Contents

Manufacturing Insight: Injection Molding Part Design

Optimizing Injection Molding Part Design for Production Success

Effective injection molding part design is the critical foundation for achieving manufacturability, cost efficiency, and end-product performance. Poorly conceived geometries, inadequate draft angles, or inconsistent wall thicknesses inevitably lead to defects, extended cycle times, and costly tooling revisions. At Honyo Prototype, we bridge the gap between innovative design and seamless production through our integrated Rapid Tooling and Injection Molding services. Our engineering team collaborates directly with clients during the design phase to conduct thorough Design for Manufacturing (DFM) analysis, identifying and resolving potential issues before tooling begins. This proactive approach prevents delays and ensures your parts are optimized for high-quality, repeatable manufacturing from the first shot.

Leveraging advanced rapid tooling techniques with precision-machined aluminum or steel molds, we deliver functional prototypes and low-to-mid volume production runs in significantly reduced timeframes compared to traditional methods. Our in-house capabilities span material selection, mold flow simulation, and rigorous quality validation, providing a single-source solution for your development lifecycle. Accelerate your path to market with Honyo Prototype’s expertise and eliminate traditional quoting delays using our Online Instant Quote platform, which provides transparent, real-time pricing and lead time estimates within minutes. Partner with us to transform your design into a robust, production-ready reality.

Technical Capabilities

Technical specifications for injection molding part design require careful consideration of mold material, part geometry, material selection, and lead time constraints. For rapid prototyping applications where a T1 sample is required within 7 days, aluminum molds are typically preferred due to faster machinability and reduced lead time. However, steel molds are used for higher production volumes due to superior durability and wear resistance.

The selection of thermoplastic materials such as ABS and Nylon influences mold design due to differences in shrinkage rates, flow characteristics, and processing temperatures. Proper draft angles, uniform wall thickness, and gate location are critical to ensure part quality and mold longevity.

Below is a summary of key technical specifications relevant to injection molding part design under the constraints of using aluminum or steel molds and achieving a T1 sample in 7 days.

| Parameter | Aluminum Mold | Steel Mold | Notes |

|---|---|---|---|

| Mold Material | 7075-T6, 6061-T6 Aluminum | P20, H13, 420 Stainless Steel | Aluminum allows faster CNC machining; steel offers longer mold life |

| Lead Time for T1 Sample | 5–7 days | 10–20 days | Aluminum molds enable T1 in 7 days; steel exceeds this target |

| Suitable for Prototypes | Yes – low to medium volume (1K–10K pcs) | Yes – high volume (100K+ pcs) | Aluminum ideal for rapid validation |

| Surface Finish Options | As-machined, bead blast, polished | Polished, textured, mirror finish | Both support cosmetic finishing; steel holds detail better over time |

| Part Material Compatibility | ABS, Nylon, Polypropylene, PC | ABS, Nylon, PC, POM, high-temp resins | Nylon requires higher mold temps and venting; ABS flows easily |

| Shrinkage Consideration | ABS: 0.4–0.7%, Nylon 6/6: 1.0–1.6% | Same as aluminum | Must be factored into mold cavity design |

| Mold Complexity | Moderate (2-plate, simple cores) | High (multi-cavity, lifters, sliders) | Aluminum limited in complex features due to strength |

| Thermal Conductivity | High (~130–170 W/m·K) | Lower (~25–40 W/m·K) | Aluminum cools faster, reducing cycle time |

| Expected Mold Life | 10,000 – 50,000 cycles | 100,000 – 1M+ cycles | Steel preferred for extended production runs |

| Tooling Cost | Lower ($1,500 – $5,000) | Higher ($5,000 – $50,000+) | Aluminum reduces initial investment for prototyping |

Design recommendations include maintaining draft angles of at least 1° per side, uniform wall thickness (typically 2–3 mm for ABS/Nylon), and proper ejection system layout. For T1 delivery in 7 days, part complexity should be minimized and DFM (Design for Manufacturing) principles strictly followed. Aluminum molds are the optimal choice under this timeline, especially when paired with easy-flowing materials like ABS. Nylon can be used but may require pre-drying and adjusted process parameters.

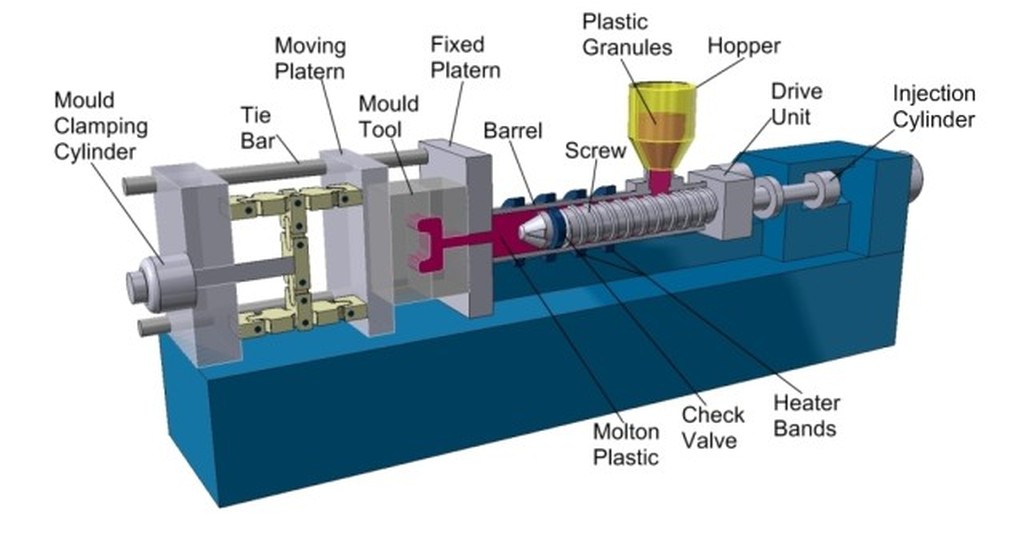

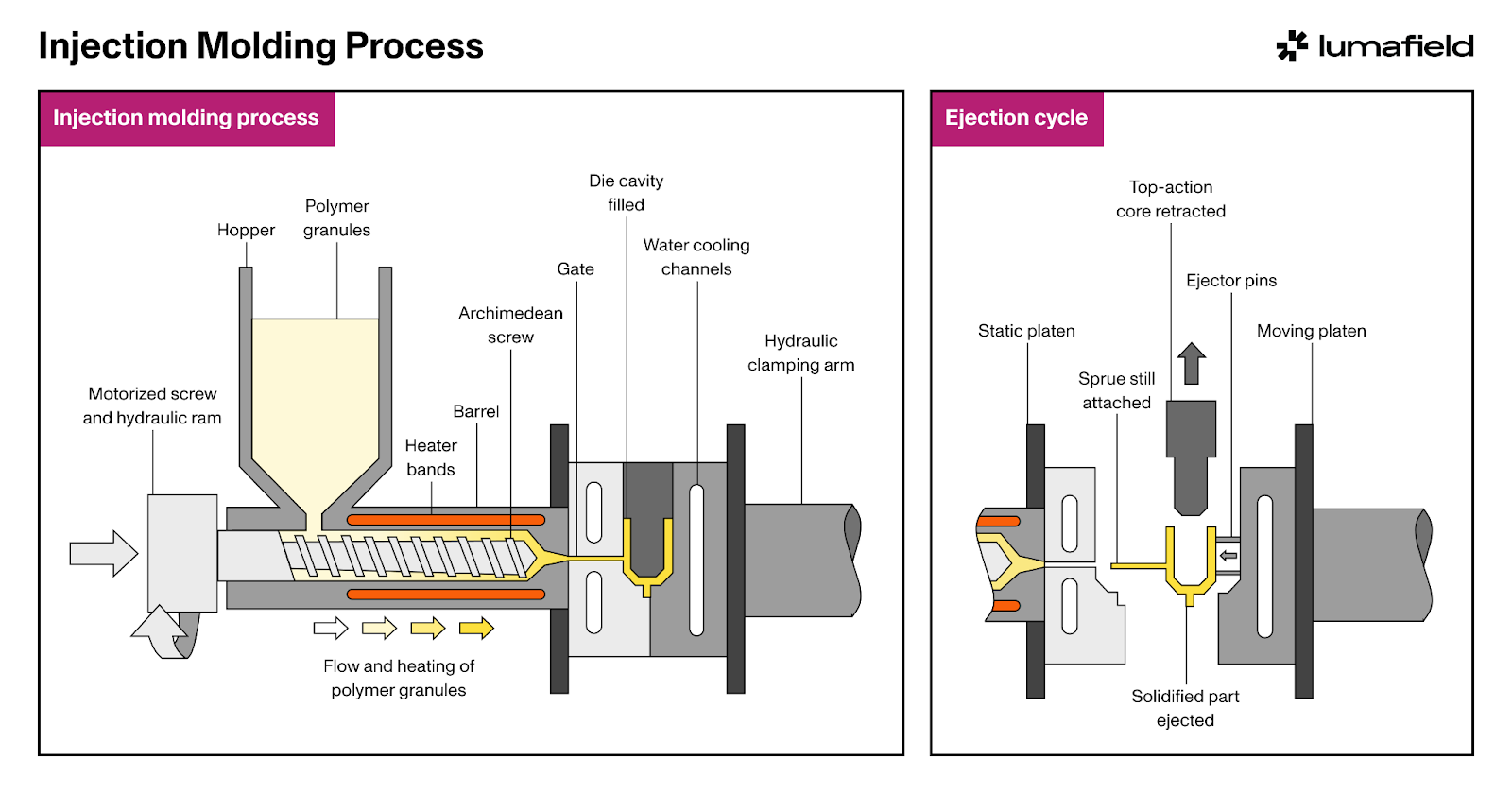

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined injection molding part design workflow engineered to minimize risk, optimize manufacturability, and accelerate time-to-market for client prototypes and low-volume production. Our process integrates advanced digital tools with deep manufacturing expertise across five critical phases.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or industry-standard 3D formats via our secure portal. Our system automatically performs geometry validation checks for watertightness, non-manifold edges, and unit consistency. This foundational step ensures downstream analysis accuracy and prevents common file-related delays. All data is handled under strict NDA protocols with ISO 27001-compliant security.

AI-Powered Quoting Engine

Uploaded geometry feeds directly into our proprietary AI quotation system. This engine analyzes over 200 manufacturability parameters including part volume, projected area, surface complexity, and material-specific flow characteristics. Unlike basic volume calculators, it cross-references real-time data from our production floor including machine availability, material pricing fluctuations, and historical cycle time databases. The output is a detailed quote within 2 business hours containing precise cost breakdowns, material options, and preliminary lead time estimates validated against actual shop floor conditions.

Collaborative DFM Analysis

Following quote acceptance, our engineering team conducts a comprehensive Design for Manufacturability review. This is not an automated checklist but an iterative engineering dialogue where our Senior Manufacturing Engineers provide actionable recommendations. Key focus areas include:

| DFM Parameter | Critical Thresholds | Common Resolution Strategies |

|---|---|---|

| Wall Thickness | <0.6mm or >3.0mm (varies by material) | Rib integration, coring, or material change |

| Draft Angles | <1° on critical surfaces | Redesign parting lines, add texture zones |

| Gate Location | Visible on A-surface | Relocate to non-cosmetic feature |

| Ejector Pin Placement | High-stress areas or thin walls | Redesign ejection system, add bosses |

| Sink Mark Risk | Thick sections >1.5x nominal wall | Adjust rib design, optimize cooling |

Clients receive a marked-up 3D PDF with annotated suggestions and tolerance stack-up analysis. We typically resolve 85% of manufacturability issues within 48 hours through this collaborative phase, preventing costly mold modifications later.

Precision Production Execution

Approved designs move to our climate-controlled molding facility featuring all-electric Toshiba and Sumitomo presses (50-500 tons). Each job follows a documented process control plan including:

Material drying protocols per resin specifications

Real-time cavity pressure monitoring for every shot

Automated visual inspection using machine vision systems

First-article inspection reports with CMM data against client GD&T

All production runs undergo statistical process control with Cp/Cpk tracking, maintaining ISO 9001:2015 compliance throughout. Typical mold setup validation requires 3-5 shots before full production release.

Quality-Controlled Delivery

Final parts undergo our triple-validation protocol: dimensional verification against CAD, functional testing per client specifications, and material certification. Parts ship in ESD-safe packaging with serialized traceability tags linking to:

Complete production batch records

Material lot traceability documentation

Full inspection reports accessible via client portal

Standard delivery occurs within 7-10 business days post-DFM approval for most geometries, with expedited options available. All shipments include digital certificates of conformance meeting AS9100 aerospace standards where applicable.

This integrated approach reduces prototyping iterations by an average of 40% compared to industry benchmarks while ensuring production-ready designs from the first mold trial. We maintain continuous process improvement through closed-loop feedback where production data directly refines our AI quoting algorithms and DFM rule sets.

Start Your Project

Optimize your injection molding part design with expert engineering support from Honyo Prototype. Our team specializes in designing manufacturable, cost-effective parts tailored to your production requirements. With our advanced capabilities and strategic location in Shenzhen, we ensure fast turnaround and high-quality prototyping and production.

Contact Susan Leo today at [email protected] to discuss your project and get a personalized consultation. Let us help you streamline your design for injection molding success.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.