Contents

Manufacturing Insight: Injection Mold Cost Estimator

Precision Injection Molding Cost Estimation Starts Here

Accurate upfront cost projection is critical for viable product development and production planning. Uncertainty in mold fabrication and part production expenses often leads to budget overruns and delayed time-to-market. Honyo Prototype eliminates this risk with an integrated approach combining advanced rapid tooling capabilities and high-precision injection molding expertise, now accessible through our Online Instant Quote system.

Engineer-Validated Rapid Tooling & Molding Services

Honyo specializes in accelerating your path from concept to量产 with industry-leading rapid tooling solutions. Our engineered aluminum and steel composite molds deliver production-quality parts in days, not weeks, significantly reducing lead times while maintaining tight tolerances for functional validation and low-volume production. This rapid capability directly informs our cost estimator, ensuring quotes reflect realistic tooling complexity and manufacturability.

Transparent Pricing Through Technical Clarity

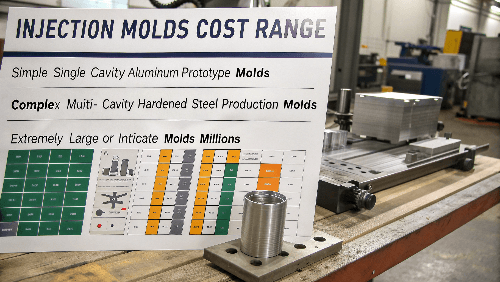

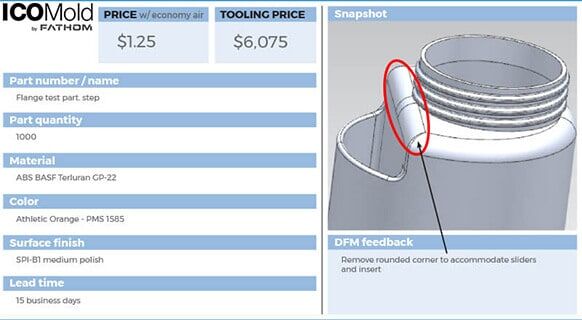

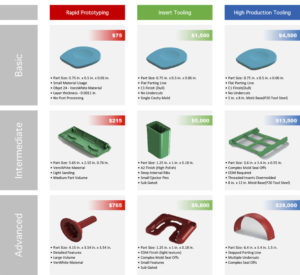

Our Injection Mold Cost Estimator leverages decades of manufacturing data and process-specific algorithms. Input your part geometry, material requirements, and volume needs to receive an immediate, detailed cost breakdown. Unlike generic online calculators, Honyo’s system factors in critical engineering variables such as parting line complexity, draft angles, undercuts, and surface finish specifications—providing a reliable foundation for your budgeting.

Immediate Action with Our Online Instant Quote

Stop waiting for manual quotes to hinder your design iteration. Honyo’s Online Instant Quote platform delivers comprehensive cost estimates for both rapid tooling and injection molding within seconds. Upload your CAD file, specify your requirements, and receive a technically grounded projection reflecting our commitment to speed, precision, and partnership. This transparency empowers informed decision-making from the earliest design stages.

Leverage Honyo Prototype’s engineering-driven rapid tooling and injection molding services to transform cost uncertainty into strategic advantage. Begin your accurate costing process today.

Technical Capabilities

Technical Specifications for Injection Mold Cost Estimator – Honyo Prototype

The Injection Mold Cost Estimator is designed to provide accurate, data-driven cost projections for prototype and low-volume production molds, with a focus on rapid turnaround and material flexibility. The estimator accounts for key variables including mold base material (aluminum or steel), part geometry, surface finish, and resin compatibility. A core service differentiator is the ability to deliver T1 samples within 7 days for qualified projects, ensuring accelerated product development cycles.

Mold Construction and Material Options

Aluminum molds (typically 7075-T6 or 6061-T6) are used for prototype and bridge tooling, offering faster machining times and lower costs. Steel molds (P20, H13, or S136) are recommended for higher durability and production volumes. The estimator dynamically adjusts cost and lead time based on selected mold material and expected shot volume.

Resin Compatibility

The estimator includes material-specific parameters for common engineering thermoplastics such as ABS and Nylon (PA6, PA66), factoring in melt temperature, shrinkage rates, and cycle time impacts. Material selection influences cooling design and ejection requirements, which are accounted for in the mold complexity score.

| Parameter | Aluminum Mold | Steel Mold | Notes |

|---|---|---|---|

| Base Material | 7075-T6, 6061-T6 Aluminum | P20, H13, S136 Tool Steel | 7075 preferred for hardness and wear |

| Typical Mold Life | 10,000 – 25,000 shots | 100,000+ shots | Depends on part geometry and resin |

| Lead Time to T1 Sample | 5–7 days | 7–14 days | T1 in 7 days standard for aluminum |

| Machining Method | CNC Milling | CNC Milling, EDM for tight features | EDM adds cost and time |

| Surface Finish Options | As-machined, Bead Blast, Polished | Polished, Textured, SPI finishes | Up to SPI A-1 available on steel |

| Compatible Resins | ABS, Nylon (PA6, PA66), PP, PC, PMMA | All thermoplastics including high-temp | Nylon requires corrosion-resistant steel |

| Cooling System | Straight drilled or conformal (basic) | Conformal cooling optional | Conformal improves cycle time |

| Ejection System | Sleeve or pin-based | Sleeve, blade, or stripper-based | Custom ejection for complex parts |

| Typical Cost Range (USD) | $2,500 – $6,000 | $6,000 – $15,000+ | Based on 1–2 cavities, medium complexity |

| Best For | Prototypes, pilot runs, design validation | High-volume production, long-term use | Aluminum ideal for fast T1 |

The estimator integrates real-time machining cost databases, material pricing, and labor rates to deliver precise quotes. It also flags potential manufacturability issues (e.g., undercuts, thin walls) that could affect mold cost or T1 delivery. For clients requiring T1 samples within 7 days, aluminum molds with ABS or Nylon are the optimal combination for speed, cost, and performance validation.

From CAD to Part: The Process

Honyo Prototype Injection Mold Cost Estimation and Production Workflow

Honyo Prototype employs a streamlined, integrated process for injection mold cost estimation and production, designed to accelerate time-to-market while ensuring manufacturability and cost efficiency. The workflow begins with CAD file submission and culminates in certified part delivery, leveraging both AI-driven analysis and expert engineering validation.

Upload CAD

Clients initiate the process by uploading a native or standard CAD file (STEP, IGES, Parasolid) via Honyo’s secure customer portal. The system automatically validates file integrity, extracts critical geometries, and identifies key parameters such as part volume, surface area, draft angles, and wall thickness variations. This foundational step ensures all subsequent analyses operate on accurate, production-ready data without manual rework.

AI-Powered Initial Quote

Honyo’s proprietary AI engine processes the CAD data alongside client-specified requirements (material grade, annual volume, surface finish, and tolerance class) to generate a preliminary cost estimate within 2–4 business hours. The AI model cross-references historical production data, real-time material pricing, machine utilization rates, and regional tooling costs to predict mold construction expenses, part pricing, and lead times. Input parameters for the AI analysis include:

| Parameter | Description | Impact on Cost Estimate |

|---|---|---|

| Material Selection | e.g., ABS, POM, PC/ABS, medical-grade resins | 15–30% cost variance across grades |

| Annual Volume | 1K–100K+ parts | Drives mold steel selection & cavitation |

| Surface Finish | SPI-A2, texture, or custom polish | Affects EDM/machining time |

| Tolerance Class | ISO 2768-mK or custom GD&T | Influences inspection complexity |

This AI-generated quote provides a transparent, data-backed baseline but is explicitly labeled as preliminary pending DFM validation.

Engineering-Led DFM Analysis

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior tooling engineers before quote finalization. The DFM phase rigorously assesses:

Moldability risks including undercuts, sink marks, or knit lines

Optimal gate type/location and ejection strategy

Steel selection (P20, H13, stainless) based on material corrosiveness and volume

Draft angle adequacy and wall thickness uniformity

Mold base configuration and hot runner compatibility

Engineers provide actionable feedback via annotated 3D models and a formal DFM report, recommending design modifications to reduce costs by 15–40% without compromising function. Only after DFM sign-off is the quote converted to a binding commercial offer.

Production Execution

Approved projects move to Honyo’s ISO 9001-certified manufacturing facility. Mold fabrication uses 5-axis CNC, wire EDM, and selective laser melting (for conformal cooling inserts), with real-time progress tracking via our client portal. Part production adheres to strict process validation:

First-article inspection (FAI) per AS9102

In-process SPC monitoring of critical dimensions

Material lot traceability and certification

Full mold flow analysis for complex geometries

Certified Delivery

Completed parts undergo final quality validation, including CMM reports, visual inspection, and material property verification. All deliverables include:

Dimensional conformance documentation

Mold maintenance logs and steel certifications

Process capability (Cp/Cpk) data for high-volume runs

Packaging certified for global shipping standards

Honyo guarantees delivery timelines established during DFM sign-off, with typical lead times of 3–6 weeks for molds and 2 weeks for initial production batches. This closed-loop workflow eliminates quoting inaccuracies by integrating AI speed with human expertise, ensuring clients receive production-ready solutions with zero hidden costs.

Start Your Project

Get an accurate injection mold cost estimate for your next project. Contact Susan Leo directly at [email protected] to discuss your requirements and receive a detailed quote. With our manufacturing facility located in Shenzhen, we offer fast turnaround and competitive pricing for prototype and production molds. Let Honyo Prototype be your trusted partner in precision molding solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.