Contents

Manufacturing Insight: Instant Sheet Metal Quote

Accelerate Your Prototyping and Production with Precision Sheet Metal Fabrication

Honyo Prototype delivers end-to-end sheet metal fabrication services engineered for speed, precision, and scalability, serving demanding industries from aerospace to medical devices. Our integrated capabilities—including laser cutting, CNC punching, precision bending, welding, and finishing—ensure complex geometries meet tight tolerances while maintaining structural integrity and surface quality. We specialize in rapid prototyping and low-to-mid volume production, leveraging advanced machinery and rigorous quality control to transform designs into certified, production-ready components.

Central to our commitment to efficiency is the Online Instant Quote platform, eliminating traditional quotation bottlenecks. Engineers and procurement teams can now upload CAD files, specify materials, finishes, and quantities, and receive a detailed, transparent cost estimate within seconds—not days. This tool integrates real-time manufacturability feedback, highlighting potential design optimizations to reduce lead times and costs upfront. By combining instant quoting with seamless transition to fabrication, Honyo Prototype streamlines your supply chain, ensuring faster time-to-market without compromising on the precision your projects demand.

| Service Feature | Capability | Impact on Your Project |

|---|---|---|

| Material Range | Aluminum, Stainless Steel, Carbon Steel, Copper | Flexible sourcing for diverse applications |

| Tolerance Precision | ±0.05 mm (bending), ±0.1 mm (cutting) | Consistent quality for critical assemblies |

| Lead Time | As fast as 3–5 business days for prototypes | Accelerated development cycles |

| Finishing Options | Anodizing, Powder Coating, Passivation | Enhanced durability and aesthetic compliance |

Technical Capabilities

Technical specifications for an instant sheet metal quote system are essential for enabling rapid, accurate manufacturing feasibility and cost assessment. The following table outlines key parameters relevant to laser cutting, bending, and welding processes, including supported materials such as Aluminum, Steel, ABS, and Nylon.

| Process | Parameter | Specification Details |

|---|---|---|

| Laser Cutting | Material Compatibility | Aluminum (5052, 6061), Cold Rolled Steel (CRS), Stainless Steel (304, 316), ABS, Nylon |

| Thickness Range | 0.5 mm – 25 mm (varies by material: up to 12 mm for ABS/Nylon) | |

| Tolerance | ±0.1 mm for metals; ±0.2 mm for plastics | |

| Minimum Feature Size | 1x material thickness (e.g., 1 mm for 1 mm sheet) | |

| Edge Quality | Burr-free cut on metals; clean melt edge on plastics with minimal charring | |

| Supported File Formats | DXF, DWG, STEP, IGES (flat pattern required for bending) | |

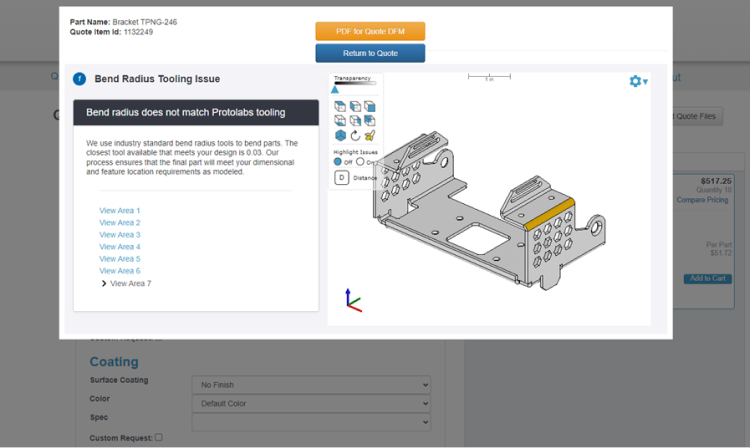

| Bending | Bend Radius | Standard: 1x material thickness; minimum 0.8 mm for metals, 1.5 mm for plastics |

| Bend Tolerances | ±0.25° angular tolerance; ±0.2 mm leg length | |

| Maximum Bend Length | Up to 3000 mm (dependent on press brake capacity) | |

| Tooling | Air bending with standard V-dies; custom tooling available on request | |

| Springback Compensation | Automatically applied based on material and thickness | |

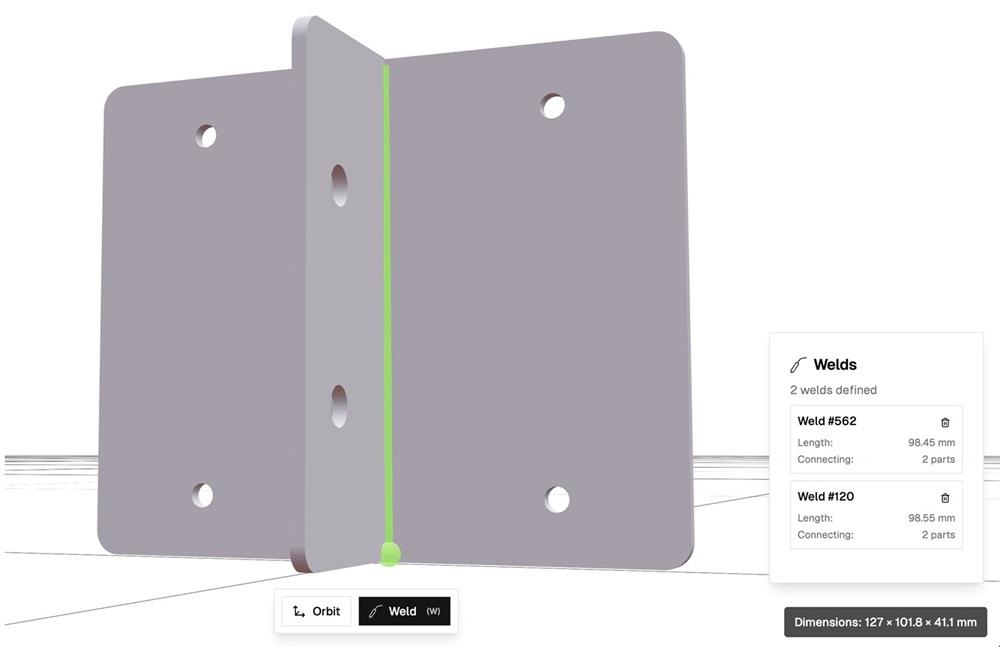

| Welding | Joining Methods | MIG, TIG, Spot Welding (metals); ultrasonic or vibration welding (ABS, Nylon) |

| Weld Quality Standards | AWS D1.1 for structural steel; cosmetic welds ground and blended per finish spec | |

| Fixturing | Custom jigs used for dimensional accuracy; GD&T compliance if specified | |

| Post-Weld Treatments | Grinding, sanding, stress relieving, or passivation (stainless) | |

| Weld Tolerance | ±0.5 mm positional tolerance on critical features | |

| Materials | Aluminum | Grades 5052, 6061-T6; max thickness 12 mm; anodizing/powder coat ready |

| Steel | CRS, HRPO, Stainless 304/316; thickness 0.8–25 mm; zinc plating or painting available | |

| ABS | Sheet form up to 10 mm; suitable for laser cutting and ultrasonic welding | |

| Nylon | Up to 8 mm thickness; limited laser cutting due to melt behavior; better for machining |

Note: ABS and Nylon are not typically processed via standard sheet metal bending or arc welding. Their inclusion requires adapted techniques such as thermal forming or plastic welding, and must be clearly specified in the quote request. Instant quoting systems must validate geometry, material suitability, and process constraints automatically to ensure manufacturability.

From CAD to Part: The Process

Honyo Prototype Instant Sheet Metal Quoting Process Overview

Honyo Prototype delivers rapid, accurate sheet metal quotations through an integrated digital workflow combining AI validation, real-time manufacturability analysis, and seamless production handoff. This eliminates traditional quoting delays while ensuring technical feasibility. Below is the detailed process flow.

Upload CAD

Customers submit native or neutral CAD files via our secure web portal. Supported formats include STEP AP203/AP214, IGES, Parasolid (.x_t, .x_b), and native SolidWorks, Fusion 360, and Creo files. The system automatically validates file integrity, checks for missing components in assemblies, and confirms geometric completeness. Invalid or corrupted files trigger immediate user notification with specific error diagnostics, preventing downstream processing failures.

AI-Powered Quoting Engine

Validated CAD geometry undergoes automated feature extraction where the AI engine identifies critical manufacturing parameters: material type/thickness, bend counts, hole patterns, cutouts, and surface finishes. Real-time cost algorithms calculate material consumption, machine time (laser/punching), secondary operations (welding, tapping), and finishing based on live shop floor data including current machine utilization rates and material pricing. This generates a technically grounded quote within 90 seconds, inclusive of precise lead time estimates derived from production capacity dashboards.

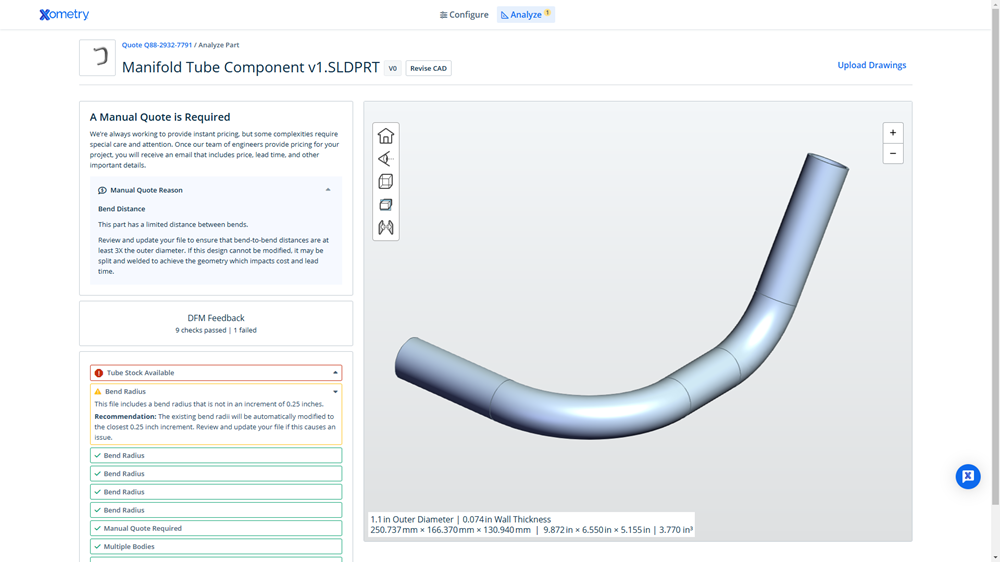

Integrated DFM Analysis

Concurrently with quoting, our proprietary DFM module performs rule-based manufacturability checks against Honyo’s process capabilities. It flags violations such as minimum bend radii violations, hole-to-edge spacing issues, inadequate flange lengths, or non-standard tolerances. Critical errors halt quote generation until resolved; advisory warnings are highlighted in the quote report with actionable redesign suggestions. This ensures all quoted parts are producible without manual engineering review cycles.

Production Handoff

Approved quotes transition directly to our MES (Manufacturing Execution System) with zero data re-entry. Nesting software optimizes material utilization across shared sheets, while CNC programs auto-generate from the validated CAD model. Quality control plans are pre-loaded with inspection points based on identified critical features. Real-time production tracking begins immediately upon work order release, with customers receiving automated milestone updates via the portal.

Delivery Commitment

Finished parts undergo final inspection against AS9102 or customer-specified FAIR documentation. Standard lead times range from 3-7 business days for simple brackets to 10-15 days for complex assemblies with multiple secondary operations, contingent on material availability. All shipments include traceable material certs and first-article reports where required. Expedited options (24-72hr) are available for qualifying geometries.

Supported CAD Formats for Instant Quoting

| Format Type | File Extensions | Validation Level |

|——————-|———————-|——————|

| Native CAD | .sldprt, .f3d, .prt | Full geometry |

| Neutral Exchange | .stp, .igs, .x_t | Surface topology |

| 2D Drawings | .dxf, .dwg (R2018+) | Profile extraction only |

This closed-loop process reduces quoting time by 95% compared to manual methods while maintaining >98% quote accuracy through embedded manufacturability intelligence. By resolving DFM conflicts upfront, we eliminate costly engineering change orders post-award, accelerating time-to-shipment for production-intent prototypes and low-volume runs.

Start Your Project

Receive an instant sheet metal quote today and accelerate your prototyping timeline. Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and streamlined processes at our Shenzhen factory, Honyo Prototype delivers fast, accurate quotes and rapid turnaround for all sheet metal fabrication needs.

Let us support your next product development cycle with precision engineering and reliable service—reach out now to get started.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.