Introduction: Navigating the Global Market for intense blue powder coat

In the dynamic world of industrial coatings, sourcing the right intense blue powder coat can pose a significant challenge for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. As the demand for high-quality, aesthetically appealing finishes grows, understanding the nuances of powder coating—such as color matching, application techniques, and substrate compatibility—becomes essential. This guide serves as a comprehensive resource, providing insights into various types of intense blue powder coats, their applications across industries, and tips for effectively vetting suppliers.

International buyers will benefit from a deep dive into the cost factors associated with intense blue powder coatings, including bulk pricing structures and shipping considerations tailored to different regions. We will also explore the importance of rigorous testing to ensure product quality and adherence to safety standards, particularly relevant for markets with stringent regulations. By arming buyers with actionable knowledge and strategic insights, this guide empowers informed purchasing decisions, facilitating smoother transactions and better outcomes in their respective projects. Whether you are looking to enhance the aesthetic appeal of automotive components or seeking durable finishes for architectural applications, understanding the global market landscape of intense blue powder coats will position your business for success.

Understanding intense blue powder coat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Intense Blue Transparent | Rich blue with a hint of purple, high gloss finish | Automotive, Industrial Equipment | Pros: Eye-catching finish, versatile applications. Cons: Requires a reflective base coat for best results. |

| Intense Blue RAL 5002 | Deep blue shade, standardized color matching | Architectural Coatings, Furniture | Pros: Consistent color across suppliers, easy to match. Cons: May lack the gloss of specialty powders. |

| Intense Blue Metallic | Flakes for added depth and shimmer | Consumer Electronics, Automotive | Pros: Enhanced visual appeal, suitable for high-end products. Cons: Higher cost due to metallic additives. |

| Intense Blue Matte | Non-reflective finish, soft appearance | Home Decor, Retail Displays | Pros: Unique aesthetic, hides imperfections well. Cons: Less durable than glossy finishes. |

| Intense Blue Custom Mix | Tailored color formulations for specific needs | Specialty Projects, Prototyping | Pros: Exact color matching for unique applications. Cons: Longer lead times, potentially higher costs. |

What Are the Key Characteristics of Intense Blue Transparent Powder Coat?

The Intense Blue Transparent powder coat is characterized by its rich blue color with a subtle hint of purple, providing a stunning high gloss finish. This type is particularly effective when applied over a bright silver substrate, which enhances its depth and vibrancy. B2B buyers in the automotive and industrial equipment sectors often favor this option for its eye-catching appearance, though it requires careful consideration of the base coat to achieve the desired visual effect.

How Does Intense Blue RAL 5002 Stand Out in the Market?

Intense Blue RAL 5002 is a standardized color that facilitates easy matching across different suppliers, making it a popular choice in architectural coatings and furniture manufacturing. Its deep blue hue offers a reliable option for businesses seeking consistency in their products. However, while it is practical for large-scale applications, it may not provide the same glossy finish as specialty powders, which could impact aesthetic preferences.

What Advantages Does Intense Blue Metallic Offer?

Intense Blue Metallic powder coat incorporates metallic flakes, resulting in a shimmering finish that adds depth to the color. This type is particularly suitable for consumer electronics and automotive applications where visual appeal is paramount. Although it enhances product aesthetics, buyers should be aware that the addition of metallic additives can increase production costs, making it essential to evaluate the return on investment for their specific use case.

Why Choose Intense Blue Matte for Your Projects?

Intense Blue Matte offers a soft, non-reflective finish that is increasingly favored in home decor and retail displays. Its unique aesthetic quality allows it to hide surface imperfections effectively, making it an excellent choice for products that prioritize visual texture. However, B2B buyers should consider that matte finishes can be less durable than their glossy counterparts, which could affect long-term performance in high-wear environments.

What Are the Benefits of Using Intense Blue Custom Mix Powder Coats?

Intense Blue Custom Mix powders enable businesses to achieve tailored color formulations that meet specific project needs. This flexibility is especially beneficial for specialty projects and prototyping, where precise color matching is critical. While the ability to customize offers significant advantages, buyers should be prepared for potentially longer lead times and higher costs associated with bespoke formulations, necessitating careful planning in procurement processes.

Key Industrial Applications of intense blue powder coat

| Industry/Sector | Specific Application of Intense Blue Powder Coat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom vehicle parts and accessories | Enhances aesthetic appeal and durability of components | Ensure compatibility with OEM specifications and color matching capabilities. |

| Architectural & Design | Architectural elements like railings and fixtures | Provides a vibrant finish that resists fading and corrosion | Verify UV resistance and local regulations on coatings. |

| Industrial Equipment | Machinery and equipment parts | Increases longevity and reduces maintenance costs | Consider powder coating thickness and application methods. |

| Consumer Electronics | Housing for electronic devices | Offers a visually appealing finish while protecting against wear | Evaluate thermal properties and electrical insulation needs. |

| Recreational Vehicles | Parts for ATVs, motorcycles, and watercraft | Improves product aesthetics and protects against harsh environments | Assess environmental resistance and custom color matching options. |

How is Intense Blue Powder Coat Used in the Automotive Industry?

In the automotive sector, intense blue powder coat is frequently applied to custom vehicle parts and accessories, such as wheels, bumpers, and interior components. This coating not only enhances the aesthetic appeal of vehicles but also provides a durable finish that withstands harsh weather conditions and road wear. B2B buyers in this industry must ensure that the coating meets OEM specifications and consider color matching for a cohesive look across different vehicle components, especially for international markets where branding consistency is crucial.

What Role Does Intense Blue Powder Coat Play in Architectural Design?

In architectural applications, intense blue powder coat is utilized for elements like railings, window frames, and outdoor fixtures. Its vibrant color and high gloss finish contribute to the visual appeal of buildings while offering protection against fading and corrosion, particularly in coastal regions. Buyers should consider the UV resistance of the coating, as well as compliance with local building codes and environmental regulations, which can vary significantly across regions such as Africa and Europe.

How Does Intense Blue Powder Coat Benefit Industrial Equipment?

Industrial equipment often requires robust finishes to endure demanding environments. Intense blue powder coat is applied to machinery and equipment parts to enhance their durability and resistance to corrosion. This not only prolongs the lifespan of the equipment but also reduces maintenance costs. Buyers should assess the coating’s thickness and application methods to ensure optimal performance, particularly when sourcing from international suppliers who may have different standards.

Why is Intense Blue Powder Coat Important for Consumer Electronics?

In the consumer electronics industry, intense blue powder coat is used for the housings of devices such as smartphones, laptops, and audio equipment. This coating provides a striking visual finish while also offering protection against scratches and wear. B2B buyers must evaluate the thermal properties of the coating to ensure it does not interfere with the device’s performance and consider electrical insulation properties, which are vital for electronic components.

How is Intense Blue Powder Coat Applied in Recreational Vehicles?

Recreational vehicles, including ATVs and motorcycles, benefit from intense blue powder coat applications on various parts such as frames and body panels. This coating not only enhances the aesthetic appeal but also protects against the elements, ensuring longevity in outdoor conditions. Buyers should assess the environmental resistance of the powder coat and explore custom color matching options, particularly for international markets where branding may require specific hues.

3 Common User Pain Points for ‘intense blue powder coat’ & Their Solutions

Scenario 1: Difficulty Achieving Desired Color Match for Intense Blue Powder Coat

The Problem: B2B buyers often struggle with obtaining an accurate color match when using intense blue powder coat. This is particularly challenging when trying to replicate OEM colors for specific applications, such as automotive or industrial components. Buyers may receive samples that do not meet their expectations, leading to wasted time and resources. For instance, some users have reported that the intense blue offered by certain suppliers did not resemble the original color, causing frustration and potential project delays.

The Solution: To ensure a precise color match, buyers should take a proactive approach by utilizing RAL color matching systems. Before placing large orders, it is advisable to order swatches and conduct tests with various substrates, as the base coat can significantly affect the final appearance of the intense blue. For example, applying the intense blue over a bright silver substrate can yield more vibrant results. Collaborating with a local powder coater that has experience with color matching can also provide insights and recommendations tailored to specific needs. Additionally, buyers should document their findings and establish a consistent testing protocol to streamline future orders.

Scenario 2: Challenges with Application Process for Intense Blue Powder Coat

The Problem: Many buyers encounter difficulties during the application process of intense blue powder coat, particularly regarding the need for specific base coats. The requirement to apply a chrome or bright silver base coat first can lead to confusion, especially for those new to powder coating. Missteps in the application process can result in unsatisfactory finishes, requiring rework and increasing costs.

The Solution: To mitigate these challenges, buyers should invest in comprehensive training for their staff on the powder coating process, emphasizing the importance of base coats. Providing detailed application guides and safety data sheets can ensure that all team members understand the necessary steps. It may also be beneficial to establish a partnership with a reputable supplier who can provide technical support and advice during the application phase. By setting up a test area for practice runs before actual production, buyers can refine their techniques and better understand how the intense blue powder coat interacts with different substrates.

Scenario 3: Concerns Over Product Quality and Compliance with Safety Standards

The Problem: International B2B buyers often face concerns regarding the quality and safety compliance of intense blue powder coats, especially when sourcing from different regions. The potential exposure to hazardous materials can lead to regulatory complications, particularly in regions with strict environmental laws. Buyers may be unsure whether the products they are sourcing meet local regulations, which can jeopardize their operations.

The Solution: To address these concerns, buyers should prioritize sourcing intense blue powder coats from reputable manufacturers that provide comprehensive documentation, including safety data sheets and certifications. Conducting thorough due diligence on suppliers—reviewing their compliance with international safety standards such as ISO and REACH—can safeguard against potential legal issues. Additionally, engaging with local regulatory bodies can provide clarity on specific requirements for importing and using powder coatings. Establishing a robust supply chain that emphasizes transparency and accountability will further enhance buyer confidence in the quality and safety of their powder coat materials.

Strategic Material Selection Guide for intense blue powder coat

What Are the Key Materials for Intense Blue Powder Coat?

When selecting materials for intense blue powder coating, it’s essential to consider the properties and suitability of various substrates. The following analysis highlights four common materials, focusing on their performance characteristics, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Aluminum for Intense Blue Powder Coating?

Aluminum is a widely used substrate for powder coating due to its lightweight and corrosion-resistant properties. It typically has a temperature rating of up to 200°C, making it suitable for various applications. The smooth surface of aluminum allows for excellent adhesion of the intense blue powder coat, resulting in a high-quality finish.

Pros: Aluminum is lightweight, easy to fabricate, and offers good resistance to corrosion. It is also relatively inexpensive compared to other metals.

Cons: While aluminum is durable, it can be prone to scratching and denting. Additionally, the cost of surface preparation can add to the overall expense.

Impact on Application: Aluminum is compatible with intense blue powder coat, providing vibrant color and gloss. However, proper surface preparation is crucial to ensure optimal adhesion.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM B117 for salt spray testing. In regions like Africa and the Middle East, the availability of aluminum may vary, impacting procurement strategies.

How Does Steel Perform with Intense Blue Powder Coating?

Steel is another common substrate for powder coating, known for its strength and durability. It can withstand high temperatures and has excellent mechanical properties. However, steel requires a protective layer to prevent corrosion, particularly in humid environments.

Pros: Steel offers high strength and is cost-effective for large-scale applications. It is also widely available and can be easily sourced.

Cons: Steel is susceptible to rust if not properly coated, which can lead to premature failure. The surface preparation process can be labor-intensive and costly.

Impact on Application: When coated with intense blue powder, steel can achieve a striking appearance. However, the need for a primer or base coat to enhance corrosion resistance can complicate the application process.

Considerations for International Buyers: Compliance with corrosion resistance standards is vital, especially in coastal regions. Buyers should be aware of local regulations regarding the use of steel and its coatings.

Why Choose Stainless Steel for Intense Blue Powder Coating?

Stainless steel is an excellent choice for applications requiring high corrosion resistance and aesthetic appeal. It can withstand harsh environments and has a high-temperature rating, making it suitable for various industrial applications.

Pros: Stainless steel is highly resistant to corrosion and staining, ensuring longevity. It also provides a premium finish that enhances the appearance of the intense blue powder coat.

Cons: The cost of stainless steel is significantly higher than other materials, which may not be suitable for all budgets. Additionally, it can be challenging to work with due to its hardness.

Impact on Application: The intense blue powder coat adheres well to stainless steel, providing a durable and attractive finish. However, the initial investment may be a barrier for some buyers.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM A240 for stainless steel. In regions like South America, the availability of stainless steel may be limited, affecting sourcing decisions.

What Role Does Plastic Play in Intense Blue Powder Coating?

Plastic substrates are increasingly popular for powder coating applications due to their lightweight and versatile nature. However, not all plastics are suitable for powder coating, and specific types must be used to achieve the desired results.

Pros: Plastic is lightweight, resistant to corrosion, and can be molded into complex shapes. It is also generally less expensive than metal substrates.

Cons: The temperature tolerance of plastics is lower than that of metals, which can limit the types of powder coatings that can be applied. Additionally, the adhesion of powder coatings to plastic can be less reliable.

Impact on Application: Intense blue powder coats can provide a vibrant finish on compatible plastics, but careful selection and testing are necessary to ensure proper adhesion.

Considerations for International Buyers: Buyers should ensure that the plastic substrates comply with local regulations regarding chemical resistance and safety standards. In regions with high humidity, additional considerations for moisture resistance may be necessary.

Summary Table of Material Selection for Intense Blue Powder Coat

| Material | Typical Use Case for intense blue powder coat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, furniture | Lightweight and corrosion-resistant | Prone to scratching and denting | Low |

| Steel | Industrial equipment, structural components | High strength and cost-effective | Susceptible to rust | Med |

| Stainless Steel | High-end appliances, marine applications | Excellent corrosion resistance | Higher cost and difficult to fabricate | High |

| Plastic | Consumer goods, electronics | Lightweight and versatile | Limited temperature tolerance | Low |

This guide provides actionable insights for B2B buyers considering intense blue powder coat applications. Understanding the properties and implications of material selection is crucial for ensuring optimal performance and compliance in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for intense blue powder coat

What Are the Main Stages of Manufacturing Intense Blue Powder Coat?

The manufacturing process for intense blue powder coat involves several key stages, each critical to achieving the desired color and quality.

1. Material Preparation

The process begins with the selection of high-quality raw materials, which typically include polyester resins, pigments, and additives. For intense blue powder coat, the pigments are particularly important, as they determine the final color and gloss level. The raw materials undergo rigorous screening and testing to ensure they meet the specific requirements for color consistency and performance. This stage may also involve pre-blending the materials to achieve uniformity.

2. Forming and Mixing

Once the materials are prepared, they are fed into a mixer where they are blended together at high speeds. This step is crucial for ensuring that the pigments are evenly distributed throughout the resin. After mixing, the material is extruded through a die to form a continuous strand. This strand is then cooled and broken into small chips or pellets, which are easier to handle and transport.

3. Quality Control During Manufacturing (IPQC)

In-Process Quality Control (IPQC) is implemented at various stages of the manufacturing process. This includes checking the consistency of the blend, monitoring the extrusion process, and ensuring that the particle size of the powder meets specifications. Continuous sampling and testing during these stages help to identify any deviations from quality standards before the product moves to the next phase.

4. Finishing and Packaging

After the powder is formed, it undergoes a final quality check to ensure that it meets the required specifications for gloss, color, and particle size. The finished powder is then packaged in moisture-resistant bags to preserve its quality during storage and transportation. Proper packaging is essential, especially for international shipments, to prevent contamination and maintain the integrity of the powder coat.

What Quality Assurance Measures Are Essential for Intense Blue Powder Coat?

Quality assurance is critical in the manufacturing of intense blue powder coat to ensure that the end product meets both customer expectations and international standards.

Relevant International Standards

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification demonstrates the manufacturer’s commitment to consistent quality and continuous improvement. Additionally, industry-specific certifications such as CE marking for products sold in Europe or API standards for products used in the oil and gas sector may also apply.

Key Quality Control Checkpoints

Quality control checkpoints are integrated throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications. This includes testing for pigment quality and resin purity.

-

In-Process Quality Control (IPQC): As described earlier, this involves continuous monitoring during the mixing, extruding, and cooling processes to ensure uniformity and adherence to quality standards.

-

Final Quality Control (FQC): The finished powder coat undergoes rigorous testing for color accuracy, gloss level, and particle size distribution. Samples are often compared against color standards to ensure consistency.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for powder coatings like intense blue powder coat are essential to verify product quality and performance.

1. Color Matching

Color matching is performed using spectrophotometers to ensure that the intense blue powder coat meets the specified color standards. This is particularly important for B2B buyers who require specific shades for branding or design.

2. Gloss Measurement

The gloss level of the powder coat is measured using a glossmeter. For intense blue powder, achieving a high gloss finish (85+ Gloss Units) is often a requirement, making this testing method critical.

3. Adhesion Testing

Adhesion tests are conducted to determine how well the powder coat adheres to various substrates. This is typically done using a cross-hatch test, where a grid is cut into the coated surface, and tape is applied to see how much of the coating is removed.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that their suppliers maintain high-quality standards in their manufacturing processes.

1. Supplier Audits

Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing capabilities, quality control processes, and adherence to international standards. This firsthand inspection can provide valuable insights into the supplier’s operations.

2. Requesting Quality Reports

Buyers should request comprehensive quality assurance reports that detail the testing methods used, results obtained, and any corrective actions taken. These documents are essential for verifying that the supplier adheres to quality standards.

3. Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be particularly beneficial for international buyers who may not have the ability to conduct on-site audits.

What QC and Certification Nuances Should International B2B Buyers Consider?

International B2B buyers must be aware of several nuances when it comes to quality control and certification for powder coatings like intense blue.

1. Regional Standards

Different regions may have varying requirements for certifications and quality standards. For instance, products sold in Europe may require CE marking, while those in the Middle East may adhere to local standards. Buyers should familiarize themselves with the specific requirements of their target markets.

2. Import Regulations

Understanding import regulations in the buyer’s country is crucial. This includes compliance with safety standards and chemical regulations, which may differ significantly from one region to another.

3. Supplier Relationships

Building strong relationships with suppliers can enhance communication regarding quality control practices and product specifications. Frequent engagement and transparency can lead to better collaboration and improved quality assurance outcomes.

By considering these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing intense blue powder coat, ensuring they receive a high-quality product that meets their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘intense blue powder coat’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to procure intense blue powder coat. With the growing demand for high-quality finishes in various industries, understanding the nuances of sourcing this specific powder coat color is essential. By following this checklist, you can ensure that you make informed decisions that align with your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of your sourcing process. Determine the required gloss level, color match, and any specific application needs. For intense blue powder coat, understanding whether a base coat is needed—such as a silver or chrome substrate—will significantly influence the final appearance of your product.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers specializing in intense blue powder coating. Look for suppliers with a diverse catalog, including options for color matching and custom formulations. Utilize industry forums, trade shows, and online directories to compile a list of reputable suppliers.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers have the necessary certifications. Certifications such as ISO or adherence to environmental standards are indicators of a supplier’s commitment to quality and safety. Ensure they provide safety data sheets (SDS) and comply with regional regulations, particularly in your target markets.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to assess color accuracy, finish quality, and adhesion properties. Ensure that the samples are applied in conditions that mimic your actual production environment to obtain reliable results.

Step 5: Assess Pricing and Order Quantities

Understand the pricing structure and minimum order quantities (MOQs) from different suppliers. Many suppliers offer tiered pricing based on quantity, so evaluate your needs carefully. Compare costs not just per pound but also consider shipping fees and potential discounts for larger orders.

Step 6: Check Production and Delivery Times

Inquire about the lead times for production and delivery. Timely access to materials is crucial for maintaining your production schedules. Suppliers should provide clear timelines and any potential delays that could affect your operations, especially if you are sourcing from international markets.

Step 7: Establish Communication Channels

Finally, ensure that you have clear communication channels with your chosen supplier. Open lines of communication are vital for addressing any issues that may arise during the procurement process. Establish a point of contact for ongoing support, updates, and inquiries to foster a strong supplier relationship.

By following this checklist, you can streamline your sourcing process for intense blue powder coat, ensuring that you find a supplier that meets your specific requirements and delivers quality products.

Comprehensive Cost and Pricing Analysis for intense blue powder coat Sourcing

What Are the Key Cost Components for Intense Blue Powder Coat Sourcing?

When sourcing intense blue powder coat, understanding the cost structure is crucial. The primary components include:

-

Materials: The base powders, additives, and colorants constitute the largest portion of costs. For intense blue powder coat, high-quality polyester resins that provide durability and gloss are essential. Prices can range from $13.79 to $15.32 per pound based on volume, with lower prices available for bulk orders.

-

Labor: This includes the costs associated with skilled labor needed for production and application. Labor costs can vary significantly based on geographic location, skill level, and the complexity of the coating process.

-

Manufacturing Overhead: Expenses related to facility maintenance, equipment, utilities, and administrative costs contribute to overhead. These fixed costs are distributed across production volumes, meaning they can be lower per unit when larger quantities are purchased.

-

Tooling: Special molds or equipment needed for specific applications or customizations can add to initial costs. While these costs are one-time investments, they can impact pricing if the production volume is low.

-

Quality Control (QC): Ensuring the powder coat meets specific industry standards requires rigorous testing and quality assurance processes, which can increase costs. Certifications, especially for international standards, can add to QC expenses.

-

Logistics: Shipping costs can vary based on the supplier’s location and the buyer’s destination. International shipping may involve additional fees, customs duties, and tariffs, which are critical to factor in for accurate total cost calculations.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. The margin can vary based on competition, market demand, and the supplier’s positioning.

What Influences Pricing for Intense Blue Powder Coat?

Several factors affect the pricing of intense blue powder coat, including:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders can yield significant discounts, making it essential for buyers to evaluate their needs and negotiate effectively.

-

Specifications and Customization: Custom formulations or specific performance characteristics (like UV resistance or chemical durability) can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: High-grade materials and recognized certifications (e.g., ISO, ASTM) typically command higher prices but ensure better performance and compliance with regulations.

-

Supplier Factors: Supplier reputation, reliability, and service quality can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is vital, as they define the responsibilities of buyers and sellers in shipping costs, insurance, and delivery obligations.

How Can Buyers Optimize Costs and Pricing for Intense Blue Powder Coat?

B2B buyers can enhance cost efficiency and negotiate better pricing by considering the following strategies:

-

Negotiate Effectively: Leverage volume commitments to negotiate lower prices. Building long-term relationships with suppliers can also yield favorable terms and pricing adjustments.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with application, maintenance, and potential rework. High-quality powder coatings may have a higher upfront cost but can reduce maintenance and replacement expenses over time.

-

Stay Informed About Market Trends: Regularly monitor market trends and pricing fluctuations to understand when to buy. Engaging with industry forums and networks can provide valuable insights.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can minimize logistics costs and lead times. It also supports regional economies.

-

Understand Pricing Nuances for International Sourcing: Buyers in the Middle East or Europe should account for currency fluctuations, import duties, and local regulations that might affect overall costs. Engaging with local consultants can provide clarity on these aspects.

In conclusion, while the indicative prices for intense blue powder coat can serve as a starting point, understanding the broader cost structure and influencing factors is essential for making informed purchasing decisions.

Alternatives Analysis: Comparing intense blue powder coat With Other Solutions

Introduction to Alternatives in Powder Coating Solutions

When considering powder coating options for industrial applications, particularly in vibrant colors like intense blue, it’s essential to evaluate various alternatives. Different technologies and methods can achieve similar aesthetic outcomes, but they vary significantly in performance, cost, and application methods. This analysis will compare the intense blue powder coat with two viable alternatives: liquid paint and anodizing. Each option has distinct characteristics that may cater to specific project requirements, especially for B2B buyers in diverse international markets.

Comparison Table

| Comparison Aspect | Intense Blue Powder Coat | Liquid Paint | Anodizing |

|---|---|---|---|

| Performance | High durability, UV resistant, and impact resistant. | Good finish but less durable than powder. | Excellent corrosion resistance and aesthetic appeal. |

| Cost | $13.79 – $15.32 per lb (bulk discounts available). | Generally lower initial cost but requires more frequent reapplication. | Higher initial setup cost but long-lasting. |

| Ease of Implementation | Requires specialized equipment and a controlled environment. | Easier to apply with conventional spray equipment. | Requires specific equipment and processes, often more complex. |

| Maintenance | Low maintenance due to durability. | Higher maintenance; needs touch-ups more frequently. | Low maintenance, but may require re-anodizing over time. |

| Best Use Case | Automotive parts, industrial applications needing durability and aesthetics. | Household items, decorative applications where cost is a factor. | Aerospace components, outdoor furniture, and applications requiring corrosion resistance. |

Detailed Breakdown of Alternatives

Liquid Paint

Liquid paint is a traditional finishing method that involves applying a liquid coating to a substrate. It offers a wider range of colors and finishes, making it a popular choice for many manufacturers. However, while the initial cost may be lower than powder coating, liquid paint often lacks the durability and UV resistance of powder coatings. This means more frequent maintenance and reapplication may be necessary, leading to higher long-term costs. Liquid paint is best suited for projects where budget constraints are critical and where the items are not exposed to harsh conditions.

Anodizing

Anodizing is an electrochemical process that converts the surface of a metal into a decorative, durable, corrosion-resistant anodic oxide finish. This method is particularly effective for aluminum and provides an appealing aesthetic with excellent resistance to wear and corrosion. However, anodizing can be more complex and costly to implement, requiring specialized equipment and handling. While it offers low maintenance and long-lasting results, the initial investment can be higher compared to both intense blue powder coating and liquid paint. Anodizing is ideal for applications in demanding environments, such as aerospace or marine industries.

Conclusion: How to Choose the Right Powder Coating Solution

Selecting the right coating solution requires careful consideration of the specific needs of your project. B2B buyers should assess factors like performance requirements, budget constraints, and the environmental conditions the coated items will face. For applications needing high durability and aesthetic appeal, intense blue powder coating remains an excellent choice. Conversely, if cost is a primary concern and durability is less critical, liquid paint might be the way to go. For industries requiring exceptional corrosion resistance, anodizing could be the best long-term investment. Understanding these options will help buyers make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for intense blue powder coat

What Are the Key Technical Properties of Intense Blue Powder Coat?

1. Material Composition

Intense blue powder coat is typically made from polyester resin, which provides excellent durability and corrosion resistance. This composition is critical for industrial applications where products may be exposed to harsh environments. Understanding the material grade helps buyers assess compatibility with their specific use cases, particularly in sectors like automotive and manufacturing.

2. Gloss Level

The intense blue powder coat features a high gloss finish, typically exceeding 85 gloss units. Gloss level is an important property as it influences both aesthetic appeal and functional attributes, such as ease of cleaning and resistance to fading. For B2B buyers, ensuring that the gloss level meets brand standards can be vital for product differentiation in competitive markets.

3. Coverage Area

Understanding the coverage area is essential when calculating material needs for a project. For intense blue powder coat, the coverage can vary depending on the substrate and application technique, generally providing around 1,000 square feet per pound. Accurate calculations help prevent over-ordering or under-ordering, which can impact project timelines and costs.

4. Curing Temperature and Time

The curing process for intense blue powder coat typically requires a temperature range of 350°F to 400°F for about 10 to 20 minutes. This property is crucial for ensuring optimal adhesion and durability. B2B buyers must consider the capabilities of their equipment and the substrates they are working with to ensure compatibility with the curing requirements.

5. Chemical Resistance

Intense blue powder coat exhibits significant resistance to chemicals and solvents, making it suitable for various applications, including outdoor furniture and automotive parts. This resistance is a key selling point for buyers in industries that require long-lasting finishes in challenging conditions.

What Trade Terminology Should B2B Buyers Know Regarding Intense Blue Powder Coat?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of intense blue powder coat, understanding OEM specifications ensures that the coatings used meet the required quality and performance standards for the original products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For intense blue powder coat, knowing the MOQ is vital for B2B buyers, especially those in smaller markets or niche applications, as it can affect inventory management and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. When seeking intense blue powder coat, submitting an RFQ allows buyers to compare prices, delivery times, and terms from different suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B transactions involving intense blue powder coat, particularly for international buyers, as they dictate the risk and cost responsibilities throughout the shipping process.

5. Color Matching

Color matching refers to the process of ensuring that the powder coat color aligns with a specified standard or existing product. For intense blue powder coat, buyers may require precise color matching for branding consistency. Familiarity with color matching techniques and standards, such as RAL or Pantone, can enhance customer satisfaction and reduce returns.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when sourcing intense blue powder coat, ensuring they meet both their operational needs and quality standards.

Navigating Market Dynamics and Sourcing Trends in the intense blue powder coat Sector

What Are the Key Market Dynamics Affecting the Intense Blue Powder Coat Sector?

The global powder coating market is experiencing robust growth, driven by the increasing demand for durable and aesthetically pleasing finishes across various industries, including automotive, architectural, and industrial applications. The intense blue powder coat, characterized by its vibrant hue and high-gloss finish, has gained particular traction among manufacturers looking for color consistency and longevity in their products. Key trends influencing this sector include the rise of e-commerce platforms facilitating direct sourcing, advancements in powder coating technology that enhance color vibrancy and durability, and a growing preference for customization among end-users.

Emerging technologies such as digital color matching and improved application techniques are reshaping sourcing strategies for international B2B buyers. For example, buyers from regions like Africa and South America are increasingly leveraging online platforms to access a wider range of suppliers, which allows for competitive pricing and faster delivery times. Additionally, the demand for eco-friendly powder coatings, including those with low VOC (volatile organic compounds) emissions, is becoming a significant factor in purchasing decisions. This trend is particularly pronounced in Europe, where regulatory frameworks are pushing for more sustainable manufacturing practices.

How Is Sustainability Reshaping the Sourcing of Intense Blue Powder Coats?

Sustainability is a critical consideration for B2B buyers in the intense blue powder coat sector, as environmental impact and ethical sourcing practices gain prominence. The production of powder coatings is generally more sustainable than traditional liquid paints due to lower solvent emissions and reduced waste. Buyers are increasingly looking for suppliers who prioritize environmentally friendly processes, such as using recycled materials in their formulations or implementing energy-efficient manufacturing practices.

Moreover, certifications such as ISO 14001 (Environmental Management) and Green Seal are becoming essential for suppliers aiming to establish credibility in the marketplace. These certifications assure buyers that the products they source align with their sustainability goals. As a result, companies that can demonstrate their commitment to ethical supply chains and sustainable sourcing are likely to gain a competitive edge, particularly in regions like the Middle East and Europe, where regulatory pressures and consumer expectations are high.

What Is the Historical Context of Intense Blue Powder Coats in B2B Applications?

The intense blue powder coat has evolved significantly since the inception of powder coating technology in the 1960s. Originally used primarily in industrial applications, advancements in formulation technology have enabled the development of a wider palette of colors, including vibrant options like intense blue. This color gained popularity in the automotive sector, where it was adopted for its ability to withstand harsh conditions while maintaining aesthetic appeal. Over the decades, intense blue has been embraced across various sectors, including architecture and consumer goods, reflecting a broader trend toward personalization and vibrant design choices.

As international B2B buyers continue to seek innovative and high-performance coatings, the evolution of intense blue powder coats exemplifies the industry’s responsiveness to market demands for both functionality and aesthetic excellence.

Frequently Asked Questions (FAQs) for B2B Buyers of intense blue powder coat

-

How do I ensure the quality of intense blue powder coat from suppliers?

To ensure quality, conduct thorough supplier vetting by requesting samples and certifications. Check for compliance with international standards such as ISO or ASTM, which indicate quality assurance processes. Additionally, ask for the Safety Data Sheet (SDS) to understand the product’s composition and handling requirements. Consider establishing a quality control process that includes testing samples before large orders, and inquire about the supplier’s return policy for defective products. -

What are the key specifications to consider when sourcing intense blue powder coat?

When sourcing intense blue powder coat, pay attention to specifications such as gloss level, base coat requirements, and application methods. The gloss level indicates the finish quality, while knowing if a base coat is necessary helps in achieving the desired color and finish. Additionally, consider the powder’s compatibility with your application equipment and whether it meets environmental regulations in your target market, especially in regions with strict chemical regulations. -

What is the typical minimum order quantity (MOQ) for intense blue powder coat?

Minimum order quantities for intense blue powder coat can vary significantly by supplier and region. Generally, MOQs can range from 25 to 200 pounds. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are a smaller business or testing new products. Some suppliers may offer flexible MOQs for first-time buyers or bulk purchase agreements. -

How can I customize the intense blue powder coat to match my brand?

Customization options may include color matching to specific Pantone or RAL codes and adjusting gloss levels. Communicate your branding needs clearly with your supplier, providing samples or color codes for accurate matching. Some suppliers also offer custom formulations, allowing for unique finishes. Always request a sample before finalizing your order to ensure the product meets your expectations. -

What payment terms should I expect when ordering intense blue powder coat internationally?

Payment terms can vary by supplier and region but commonly include options like upfront payment, net 30, or letters of credit. For international transactions, consider using secure payment methods that offer buyer protection, such as PayPal or escrow services. Discuss payment terms upfront to avoid misunderstandings and ensure that they align with your cash flow and budgeting needs. -

What are the logistics considerations when importing intense blue powder coat?

When importing powder coat, consider shipping costs, customs duties, and delivery timelines. Ensure that your supplier can provide necessary shipping documentation, including invoices and packing lists. It’s also crucial to verify whether the product complies with local regulations in your country, which may impact clearance times. Partnering with a logistics provider experienced in handling chemical products can streamline the process. -

How can I verify the supplier’s reputation in the powder coating industry?

To verify a supplier’s reputation, conduct online research, including reading customer reviews and testimonials. Utilize platforms like LinkedIn to connect with industry professionals and gather insights about the supplier’s reliability and service quality. Additionally, consider requesting references from previous clients or checking for participation in industry associations, which can indicate a commitment to quality and ethical practices. -

What should I do if the intense blue powder coat does not match my expectations?

If the powder coat does not meet your expectations, first refer to the supplier’s return policy regarding defective or unsatisfactory products. Document the discrepancies by taking photographs and noting specific issues. Communicate directly with the supplier to discuss the problem and seek a resolution, whether through a refund, exchange, or additional support. Establishing clear communication upfront can facilitate smoother resolutions in such situations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Intense Blue Powder Coat Manufacturers & Suppliers List

1. Metal Clay Alchemist – Intense Blue Powder Coating

Domain: metalclayalchemist.com

Registered: 2011 (14 years)

Introduction: Powder Coating – Intense Blue – 2oz glossy

Price: $5.91

Color: Intense Blue (transparent rich blue with a hint of purple)

Finish: High gloss

Type: Polyester metallic powder coat

Application: Suitable for metal, fired metal clay, glass, plastic, wood, etc.

Curing Instructions: Bake at 400°F/204°C for 10 minutes before application.

2. Prismatic Powders – Can Am Intense Blue Powder Coat

Domain: maverickforums.net

Registered: 2012 (13 years)

Introduction: Can Am Intense Blue powder coat; Product ID: PPB-4474; Offered by Prismatic Powders; RAL color match options: RAL 5002 and RAL 5005; RAL 5002 confirmed as an excellent match for Can Am Intense Blue.

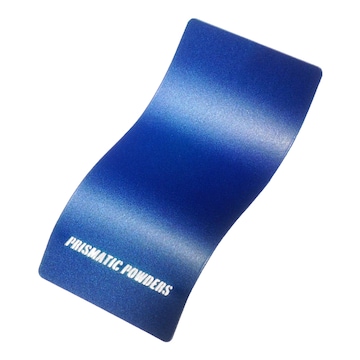

3. Prismatic Powders – INTENSE BLUE (PPB-4474)

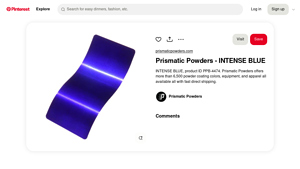

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: INTENSE BLUE, product ID PPB-4474. Prismatic Powders offers more than 6,500 powder coating colors, equipment, and apparel all available with fast direct shipping.

4. Reddit – EDC Bushcraft Belt Knife

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Transparent intense blue powder coat; made from 80crv2 steel; designed as a small EDC (Everyday Carry) belt knife in the bushcraft style; features kiln dried and stabilized Elm handle; powder coat allows visibility of the steel underneath, creating a holographic appearance.

5. Mercury Racing – Blue Powder Coat Alternatives

Domain: offshoreonly.com

Registered: 1998 (27 years)

Introduction: Mercury Racing Blue Powder Coat; Users are seeking alternatives to achieve the luster of the Mercury color; Suggested to use sample cards from local powder coaters to match the color; Mention of trying Eastwood Mirror Blue and Prismatic Powders’ Intense Blue; Discussion on base coats (gray or silver) before applying blue; Two-stage powder coating with bright silver and candy blue; Mention of Dodge…

6. 7Gate – Metallic Blue Powder Coat

7. The Powder Coat Store – Premium Powder Coating Supplies

Domain: thepowdercoatstore.com

Registered: 2013 (12 years)

Introduction: This company, The Powder Coat Store – Premium Powder Coating Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for intense blue powder coat

In the competitive landscape of powder coating, sourcing the right products, such as intense blue powder coat, is crucial for businesses aiming to deliver high-quality finishes. Intense blue, characterized by its vibrant hue and glossy finish, not only enhances aesthetic appeal but also ensures durability across various applications—from automotive to architectural designs. Buyers should prioritize suppliers that provide reliable color matching and extensive product documentation, ensuring compatibility with base coats for optimal results.

Strategic sourcing is essential to mitigate risks associated with supply chain disruptions and to secure consistent quality. By establishing strong partnerships with reputable manufacturers, businesses can benefit from better pricing, timely deliveries, and access to innovative products. Furthermore, with the increasing demand for custom finishes in regions like Africa, South America, the Middle East, and Europe, there lies a significant opportunity for international buyers to diversify their portfolios.

As the market continues to evolve, staying informed about trends in powder coating technology will empower buyers to make proactive decisions. Engage with trusted suppliers, explore new formulations, and leverage local insights to enhance your offerings. Embrace the potential of intense blue powder coat to elevate your product line and meet the expectations of discerning customers worldwide.