Introduction: Navigating the Global Market for industrial cnc milling machine

In today’s competitive manufacturing landscape, sourcing an industrial CNC milling machine is a critical challenge for B2B buyers seeking efficiency and precision. As businesses strive to meet rising demands for high-quality production, understanding the diverse types of CNC milling machines and their applications becomes essential. This guide delves into the complexities of the global market, offering insights into various machine types, from 3-axis to advanced 5-axis milling centers, ensuring you have the knowledge needed to make informed purchasing decisions.

With a focus on key factors such as supplier vetting, cost considerations, and the latest technological advancements, this comprehensive resource is designed specifically for international B2B buyers from regions like Africa, South America, the Middle East, and Europe. Whether you are in Nigeria looking to enhance your manufacturing capabilities or in Germany aiming to streamline production processes, this guide empowers you to navigate the nuances of sourcing effectively.

By equipping you with actionable insights and best practices, we aim to facilitate not just your purchasing process but also enhance your operational efficiency and competitiveness in the global market. Explore the intricacies of CNC milling machines and unlock the potential for greater productivity and profitability in your business.

Understanding industrial cnc milling machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Axis CNC Milling Machine | Moves in X, Y, and Z directions; ideal for simple cuts | Basic machining, woodwork, and prototypes | Pros: Cost-effective; easy to operate. Cons: Limited complexity in machining. |

| 5-Axis CNC Milling Machine | Capable of simultaneous movement in five directions; allows complex geometries | Aerospace, automotive, and medical parts | Pros: High precision; reduces setup time. Cons: Higher cost; requires skilled operators. |

| Vertical CNC Milling Machine | Spindle is oriented vertically; suitable for face milling | Die making, mold production, and machining of flat surfaces | Pros: Versatile for various materials; easy to access. Cons: Limited to vertical operations. |

| Horizontal CNC Milling Machine | Features horizontal spindle; better for heavy-duty applications | Heavy machining, large-scale production | Pros: Efficient for large workpieces; better chip removal. Cons: Larger footprint; typically more expensive. |

| CNC Router | Specialized for cutting and engraving; uses rotary tools | Sign making, furniture, and intricate designs | Pros: Versatile for various materials; user-friendly. Cons: Less suitable for metal machining. |

What Are the Characteristics of 3-Axis CNC Milling Machines?

3-axis CNC milling machines are the most common type, primarily moving along the X, Y, and Z axes. They are particularly suitable for straightforward machining tasks, making them ideal for B2B applications such as basic machining, woodworking, and prototyping. Buyers considering this option should evaluate the machine’s speed, accuracy, and ease of use, as these factors can significantly impact productivity and operational efficiency.

How Do 5-Axis CNC Milling Machines Enhance Precision?

5-axis CNC milling machines extend the capabilities of traditional 3-axis machines by allowing simultaneous movement across five axes. This advanced functionality enables the creation of complex geometries, making them essential for industries like aerospace, automotive, and medical manufacturing. Buyers should focus on the machine’s precision, software compatibility, and the necessary training for operators, as these will affect the overall return on investment.

What Are the Advantages of Vertical CNC Milling Machines?

Vertical CNC milling machines feature a vertically oriented spindle, which is particularly effective for face milling and machining flat surfaces. They are widely used in die making and mold production. Businesses looking for versatility in material handling will find these machines advantageous. However, buyers should consider their limitations regarding vertical operations and assess the machine’s adaptability for various tasks.

When Should You Choose Horizontal CNC Milling Machines?

Horizontal CNC milling machines are designed for heavy-duty applications, featuring a horizontal spindle that is ideal for large-scale production. They excel in heavy machining tasks and are preferred for their efficient chip removal capabilities. While these machines may require a larger footprint and come with a higher price tag, they are suitable for businesses focused on large workpieces and high-volume production.

What Makes CNC Routers a Popular Choice?

CNC routers are specialized machines designed for cutting and engraving, utilizing rotary tools to handle various materials, including wood, plastic, and composites. They are commonly employed in sign making, furniture production, and intricate design applications. Buyers should consider the machine’s versatility and user-friendliness, particularly if they require a machine that can handle multiple materials. However, they should also note that CNC routers may not be suitable for metal machining tasks.

Key Industrial Applications of industrial cnc milling machine

| Industry/Sector | Specific Application of Industrial CNC Milling Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing for aircraft parts | Enhanced accuracy and reduced material waste | Compliance with aerospace standards and certifications |

| Automotive | Production of engine components and assembly fixtures | Improved production speed and cost efficiency | Supplier reliability and machine capacity |

| Medical Devices | Fabrication of custom implants and surgical instruments | High precision and customization capabilities | Quality control and biocompatibility requirements |

| Electronics | Manufacturing of circuit boards and enclosures | Streamlined production and scalability | Advanced technology and software compatibility |

| Energy Sector | Production of turbine components and structural parts | Durability and reliability in harsh environments | Material specifications and lead times |

How Are Industrial CNC Milling Machines Used in Aerospace?

In the aerospace industry, industrial CNC milling machines are essential for manufacturing intricate components like turbine blades and fuselage parts. These machines ensure high precision, which is critical for safety and performance in aviation. By minimizing material waste through accurate machining, companies can significantly reduce costs. Buyers in this sector must consider sourcing machines that comply with stringent aerospace standards and certifications, ensuring that their production processes meet regulatory requirements.

What Role Do CNC Milling Machines Play in Automotive Production?

CNC milling machines are widely used in the automotive sector for the production of engine components, transmission parts, and assembly fixtures. They facilitate rapid prototyping and production, allowing manufacturers to keep up with the fast-paced automotive market. The ability to produce complex geometries with high precision helps in enhancing vehicle performance and reducing production costs. When sourcing, automotive manufacturers should prioritize supplier reliability and machine capacity to handle high-volume production runs.

Why Are CNC Milling Machines Important in the Medical Devices Industry?

In the medical devices industry, CNC milling machines are pivotal in fabricating custom implants, surgical instruments, and diagnostic equipment. These machines offer high precision and the ability to create intricate designs tailored to specific patient needs. The customization capabilities of CNC milling can lead to better patient outcomes and increased market competitiveness. Buyers must focus on quality control measures and ensure that the materials used meet biocompatibility standards to avoid adverse reactions.

How Do CNC Milling Machines Enhance Electronics Manufacturing?

The electronics industry benefits from CNC milling machines in the production of circuit boards, enclosures, and other components. These machines streamline the production process, allowing for rapid scaling and adaptation to new technologies. By ensuring precise cuts and features, CNC milling enhances the overall functionality and reliability of electronic products. Buyers should look for advanced technology and software compatibility to optimize their production capabilities and maintain a competitive edge.

What Benefits Do CNC Milling Machines Provide in the Energy Sector?

In the energy sector, CNC milling machines are used to produce turbine components, structural parts, and specialized tools. The durability and reliability of these components are crucial, especially in harsh operational environments like wind and hydroelectric power plants. By utilizing CNC milling, companies can achieve the necessary precision and strength required for energy applications. Key sourcing considerations include material specifications and lead times, which are critical for project timelines and operational efficiency.

3 Common User Pain Points for ‘industrial cnc milling machine’ & Their Solutions

Scenario 1: Downtime Due to Machine Malfunction

The Problem: Industrial CNC milling machines are the backbone of many manufacturing operations. However, unexpected breakdowns can lead to significant downtime, crippling productivity and delaying order fulfillment. B2B buyers often face the challenge of sourcing reliable machines that can withstand rigorous use while minimizing the risk of failure. This concern is compounded by the potential high costs of repairs and the lengthy lead times associated with acquiring replacement parts, which can disrupt operations and negatively impact customer satisfaction.

The Solution: To mitigate the risk of downtime, it is crucial for buyers to invest in high-quality CNC milling machines with robust warranties and reliable technical support. When sourcing machines, prioritize manufacturers that provide comprehensive after-sales support, including lifetime technical assistance and readily available spare parts. Conduct thorough research on the machine’s reliability and read reviews from other businesses in similar industries. Additionally, implementing a proactive maintenance schedule can help identify potential issues before they lead to malfunctions. Training staff on proper operation and care can also significantly reduce wear and tear on the machines, ensuring smoother operations.

Scenario 2: Complexity in Programming and Operation

The Problem: One of the most common pain points for B2B buyers is the complexity associated with programming CNC milling machines. Many industrial machines come with advanced features and capabilities that can be daunting, particularly for teams with limited experience in CNC operations. This complexity can lead to errors in production, wasted materials, and ultimately, increased costs. Buyers may feel overwhelmed by the learning curve associated with new technology, which can hinder their ability to fully utilize the machine’s capabilities.

The Solution: To overcome this challenge, it is essential to select CNC milling machines that offer user-friendly software interfaces and intuitive controls. Look for vendors that provide comprehensive training programs as part of the purchase, ensuring that your team is well-equipped to operate the machine efficiently. Additionally, consider investing in CAD/CAM software that integrates seamlessly with the milling machine, simplifying the programming process. Many manufacturers also offer online resources, such as tutorials and webinars, that can help staff become proficient quickly. By fostering a culture of continuous learning and encouraging feedback from operators, businesses can enhance their team’s skills and maximize the machine’s potential.

Scenario 3: Sourcing the Right Machine for Specific Applications

The Problem: B2B buyers often struggle with selecting the right CNC milling machine that aligns with their specific production needs. With various models available—ranging from basic 3-axis machines to advanced 5-axis systems—the decision-making process can be overwhelming. This difficulty is exacerbated by the need to balance performance with budget constraints. Choosing the wrong machine can lead to inefficient production processes and increased operational costs.

The Solution: To effectively source the right CNC milling machine, it is critical to conduct a thorough needs assessment that evaluates your production requirements, including material types, part sizes, and complexity of designs. Engage with machine suppliers to discuss your specific applications and ask for demonstrations or case studies that illustrate how their machines have performed in similar scenarios. Consider creating a checklist of must-have features, such as the machine’s work envelope, spindle speed, and tooling options, to guide your selection. Collaborating with an experienced consultant who specializes in CNC technology can also provide valuable insights and recommendations tailored to your business needs, ensuring you make a well-informed investment that drives efficiency and profitability.

Strategic Material Selection Guide for industrial cnc milling machine

What Are the Key Materials Used in Industrial CNC Milling Machines?

When selecting materials for industrial CNC milling machines, it’s essential to consider their properties, advantages, disadvantages, and the specific requirements of international markets. Here, we analyze four common materials used in this context: Aluminum, Steel, Titanium, and Plastics.

How Does Aluminum Perform in CNC Milling Applications?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It typically has a temperature rating of around 660°C before melting, making it suitable for various applications. Its low density allows for faster machining speeds, which can enhance productivity.

Pros: Aluminum is durable, cost-effective, and offers a good surface finish, making it ideal for components that require aesthetic appeal. It is also relatively easy to machine, reducing manufacturing complexity.

Cons: However, aluminum’s lower strength compared to steel can be a limitation in high-stress applications. Additionally, it can be prone to scratching and denting.

Impact on Application: Aluminum is commonly used in automotive and aerospace industries, where weight reduction is critical. It is compatible with various media, including lubricants and coolants, which are often used during machining.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 573 for aluminum alloys, while those in South America may need to consider local regulations regarding material sourcing.

What Are the Advantages of Using Steel in CNC Milling?

Steel is renowned for its strength and durability, making it a preferred choice for heavy-duty applications. With temperature ratings that can exceed 1500°C, steel is suitable for high-stress environments.

Pros: Steel offers excellent wear resistance and can withstand high pressures, making it ideal for manufacturing components like gears and shafts. Its versatility allows for various grades, catering to different performance needs.

Cons: The primary drawback is the higher cost and complexity of machining compared to softer materials like aluminum. Steel also requires more robust tooling and can lead to longer machining times.

Impact on Application: Steel is widely used in construction and manufacturing sectors, where structural integrity is paramount. Its compatibility with various cutting fluids enhances its machining performance.

Considerations for International Buyers: Compliance with ASTM standards is crucial for buyers in Africa and Europe, ensuring that the steel grades meet specific performance criteria.

How Does Titanium Compare in CNC Milling?

Titanium is a high-performance metal known for its strength-to-weight ratio and exceptional corrosion resistance. It can withstand temperatures up to 1660°C, making it suitable for extreme environments.

Pros: Titanium’s durability and lightweight properties make it ideal for aerospace and medical applications. It is also biocompatible, which is essential for medical implants.

Cons: The primary disadvantage is its high cost and the complexity involved in machining, which can increase production times and costs.

Impact on Application: Titanium is often used in aerospace components and medical devices, where performance and safety are critical. It is compatible with various media, including saline solutions in medical applications.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM F136 for titanium alloys, especially in the medical field.

What Role Do Plastics Play in CNC Milling?

Plastics, particularly engineering plastics like Nylon and Polycarbonate, are increasingly used in CNC milling due to their lightweight and corrosion-resistant properties. They typically have lower melting points, around 200-300°C, depending on the type.

Pros: Plastics are cost-effective, easy to machine, and can be produced in various colors and finishes. They are ideal for applications where weight reduction and resistance to chemicals are necessary.

Cons: However, plastics can be less durable than metals and may not withstand high temperatures or mechanical stresses.

Impact on Application: Plastics are commonly used in the manufacturing of consumer goods and electronic components, where lightweight and corrosion resistance are significant advantages.

Considerations for International Buyers: Buyers should consider compliance with standards such as ISO 1043 for plastics, ensuring that the materials meet the necessary performance criteria.

Summary Table of Material Selection for CNC Milling

| Material | Typical Use Case for industrial cnc milling machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and aerospace components | Lightweight and easy to machine | Lower strength compared to steel | Medium |

| Steel | Heavy-duty manufacturing components | High strength and durability | Higher machining complexity | High |

| Titanium | Aerospace and medical applications | Excellent strength-to-weight ratio | High cost and machining complexity | High |

| Plastics | Consumer goods and electronic components | Cost-effective and lightweight | Less durable than metals | Low |

This guide provides a comprehensive overview of material selection for industrial CNC milling machines, enabling B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for industrial cnc milling machine

What Are the Key Stages in the Manufacturing Process of Industrial CNC Milling Machines?

The manufacturing process of industrial CNC milling machines involves several critical stages that ensure precision, durability, and quality. Each phase is designed to meet stringent industry standards and accommodate the diverse needs of international B2B buyers.

1. Material Preparation: What Materials Are Used and How Are They Prepared?

The first stage involves selecting high-quality materials suitable for CNC milling machines, typically including various grades of steel, aluminum, and composite materials. The choice of material significantly affects the machine’s performance, durability, and cost-effectiveness.

Once the materials are selected, they undergo preparation processes such as cutting, shearing, and machining to achieve the desired dimensions. This preparation stage is crucial for ensuring that the materials can be accurately processed in subsequent stages. Advanced techniques, including laser cutting and water jet cutting, may be employed to enhance precision and minimize waste.

2. Forming: How Are the Components Shaped?

The forming stage is where the bulk of the machine components are shaped and machined. This involves processes such as milling, turning, and drilling, using CNC machines to achieve high precision and repeatability.

CNC machining centers, equipped with multi-axis capabilities, allow for complex geometries and intricate designs to be produced efficiently. Techniques like 5-axis machining enable manufacturers to create components with complex contours and features, which are essential for modern CNC milling machines.

3. Assembly: What Are the Steps in Assembling CNC Milling Machines?

Once the individual components are machined, they move to the assembly stage. This process involves integrating various sub-assemblies, such as the spindle, tool holders, and control systems, into a cohesive unit.

Assembly is often conducted in a clean environment to prevent contamination and ensure that all components fit precisely. Skilled technicians perform this task, using specialized tools and techniques to align and secure components accurately. Attention to detail during this phase is crucial, as it directly impacts the machine’s performance and longevity.

4. Finishing: How Is the Final Product Prepared for Delivery?

The finishing stage includes surface treatments and coatings that enhance the durability and aesthetics of the CNC milling machine. Common finishing techniques involve anodizing, painting, or applying protective coatings to prevent corrosion and wear.

Quality assurance checks are performed throughout the finishing process to ensure that the machine meets the required specifications and standards before it is packaged and shipped to customers.

What Quality Assurance Measures Are Commonly Implemented in CNC Milling Machine Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, especially for CNC milling machines, where precision is paramount. Effective QA measures ensure that machines not only meet regulatory standards but also fulfill customer expectations.

Relevant International Standards: What Certifications Should B2B Buyers Look For?

B2B buyers should prioritize suppliers that comply with international quality standards, such as ISO 9001, which focuses on quality management systems, and ISO 13485 for medical devices, where applicable. Additionally, industry-specific certifications like CE marking for safety and performance in the European market, and API standards for the oil and gas industry, are crucial for ensuring that products are safe and reliable.

Key Quality Control Checkpoints: Where Are the Critical Control Points?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial step ensures that the raw materials meet specified quality standards before they enter the production line. Suppliers often provide material certification documents that verify compliance with industry standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections and tests are conducted to monitor the quality of components. This can include dimensional checks, material properties tests, and functional tests to ensure that each part meets design specifications.

-

Final Quality Control (FQC): Once assembly is complete, a comprehensive evaluation is performed on the finished machine. This includes operational tests, safety assessments, and performance evaluations to confirm that the machine operates as intended.

What Testing Methods Are Commonly Used to Ensure Quality in CNC Milling Machines?

Several testing methods are utilized to validate the quality of CNC milling machines:

-

Dimensional Inspection: Utilizing tools such as calipers and coordinate measuring machines (CMM), manufacturers verify that the dimensions of components align with engineering specifications.

-

Functional Testing: This involves running the machine through its operational cycles to ensure that all systems, including the CNC controls and motion systems, function correctly.

-

Material Testing: Non-destructive testing (NDT) methods such as ultrasonic or magnetic particle testing can be employed to assess the integrity of materials without damaging them.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must conduct thorough due diligence when selecting suppliers, particularly in international markets. Here are some actionable steps:

-

Supplier Audits: Requesting audits of the supplier’s manufacturing facilities can provide insights into their quality management practices, production capabilities, and adherence to international standards.

-

Quality Reports: Buyers should ask for detailed quality reports that outline the results of QC checks, testing methods used, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and final products, ensuring compliance with required standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those in regions like Africa and South America, understanding local regulations and standards is crucial. Buyers should be aware of the following:

-

Regional Standards Compliance: Different regions may have specific standards and regulations governing the quality and safety of machinery. Ensuring that the supplier adheres to these local requirements is vital for smooth operations.

-

Logistics and Shipping Considerations: Quality assurance does not end at the factory. Buyers should consider how machines are packaged and transported to avoid damage during transit, which can affect performance and reliability.

-

Cultural and Communication Factors: Establishing clear communication channels with suppliers can mitigate misunderstandings regarding quality expectations and standards.

In conclusion, the manufacturing processes and quality assurance measures for industrial CNC milling machines are comprehensive and multifaceted. By understanding these stages and implementing rigorous quality checks, B2B buyers can ensure they invest in machines that deliver performance, reliability, and value.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘industrial cnc milling machine’

Introduction

This practical sourcing guide provides B2B buyers with a structured checklist for procuring industrial CNC milling machines. By following these steps, you can ensure that you select the right equipment that meets your operational needs while maximizing your investment.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline your technical requirements, including the types of materials you’ll be machining, the dimensions of the parts, and the complexity of the designs. This step is crucial as it will guide your selection process and help you communicate effectively with suppliers.

- Material Compatibility: Determine if you need a machine that can handle metals, plastics, or composites.

- Axis Configuration: Decide between 3-axis, 4-axis, or 5-axis machines based on your machining needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of industrial CNC milling machines. This includes looking for manufacturers with a proven track record and positive customer feedback.

- Industry Experience: Focus on suppliers that have been in the industry for a significant period, as they are likely to have more expertise.

- Customer Reviews: Check online platforms for reviews and testimonials to gauge the reliability of the supplier.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers have the necessary industry certifications, such as ISO 9001 or CE marking. Certifications indicate that the supplier adheres to international quality standards, which can affect the performance and reliability of the machine.

- Quality Assurance Processes: Inquire about the quality control measures they have in place during manufacturing.

- After-Sales Support: Ensure they offer robust customer support and maintenance services.

Step 4: Request Detailed Quotes

Once you have a list of potential suppliers, request detailed quotes that include machine specifications, pricing, delivery timelines, and warranty terms. This step is essential for comparing options and understanding the total cost of ownership.

- Breakdown of Costs: Look for a transparent breakdown of costs, including shipping and installation.

- Warranty Information: Pay attention to warranty terms, as a longer warranty often reflects confidence in the machine’s reliability.

Step 5: Assess Machine Performance and Technology

Evaluate the technological features of the machines being offered. Consider aspects such as precision, speed, and the control software used. Advanced technology can enhance productivity and reduce operational costs.

- Automation Features: Look for machines that offer automation capabilities to increase efficiency.

- Software Compatibility: Ensure the machine is compatible with your existing CAD/CAM software for seamless operation.

Step 6: Visit Supplier Facilities (If Possible)

If feasible, schedule visits to the suppliers’ facilities to see the machines in action. This firsthand experience allows you to assess the build quality and operational capabilities.

- Live Demonstrations: Request a demonstration to observe the machine’s performance.

- Facility Conditions: Evaluate the cleanliness and organization of the supplier’s facility, as it reflects their operational standards.

Step 7: Negotiate Terms and Finalize the Purchase

Once you have selected a supplier, negotiate terms of purchase, including payment options and delivery schedules. Finalizing these details ensures that both parties have clear expectations.

- Flexible Payment Terms: Discuss payment options that align with your budget and financial planning.

- Delivery and Installation: Confirm delivery timelines and installation support to minimize downtime in your operations.

By following this checklist, you can streamline your procurement process and make informed decisions that align with your operational goals.

Comprehensive Cost and Pricing Analysis for industrial cnc milling machine Sourcing

What Are the Key Cost Components in Sourcing Industrial CNC Milling Machines?

When evaluating the cost structure of industrial CNC milling machines, several key components should be meticulously analyzed. These include:

-

Materials: The quality and type of materials used in manufacturing CNC machines significantly affect pricing. Premium materials often lead to higher durability and performance, justifying a higher initial cost.

-

Labor: Labor costs can vary based on geographic location and the skill level required for assembly and quality control. Countries with higher labor costs may see this reflected in the overall price of the machine.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses. Manufacturers in regions with high operational costs may charge more for their machines.

-

Tooling: The costs associated with specialized tooling for CNC machining can also impact pricing. Custom tools tailored for specific applications may increase the overall investment.

-

Quality Control (QC): Rigorous quality assurance processes ensure that machines meet industry standards, but they can add to the cost. High-quality certifications can also influence the final price.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. The distance from the supplier and the complexity of logistics can affect the total price significantly.

-

Margin: Suppliers typically build a profit margin into their pricing. This margin varies based on market competition and the perceived value of the machine.

How Do Price Influencers Affect the Cost of CNC Milling Machines?

Several factors can influence the pricing of CNC milling machines, especially for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities can lead to significant discounts. Buyers should assess their needs carefully to determine if bulk purchasing is feasible.

-

Specifications and Customization: Customized machines tailored to specific applications often come at a premium. Buyers should weigh the benefits of customization against the additional costs.

-

Materials and Quality Certifications: The choice of materials and the presence of certifications (such as ISO) can impact pricing. Machines made from high-grade materials with recognized certifications typically command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established manufacturers with a proven track record may charge more due to their brand value.

-

Incoterms: Understanding international shipping terms is crucial. Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) affect who bears the risk and costs at various stages of shipping, influencing the overall price.

What Buyer Tips Can Help in Negotiating CNC Milling Machine Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are several actionable tips:

-

Negotiation: Engage in open discussions with suppliers to negotiate prices. Be prepared to discuss volume discounts, payment terms, and warranties.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and potential downtime. A machine with a higher initial cost may offer better long-term savings.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that may affect the final cost. Understanding local regulations and compliance requirements can prevent unexpected expenses.

-

Research and Comparison: Conduct thorough market research to compare different suppliers and machines. This helps in identifying the best value for money based on specifications and performance.

-

Request for Quotes (RFQs): Sending out RFQs to multiple suppliers can help gauge the market price and provide leverage during negotiations.

Disclaimer on Indicative Prices

Prices for CNC milling machines can fluctuate based on various factors including market demand, technological advancements, and economic conditions. Buyers should consider these dynamics when budgeting for their purchases and consult directly with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing industrial cnc milling machine With Other Solutions

Exploring Alternatives to Industrial CNC Milling Machines

In the industrial landscape, CNC milling machines are a cornerstone technology for precision machining. However, businesses often consider alternative solutions that may suit their specific operational needs, budget constraints, and production goals. This section presents a comparative analysis of industrial CNC milling machines against two viable alternatives: CNC routers and manual milling machines.

Comparison Table

| Comparison Aspect | Industrial CNC Milling Machine | CNC Router | Manual Milling Machine |

|---|---|---|---|

| Performance | High precision, complex geometries, multi-axis capabilities | Good for flat materials, less precision | Limited precision, manual adjustments |

| Cost | High initial investment | Generally lower cost | Lowest initial cost |

| Ease of Implementation | Requires skilled operators and setup | User-friendly, less training needed | Requires skilled labor for operation |

| Maintenance | Regular maintenance, complex parts | Lower maintenance, simpler design | High maintenance due to manual wear |

| Best Use Case | High-volume, complex parts | Sign making, furniture, light production | Prototyping, small batch jobs |

Detailed Breakdown of Alternatives

CNC Router: A Cost-Effective Solution for Flat Materials

CNC routers serve as a viable alternative to CNC milling machines, especially for businesses focused on processing flat materials like wood, plastic, and soft metals. They are typically more affordable and easier to operate, making them accessible for small businesses and workshops. However, while they excel in speed and ease of use, CNC routers may lack the precision required for complex geometries found in more demanding applications like aerospace or automotive parts.

Manual Milling Machine: The Traditional Approach

Manual milling machines represent a more traditional machining method, relying on the operator’s skills to guide the tool. These machines have a significantly lower initial cost, making them attractive for small-scale operations and startups. However, they require considerable manual labor and expertise, which can lead to inconsistencies in production quality. Additionally, the time-consuming nature of manual milling may not meet the demands of high-volume production environments, limiting their suitability for larger operations.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between an industrial CNC milling machine, CNC router, or manual milling machine, B2B buyers must evaluate their specific requirements, including production volume, material types, budget, and the desired precision of the final product. An industrial CNC milling machine is ideal for high-precision, complex components, whereas CNC routers may be better suited for less intricate, flat materials at a lower cost. Manual milling machines can be beneficial for prototyping or small batch jobs where labor costs are manageable. Ultimately, understanding the strengths and limitations of each option will empower businesses to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for industrial cnc milling machine

What Are the Key Technical Properties of Industrial CNC Milling Machines?

Understanding the technical specifications of industrial CNC milling machines is crucial for making informed purchasing decisions. Here are some essential properties that buyers should consider:

1. Material Grade

The material grade of a CNC milling machine refers to the quality and type of materials used in its construction, such as cast iron, steel, or aluminum. Higher-grade materials generally lead to enhanced durability and stability during operation. For B2B buyers, investing in machines made from high-quality materials can result in lower maintenance costs and longer service life, ultimately improving ROI.

2. Tolerance Levels

Tolerance levels indicate the precision of the machine’s milling capabilities, usually expressed in microns (µm) or millimeters (mm). High tolerance levels ensure that parts are produced with minimal deviation from specified dimensions, which is critical in industries such as aerospace and automotive. For buyers, understanding tolerance requirements is vital to meet industry standards and customer specifications.

3. Axis Configuration

CNC milling machines can be categorized by their axis configurations, such as 3-axis, 4-axis, or 5-axis systems. A 3-axis machine operates along the X, Y, and Z axes, while a 5-axis machine allows for more complex geometries by enabling movement along additional rotational axes. B2B buyers should consider the complexity of their projects and choose a machine that can efficiently handle the required machining tasks.

4. Spindle Speed

The spindle speed, measured in revolutions per minute (RPM), indicates how quickly the cutting tool can rotate. Higher spindle speeds enable faster machining, which is essential for increasing productivity. For businesses looking to optimize their production capabilities, selecting a machine with an appropriate spindle speed can significantly impact output and efficiency.

5. Table Size and Load Capacity

The table size and load capacity determine the maximum dimensions and weight of the workpieces that can be processed. A larger table size allows for the machining of bigger parts, while sufficient load capacity ensures that heavier materials can be handled safely. Buyers should assess their production needs to choose a machine that aligns with their operational requirements.

6. Control System

The control system is the software that operates the CNC machine, often featuring user-friendly interfaces and advanced programming capabilities. Systems like FANUC, Siemens, or Haas are popular for their reliability and ease of use. For B2B buyers, investing in a machine with a robust control system can enhance operational efficiency and reduce training time for operators.

What Are Common Trade Terms Used in CNC Milling?

Familiarity with trade terminology can help B2B buyers navigate negotiations and contracts more effectively. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are sold under another company’s brand name. Understanding OEM relationships can be crucial when sourcing machinery or components, ensuring that buyers receive high-quality products that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budget planning and inventory management. It can also affect purchasing decisions, especially for startups or smaller companies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specified products or services. For buyers, issuing an RFQ allows for comparative analysis of different suppliers, helping to secure the best possible deal.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery obligations, ensuring smoother negotiations.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for project planning and meeting production schedules, especially in industries where timing is crucial.

6. After-Sales Support

After-sales support encompasses the services provided by suppliers post-purchase, including maintenance, repairs, and technical assistance. For B2B buyers, strong after-sales support can be a decisive factor, ensuring the longevity and optimal performance of their machinery.

In summary, a solid grasp of the technical properties and trade terminology related to CNC milling machines is essential for B2B buyers to make informed decisions and optimize their manufacturing processes.

Navigating Market Dynamics and Sourcing Trends in the industrial cnc milling machine Sector

What Are the Current Market Dynamics and Key Trends in the Industrial CNC Milling Machine Sector?

The industrial CNC milling machine sector is witnessing significant growth, driven by several global factors. The ongoing industrial revolution, characterized by automation and smart manufacturing, is pushing companies to adopt advanced machining technologies. This is particularly evident in regions like Africa and South America, where rapid urbanization and infrastructure development are creating a demand for precision machining. In Europe and the Middle East, manufacturers are focusing on enhancing productivity and reducing operational costs through the integration of CNC technology.

Emerging trends in B2B sourcing include the rise of Industry 4.0 technologies, which incorporate IoT, big data, and AI into manufacturing processes. This integration allows for real-time monitoring and predictive maintenance, significantly improving operational efficiency. Additionally, the demand for versatile machines capable of performing multiple tasks—such as 5-axis machining—continues to grow. These machines not only increase production flexibility but also reduce the need for multiple setups, streamlining the overall manufacturing process.

International buyers are also prioritizing suppliers that offer strong after-sales support, including training and technical assistance. This trend is particularly important for buyers in regions like Nigeria and Germany, where the skill level of the workforce may vary. The competitive landscape is increasingly influenced by suppliers who can provide tailored solutions to meet the specific needs of diverse markets, ensuring that buyers can maintain a competitive edge.

How Is Sustainability and Ethical Sourcing Influencing the Industrial CNC Milling Machine Sector?

Sustainability has become a pivotal concern for B2B buyers in the industrial CNC milling machine sector. The environmental impact of manufacturing processes is under scrutiny, leading companies to adopt more sustainable practices. This includes the use of energy-efficient machines, waste reduction initiatives, and recycling programs. Buyers are increasingly looking for suppliers who can demonstrate a commitment to sustainability through certifications and transparent practices.

Ethical sourcing is also gaining traction, with businesses seeking to ensure that their supply chains are free from exploitation and environmental harm. This has led to a growing demand for ‘green’ certifications and materials that minimize environmental impact. Suppliers who can provide machines made from recyclable materials or those that utilize eco-friendly lubricants and coolants are becoming more attractive to international buyers.

Furthermore, the push for sustainability is influencing product design, with manufacturers exploring ways to create machines that are not only efficient but also have a lower carbon footprint. This shift is not just a regulatory requirement but a market differentiator, as buyers increasingly favor brands that align with their values regarding social responsibility and environmental stewardship.

What Is the Brief Evolution and History of CNC Milling Machines Relevant for B2B Buyers?

CNC milling machines have evolved significantly since their inception in the mid-20th century. Initially developed for high-precision manufacturing, these machines have transitioned from mechanical systems to fully automated digital solutions. The introduction of computer numerical control (CNC) technology in the 1960s marked a turning point, enabling manufacturers to produce complex parts with unparalleled accuracy.

Over the decades, advancements in computer technology and software have enhanced the capabilities of CNC milling machines. The shift towards multi-axis machining and the integration of CAD/CAM software have allowed manufacturers to streamline operations and improve design flexibility. Today, CNC milling machines are essential tools in industries ranging from aerospace to automotive, providing manufacturers with the ability to meet the increasing demand for precision-engineered components.

This historical perspective underscores the importance of selecting suppliers who not only offer cutting-edge technology but also have a track record of innovation and reliability in the CNC milling machine sector. For international B2B buyers, understanding this evolution can inform decisions about the technology that best suits their operational needs and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of industrial cnc milling machine

-

How do I choose the right CNC milling machine for my business needs?

Choosing the right CNC milling machine involves assessing your specific production requirements, including the types of materials you will be working with, the complexity of the parts, and the desired precision. Evaluate the machine’s specifications, such as axis configuration (3-axis, 4-axis, or 5-axis), spindle speed, and tooling compatibility. Additionally, consider your budget and the machine’s operational costs. It’s beneficial to consult with manufacturers to understand the best options tailored to your production goals and to request demonstrations where possible. -

What are the key features to look for in an industrial CNC milling machine?

When selecting an industrial CNC milling machine, prioritize features like precision, durability, and versatility. Look for machines with high spindle speeds and feed rates, which enhance efficiency. A robust control system and user-friendly software are essential for ease of operation. Additionally, consider the machine’s ability to handle various materials and complex geometries, as well as its maintenance requirements. Comprehensive after-sales support and warranty options are also crucial for long-term investment security. -

What are the typical payment terms for purchasing CNC milling machines in international trade?

Payment terms can vary significantly depending on the supplier and the nature of the transaction. Common arrangements include a deposit (typically 30-50%) upfront, with the balance due upon delivery or prior to shipment. Some suppliers may offer financing options or extended payment plans. It’s vital to clarify payment methods accepted, such as wire transfers or letters of credit, and to consider currency fluctuations when negotiating terms. Always ensure that the terms are clearly outlined in the contract to avoid disputes. -

What is the minimum order quantity (MOQ) for CNC milling machines?

The minimum order quantity for CNC milling machines often depends on the manufacturer and the specific model. Some manufacturers may have an MOQ of one machine, while others may require larger orders to justify production costs. It’s essential to communicate with suppliers about your specific needs and to inquire if they can accommodate smaller orders. Additionally, bulk purchases may offer opportunities for discounts, so consider your long-term production needs when negotiating. -

How can I ensure the quality of CNC milling machines before purchasing?

To ensure quality, it’s crucial to perform thorough due diligence on potential suppliers. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Ask for references from previous clients and review case studies or testimonials. If possible, visit the supplier’s manufacturing facility to observe production processes. Additionally, consider requesting a sample product or trial period to evaluate the machine’s performance and reliability before committing to a purchase. -

What are the logistics involved in shipping CNC milling machines internationally?

Shipping CNC milling machines internationally requires careful planning and coordination. Key logistics considerations include selecting a reliable freight forwarder experienced in handling heavy machinery. Ensure compliance with export and import regulations, including customs documentation and tariffs. It’s essential to discuss packaging requirements with the supplier to prevent damage during transit. Additionally, consider insurance options to cover potential losses during shipping. Timely communication with all parties involved will facilitate a smoother logistics process. -

Can CNC milling machines be customized to fit specific production needs?

Yes, many manufacturers offer customization options for CNC milling machines to meet specific production requirements. Customizations may include modifications to the machine’s size, additional axes, specialized tooling, or enhanced software features. When discussing customization, provide detailed specifications and examples of your production needs to help the manufacturer understand your requirements. Keep in mind that customized machines may have longer lead times and potentially higher costs, so plan accordingly. -

What support should I expect after purchasing a CNC milling machine?

After purchasing a CNC milling machine, you should expect comprehensive support from the supplier, including installation assistance, training for your operators, and ongoing technical support. Many reputable manufacturers offer free lifetime technical support and maintenance services. It’s advisable to clarify the warranty terms and what is covered, including parts and labor. Additionally, inquire about access to online resources such as user manuals, troubleshooting guides, and software updates to ensure smooth operation and maintenance of your machine.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Industrial Cnc Milling Machine Manufacturers & Suppliers List

1. Tormach – Compact CNC Mills

Domain: tormach.com

Registered: 2002 (23 years)

Introduction: This company, Tormach – Compact CNC Mills, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Industrial CNC – Pro Series SHORT CUT 203

Domain: industrialcnc.com

Registered: 2011 (14 years)

Introduction: Industrial CNC offers a range of CNC routers designed for various applications including sign making, cabinetry, exhibits, schools, furniture, luthiers, and woodworking. Their Pro Series line includes the following models: 1. SHORT CUT 203 – 2’X3′ work area, engineered to the specs of larger systems. 2. APPRENTICE 404 – 4’X4′ table, suitable for full-size sheet jobs. 3. ARTISAN 408 – 4’X8′ CNC Rou…

3. CNC Machines – Used Industrial Routers

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: Used Industrial CNC Routers available for sale. Key brands include Multicam, Laguna, Industrial CNC, Avid, ShopSabre, C.R. Onsrud, and Vision. Models include LAGUNA SMARTSHOP M, INDUSTRIAL CNC ARTISAN 408, BIESSE ROVER K FT1531, AVID PRO 60120, and more. Specifications include various sizes such as 60″x120″x10.5″, 48″x96″x12″, and 49.5″x98.75″ with features like Vacuum Systems, Dust Collectors, an…

4. FANUC – ROBODRILL Plus

Domain: fanucamerica.com

Registered: 1998 (27 years)

Introduction: FANUC CNCs are designed for various manufacturing processes, including high-volume and complex multi-axis procedures. Key products include the ROBODRILL Plus, a vertical machining center available in small, medium, and large models, ideal for both high-volume and low-volume applications. The FANUC 30 Plus Series is enhanced for 5-axis operations and faster cycle times, while the 0 i -MF Plus Serie…

5. DMG MORI – DMC 125 U (FD) duoBLOCK

Domain: us.dmgmori.com

Registered: 2013 (12 years)

Introduction: CNC Milling Machines – DMG MORI offers a range of CNC milling machines with over 100 years of experience. The portfolio includes affordable 3-axis models and advanced 5-axis simultaneous machining centers. Key products include:

1. **DMC 125 U (FD) duoBLOCK**

– Max. X-axis travel: 49.2 in.

– Max. Y-axis travel: 49.2 in.

– Max. Z-axis travel: 39.4 in.

– Max. workpiece diameter:…

6. Grizzly – CNC Machines

Domain: grizzly.com

Registered: 1991 (34 years)

Introduction: This company, Grizzly – CNC Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Langmuir Systems – MR-1 CNC Gantry Mill

Domain: langmuirsystems.com

Registered: 2017 (8 years)

Introduction: MR-1 CNC Gantry Mill is a 3-Axis vertical CNC milling machine designed for hobbyist, light industrial, and educational uses. It can cut aluminum, steel, titanium, and stainless steel, removing up to 30 pounds of steel per hour with high accuracy and precision. The base price is $4495, with a $500 discount available for a limited time. Key specifications include:

– Machine Table Size: 20″ x 20.25″…

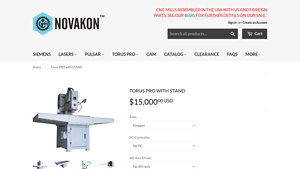

8. NovaKon – Torus PRO CNC Milling Machine

Domain: novakon.net

Registered: 2006 (19 years)

Introduction: Product Name: Torus PRO

Type: Industrial CNC Milling Machine

Assembly: Assembled in the USA with US and foreign parts

Price Options:

– Stepper / No PC / No 4th axis: $15,000.00

– Stepper / No PC / Add 4th axis: $15,450.00

– Stepper / Add PC / No 4th axis: $16,100.00

– Stepper / Add PC / Add 4th axis: $16,450.00

– Servo / No PC / No 4th axis: $18,660.00

– Servo / No PC / Add 4th axis: $19,014.00

– …

9. MSC Industrial Supply – CNC Machines

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Industrial Supply – CNC Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for industrial cnc milling machine

The landscape of industrial CNC milling machines presents significant opportunities for strategic sourcing that can enhance operational efficiency and drive profitability. As manufacturers increasingly seek to optimize production capabilities, understanding the nuances of various CNC systems—from affordable routers to advanced 5-axis machines—becomes crucial. Key takeaways for international B2B buyers include the importance of investing in robust and versatile machinery that not only meets current needs but also adapts to future demands.

Strategic sourcing enables businesses to leverage competitive pricing, exceptional quality, and comprehensive support from manufacturers. By fostering relationships with suppliers who prioritize innovation and reliability, buyers can ensure their operations are well-equipped to handle complex machining tasks, ultimately enhancing productivity and reducing lead times.

Looking ahead, the global market for CNC milling machines is expected to expand, driven by technological advancements and increasing demand across diverse industries. B2B buyers from regions such as Africa, South America, the Middle East, and Europe should act now to evaluate their sourcing strategies. Embrace the potential of CNC technology to not only meet but exceed your production goals—connect with trusted suppliers today to secure the machinery that will propel your business into the future.