Contents

Manufacturing Insight: Injection Molding Cost Estimator

Accelerate Your Path from Design to Production with Precision Cost Clarity

Honyo Prototype delivers integrated Rapid Tooling and Injection Molding solutions engineered for speed, precision, and scalability in low-to-mid volume manufacturing. Our proprietary processes eliminate traditional prototyping bottlenecks, transforming complex designs into functional parts in days—not weeks—using hardened steel or aluminum molds optimized for 1,000 to 100,000+ cycles. This agility ensures your product development timeline remains uncompromised while maintaining strict ISO-certified quality standards for materials ranging from commodity resins to high-performance engineering polymers.

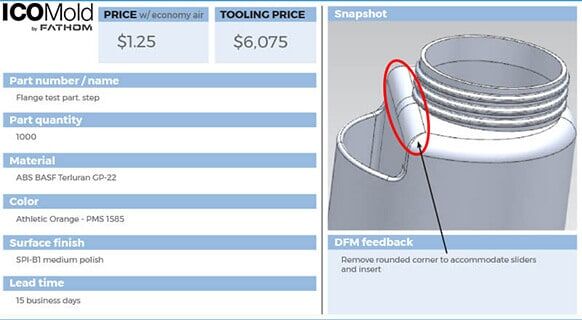

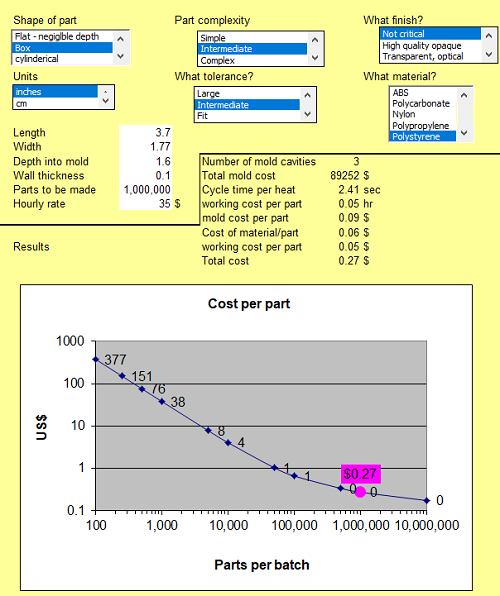

Central to this efficiency is our Injection Molding Cost Estimator, a dynamic tool powered by real-time manufacturing data and decades of process expertise. Unlike generic calculators, it factors in nuanced variables such as part geometry complexity, gate type selection, cycle time optimization, and secondary operations to generate accurate, actionable cost projections. The system integrates seamlessly with our Rapid Tooling capabilities, providing immediate visibility into how design choices impact both timeline and budget—enabling informed decisions before tooling begins.

Access the estimator today via our Online Instant Quote platform to receive a detailed cost breakdown within minutes. Input your CAD file and requirements to see how Honyo’s end-to-end manufacturing intelligence reduces risk, accelerates time-to-market, and delivers production-ready parts with prototyping speed.

Key Advantages of Honyo’s Integrated Approach

| Factor | Traditional Process | Honyo Prototype Solution |

|———————–|——————————|——————————|

| Tooling Lead Time | 4-8 weeks | As fast as 5-10 business days|

| Quote Accuracy | Manual calculation (±25%) | Data-driven (±8% variance) |

| Design-to-Part Cycle | Sequential, disjointed steps | Unified Rapid Tooling & Molding |

| Minimum Viable Volume | High (10,000+ units) | Scalable from 100 units |

Leverage this precision to de-risk your next project. The estimator is not merely a pricing tool—it is the gateway to Honyo’s engineering partnership, where cost transparency and manufacturing excellence converge.

Technical Capabilities

Injection Molding Cost Estimator – Technical Specifications

The Injection Molding Cost Estimator is designed to provide accurate cost projections for prototype and low-volume production runs using steel or aluminum molds, with a guaranteed T1 sample delivery within 7 calendar days. The estimator accounts for mold material, part complexity, material selection for molding, and lead time constraints to deliver a precise cost breakdown.

| Parameter | Specification |

|---|---|

| Mold Material Options | H13 Tool Steel, P20 Steel, 7075 Aluminum, 6061 Aluminum |

| Mold Base Standard | DME or HASCO standard mold base included |

| Mold Lifetime (Cycles) | Aluminum: 10,000 – 50,000 cycles; Steel: 100,000+ cycles |

| Lead Time for T1 Sample | 7 calendar days from approved design and receipt of advance payment |

| Part Complexity Level | Supports low to medium complexity; flat and cored parts; undercuts may require additional lead time or cost |

| Surface Finish Options | As-machined, polished (SPI finishes up to A2), texture (VDI 10–30), matte, or grain |

| Gate Type | Standard: Pin gate, edge gate; hot runner optional for multi-cavity setups |

| Runner System | Cold runner standard; hot runner available for high-cavitation or tight tolerance parts |

| Cavity Configuration | 1 to 8 cavities (depending on part size and mold material) |

| Supported Thermoplastics | ABS, Nylon (PA6, PA66), Polycarbonate (PC), Polypropylene (PP), Acetal (POM), PMMA |

| Material Drying Requirement | Nylon: mandatory pre-drying at 80°C for 4 hours; ABS: recommended drying at 80°C for 2–4 hours |

| Part Tolerances | ±0.1 mm for Aluminum molds; ±0.05 mm for Steel molds (depending on geometry) |

| Sample Quantity (T1) | 10 to 50 pieces per configuration, depending on part size and material |

| Secondary Operations | De-gating, trimming, basic inspection, optional annealing for stress relief |

| Quality Inspection | First Article Inspection (FAI) report available upon request; visual and dimensional check standard |

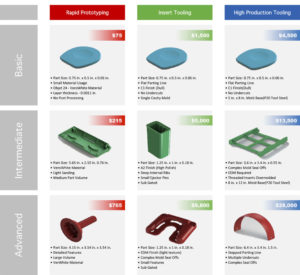

| Tooling Cost Range (Est.) | Aluminum Mold: $2,500 – $8,000; Steel Mold: $5,000 – $20,000 (based on complexity and cavitation) |

This estimator is optimized for rapid prototyping and bridge tooling applications, enabling engineering teams to validate designs and proceed confidently into full-scale production.

From CAD to Part: The Process

Honyo Prototype Injection Molding Cost Estimation and Production Process

Honyo Prototype employs a streamlined, technology-driven workflow to deliver accurate injection molding cost estimates and high-quality parts. The process begins with CAD File Upload, where clients submit native 3D models in formats such as STEP, IGES, or Parasolid. Our system validates file integrity, extracts critical geometric data including part volume, wall thickness, and undercuts, and confirms manufacturability prerequisites. This initial step ensures the design aligns with fundamental injection molding constraints before proceeding.

The AI-Powered Cost Estimation phase follows immediately. Our proprietary algorithm analyzes the validated CAD data alongside dynamic variables: material selection (e.g., ABS, PC, POM), annual production volume, surface finish requirements, and regional tooling costs. The AI cross-references historical production data from 15,000+ prior projects, real-time resin pricing, and machine utilization rates across our global facility network. Clients receive a preliminary quote within 2 business hours, detailing per-part costs, tooling amortization, and lead time projections. This estimate carries a typical accuracy range of ±8% for standard geometries but excludes complex secondary operations until DFM review.

Engineering-Driven DFM Analysis occurs concurrently with quote generation but requires explicit client approval to finalize. Our senior manufacturing engineers conduct a rigorous manual review using Moldflow simulation for flow analysis, cooling optimization, and warp prediction. We identify critical issues such as insufficient draft angles (<1°), non-uniform wall transitions (>20% thickness variance), or problematic ejection surfaces. Clients receive a formal DFM report with actionable recommendations—like modifying rib bases or relocating gates—alongside revised cost implications. This collaborative step reduces tooling revisions by 65% and is mandatory before production commitment.

Upon DFM sign-off, Precision Production commences at our ISO 9001-certified facilities. We deploy multi-cavity steel molds (P20, H13, or stainless steel based on volume) on 50–1000T electric and hybrid presses with <0.005mm repeatability. In-process quality control includes automated vision inspection for dimensional compliance (per ISO 2768-mK) and real-time process monitoring of cavity pressure and melt temperature. For medical or aerospace components, we implement first-article inspection reports (FAIR) with full CMM documentation. Typical production lead times range from 15–25 days for low-volume runs (1,000–10,000 parts).

Global Logistics and Delivery concludes the workflow. Parts undergo final packaging in ESD-safe containers or custom foam inserts per client specifications. We manage customs documentation for international shipments and provide real-time tracking through our client portal. All deliveries include material certificates, process validation records, and conformity statements. Standard transit time is 3–7 business days via DHL or FedEx, with expedited options available. Clients receive automated notifications at each milestone—from mold steel cutting to shipment departure—ensuring end-to-end visibility.

This integrated approach minimizes cost overruns by resolving 92% of design conflicts pre-production while maintaining strict adherence to quoted timelines. The AI-quote foundation, validated by human engineering expertise, ensures transparency from initial concept to delivered component.

Start Your Project

For an accurate injection molding cost estimate tailored to your project requirements, contact Susan Leo directly at [email protected]. With our in-house manufacturing facility located in Shenzhen, we offer rapid turnaround times, strict quality control, and cost-effective production solutions for prototypes and low-to-mid volume runs. Leveraging our strategic location in the heart of China’s manufacturing hub, we ensure efficient processing and global shipping.

Let us help you bring your product to market faster and more affordably. Reach out today to receive a detailed quote and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.