Contents

Manufacturing Insight: Injection Mold Cost Calculator

Introduction to Honyo Prototype’s Injection Mold Cost Calculator

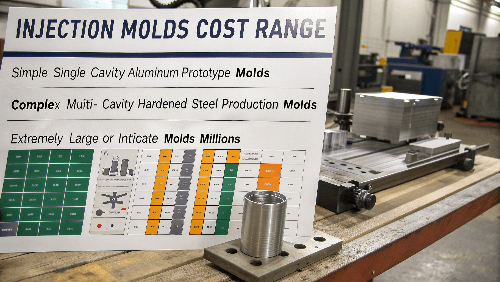

Accurate cost estimation is critical during the early design phases of plastic part development, yet traditional quoting processes often introduce delays that hinder prototyping and production timelines. At Honyo Prototype, we eliminate this bottleneck with an integrated approach combining Rapid Tooling and Injection Molding expertise. Our specialized services leverage high-precision aluminum and soft steel molds to deliver production-intent prototypes and low-volume production parts in as little as 5–15 business days, ensuring design validation aligns with real-world manufacturing constraints.

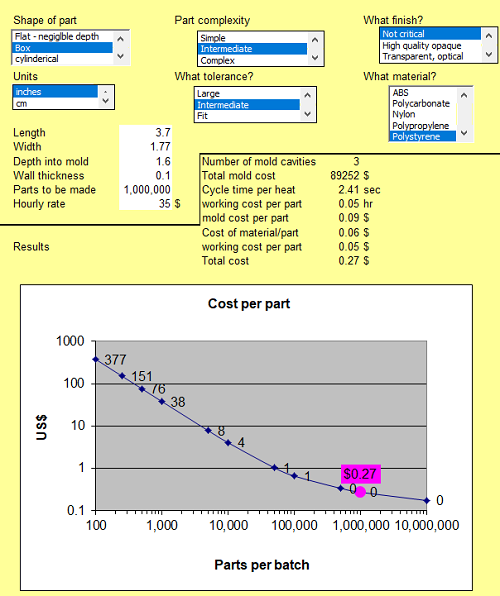

This Injection Mold Cost Calculator provides immediate transparency by translating your part geometry, material selection, and volume requirements into a detailed cost breakdown. Unlike generic estimators, it reflects Honyo’s proprietary tooling methodologies and material science insights, accounting for factors like mold complexity, cycle time optimization, and secondary operations. The result is a data-driven projection that mirrors our actual production economics.

Central to this efficiency is our Online Instant Quote system, which generates actionable pricing within seconds—no manual review or sales follow-up required. Engineers and procurement teams gain direct access to validated cost intelligence, empowering faster design-for-manufacturability decisions and accelerating time-to-market. Leverage this tool to align your project’s financial and technical objectives from the outset, backed by Honyo’s commitment to rapid, repeatable manufacturing excellence.

Begin optimizing your next project today by entering your specifications for an immediate, obligation-free cost analysis.

Technical Capabilities

Injection Mold Cost Calculator Technical Specifications

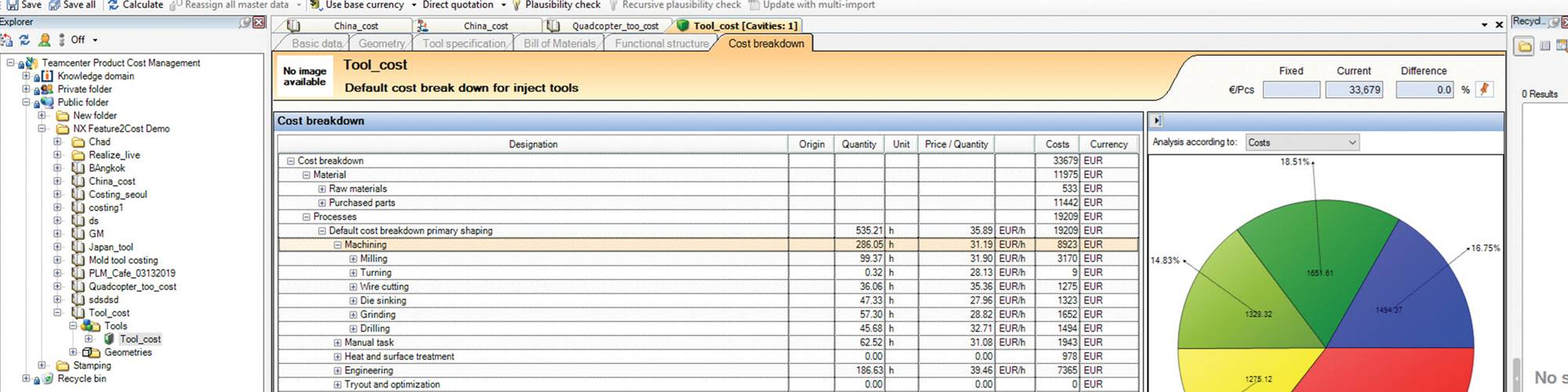

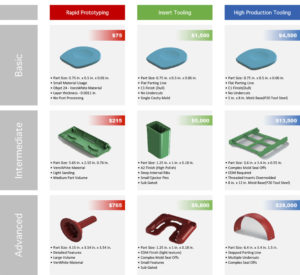

The Injection Mold Cost Calculator is a precision-engineered estimation tool designed for rapid prototyping and low-to-medium volume production applications. It specializes in evaluating cost drivers for molds fabricated from aluminum and steel, with the capability to deliver first-article samples (T1) within 7 days. The calculator integrates material costs, machining time, complexity factors, and part geometry to provide accurate upfront cost projections for injection molds used with common engineering thermoplastics such as ABS and Nylon.

Key inputs include mold base material (aluminum or steel), part volume, number of cavities, surface finish, ejection mechanism, and gate type. The system factors in lead time constraints, tool longevity, and material compatibility to ensure optimal mold selection for both prototyping and bridge tooling.

The following table outlines the core technical specifications and material considerations:

| Parameter | Specification Description |

|---|---|

| Mold Material Options | 7075-T6 Aluminum, NAK80 Steel, P20 Steel, H13 Steel |

| Mold Base Compatibility | Standard mold bases (DME, Hasco) included in cost model |

| Minimum Lead Time (T1 Sample) | 7 business days from design approval |

| Part Materials Supported | ABS, Nylon (PA6, PA66), Polypropylene (PP), Polyethylene (PE), PC, PMMA |

| Cavity Configurations | Single cavity (default), multi-cavity up to 8 cavities |

| Part Volume Range | 0.1 cm³ to 500 cm³ |

| Surface Finish Options | As-machined (Al: 3.2 µm, Steel: 0.8 µm), Polished (SPI A2, B2), Textured (MT-11000) |

| Cooling System Design | Simulated conformal cooling for aluminum; standard line bores for steel |

| Ejection Type | Pin, sleeve, stripper, or blade – selection affects cost |

| Gate Types | Edge, tunnel, pin, hot tip – automated suggestion based on geometry |

| Tool Life Expectancy | Aluminum: 10,000–25,000 cycles; Steel: 100,000–1M+ cycles |

| Machining Process | CNC milling (5-axis for complex cores), EDM for fine details |

| Cost Model Inputs | Material cost, labor rate, machine hourly rate, overhead, risk factor |

| Software Integration | CAD import (STEP, Parasolid), automated parting line detection |

| Accuracy of Estimate | ±10% of final tooling quote based on qualified geometry |

This calculator enables manufacturers and product developers to make informed decisions between aluminum and steel tooling based on project duration, production volume, and budget. Aluminum molds are optimized for fast turnaround and lower initial cost, ideal for prototyping with ABS or Nylon. Steel molds are recommended for extended life and higher-volume runs, particularly with abrasive or high-temperature materials.

From CAD to Part: The Process

Honyo Prototype Injection Mold Cost Calculation Process Overview

Our streamlined injection mold cost calculation workflow integrates advanced AI with expert engineering validation to deliver rapid, accurate quotes while ensuring manufacturability. The process begins when a client uploads a native CAD file (STEP, IGES, Parasolid, or native SOLIDWORKS) through our secure customer portal. Our system performs immediate geometric validation, checking for file integrity, unit consistency, and basic topology errors. All data transmission and storage utilize AES-256 encryption to maintain IP security, with files automatically purged post-project completion per NDA terms.

AI-Powered Preliminary Quote Generation

Within 24 hours, our proprietary AI engine analyzes the validated CAD geometry against Honyo’s live database of 12,000+ historical mold builds, material costs, and machine utilization rates. The algorithm calculates core cost drivers including:

Mold base dimensions and steel requirements (P20, 718H, S136, etc.)

Cavity count and complexity (side actions, lifters, unscrewing mechanisms)

Estimated cycle time based on wall thickness, gate type, and cooling analysis

Material waste factors and standard hardware costs

This generates a preliminary quote with ±8% accuracy, including a breakdown of steel, machining, assembly, and overhead costs. Crucially, this is not a final quote but a data-driven starting point for engineering review.

Engineering-Led DFM Analysis and Quote Finalization

All AI outputs undergo mandatory review by Honyo’s senior mold design team. This phase identifies critical manufacturability issues the AI may flag but cannot resolve, such as:

| Parameter | Standard Tolerance | Critical Threshold | Honyo Resolution Action |

|---|---|---|---|

| Wall Thickness | ±0.05mm | <0.8mm or >4.0mm | Recommend rib redesign or material change |

| Draft Angles | 1°–3° | <0.5° | Propose EDM texturing or side-action solution |

| Undercut Severity | N/A | >15° undercut | Evaluate lifters vs. collapsible cores |

| Gate Vestige | 0.1mm max | Visible on A-surface | Suggest tunnel gate relocation |

The DFM report details all necessary design modifications with annotated 3D visuals, explaining how each change impacts cost and lead time. Only after client approval of DFM recommendations do we issue the binding quote, now refined to ±3% accuracy with formal mold construction drawings.

Precision Mold Production and Validation

Approved designs move to our Shenzhen facility where CNC machining (Makino, DMG MORI), EDM (AgieCharmilles), and polishing occur under ISO 9001 protocols. We implement real-time process monitoring:

In-process CMM checks at 30% and 70% completion milestones

Moldflow simulation validation against initial cycle time estimates

First-article testing with client-approved material lots

Any deviations exceeding 0.02mm tolerance trigger automatic engineering escalation before proceeding.

Global Delivery and Post-Production Support

Finished molds undergo 48-hour continuous run testing with documented part quality metrics. We ship via DHL Express with climate-controlled packaging and provide:

Digital twin of the mold with maintenance logs

Real-time production tracking portal access

12-month warranty covering steel failure and critical dimension drift

Average lead time from CAD upload to mold delivery is 18–25 days for 2-plate molds under 600mm, with expedited options available. This closed-loop process ensures clients receive not just a mold, but a validated, production-ready tooling solution with transparent cost drivers at every stage.

Start Your Project

Use our injection mold cost calculator to get an accurate estimate for your next prototyping project. For personalized support and detailed quotations, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring fast turnaround and high-quality production standards.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.