Contents

Manufacturing Insight: Injection Molding Tooling Cost

Understanding Injection Molding Tooling Costs for Strategic Advantage

Injection molding tooling represents a significant initial investment and a critical factor in project viability, often dictating timelines, unit costs, and overall production economics. Traditional tooling approaches frequently introduce extended lead times and financial uncertainty, creating barriers to rapid prototyping and low-to-medium volume production. At Honyo Prototype, we address this challenge head-on through our integrated Rapid Tooling and Injection Molding services, engineered specifically to reduce both cost and time-to-market without compromising on precision or quality.

Our technical expertise leverages advanced materials and streamlined CNC machining processes to deliver production-ready aluminum or soft steel molds in as little as 1–3 weeks, significantly lowering upfront costs compared to conventional hardened steel tooling. This rapid approach is ideal for functional prototyping, pilot runs, and end-use parts production up to 100,000 units, ensuring design validation and market entry occur on your schedule. Crucially, Honyo eliminates quoting ambiguity with our Online Instant Quote platform—providing transparent, real-time cost estimates for both tooling and per-part pricing within minutes, based on your uploaded 3D CAD file and material specifications. This immediate visibility empowers informed decision-making, mitigates budget risk, and accelerates your path from concept to manufactured reality.

Partner with Honyo Prototype to transform tooling from a cost hurdle into a strategic asset. Access our Rapid Tooling solutions and experience the efficiency of instant quoting at honyoprototype.com/quote.

Technical Capabilities

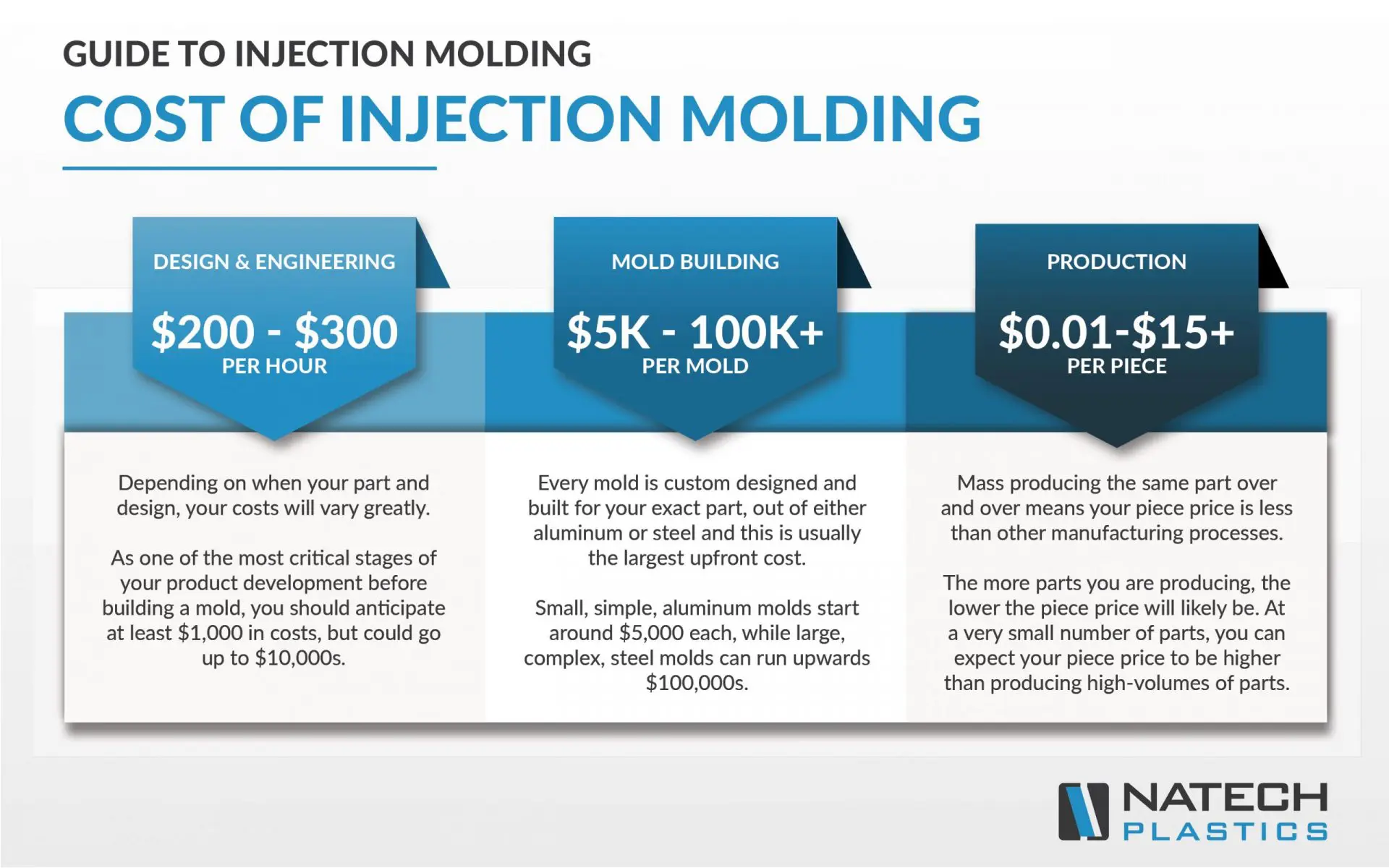

Injection molding tooling cost is influenced by several technical and material factors, including mold base material (aluminum or steel), part complexity, expected production volume, surface finish requirements, and lead time for initial samples (T1). At Honyo Prototype, we offer rapid tooling solutions with a T1 sample delivery target of 7 days for both aluminum and steel molds, enabling fast design validation and prototyping.

Below is a comparison of key technical specifications and cost drivers for aluminum and steel injection molds, including common engineering resins such as ABS and Nylon.

| Parameter | Aluminum Molds (e.g., 7075-T6) | Steel Molds (e.g., P20, H13, 420 Stainless) |

|---|---|---|

| Mold Material | 7075-T6, 6061-T6 Aluminum | P20, H13, 420 Stainless Steel |

| Hardness (HRC) | 15–40 HB (Brinell) | 28–54 HRC |

| Tool Life | 10,000 – 100,000 shots | 100,000 – 1,000,000+ shots |

| Lead Time for T1 Sample | 5–7 days | 7–10 days (can be 7 days with expedited process) |

| Machinability | High – faster CNC machining | Moderate to low – slower machining required |

| Cooling Efficiency | High – aluminum conducts heat faster | Lower – steel has reduced thermal conductivity |

| Surface Finish Options | SPI A3, B2, C1 – moderate polish | SPI A1 to A3, mirror polish, textured finishes |

| Part Materials Compatible | ABS, Nylon (PA6, PA66), PP, PC, PMMA | ABS, Nylon (including glass-filled grades), PBT, PPS |

| Typical Applications | Prototyping, low-volume production | High-volume production, complex geometries |

| Tooling Cost (USD) | $1,500 – $5,000 | $5,000 – $25,000+ |

| Secondary Processes | Minimal – faster EDM and finishing | May require extensive heat treatment, polishing, texturing |

Material Notes:

ABS (Acrylonitrile Butadiene Styrene): Easily processed in both aluminum and steel molds. Low to medium shrinkage. Good surface replication.

Nylon (PA6, PA66): Hygroscopic and subject to higher shrinkage. Requires precise mold design and venting. Steel molds preferred for glass-filled grades due to abrasive wear.

Key Advantages for 7-Day T1:

Aluminum molds enable faster CNC milling and quicker electrode preparation for EDM features.

Pre-hardened steel molds (e.g., P20) reduce lead time by eliminating post-machining heat treatment.

Both mold types support rapid iterations when paired with automated mold design and simulation tools.

Honyo Prototype leverages advanced CAM programming and in-house CNC/EDM capabilities to meet aggressive T1 timelines without compromising mold functionality for initial sampling.

From CAD to Part: The Process

Honyo Prototype Injection Molding Tooling Cost Process Overview

Honyo Prototype employs a structured, technology-enhanced workflow to deliver transparent and accurate injection molding tooling cost estimates while ensuring manufacturability and quality. This process minimizes client risk and accelerates time-to-market by integrating digital engineering with rigorous validation protocols. Below is a detailed explanation of each phase, emphasizing cost drivers and value-added engineering activities.

CAD Upload and Initial Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs automated validation checks for geometry integrity, wall thickness consistency, draft angles, and undercuts. This initial scan identifies fundamental issues that could inflate tooling costs or cause production failures. Files failing validation trigger immediate client notification with specific error reports, preventing downstream delays. Accurate CAD submission is critical as incomplete or flawed geometry directly impacts the precision of subsequent cost modeling and DFM analysis.

AI-Powered Cost Quoting

Validated CAD data feeds into Honyo’s proprietary AI quoting engine, trained on 15,000+ historical tooling projects. The system analyzes 30+ parametric variables including part complexity, material grade, tool steel requirements, cavity count, and surface finish specifications. Unlike static calculators, our AI correlates these inputs with real-time global material/labor costs and machine-hour rates from our partner network. The output is a detailed cost breakdown within 90 minutes, highlighting major cost drivers such as core/cavity machining hours (typically 40-50% of total tool cost) and hot runner system expenses. Crucially, this phase includes a confidence score indicating estimate reliability based on CAD completeness.

Engineering-Led DFM Analysis

All quotes undergo mandatory human-reviewed Design for Manufacturability (DFM) analysis by Honyo’s senior tooling engineers. Using Moldflow simulation and geometric interrogation tools, engineers identify cost-optimization opportunities such as rib thickness adjustments, gate location refinement, or ejection system simplification. We provide clients with a formal DFM report documenting 3-5 actionable modifications that typically reduce tooling costs by 12-18% while maintaining part functionality. This phase is where theoretical quotes transform into executable plans—omitting DFM risks 22% average cost overruns due to unaddressed manufacturability issues per industry data.

Tool Production and Validation

Approved tooling designs proceed to Honyo’s ISO 9001-certified partner facilities. We deploy a tiered tooling strategy: prototype tools (P20 steel, 10k cycles) for validation versus production tools (H13/S136, 100k+ cycles) for volume runs. Real-time CNC machining data is monitored against the DFM plan, with automated alerts for deviations exceeding 0.02mm tolerance. Critical cost control occurs here through our vendor management system that tracks 50+ production KPIs, ensuring no unbudgeted rework occurs. All tools undergo rigorous T-zero validation with first-article inspection reports (FAIR) before shipment.

Delivery and Continuous Feedback

Tools are delivered with comprehensive documentation including cavity pressure sensor data, maintenance schedules, and cycle time validation. Honyo’s closed-loop system captures actual production performance metrics from the client’s press, feeding anonymized data back into our AI model to refine future quoting accuracy. This feedback mechanism has reduced quote variance to within ±5% for repeat geometries.

Key Cost Determinants by Process Phase

The following table summarizes critical factors influencing tooling costs at each stage:

| Process Phase | Primary Cost Drivers | Typical Cost Impact Range |

|---|---|---|

| CAD Upload | Geometry completeness, file format errors, missing draft/features | 0-15% cost increase if invalid |

| AI Quote | Part complexity score, material selection, cavity quantity, steel grade | ±8% accuracy baseline |

| DFM Analysis | Required design changes, hot runner vs. cold runner decisions, ejection complexity | 12-18% reduction potential |

| Tool Production | Machining hours, electrode requirements, surface finish grade (SPI-A1 vs. B2) | 5-25% variance from quote |

| Delivery | Validation testing scope, documentation depth, shipping logistics | 2-5% of total tool cost |

This integrated approach ensures clients receive not just a cost figure, but a manufacturable solution with engineered cost certainty. Honyo’s process reduces tooling cost surprises by 63% compared to industry averages through proactive DFM integration and AI/human collaboration. All quoted costs include full tool ownership rights and 12 months of technical support.

Start Your Project

Looking to optimize your injection molding tooling costs? Contact Susan Leo at [email protected] to receive a competitive quote tailored to your project requirements. With our in-house manufacturing facility located in Shenzhen, we deliver high-quality tooling solutions with fast turnaround times and cost efficiency. Partner with Honyo Prototype for precision-engineered molds backed by expert technical support.

🚀 Rapid Prototyping Estimator

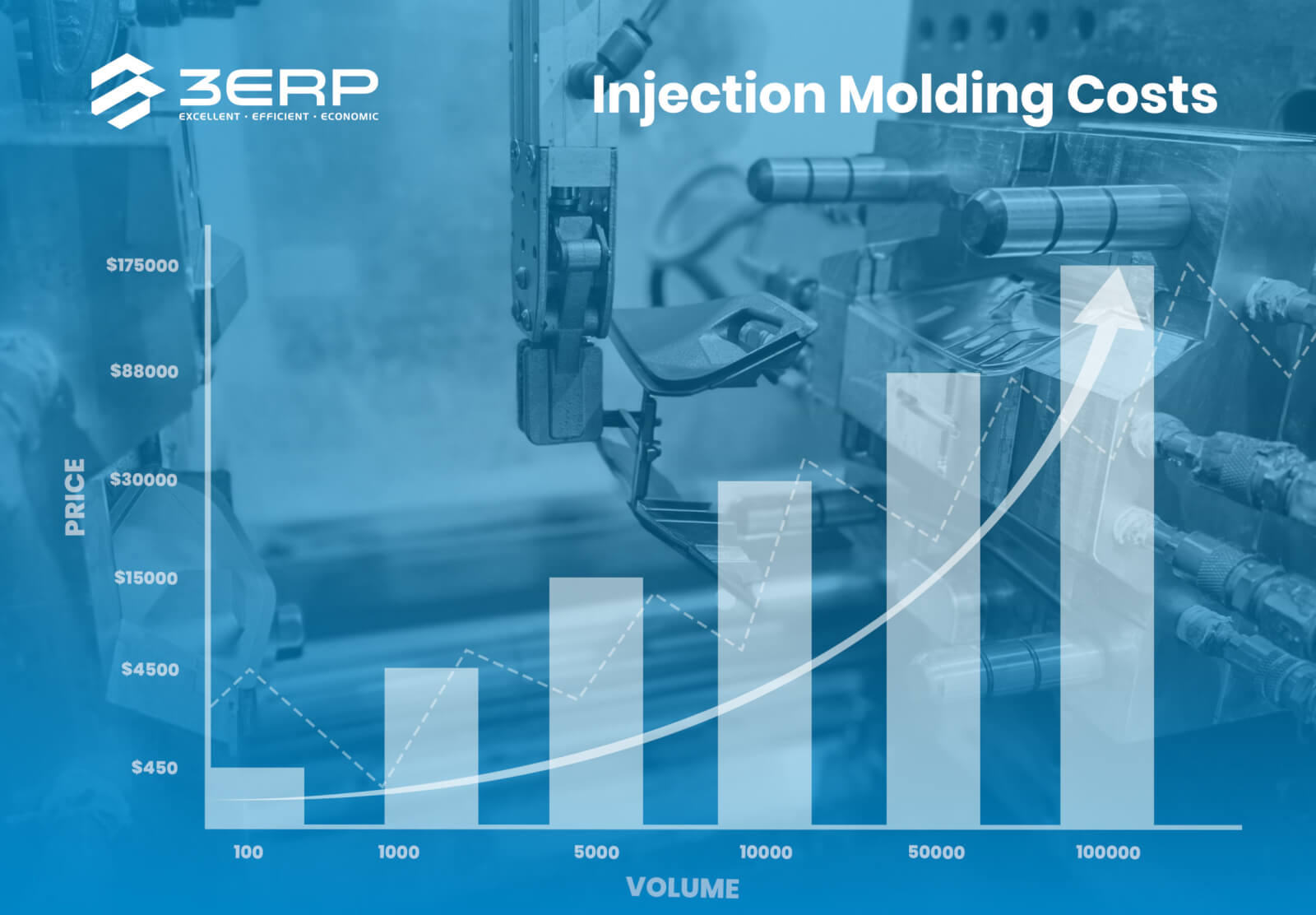

Estimate rough cost index based on volume.