Guide Contents

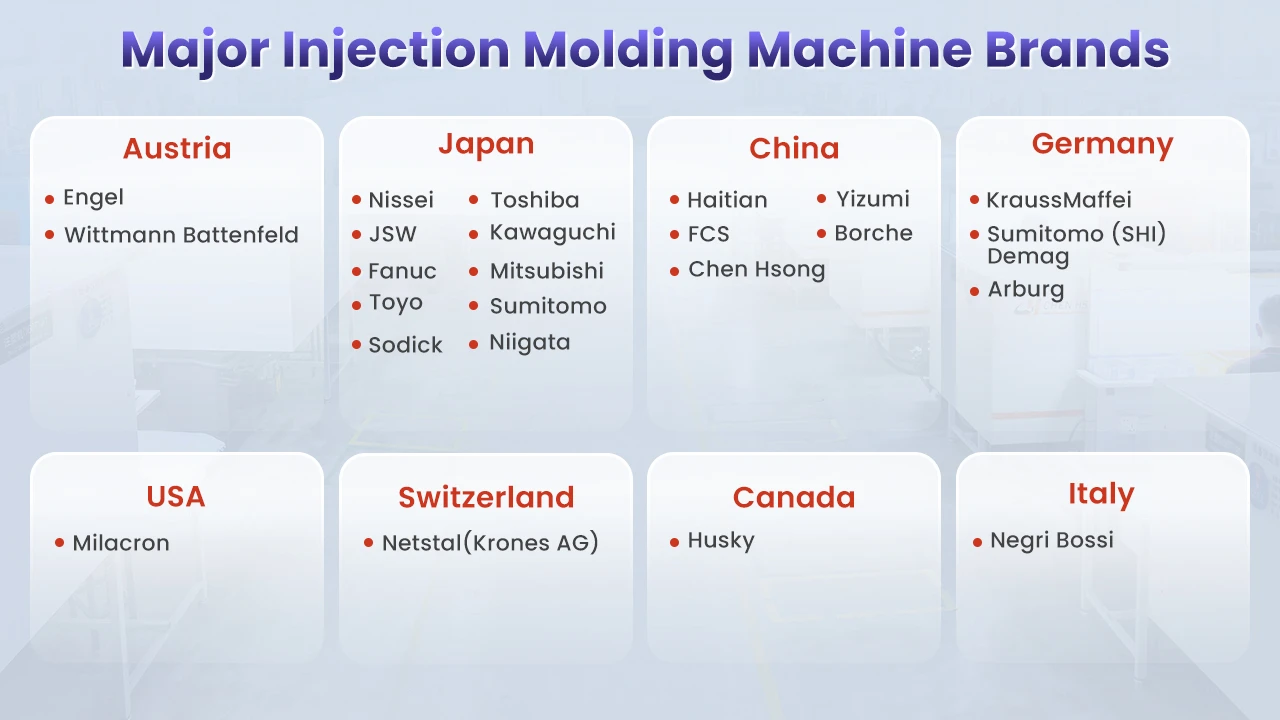

Project Insight: Injection Molding Machine Brands

Manufacturing Insight: Injection Molding Machine Brands

The Machine Cost Misconception

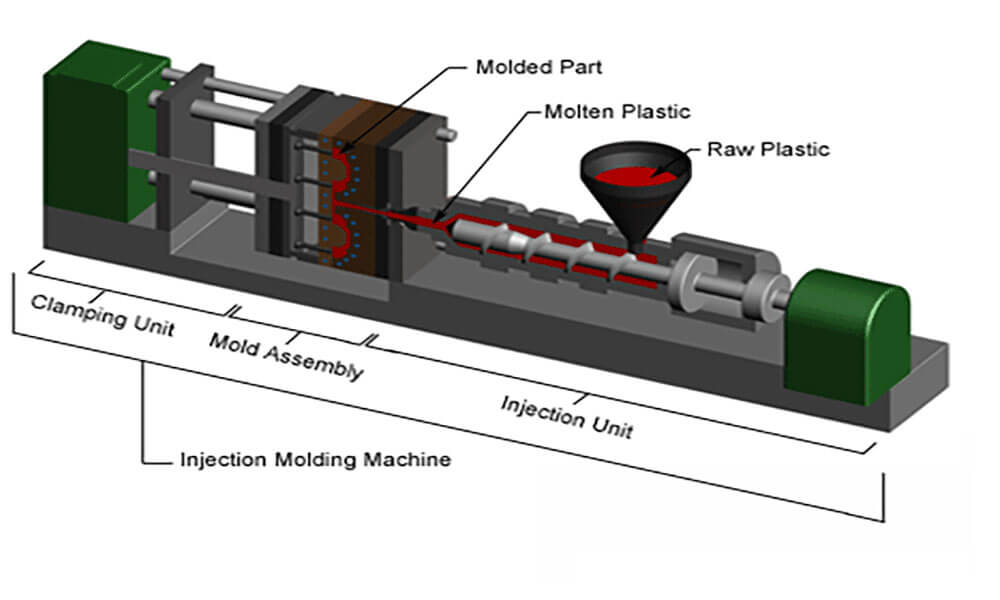

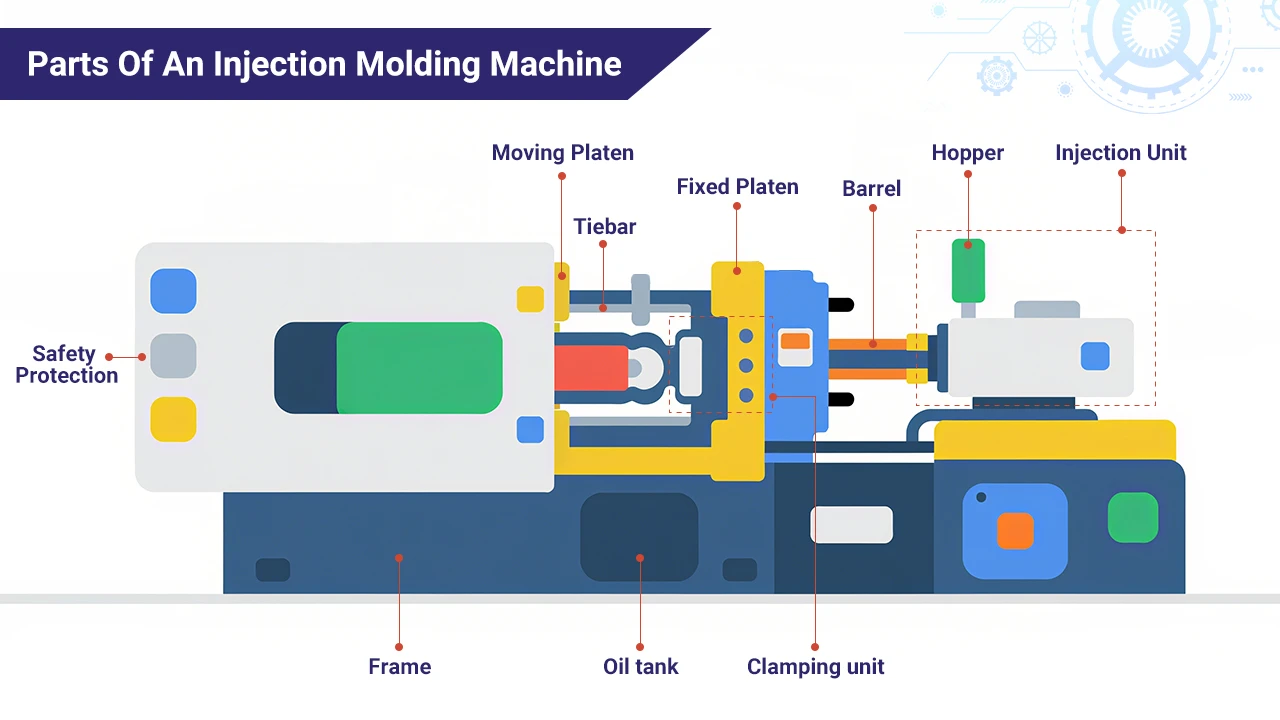

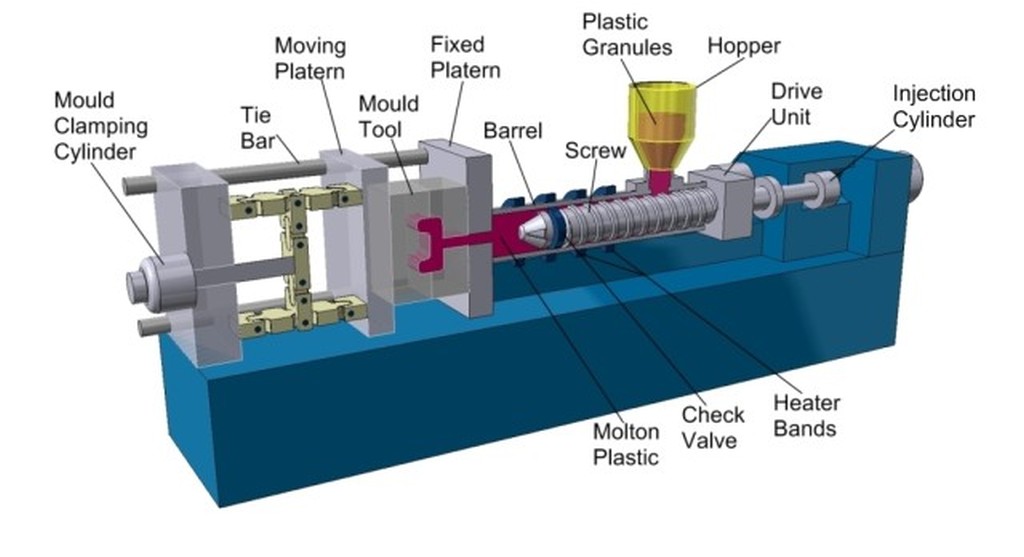

Industrial injection molding machines from leading brands (e.g., Haitian, Arburg, Engel) require $50,000–$200,000+ investments and specialized facility upgrades—prohibitive for low-volume production needs.

Traditional machine ownership leads to 8–12+ week lead times for tooling, high minimum order quantities, and underutilized assets for startups scaling from prototypes to early production.

Honyo’s Digital Manufacturing Advantage

Online Instant Quote: Receive real-time pricing within minutes—no phone calls or waiting. Our platform instantly analyzes your design for manufacturability and cost.

AI-Powered Platform: Automated Design for Manufacturability (DFM) checks, material selection guidance, and process optimization to eliminate errors and reduce costs before production.

Fast Turnaround: Mold production in 7–10 days, parts delivered in 2–3 weeks—accelerate time-to-market without compromising precision or quality.

Bridge Tooling for Agile Innovation

Specialized bridge tooling for 100–10,000+ parts with steel and aluminum molds, balancing durability and cost-efficiency.

Overmolding and insert molding capabilities for complex assemblies, eliminating secondary operations and reducing assembly time.

Seamless scalability: Start with prototypes, scale to production volumes without retooling or delays.

Honyo transforms your design from concept to reality—faster, smarter, and with zero capital risk.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Advanced Tooling Technologies

Steel & Aluminum Molds: Precision-engineered for optimal performance—steel molds for high-volume durability (100k+ parts) and aluminum molds for rapid prototyping and low-volume bridge tooling (100–10k parts), all designed to balance cost efficiency with exceptional surface finish and dimensional accuracy.

Overmolding & Insert Molding: Seamlessly integrate multiple materials or components in a single process—eliminating secondary assembly steps while enhancing product functionality, reliability, and design flexibility for complex hardware applications.

Flexible Production Capacity

Bridge Tooling Expertise: Specialized in low-to-medium volume production (100–10,000+ parts), enabling startups and enterprises to validate designs cost-effectively before scaling to full production—no need for expensive high-volume tooling upfront.

Scalable Solutions: Adjust production volumes on-demand with minimal tooling modifications, ensuring seamless transition from concept to commercialization without retooling costs or delays.

Quality Assurance & Compliance

ISO 9001-Certified Processes: Rigorous in-process inspections, statistical process control (SPC), and final quality audits to guarantee every part meets aerospace, medical, and consumer electronics standards.

Full Traceability: Comprehensive documentation from raw materials to finished parts, simplifying regulatory compliance and supply chain audits for your business.

Smart Manufacturing Ecosystem

Online Instant Quote: Upload your CAD file and receive an immediate, transparent cost estimate with customizable options—adjust parameters in real-time to balance cost, timeline, and quality without manual quotes.

AI-Powered Optimization: Proprietary AI analyzes part geometry, material flow, and cooling requirements to optimize mold design and production parameters—reducing defects, cycle times, and costs by up to 30%.

Rapid Turnaround: Standard tooling lead times of 7–14 days with expedited options for urgent projects—ensuring your product reaches market faster without compromising quality.

Honyo Prototype: Where innovation meets precision. Let’s build your vision—faster, smarter, and with zero compromise.

Materials & Surface Finishes

Material Options & Finishes for Precision Injection Molding

Selecting the Right Thermoplastic Material

Optimize part performance with thermoplastics engineered for real-world applications. We prioritize materials that balance functionality, cost, and manufacturability for low-volume production.

ABS: Ideal for consumer electronics, automotive interiors, and industrial housings. Combines impact resistance, ease of painting, and dimensional stability.

Polycarbonate (PC): Superior heat and UV resistance for optical lenses, protective gear, and medical devices requiring transparency and durability.

Polypropylene (PP): Chemical-resistant and fatigue-tolerant for living hinges, medical components, and food-grade applications.

Thermoplastic Elastomer (TPE): Flexible, rubber-like properties for ergonomic grips, seals, and soft-touch surfaces without vulcanization.

Surface Finishes That Enhance Functionality & Aesthetics

Elevate your parts with finishes tailored to both aesthetics and performance—whether for plastic surfaces or integrated metal components.

For Plastic Parts

High-Gloss Polishing: Mirror-like finish for premium consumer electronics or luxury product housings.

Textured Finishes (SPI Standards): Custom patterns (e.g., leather grain, matte) for improved grip, scratch resistance, and visual appeal.

Painting & Powder Coating: Custom color matching with durable, scratch-resistant coatings for outdoor or high-wear applications.

Silk Screening & Laser Engraving: Permanent branding, labels, or functional markings without compromising structural integrity.

For Metal Components (e.g., Inserts in Overmolding)

Anodizing: Corrosion-resistant aluminum finishes with vibrant color options for aerospace or medical inserts.

Electroplating: Chrome or nickel plating for metallic aesthetics on plastic surfaces (e.g., automotive trim or luxury accessories).

How to Choose the Best Material & Finish for Your Project

Engineer smarter with data-driven decisions:

Functionality First: Match materials to environmental demands (e.g., PC for UV exposure, PP for chemical contact).

Cost vs. Performance: Optimize budgets with materials like ABS for high-impact applications or TPE for flexible features without custom tooling.

Aesthetic Alignment: Pair finishes with material capabilities—e.g., ABS with high-gloss polish for sleek electronics or textured PP for ergonomic tools.

Volume Efficiency: Leverage Honyo’s bridge tooling to produce 100–10,000+ parts with zero compromise on quality or lead time.

Why Honyo Prototype Delivers Speed & Precision

Your Partner for Agile Low-Volume Production

Instant Online Quote: Our AI-powered platform analyzes your CAD files in seconds, delivering real-time pricing and material/finish recommendations—no manual quotes, no delays.

Smart Design Optimization: Machine learning algorithms identify cost-saving opportunities while ensuring your parts meet functional and aesthetic requirements.

Rapid Turnaround: Bridge tooling capabilities produce production-ready parts in 10–15 days, accelerating your product launch cycle for prototypes and low-volume runs.

“At Honyo Prototype, we don’t just manufacture parts—we solve engineering challenges. Whether you’re prototyping a wearable device or scaling a medical product, our material and finish expertise ensures your vision hits the market faster, smarter, and with fewer compromises.”

— Susan Leo, Founder of Honyo Prototype

From Quote to Part: Our Process

How It Works: From CAD to Part

Step 1: Upload Your CAD File

Seamless submission: Drag-and-drop your design files (STP, STEP, STL, IGES, etc.) in seconds—no engineering expertise required.

Smart compatibility: Our platform automatically processes complex geometries and validates file integrity.

Enterprise-grade security: End-to-end encryption ensures your intellectual property stays protected at all times.

Step 2: Get Instant AI-Powered Quote

Real-time analysis: Proprietary AI engine evaluates part complexity, materials, and volumes in <60 seconds—no waiting for manual quotes.

Transparent pricing: Breakdown includes mold costs, part costs, tooling, and shipping with zero hidden fees.

Dynamic adjustments: Instantly compare options for materials (ABS, PC, PEEK, etc.) and volume tiers (100–10,000+ parts) to optimize budget.

Step 3: DFM Analysis & Optimization

Proactive design feedback: AI-driven checks for draft angles, wall thickness, gate placement, and moldability issues.

Collaborative refinement: Work directly with Honyo engineers via our platform to resolve issues before production starts.

Risk reduction: Eliminate costly mold revisions—up to 30% faster time-to-market by fixing errors early.

Step 4: Rapid Production & Delivery

Shenzhen-powered agility: ISO-certified facility with steel/aluminum molds, overmolding, and insert molding capabilities for low-volume bridge tooling.

10–15 day turnaround: From mold fabrication to final parts—ideal for prototypes, pre-production runs, and small-batch launches.

Full visibility: Live production tracking, quality control reports at every stage, and global shipping with customs support.

Why Choose Honyo?

Founder-led innovation: Susan Leo’s vision delivers agile, startup-friendly manufacturing tailored to your growth stage.

Bridge tooling expertise: Cost-effective solutions for 100–10,000+ parts—no need for expensive high-volume molds.

End-to-end transparency: Control your project from quote to delivery with real-time updates and no surprises.

“We don’t just make parts—we build confidence. Every step of your journey is designed to accelerate innovation while eliminating manufacturing guesswork.”

— Susan Leo, Founder of Honyo Prototype

Start Your Project with Honyo

Start Your Project with Honyo: Precision Molding, Simplified

Honyo Prototype delivers end-to-end injection molding solutions tailored for startups and engineers—no heavy machinery investment, no guesswork. Our AI-driven platform and bridge tooling expertise turn complex designs into high-quality parts faster and more cost-effectively than traditional methods.

AI-Powered Cost Estimation & Instant Quotes

Real-time pricing: Upload your CAD file for an instant, transparent cost breakdown—no manual quotes or delays.

Design optimization: AI analyzes geometry for mold efficiency, reducing costs while maintaining part integrity.

No hidden fees: Clear breakdown of mold, material, and production costs upfront—always.

Bridge Tooling for Scalable Production

Low-volume excellence: Produce 100–10,000+ parts with precision steel or aluminum molds—ideal for prototyping, market testing, or small-batch runs.

Flexible capabilities: Expertise in overmolding, insert molding, and engineering-grade resins for complex requirements.

Cost-smart: Skip $50k–$200k+ machine investments; pay only for the molds and production you need.

Rapid Turnaround Without Compromise

7–10 day lead times: From design to first parts—our Shenzhen/Dongguan facilities accelerate timelines without sacrificing quality.

Agile iterations: Modify molds in days, not weeks, for rapid design refinement and market adaptation.

Global support: Dedicated project managers ensure seamless collaboration across time zones and requirements.

Ready to launch your product with confidence?

Susan Leo and our engineering team are here to help.

📞 +86 139 2843 8620

📧 [email protected]

📍 Visit our Shenzhen/Dongguan facilities for a personalized tour

No project is too small. Let’s build the future, together.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.