Contents

Manufacturing Insight: Images Of Cnc Machines

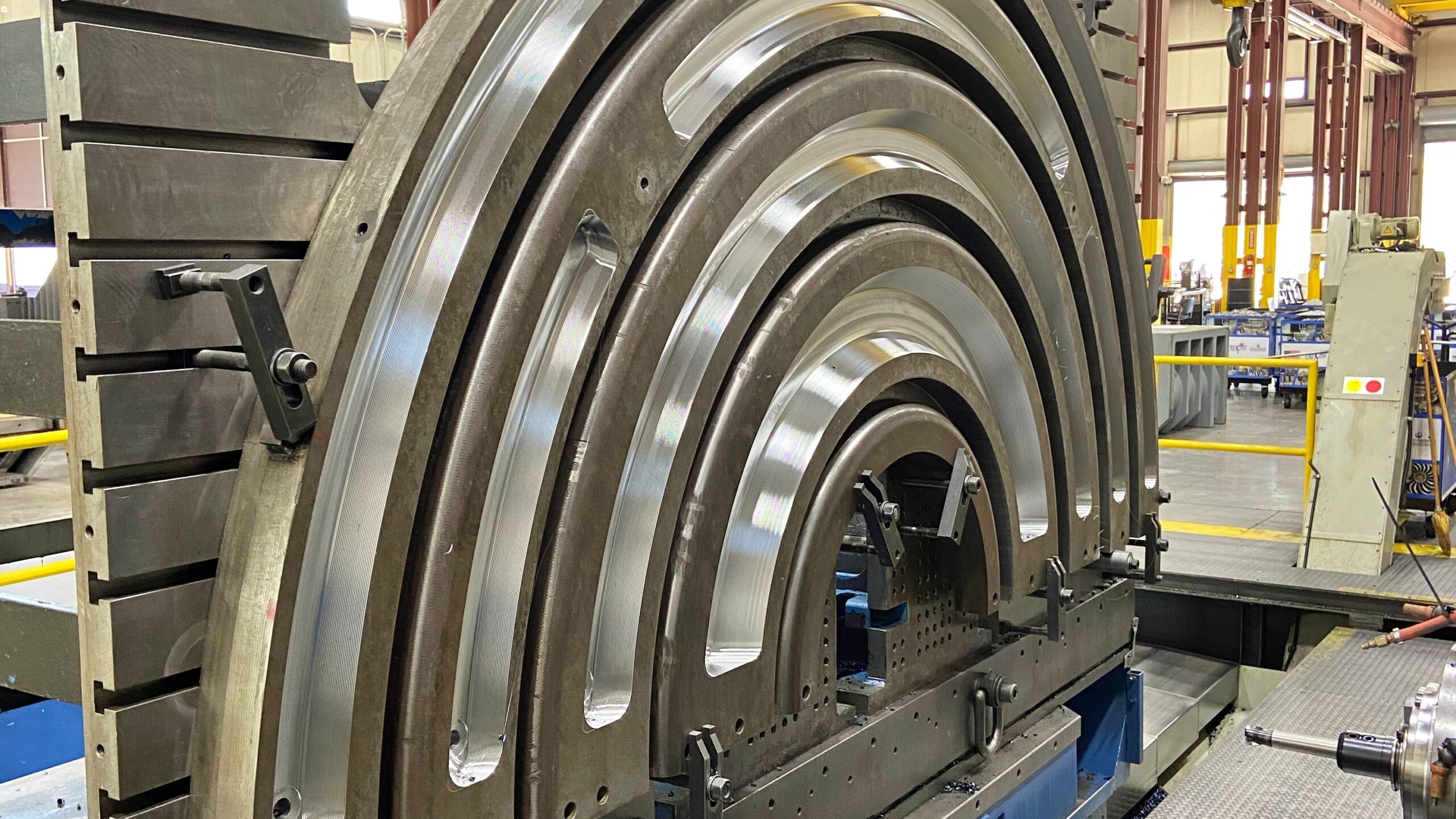

Precision CNC Machining Capabilities Showcased

Honyo Prototype delivers advanced CNC machining services engineered for complex, high-accuracy components across aerospace, medical, and industrial sectors. Our facility integrates state-of-the-art multi-axis CNC mills and lathes, operating under ISO 9001-certified processes to consistently achieve tight tolerances down to ±0.0002 inches. These machines handle diverse materials—from titanium and Inconel to engineering plastics—with optimized toolpaths that minimize lead times while ensuring repeatability for both prototyping and low-volume production.

The images presented reflect our commitment to technological precision, where each system undergoes rigorous calibration and thermal compensation protocols. This infrastructure supports rapid iteration cycles, critical for clients accelerating product development without compromising on dimensional stability or surface finish quality.

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload CAD files to receive detailed, transparent pricing and manufacturability feedback within hours—not days—enabling faster decision-making and seamless transition from design to physical part.

Material & Process Capabilities

| Material Category | Examples | Max Work Envelope | Tolerance Range |

|——————-|———-|——————-|—————–|

| Metals | Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 5 | 24″ x 16″ x 12″ | ±0.0002″ – ±0.001″ |

| Plastics | PEEK, Delrin, Nylon, Polycarbonate | 20″ x 14″ x 10″ | ±0.0005″ – ±0.002″ |

| Exotics | Inconel 718, Monel, Tungsten Carbide | 18″ x 12″ x 8″ | ±0.0003″ – ±0.0015″ |

Partner with Honyo to transform digital designs into mission-critical components through CNC expertise where speed, precision, and technical accountability converge. Access real-time pricing today via our Online Instant Quote system to validate your next project’s feasibility.

Technical Capabilities

The following table outlines the technical specifications relevant to images of CNC machines, focusing on 3-axis, 4-axis, and 5-axis milling systems, CNC turning centers, and their capabilities in achieving tight tolerances across common engineering materials such as aluminum, steel, ABS, and nylon. These specifications are representative of industrial-grade equipment used in precision prototyping and production environments.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes on Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + rotary A-axis (rotates around X) | X, Y, Z + two rotary axes (e.g., A & B or trunnion table) | X, Z linear axes + optional C-axis (rotary spindle) | 5-axis enables complex geometry with single-setup accuracy |

| Typical Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm | High-end machines achieve ±0.002 mm with calibration |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.002 mm | Critical for batch consistency in tight-tolerance runs |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM | 3,000 – 12,000 RPM | Higher speeds optimize finish and tool life in aluminum and plastics |

| Maximum Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon, Titanium | Aluminum, Steel, ABS, Nylon | Steel and titanium require rigid setups and lower feed rates |

| Typical Tolerance Range | ±0.010 mm | ±0.010 mm | ±0.008 mm | ±0.005 mm (diameter) | Tight tolerances require thermal stability and vibration control |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.4 – 1.6 µm | Fine finishes achievable with proper toolpath and tooling |

| Coolant Through Spindle | Optional | Optional | Standard | Standard | Enhances tool life and dimensional stability |

| Tool Changer (ATC) | Optional (20–30 tool capacity) | Standard (30+ tools) | Standard (30–60 tools) | Standard (8–12 tools) | Reduces cycle time and human error |

| Control System | Fanuc, Siemens, Heidenhain, Mitsubishi | Fanuc, Siemens, Heidenhain | Siemens, Heidenhain, Mitsubishi | Fanuc, Siemens | Advanced controls support high-precision interpolation |

| Work Envelope (Typical) | 500 x 400 x 300 mm | 700 x 500 x 400 mm | 600 x 500 x 400 mm | Ø300 x 500 mm (bar capacity) | Larger envelopes support complex or multi-part setups |

| Applications by Material | Aluminum: High speed, tight tolerance Steel: Moderate speed, high rigidity ABS/Nylon: Low heat, sharp tools |

Same as 3-axis, with added undercuts | Complex aerospace, mold, and medical parts in all materials | High-volume shafts, fittings, inserts in metal and plastic | Material-specific tooling and feeds critical for ±0.005 mm or better |

Notes for Image Interpretation

When analyzing or presenting images of CNC machines, visual cues such as rotary tables (4-axis), tilting spindles or trunnions (5-axis), bar feeders (turning), and tool magazines (ATC) help identify machine class and capability. Machines designed for tight tolerances often feature enclosed structures, thermal compensation systems, and linear scales (for feedback). Images should ideally show rigidity, tooling precision, and integration with probing systems for in-process measurement—key for maintaining tolerances across aluminum, steel, ABS, and nylon.

From CAD to Part: The Process

Honyo Prototype utilizes a streamlined digital manufacturing workflow optimized for CNC machining services. The process begins when a customer uploads native CAD files (STEP, IGES, Parasolid) or high-fidelity 2D drawings through our secure customer portal. We do not process standalone images of CNC machines for quoting or production; our system requires precise geometric data from engineering files to initiate manufacturing.

Upon CAD upload, our proprietary AI quotation engine performs automated feature recognition and geometry analysis. This system cross-references material selections, tolerances, and machine capabilities against real-time shop floor data to generate a detailed cost estimate within 2 hours. The AI output includes preliminary cycle time projections and material consumption metrics, validated against our historical production database.

The Design for Manufacturability (DFM) phase follows immediately after quote acceptance. Our certified manufacturing engineers conduct a rigorous technical review focusing on machinability, tool access, fixturing requirements, and tolerance stack-up analysis. This stage typically identifies 15-30% cost-saving opportunities through geometry simplifications or material substitutions while maintaining functional intent. Customers receive a formal DFM report with actionable recommendations before production release.

Production executes on our certified Haas and DMG MORI machining centers under ISO 9001:2015 controls. Each job undergoes first-article inspection per AS9102 standards, with in-process CMM checks at critical stages. For multi-axis work, we implement Renishaw probing systems to ensure 5-axis contour accuracy within ±0.005mm. All machining parameters are logged in our MES for full traceability.

Final delivery includes first-article inspection reports, material certifications, and clean-room packaged components. Standard lead times vary by complexity as shown below:

| Part Complexity | Material Type | Typical Lead Time |

|---|---|---|

| Low (2.5-axis) | Aluminum | 3-5 business days |

| Medium (3-axis) | Engineering Plastics | 5-7 business days |

| High (5-axis) | Titanium/Inconel | 8-12 business days |

This integrated workflow reduces traditional quotation cycles by 70% while maintaining rigorous quality controls. We prioritize geometric fidelity from CAD to finished part, ensuring dimensional compliance through embedded metrology at every production stage.

Start Your Project

Explore our high-precision CNC machining capabilities through detailed images of our state-of-the-art CNC machines in operation at our Shenzhen factory.

To request visuals or learn more about our manufacturing processes, contact Susan Leo at [email protected].

We provide professional-grade CNC prototyping and production services with fast turnaround times, backed by rigorous quality control standards.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.