional handoffs between quoting and production teams while maintaining rigorous quality controls throughout. The integration of AI-driven analysis with decades of casting expertise ensures optimal manufacturability without compromising design intent for demanding aerospace, medical, and industrial applications.

Start Your Project

Interested in high-precision investment casting solutions? Explore our advanced investment casting machines designed for superior accuracy and efficiency in metal component production.

Contact Susan Leo today to learn more about our capabilities and pricing.

Email: [email protected]

Manufactured with excellence at our Shenzhen factory, where engineering precision meets scalable production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.