Guide Contents

Project Insight: Injection Molding Steel

Manufacturing Insight: Injection Molding Steel

Why Speed & Precision Define Modern Product Development

Time-to-Market Pressure: Startups and product teams operate on razor-thin windows—delays in tooling can derail launches, erode investor confidence, and cede market share.

Quality Consistency: Minor mold imperfections cause part defects, rework, and supply chain bottlenecks. Precision engineering ensures functional reliability from the first prototype.

Bridge Tooling Advantage: Steel molds deliver the perfect balance of durability and cost-efficiency for low-to-medium volumes (100–10,000+ parts), eliminating the need for expensive high-volume tooling while outperforming aluminum or 3D-printed alternatives.

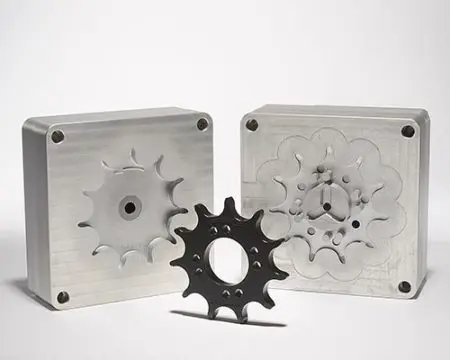

Steel Molds: The Strategic Choice for Agile Manufacturing

Unmatched Durability: Withstand 100,000+ cycles without wear—ideal for iterative testing, pre-production runs, and scaling to full-scale manufacturing.

Precision Engineering: Tight tolerances (<±0.001″) for complex geometries, critical for functional prototypes, medical devices, and consumer electronics.

Cost-Effective Scaling: Lower per-part costs than aluminum molds for volumes beyond 500+ units, reducing long-term production expenses while avoiding the “cheap tooling trap” (hidden costs from premature failure).

Your Digital Manufacturing Partner: Fast, Transparent, Reliable

Online Instant Quote: Upload your CAD in seconds—our AI-powered platform delivers accurate cost estimates with no hidden fees or weeks-long wait times.

7-Day Tooling Lead Time: From design validation to mold delivery, we compress traditional timelines by 60%+—accelerating your path to market without compromising quality.

End-to-End Expertise: Seamlessly integrate overmolding, insert molding, and material selection—all managed through a single digital workflow, so you focus on innovation, not logistics.

“At Honyo Prototype, we don’t just build molds—we engineer speed into your product lifecycle. With steel molds optimized for bridge tooling, you get the precision of production-grade tooling at startup-friendly speeds.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

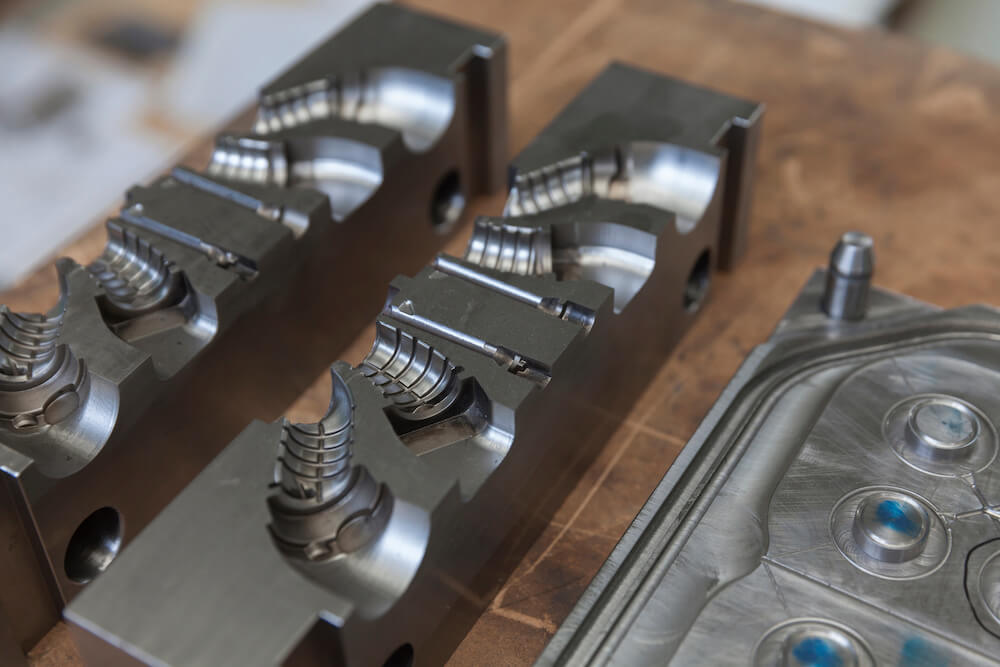

Precision Steel Mold Engineering

High-Grade Tool Steels: Precision-engineered with P20, H13, and S136 steel for exceptional wear resistance, thermal stability, and longevity.

Tight Tolerances: ±0.001″ dimensional accuracy and customizable surface finishes (mirror polish, texture, coatings) for flawless part quality.

Multi-Cavity Flexibility: Configurable single or multi-cavity molds to optimize production efficiency for your specific volume needs.

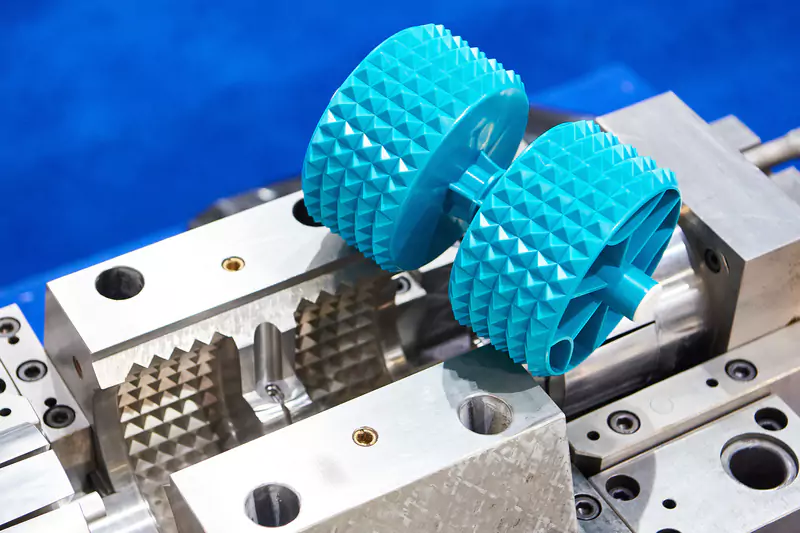

Bridge Tooling for Scalable Production

Cost-Optimized for Low-Volume: Steel molds designed for 100–10,000+ parts with 30–40% lower upfront costs vs. traditional high-volume tooling—no compromise on durability.

Seamless Scalability: Transition smoothly from prototyping to full-scale production using the same mold, eliminating costly retooling delays.

Superior Wear Performance: Outperforms aluminum in high-wear applications (e.g., abrasive resins, high-cycle runs), ensuring consistent quality across thousands of parts.

AI-Powered Digital Manufacturing Platform

Online Instant Quote: Get real-time, transparent pricing in seconds—no hidden fees, no delays. Our platform instantly calculates costs for mold, material, and production.

AI-Driven DFM Optimization: Proprietary algorithms analyze your design for manufacturability, reducing costs by up to 25% while enhancing part performance.

Industry-Leading Turnaround: Standard molds delivered in 7–10 days; complex geometries in 15 days—50% faster than traditional manufacturers.

ISO-Certified Quality Assurance

End-to-End Control: ISO 9001-certified processes with 100% first-article inspection and in-process IoT monitoring for zero-defect consistency.

Full Traceability: Detailed documentation of materials, processes, and QC checks for every batch—ensuring compliance and audit readiness.

Proactive Support: Dedicated engineering team collaborates from design to delivery, solving challenges before they arise.

“At Honyo, we redefine ‘bridge tooling’—combining steel’s durability with agile, AI-driven manufacturing to turn your prototype into production-ready reality, faster and smarter.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes

Optimize Your Part Performance with Precision Material Selection

Choosing the right thermoplastic isn’t just about specs—it’s about aligning material properties with your product’s real-world demands. Our steel mold tooling (designed for 100-10,000+ parts) ensures consistent results across your entire production run, while our AI-powered platform instantly matches your requirements to the ideal material.

ABS: Ideal for durable consumer products with good impact resistance and easy post-processing. Perfect for housings, automotive interiors, and prototyping.

Polycarbonate (PC): High heat and impact resistance. Best for optical clarity, medical devices, and structural components requiring transparency.

Polypropylene (PP): Chemical resistance and flexibility. Ideal for living hinges, medical containers, and food-safe applications.

Thermoplastic Elastomers (TPE): Rubber-like flexibility with injection molding efficiency. Used for grips, seals, and soft-touch surfaces.

Tailored Surface Finishes for Enhanced Functionality

Surface finish isn’t just cosmetic—it enhances durability, usability, and brand perception. Our integrated finishing capabilities ensure precision without compromising part integrity.

High-Gloss Polishing: Mirror-like finish for premium electronics or optical components (e.g., smartphone cases, lenses).

Textured Finishes (SPI Standards): Custom textures for grip enhancement, scratch resistance, or aesthetic branding (e.g., leather grain, wood grain).

Painting & Powder Coating: Uniform color and corrosion protection for automotive or outdoor equipment.

Anodizing (for Metal Inserts): Wear-resistant, color-stable finishes for aluminum components integrated via insert molding.

Matte Finishes: Non-reflective surfaces for medical devices or ergonomic designs where glare reduction is critical.

Why Honyo Prototype Delivers Superior Results

Instant AI-Driven Quotes: Upload your CAD in seconds to receive a cost breakdown with material and finish recommendations—no back-and-forth.

Bridge Tooling Expertise: Steel molds optimized for low-volume production (100-10,000+ parts), reducing upfront costs while maintaining production-grade quality.

End-to-End Integration: From material selection to finishing, our Shenzhen-based team ensures seamless execution with 5-7 day lead times.

Cost Transparency: No hidden fees—our platform breaks down costs by material, finish, and mold complexity so you know exactly what you’re paying for.

Innovation Tip: Use our AI tool to simulate material behavior under real-world conditions (e.g., thermal stress, UV exposure) before committing to production. “We don’t just build molds—we build solutions that scale with your vision.” — Susan Leo, Founder

From Quote to Part: Our Process

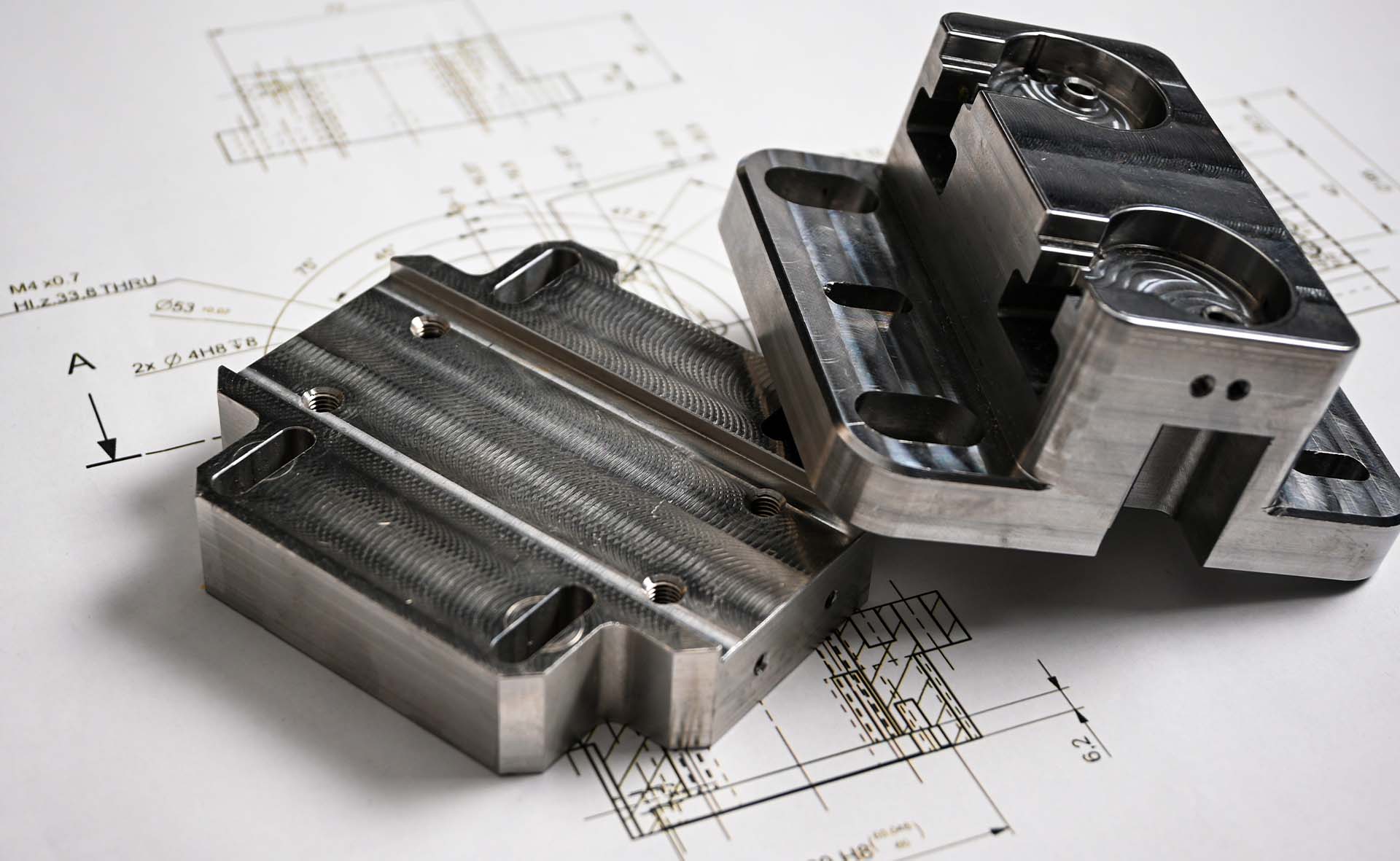

How It Works: From CAD to Part

Honyo’s end-to-end process transforms complex manufacturing into a simple, transparent journey—so you can focus on innovation, not logistics. Here’s how we turn your design into production-ready parts in record time:

Step 1: Upload Your CAD File

Seamless cloud-based submission of STEP, STL, or native CAD files (SolidWorks, Fusion 360, etc.)—no proprietary software required.

Instant geometry validation for steel tooling compatibility, ensuring your design is production-ready from day one.

Step 2: Get Instant AI-Powered Quote

Receive detailed pricing in seconds—our AI engine analyzes part complexity, material, volume, and tooling requirements to eliminate guesswork.

Transparent, itemized costs for tooling, materials, per-part pricing, and shipping—no hidden fees. Traditional quotes take weeks; Honyo delivers precision pricing in real time.

Step 3: Collaborative DFM Analysis

AI + expert engineering review to optimize draft angles, wall thickness, gate placement, and material flow for steel molds—reducing costs and avoiding production delays.

Iterate seamlessly via our platform: receive actionable feedback, revise designs, and approve changes before tooling begins.

Step 4: Rapid Production & Delivery

Bridge tooling for 100–10,000+ parts with lead times as short as 10 days—far faster than conventional steel molds.

ISO-certified Shenzhen facility handles everything in-house: mold fabrication, injection molding, and quality inspection. Track your project in real time with zero surprises.

“Honyo’s AI-driven workflow cuts traditional lead times by 70% while delivering steel molds built for durability—perfect for startups scaling from prototype to low-volume production.”

— Susan Leo, Founder

Start Your Project with Honyo

Start Your Project with Honyo: Precision Injection Molding, Accelerated

Why Bridge Tooling with Honyo?

Engineered steel molds optimized for 100–10,000+ parts—no over-engineering, no wasted investment

30–50% lower upfront costs vs. full-production tooling, with 500K+ cycle longevity

Precision tolerances (±0.005mm) and ISO 9001-certified quality control for consistent, production-grade parts

AI-Powered Efficiency from Design to Delivery

Instant online quote in under 5 minutes with transparent cost breakdown—no hidden fees, no guesswork

Real-time Design for Manufacturability (DFM) analysis to eliminate redesigns and material waste before tooling starts

7–14 day mold lead time for standard projects, with expedited options for urgent launches

Partner with Industry Experts

Founded by Susan Leo, a veteran mold engineer with 15+ years refining Shenzhen’s manufacturing ecosystem

Dedicated engineering team providing end-to-end support—from CAD optimization to final part validation

On-site facilities in Shenzhen & Dongguan for seamless collaboration and quality assurance

Ready to launch your product faster?

📧 [email protected] | 📞 +86 139 2843 8620

🌐 Visit our Shenzhen/Dongguan facilities for a personalized consultation—where innovation meets precision.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.