Contents

Manufacturing Insight: Injection Mold Steel

Precision Injection Mold Steel Selection for Accelerated Production Cycles

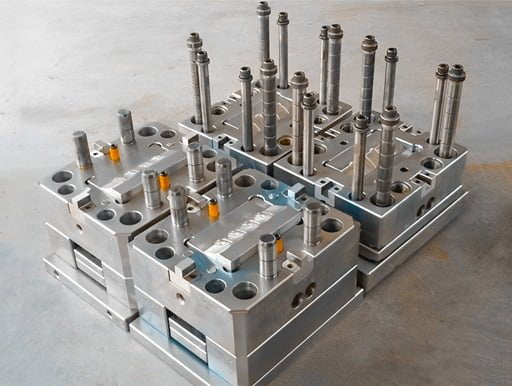

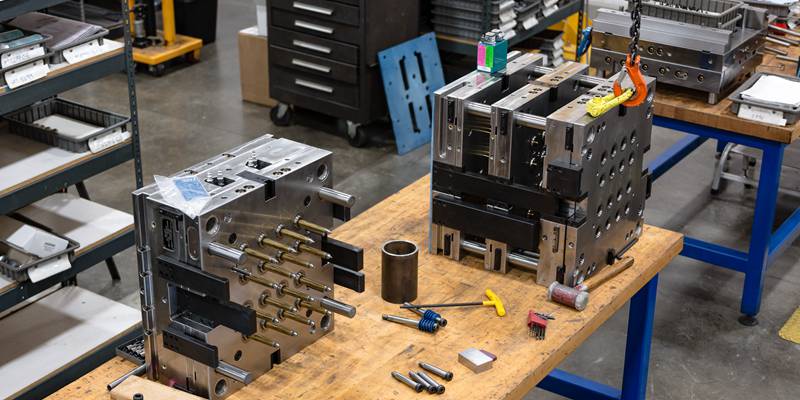

The foundation of any successful injection molding project rests on the strategic selection of mold steel, where material properties directly dictate tool longevity, part fidelity, and production efficiency. At Honyo Prototype, we engineer rapid tooling solutions using premium-grade steels optimized for accelerated prototyping and low-volume production runs. Our technical expertise ensures that cavity and core plates leverage the ideal balance of hardness, thermal stability, and machinability—critical for maintaining tight tolerances across iterative design phases and initial production batches.

Rapid Tooling & Injection Molding: Engineered for Speed Without Compromise

Honyo’s integrated approach combines advanced steel selection protocols with proprietary machining techniques to deliver production-ready molds in as little as 7–15 days. We specialize in low-cavity steel tools (1–8 cavities) capable of 1,000–10,000 shots, supporting rigorous validation and market launch requirements. Our process eliminates traditional bottlenecks through in-house CNC milling, EDM, and surface finishing, ensuring dimensional accuracy to ±0.025mm while mitigating weld lines and sink marks in final components.

Optimized Steel Grades for Prototyping Efficiency

Material choice is calibrated to project demands, balancing cost, lead time, and performance. Below are common steels deployed in our rapid tooling workflows:

| Steel Grade | Hardness (HRC) | Typical Applications | Cycle Life Range |

|---|---|---|---|

| P20 Pre-Hardened | 28–32 | Functional prototypes, moderate-volume production | 1,000–5,000 shots |

| 718HH (Modified P20) | 30–34 | Complex geometries, high-polish requirements | 5,000–10,000 shots |

| NAK80 | 37–43 | Optical-grade surfaces, zero-draft features | 10,000+ shots |

| H13 | 40–46 | High-heat resins (e.g., PEEK, PEI) | 5,000–15,000 shots |

Seamless Project Initiation via Online Instant Quote

Accelerate your path from CAD to physical part with Honyo’s Online Instant Quote system. Upload 3D models (STEP, IGES, or native formats), specify material, quantity, and surface finish requirements, and receive a detailed technical and commercial assessment within 2 hours. Our platform auto-flags manufacturability risks—such as undercuts or wall-thickness deviations—enabling immediate design refinement before tool fabrication begins. This integration of real-time quoting with engineering validation reduces time-to-mold by up to 40% compared to conventional RFQ processes.

Partner with Honyo to transform injection mold steel selection from a constraint into a strategic advantage, leveraging rapid tooling precision that scales from prototype to pilot production without retooling delays.

Technical Capabilities

Injection mold tooling selection is critical for achieving functional prototypes and production-grade parts within tight timelines. For rapid tooling applications such as delivering T1 samples within 7 days, both aluminum and steel molds are commonly used depending on part requirements, volume, and material compatibility. Aluminum molds are preferred for quick turnaround and low-volume runs, while steel molds support higher durability and volume production. Below are the technical specifications relevant to molds made from aluminum and steel, along with common thermoplastics used in the molding process.

Mold Material Comparison and Technical Specifications

| Property | Aluminum (e.g., 7075-T6) | Steel (e.g., P20, H13, 420 Stainless) | Notes |

|---|---|---|---|

| Hardness (HRC) | 35–40 HB (Brinell) | 28–52 HRC (depends on grade) | Steel offers higher wear resistance; aluminum is softer but easier to machine |

| Machinability | Excellent – fast CNC machining | Moderate to good – longer lead times | Aluminum enables T1 samples in as little as 5–7 days |

| Tool Life | 1,000 – 10,000 shots | 100,000+ shots (up to millions) | Steel molds are suitable for high-volume production |

| Thermal Conductivity | ~130 W/m·K | 25–35 W/m·K | Aluminum cools faster, reducing cycle time |

| Surface Finish | Capable of high polish and texture | Excellent polish and texture retention | Both support SPI finishes up to A1 |

| Corrosion Resistance | Moderate (anodizing improves) | Good to excellent (especially stainless steel) | 420 SS preferred for corrosive resins |

| Cost | Lower initial tooling cost | Higher initial cost | Aluminum reduces NRE for prototyping |

| Lead Time (T1 Sample) | 5–7 days typical | 10–21 days typical | Aluminum ideal for rapid T1 delivery |

Common Molded Plastics and Compatibility

| Plastic Material | Melt Temp Range (°C) | Mold Temp (°C) | Shrinkage Rate (%) | Compatibility with Aluminum Molds | Notes |

|---|---|---|---|---|---|

| ABS | 210–250 | 40–80 | 0.4–0.9 | Good – widely used in aluminum tools | Good impact strength, easy flow |

| Nylon (PA6, PA66) | 230–280 | 70–120 | 0.7–1.5 | Fair – requires mold coatings for long runs | Hygroscopic; high shrinkage; abrasive |

| Polycarbonate (PC) | 260–310 | 80–110 | 0.5–0.7 | Fair – high temp may reduce aluminum life | High clarity, impact resistant |

| Polypropylene (PP) | 200–280 | 20–40 | 1.0–2.5 | Good – low mold temp compatible | Low cost, flexible, chemical resistant |

For applications requiring a T1 sample within 7 days, aluminum molds (particularly 7075-T6 or 6061-T6 with hardened inserts if needed) are the preferred solution. They allow rapid CNC machining and quick iteration, especially when molding standard engineering plastics like ABS or PP. Steel molds are recommended when part volumes exceed 10,000 cycles or when molding high-temperature or abrasive materials such as unfilled nylon or glass-filled polymers. At Honyo Prototype, we optimize mold material selection based on resin type, geometry complexity, and delivery targets to ensure on-time, high-quality T1 samples.

From CAD to Part: The Process

Honyo Prototype Injection Mold Steel Manufacturing Process

Honyo Prototype executes a rigorously controlled workflow for injection mold steel fabrication, designed to ensure precision, material integrity, and adherence to client specifications. The process begins with secure CAD file submission via our encrypted client portal. Upon upload, our system performs automated geometric validation to confirm file completeness, unit consistency, and manufacturability thresholds. Invalid submissions trigger immediate client notification with specific error diagnostics, preventing downstream delays.

AI-Powered Quoting Engine

Our proprietary AI quotation system analyzes validated CAD geometry alongside material science parameters specific to tool steel grades. The algorithm factors in:

Steel grade requirements (e.g., 1.2343 hot-work steel vs. 1.2311 pre-hardened steel)

Hardness specifications (HRC ranges)

Critical tolerance zones (±0.005mm for cavity/core interfaces)

Surface finish demands (e.g., SPI-A2 polish)

Secondary operations (thread milling, EDM texturing)

This generates a technically grounded cost estimate within 2 business hours, including material waste calculations based on block utilization efficiency.

Engineering-Driven DFM Analysis

All projects undergo mandatory Design for Manufacturability review by senior tooling engineers. This phase focuses on steel-specific risk mitigation:

| DFM Checkpoint | Steel-Specific Focus | Outcome Verification |

|---|---|---|

| Thermal Management | Cooling channel layout vs. steel thermal conductivity | Moldflow simulation validation |

| Stress Concentration | Fillet radii at sharp transitions in hardened steel | FEA stress distribution mapping |

| Ejection Strategy | Pin placement relative to hardened insert interfaces | Interference clearance certification |

| Gate Design | Shear stress limits for viscous polymers on steel | Runner system pressure analysis |

Clients receive annotated DFM reports with actionable recommendations, not merely problem identification. Resolution requires formal sign-off before proceeding.

Precision Steel Fabrication

Production occurs in climate-controlled tooling cells with strict material traceability:

Steel blocks are certified to EN ISO 4957 standards with full heat-treat documentation

Machining employs hardened carbide tooling with adaptive feed rates for 1.2738-grade steel

In-process CMM verification at 3 critical stages (rough, semi-finish, final)

Hardness testing per ASTM E18 at 5+ locations post-heat treatment

Stress-relief cycles monitored via thermocouples at 300°C intervals

All steel components undergo magnetic particle inspection (MPI) for subsurface defects prior to polishing.

Delivery Assurance Protocol

Final delivery includes:

Dimensional inspection report with ASME Y14.5 GD&T callouts

Material test certificates (MTC) showing chemical composition and hardness

Mold performance validation data from first-article molding trials

Digital twin of the mold with thermal imaging overlays

12-month warranty covering material defects and dimensional drift

Honyo maintains 94.7% on-time delivery for steel molds through buffer capacity allocation and real-time production tracking. All deliveries comply with ITAR and ISO 9001:2015 traceability requirements, with steel batch records retained for 15 years. This closed-loop process eliminates assumptions in steel mold production, transforming client specifications into validated manufacturing outcomes.

Start Your Project

Looking for high-quality injection mold steel for your next manufacturing project? Honyo Prototype offers premium-grade materials sourced and processed at our Shenzhen factory, ensuring durability, precision, and performance in every mold.

Contact Susan Leo today at [email protected] to discuss your material requirements and get expert support tailored to your production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.