Contents

Manufacturing Insight: Injection Molding Steel

Material Selection Precision for Injection Molding Steel

The performance and longevity of any injection molded component begin with strategic steel selection for the mold tool. At Honyo Prototype, we recognize that optimal steel grade—whether P20 for prototyping, 718HH for medium production, H13 for high-heat applications, or S136 for corrosion resistance—directly impacts part integrity, cycle times, and total cost of ownership. Our engineering team leverages deep metallurgical expertise to match your project’s thermal stability, wear resistance, and surface finish requirements with the precise steel solution, eliminating costly trial-and-error in tool fabrication.

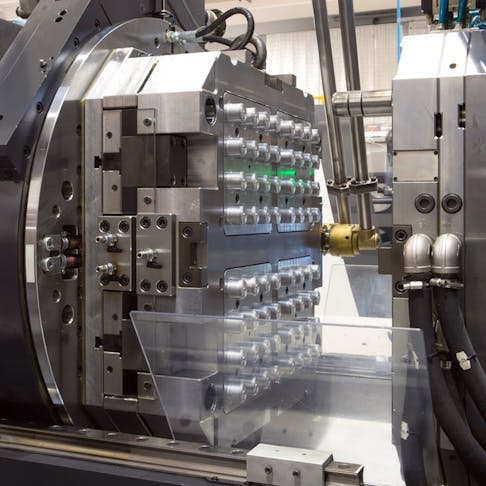

Integrated Rapid Tooling & Production Capabilities

Honyo Prototype bridges prototyping and volume production through our unified Rapid Tooling and Injection Molding services. We deploy CNC-machined aluminum or steel molds for functional validation within 7–15 days, transitioning seamlessly to hardened steel production tools without design rework. This integrated workflow ensures dimensional continuity from first-article approval to high-volume runs, reducing time-to-market by up to 50% while maintaining ISO 9001-certified process control for critical features like tight tolerances and complex geometries.

Accelerate Your Project Timeline Today

Eliminate procurement delays with Honyo’s Online Instant Quote platform. Upload your 3D CAD file to receive a detailed, no-obligation cost analysis for both rapid tooling and production molding within hours—not days. Our system dynamically factors in steel grade recommendations, cavity count, material selection, and secondary operations, providing transparent pricing aligned with your technical specifications. Begin optimizing your injection molding steel strategy with engineering-grade accuracy at honyoprototype.com/quote.

Technical Capabilities

Honyo Prototype delivers high-performance injection molding solutions with rapid turnaround for T1 samples in as little as 7 days. Our expertise spans both aluminum and steel mold bases, optimized for use with engineering-grade thermoplastics such as ABS and Nylon. Below are the technical specifications and material options for our injection molding tooling and processes.

| Parameter | Aluminum Molds (7075-T6, 6061-T6) | Steel Molds (P20, H13, S136) | Notes |

|---|---|---|---|

| Mold Base Material | 7075-T6, 6061-T6 Aluminum | P20 (pre-hardened), H13 (tool steel), S136 (stainless) | Aluminum for rapid prototyping; steel for high-volume production |

| Hardness (HRC) | 15–30 HRC | 28–52 HRC (varies by grade) | Steel offers higher wear resistance and longevity |

| Surface Finish Options | As-machined, Polished, Textured (VDI 13–28) | Polished (up to SPI A1), Textured, Coated | Available per customer specifications |

| Typical Tool Life | 10,000 – 50,000 shots | 100,000 – 1,000,000+ shots | Steel molds preferred for high-volume runs |

| Lead Time (T1 Sample) | As fast as 5–7 days | 7–14 days (depending on complexity) | Rapid delivery with full functionality and first-article inspection |

| Compatible Resins | ABS, Nylon (PA6, PA66), PP, PC, PMMA | ABS, Nylon (including glass-filled grades), POM, PSU | Both mold types support engineering thermoplastics |

| Cooling Efficiency | High (due to aluminum’s thermal conductivity) | Moderate to High (design-dependent) | Aluminum enables faster cycle times |

| Secondary Operations | CMM inspection, Heat Treatment (steel), EDM, CNC Finishing | Same as aluminum, plus nitriding or chrome plating for steel | Ensures dimensional accuracy and durability |

| Applications | Prototypes, Bridge Tooling, Low-to-Mid Volume | Mid-to-High Volume, Long-Run Production | Material choice depends on production volume and part requirements |

We utilize high-grade 7075-T6 and 6061-T6 aluminum for rapid mold fabrication, enabling T1 sample delivery in 7 days without compromising part quality. For extended production, we offer P20, H13, and corrosion-resistant S136 steels, supporting demanding resins like glass-filled nylon and high-flow ABS. All molds are built to ISO 2768-mK standards with full first-article reporting and dimensional validation.

From CAD to Part: The Process

Honyo Prototype utilizes a defined digital workflow for manufacturing precision components, including those produced via Metal Injection Molding (MIM) for steel alloys. It is critical to clarify that “injection molding steel” refers to Metal Injection Molding (MIM), a distinct process from plastic injection molding. MIM combines powdered metal (such as stainless steel, tool steel, or low-alloy steel) with a polymer binder, injects the mixture into a mold, and then removes the binder and sinters the part to achieve a dense metal component. The following outlines our standardized process for MIM steel projects:

Upload CAD

The process initiates when a client uploads a 3D CAD model of the target steel component through our secure customer portal. Our system accepts industry-standard formats including STEP, IGES, and native SOLIDWORKS files. This model must accurately represent the final geometry, including critical features like undercuts, wall transitions, and draft angles essential for successful MIM processing. Early-stage design files are acceptable, but final production requires fully detailed geometry meeting MIM feasibility criteria.

AI Quote

Upon CAD upload, our proprietary AI quoting engine immediately analyzes the geometry, material selection (e.g., 17-4PH stainless steel, 316L, or 420F), and requested quantity. The AI assesses key parameters such as part volume, projected footprint, feature complexity, and surface finish requirements against real-time data on material costs, machine utilization, and historical process yields for steel MIM. Within minutes, the client receives a preliminary quote detailing estimated unit cost, lead time bracket, and high-level manufacturability flags. This AI-driven step provides rapid initial feedback without requiring manual engineering review at this stage.

DFM Analysis

Following quote acceptance, Honyo’s senior MIM engineering team conducts a comprehensive Design for Manufacturability (DFM) review specific to steel MIM. This critical phase identifies potential issues that could compromise part integrity, dimensional accuracy, or cost efficiency in the sintering phase. Key considerations for steel alloys include managing shrinkage rates (typically 15-20%), avoiding excessive section thickness causing sink marks, ensuring adequate draft for ejection, and verifying tolerance feasibility post-sintering. The DFM report provides actionable recommendations with engineering rationale.

The following table summarizes critical DFM factors evaluated for steel MIM components:

| DFM Factor | Steel MIM Requirement | Potential Issue if Ignored |

|---|---|---|

| Wall Thickness Uniformity | Maintain consistent thickness; max 6mm for most steels | Sintering distortion, density variations, sink marks |

| Draft Angles | Minimum 1°–2° per side on vertical walls | Part sticking, ejection damage, increased flash |

| Feature Radius | Internal radii ≥ 0.2mm; external radii ≥ 0.5mm | Stress concentrations, cracking during sintering |

| Tolerance Capability | ±0.3% to ±0.5% of dimension typical post-sintering | Assembly failures, secondary machining costs |

| Undercuts | Avoid or design for collapsible cores | Mold complexity, cost escalation, part defects |

Production

After DFM approval and client sign-off, Honyo proceeds to production. For steel MIM, this involves: feedstock preparation (blending metal powder with binder), injection molding using hardened steel molds, catalytic or thermal debinding to remove the binder phase, and high-temperature sintering in controlled atmosphere furnaces to achieve near-full density. All steel MIM production occurs in our ISO 9001-certified facility with in-process checks for dimensional stability, density, and material properties per ASTM standards. Secondary operations like heat treatment, machining, or surface finishing are integrated as specified.

Delivery

Finished steel MIM components undergo final inspection against the approved drawing, including CMM verification, visual examination, and material certification review. Parts are packaged to prevent transit damage, especially critical for high-precision steel components susceptible to corrosion or handling marks. Honyo provides full traceability documentation including lot-controlled material test reports, process parameter logs, and first-article inspection data. Shipment occurs via client-preferred carriers with real-time logistics tracking, ensuring on-time delivery to global destinations per the agreed schedule. Post-delivery, our engineering team remains available for technical support and continuous improvement feedback.

Start Your Project

Looking for high-quality injection molding steel for your next project? Source directly from our factory in Shenzhen with fast lead times and consistent material performance.

Contact Susan Leo today at [email protected] to discuss your material requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.