Contents

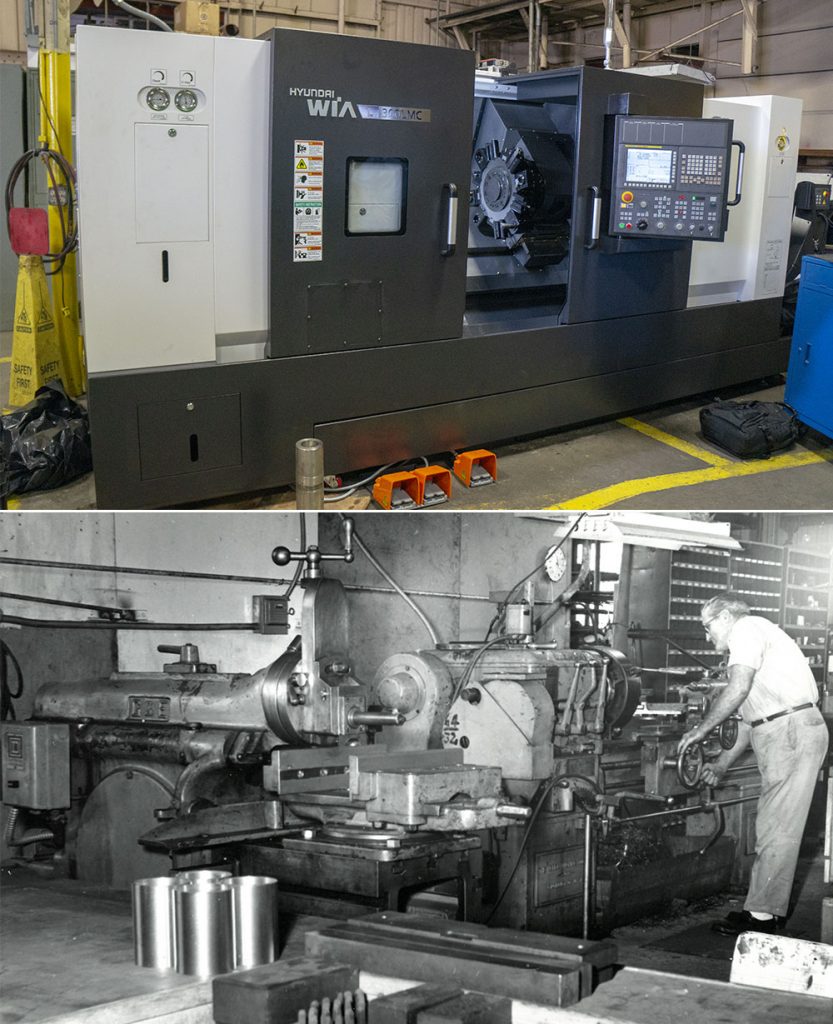

Manufacturing Insight: Hyundai Wia Cnc Machine

Precision Through Advanced Technology: Hyundai WIA CNC at Honyo Prototype

Honyo Prototype leverages the engineering excellence of Hyundai WIA CNC machines to deliver exceptional precision, repeatability, and efficiency for your most demanding prototyping and low-volume production requirements. As a cornerstone of our manufacturing capability, Hyundai WIA’s robust turning centers and multi-axis machining platforms provide the thermal stability, high-torque spindle designs, and rigid construction essential for maintaining tight tolerances on complex geometries in aerospace, medical, and automotive components. Our manufacturing engineers specifically select Hyundai WIA equipment for its proven Y-axis capabilities, integrated sub-spindles, and advanced control systems, ensuring optimal material removal rates while minimizing secondary operations and lead times.

This strategic investment translates directly into measurable value for your projects. We consistently achieve tolerances down to ±0.005 mm across challenging materials like titanium, Inconel, and high-strength alloys—critical for functional prototypes and end-use parts requiring certification. The inherent reliability of Hyundai WIA’s linear guide systems and precision ball screws guarantees long-term process stability, reducing scrap rates and ensuring batch-to-batch consistency you can trust.

Accelerate Your Project Timeline with Instant Clarity

Understanding that speed-to-quote is critical in competitive development cycles, Honyo Prototype integrates this advanced machining capability with our industry-leading Online Instant Quote portal. Upload your CAD file, specify materials and quantities, and receive a detailed, transparent cost and lead time estimate within minutes—powered by real-time machine availability and our deep expertise with Hyundai WIA’s performance parameters. This seamless digital workflow eliminates traditional quoting bottlenecks, allowing you to move from design intent to manufactured reality faster than conventional procurement channels. Partner with Honyo to transform complex engineering challenges into high-integrity components, backed by the precision of Hyundai WIA and the agility of modern digital manufacturing.

Technical Capabilities

Hyundai WIA is a leading manufacturer of high-precision CNC machine tools, offering a comprehensive range of 3-axis, 4-axis, and 5-axis milling centers, as well as advanced turning centers. These machines are engineered for high rigidity, thermal stability, and dynamic performance, making them ideal for applications requiring tight tolerances and complex geometries across a variety of materials including aluminum, steel, ABS, and nylon.

Below is a summary of the key technical specifications relevant to Hyundai WIA CNC machines focused on multi-axis milling and turning, with emphasis on precision and material compatibility.

| Feature | Specification |

|---|---|

| Machine Type | 3-Axis, 4-Axis, and 5-Axis CNC Vertical Machining Centers; CNC Turning Centers (including multi-tasking turn-mill models) |

| Spindle Speed | Up to 12,000 rpm (standard), optional high-speed spindles up to 20,000 rpm for aluminum and plastics |

| Positioning Accuracy | ±0.005 mm (standard models), ±0.002 mm with optional high-precision linear scales and thermal compensation |

| Repeatability | ±0.003 mm (standard), ±0.001 mm with precision feedback systems |

| Axis Travel (Typical 5-axis VMC) | X: 800–1,200 mm, Y: 600–1,000 mm, Z: 500–800 mm; Rotary axes (A/C or B/C): ±360° indexing, continuous cutting |

| Control System | Fanuc 31i/32i or Siemens 840D sl, supporting 5-axis simultaneous interpolation, tool path smoothing, and high-speed machining |

| Tool Magazine Capacity | 24–60 tools (standard), up to 120 tools with extendable ATC |

| Rapid Traverse Rate | 36–60 m/min per axis, depending on model and configuration |

| Cutting Tool Interface | BT40, BT50 (machining centers); Capto C6 or HSK-T for 5-axis and turn-mill models |

| Materials Processed | Aluminum (including 6061, 7075), Steel (mild, alloy, stainless), Plastics (ABS, Nylon, PEEK), Titanium (with appropriate tooling and cooling) |

| Tolerance Capability | Capable of holding ±0.01 mm for general features; ±0.005 mm or tighter achievable with process optimization and environmental control |

| Coolant System | High-pressure through-spindle cooling (up to 70 bar), optional mist and minimum quantity lubrication (MQL) for plastics |

| Rigidity & Frame Construction | Meehanite cast iron base with finite element analysis-optimized structure for vibration damping and thermal stability |

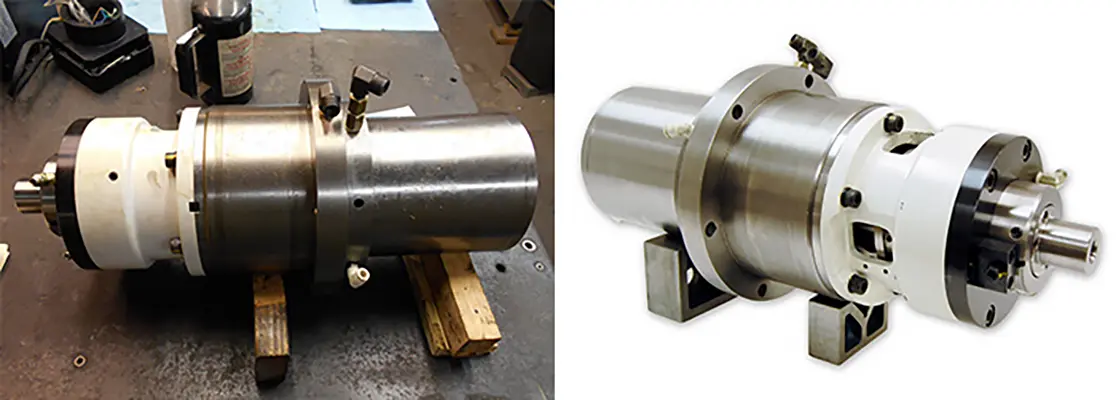

| Applications | Aerospace components, medical devices, mold & die, automotive powertrain parts, precision housings, and engineering prototypes |

Hyundai WIA machines are particularly well-suited for industries requiring tight tolerance machining across both metallic and non-metallic materials. The integration of advanced linear guides, direct-coupled spindles, and real-time compensation systems ensures consistent accuracy across production runs. For materials such as aluminum and plastics (ABS, nylon), high-speed machining packages are available to maximize throughput while maintaining surface integrity and dimensional precision.

From CAD to Part: The Process

Honyo Prototype Hyundai WIA CNC Machining Process Overview

Our end-to-end process for Hyundai WIA CNC machining projects integrates advanced automation with rigorous engineering validation to ensure precision, cost efficiency, and on-time delivery. This workflow is optimized specifically for Hyundai WIA’s high-rigidity vertical and horizontal machining centers, leveraging their sub-micron accuracy, thermal compensation systems, and Y-axis capabilities.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs an immediate automated validation check, confirming geometric integrity, unit consistency, and file completeness. For Hyundai WIA workflows, the system specifically flags potential clashes with machine envelope constraints—such as Z-axis travel limits on VMC models or pallet size compatibility for HMC variants—to prevent downstream delays.

AI Quote Generation

Validated CAD data feeds into our proprietary AI quoting engine, trained on 12,000+ historical Hyundai WIA production runs. The AI analyzes part geometry, material specifications, tolerances, and surface finish requirements against real-time machine utilization data for our WIA fleet (including models like the Hi-VM series and QTT series). It calculates precise machining time by simulating toolpaths within WIA’s control environment, accounting for machine-specific parameters such as rapid traverse rates (60m/min on Hi-VM), spindle power (22kW–50kW), and coolant-through-tool capabilities. The output is a detailed quote with cost breakdowns for setup, machining, and inspection, typically delivered within 2 business hours.

DFM Analysis

Engineers conduct a dual-layer Design for Manufacturability review. First, our AI cross-references the design against Hyundai WIA’s operational boundaries—verifying clearances for live tooling on turning centers, minimum hole depth-to-diameter ratios for deep-hole drilling cycles, and thermal stability requirements for tight-tolerance features. Second, a senior manufacturing engineer performs a manual review focusing on WIA-specific optimizations: recommending alternative tooling strategies to exploit the machine’s 1.2-second tool-to-tool change time, suggesting fixture modifications to leverage the WIA pallet system, and identifying opportunities to consolidate operations using the machine’s B-axis capability. Clients receive a formal DFM report with actionable suggestions, typically within 24 hours of quote acceptance.

Production Execution

Approved designs move to production in our climate-controlled WIA-dedicated cell. All Hyundai WIA machines operate under SPC-monitored conditions with real-time thermal drift compensation activated. Key practices include:

Utilizing WIA’s proprietary M+G code programming for complex 5-axis contours

Implementing in-process probing cycles via Renishaw systems to validate datum alignment per ISO 230-2 standards

Running first-article inspections against CMM reports traceable to NIST standards before batch release

Material traceability and machine performance logs are digitally recorded, with live progress updates accessible via the client portal.

Delivery and Certification

Final parts undergo comprehensive dimensional verification using calibrated CMMs and surface roughness testers, with all data mapped to the original CAD model. For Hyundai WIA projects, delivery packages include:

A machine-specific production log detailing WIA control parameters (spindle load curves, thermal compensation records)

Material certification with heat numbers

FAI reports per AS9102 or PPAP Level 3 as required

Shipping documentation with real-time logistics tracking

Standard lead time from CAD upload to delivery is 7–12 business days for 1–100 units, with expedited options available for WIA-optimized geometries.

This process ensures clients achieve maximum value from Hyundai WIA’s precision engineering while minimizing time-to-part through machine-aware digital workflows. All stages adhere to ISO 9001:2015 and IATF 16949 quality management protocols.

Start Your Project

Interested in Hyundai WIA CNC machines for your manufacturing operations?

Contact Susan Leo today to learn more about our high-precision machining solutions.

Email: [email protected]

Our manufacturing facility is located in Shenzhen, ensuring fast local support and seamless production integration.

Let us help you achieve superior machining performance with reliable Hyundai WIA technology.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.