Contents

Manufacturing Insight: Industrial Cnc Milling Machine

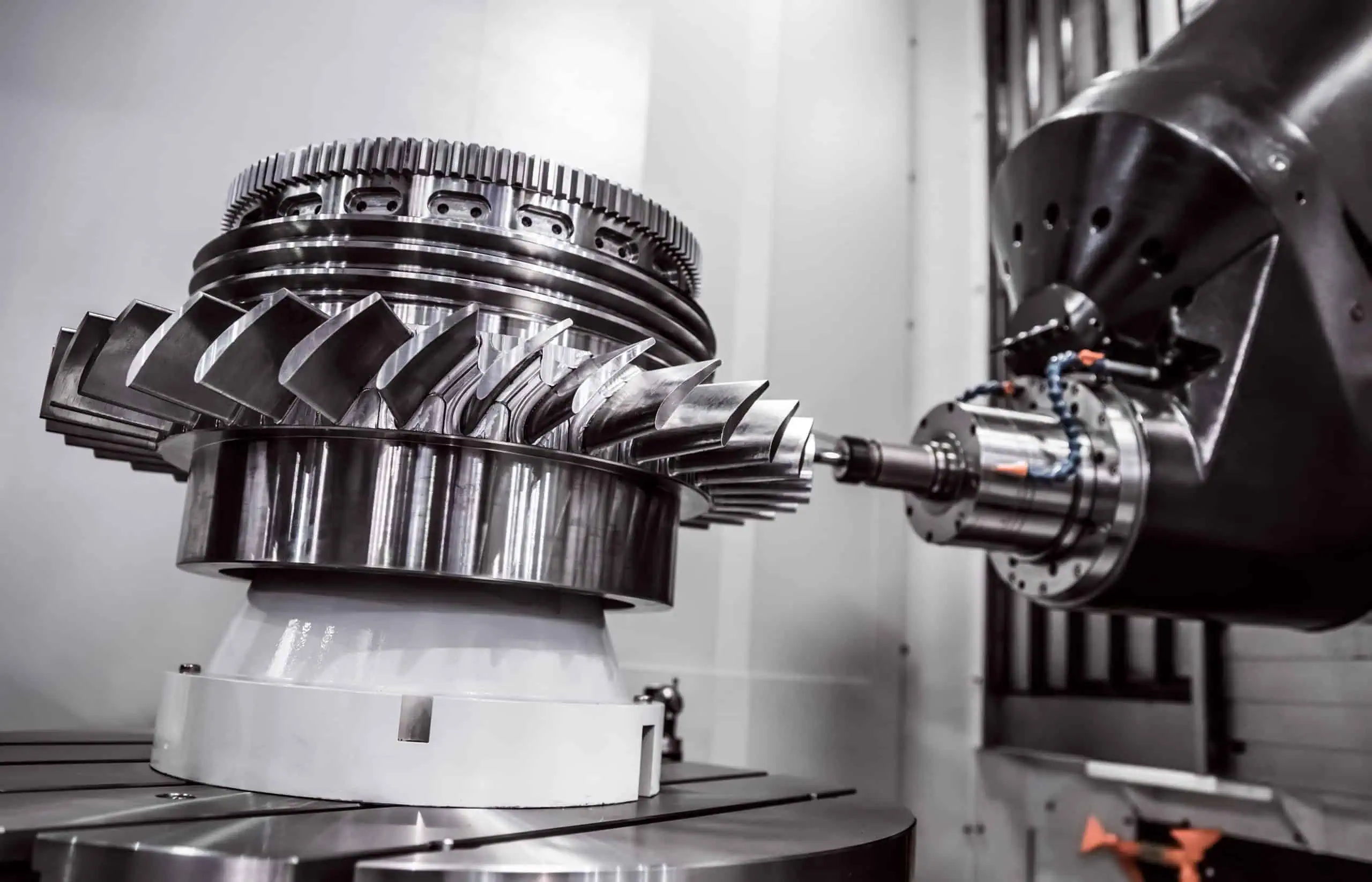

Precision CNC Milling Solutions Engineered for Complex Industrial Applications

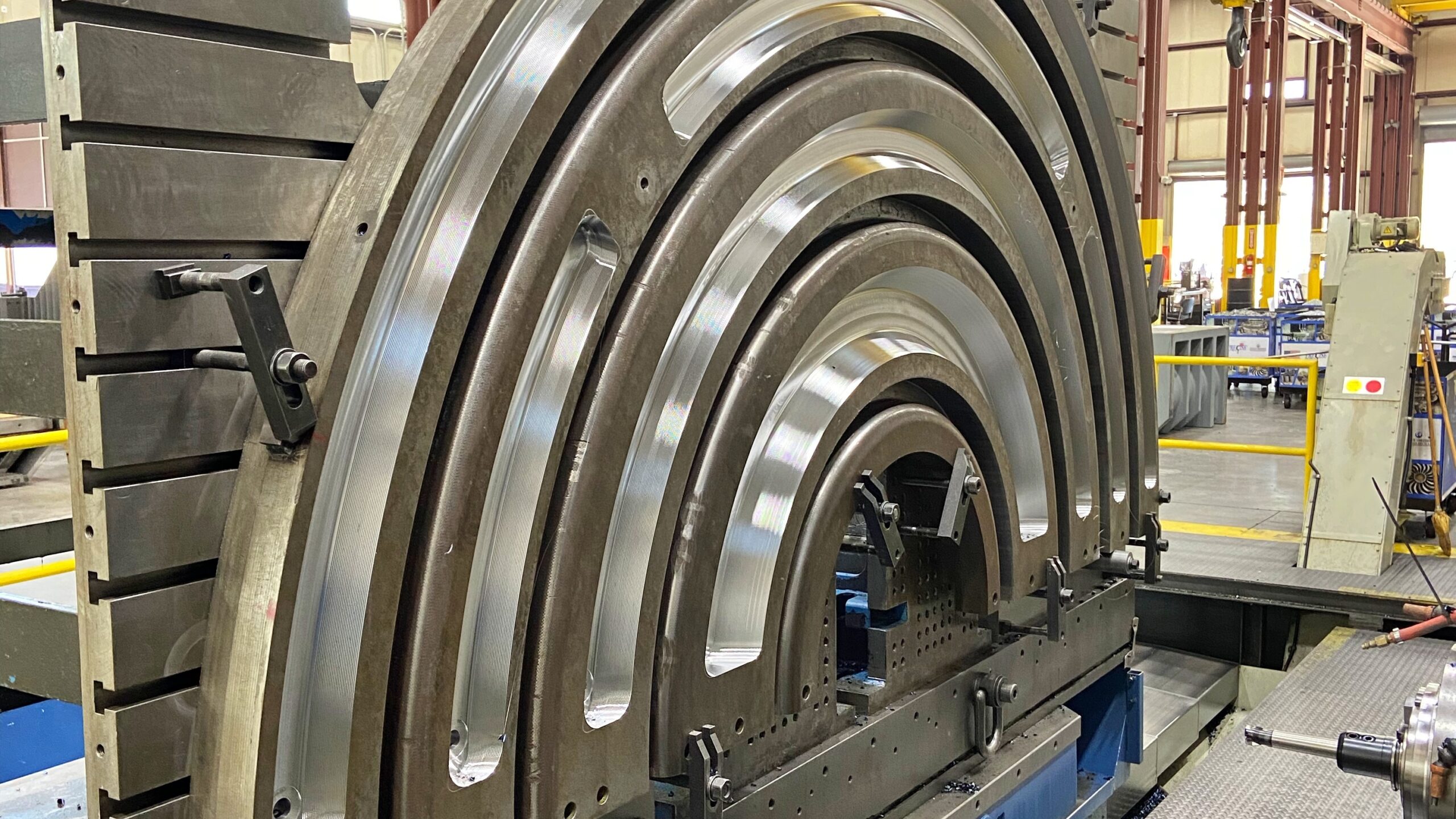

At Honyo Prototype, we transform demanding design challenges into high-integrity components through advanced industrial CNC milling capabilities. Our multi-axis machining centers, including 3-axis, 4-axis, and 5-axis configurations, deliver micron-level accuracy for mission-critical parts across aerospace, medical, automotive, and energy sectors. We specialize in machining complex geometries from technical alloys, composites, and high-performance polymers, ensuring strict adherence to GD&T standards and material certifications.

Our engineering-driven approach integrates rigorous process validation with cutting-edge technology to eliminate prototyping and low-volume production bottlenecks. Every project leverages optimized toolpaths, in-process metrology, and real-time adaptive control to maintain ±0.005 mm tolerances while maximizing material yield and surface integrity.

Core Capabilities at a Glance

| Parameter | Specification |

|---|---|

| Max Work Envelope | 1000 x 600 x 500 mm |

| Positional Accuracy | ±0.002 mm |

| Spindle Speed | Up to 24,000 RPM |

| Material Range | Aluminum, Titanium, Inconel, PEEK, Tool Steels |

| Finishes | As-machined, Anodized, Passivated, Precision Ground |

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours—not days. This seamless digital workflow eliminates procurement delays while providing transparent lead time estimates and DFM feedback from our engineering team. For prototypes requiring rapid iteration or production runs demanding zero-defect compliance, we deliver end-to-end traceability from CAD model to certified shipment. Partner with Honyo to convert engineering intent into precision reality.

Access your quote today at honyoprototype.com/quote.

Technical Capabilities

Industrial CNC Milling Machine Technical Specifications

The following table outlines key technical specifications for an industrial-grade CNC milling machine capable of 3-axis, 4-axis, and 5-axis operations, with integrated turning functionality (mill-turn capability), designed for high-precision machining of tight-tolerance components. The machine supports a wide range of materials including aluminum, steel, ABS, and nylon.

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Mill-Turn Center (with 3-axis, 4-axis, and 5-axis modes) |

| Control System | Fanuc 31i-B5 or Siemens 840D Solutionline |

| Spindle Speed | 12,000 RPM (standard), up to 24,000 RPM with high-speed option |

| Spindle Power | 30 kW (40 HP) continuous duty |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.00008 in) |

| X/Y/Z Travel | 800 mm × 600 mm × 500 mm (31.5 in × 23.6 in × 19.7 in) |

| Rotary Axes (B and C) | B-axis: ±120°, C-axis: Continuous 360° rotation |

| 4th Axis (Optional) | Integrated indexing or continuous rotary table (A-axis: 360° indexing) |

| Tolerance Capability | ±0.01 mm (±0.0004 in) typical; down to ±0.005 mm with precision tooling |

| Tool Magazine Capacity | 30–60 tools (automatic tool changer, ATC) |

| Tool-to-Tool Change Time | < 2.5 seconds |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) |

| Work Envelope (Max Part) | Ø600 mm × 500 mm height (for turning); up to 800 mm length in milling mode |

| Materials Supported | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 304/316), ABS, Nylon (PA6, PA66) |

| Surface Finish Capability | As low as 0.8 μm Ra (32 μin) with fine finishing tools |

| Machine Bed Construction | Thermally stable mineral cast or high-rigidity Meehanite cast iron |

| Linear Guideways | Preloaded box ways or high-precision linear roller guides |

| Feedback System | High-resolution linear scales on all axes (optional full closed-loop) |

| Programming Interface | CAD/CAM integration (Siemens NX, Mastercam, Autodesk Fusion 360) |

| Automation Ready | Compatible with robotic loading/unloading systems and pallet changers |

This machine is engineered for high-mix, low- to medium-volume production environments requiring tight-tolerance components in aerospace, medical, automotive, and industrial equipment sectors. It delivers exceptional versatility in machining both metallic and engineering-grade thermoplastic materials with consistent accuracy across multi-axis operations.

From CAD to Part: The Process

Honyo Prototype Industrial CNC Milling Process Overview

Honyo Prototype executes industrial CNC milling projects through a rigorously defined workflow designed for precision, efficiency, and client transparency. This process ensures manufacturability while minimizing lead time and cost overruns. Below is a technical breakdown of each phase:

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure customer portal. Our system validates geometric integrity, checks for non-manufacturable features (e.g., undercuts without draft), and confirms unit consistency (metric/imperial). File corruption or unsupported formats trigger immediate automated alerts, preventing downstream delays. All data undergoes AES-256 encryption, with version control maintained for audit compliance.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI engine analyzes part geometry, material specifications, tolerances, and surface finish requirements. The system cross-references 12+ million historical production datasets to generate a preliminary quote within 2 business hours. Key factors include:

Machine time estimation based on toolpath complexity and material removal rates

Raw material waste optimization via nesting algorithms

Secondary operation costing (e.g., deburring, anodizing)

Real-time material availability checks against our ISO 9001-certified inventory

The quote includes a risk assessment score highlighting potential cost drivers (e.g., tolerances tighter than ±0.025mm). Clients may adjust parameters and re-quote iteratively.

Engineering-Driven DFM Analysis

After quote acceptance, Honyo’s certified manufacturing engineers conduct a formal Design for Manufacturability review. This phase is collaborative and iterative:

Geometric feasibility assessment using Mastercam Simulator to detect collisions, chatter risks, or inaccessible features

Tolerance stack-up validation against ASME Y14.5 standards

Material suitability analysis (e.g., recommending 7075-T6 over 6061 for high-stress aerospace components)

Cost-reduction suggestions (e.g., modifying fillet radii to reduce tool changes)

A formal DFM report is issued within 48 hours, with mandatory client sign-off before production. Over 83% of projects see at least one actionable DFM recommendation that reduces cost by 15–30%.

Precision Production Execution

Approved designs move to our climate-controlled machining floor equipped with Haas VF-4SS and DMG MORI 5-axis mills. Production adheres to:

Real-time SPC monitoring of critical dimensions via Renishaw probes

Tool wear compensation using Zoller presetter data

In-process CMM checks at 50% and 90% completion milestones

All operations follow documented work instructions referencing ISO 2768-mK for general tolerances. For high-mix/low-volume industrial jobs, we deploy flexible manufacturing cells with automated pallet changers to maintain ≤72-hour turnaround for standard components.

Certified Delivery & Traceability

Final parts undergo 100% dimensional verification against the original CAD model using Hexagon GLOBAL S-1515 CMMs. Delivery includes:

Full FAI documentation (AS9102 compliant for aerospace)

Material certs (MTRs) and process validation records

Digital twin comparison report showing deviation heatmaps

Climate-controlled shipping with IoT-enabled tracking (temperature/humidity monitoring)

Standard lead time is 5–10 business days from DFM sign-off, with expedited options for critical-path components. All deliverables include a unique QR code linking to the complete production audit trail.

Typical Industrial Tolerances Achievable

| Feature Type | Standard Tolerance | Tight Tolerance Option |

|——————–|——————-|————————|

| Linear Dimensions | ±0.05 mm | ±0.0125 mm |

| Hole Position | ±0.075 mm | ±0.025 mm |

| Surface Finish | 3.2 μm Ra | 0.8 μm Ra |

| Flatness | 0.1 mm | 0.025 mm |

This closed-loop process ensures Honyo delivers industrial-grade CNC milled components with 99.2% first-pass yield rate, backed by our on-time delivery guarantee. Clients retain full visibility via our production dashboard, which provides live machining status and quality metrics.

Start Your Project

Explore high-precision industrial CNC milling machines engineered for demanding manufacturing applications. Built for reliability, accuracy, and performance, our machines are ideal for prototyping and low- to high-volume production runs.

All units are manufactured at our ISO-certified factory in Shenzhen, ensuring strict quality control and consistent output. We specialize in custom configurations to meet your specific production requirements.

For technical specifications, pricing, or to schedule a factory tour, contact Susan Leo at [email protected]. Let’s discuss how we can support your manufacturing goals with robust CNC solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.