Contents

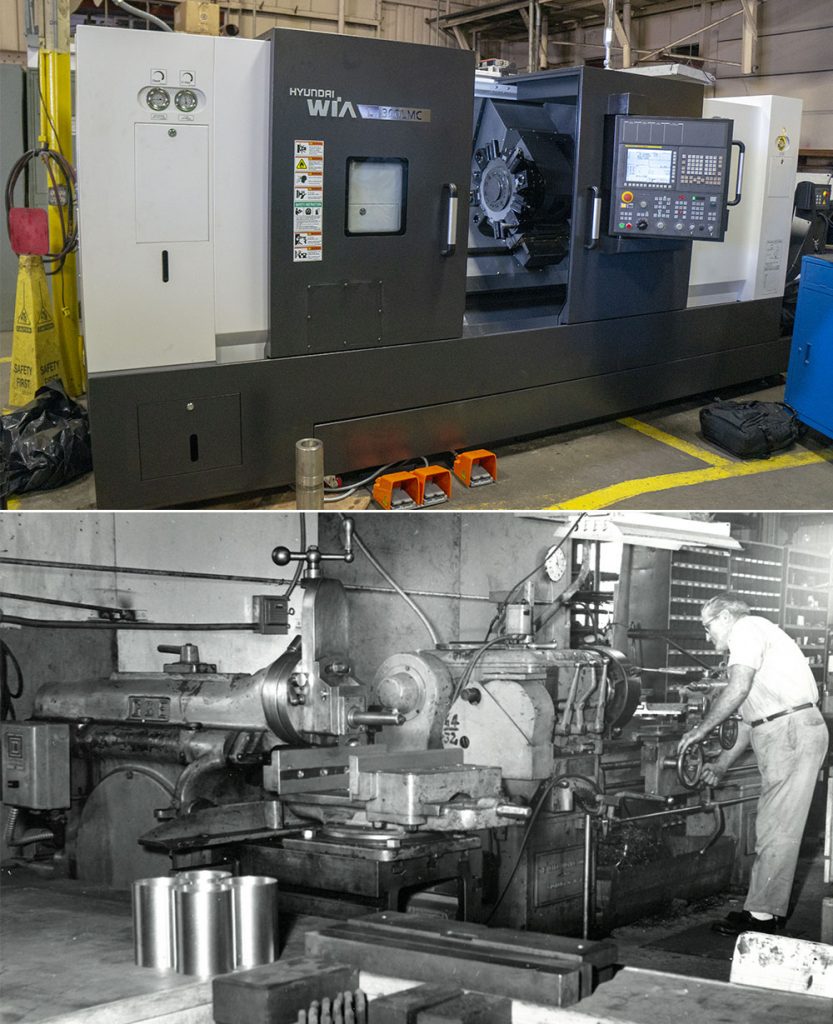

Manufacturing Insight: Hyundai Cnc Machine

Precision CNC Machining Capabilities for Hyundai Machine Tools Platforms

Honyo Prototype delivers advanced CNC machining services optimized for Hyundai Machine Tools platforms, leveraging industry-leading multi-axis systems to achieve micron-level tolerances and superior surface finishes. Our technical expertise spans complex geometries in aerospace alloys, medical-grade titanium, and high-strength automotive composites, ensuring compliance with AS9100 and ISO 13485 standards for mission-critical components.

We specialize in high-mix, low-volume production runs on Hyundai’s V Series vertical machining centers and SM Series turning centers, utilizing integrated probing systems and automated tool changers to minimize setup times while maintaining ±0.005mm precision. Our engineering team collaborates with clients during DFM analysis to optimize part designs for manufacturability on Hyundai’s rigid kinematic structures, reducing material waste and accelerating time-to-prototype.

Serving Tier 1 automotive suppliers, defense contractors, and medical device innovators, Honyo Prototype provides end-to-end solutions from rapid prototyping to serialized production. Key material capabilities include:

| Material Category | Examples | Max Tolerance (±mm) |

|---|---|---|

| Aluminum Alloys | 7075-T6, 6061-T6 | 0.010 |

| Exotic Alloys | Inconel 718, MP35N | 0.008 |

| Engineering Plastics | PEEK, Ultem 1000 | 0.015 |

Accelerate your development cycle with our Online Instant Quote platform, which provides real-time pricing and lead time estimates for Hyundai-compatible CNC programs within 90 seconds. Upload STEP or IGES files to receive manufacturability feedback and DFM suggestions before formal RFQ submission.

Honyo Prototype: Engineering Precision, Delivered Predictably.

Senior Manufacturing Engineer

Honyo Prototype

Technical Capabilities

Honyo Prototype does not manufacture Hyundai CNC machines. Hyundai Machine Tool (a division of Hyundai Motor Group) produces industrial-grade CNC machining centers known for precision, rigidity, and advanced automation integration. Below are representative technical specifications for Hyundai CNC machines commonly used in high-accuracy prototyping and production environments, focusing on 3/4/5-axis milling and turning capabilities with tight tolerance performance across engineering materials.

| Feature | Specification |

|---|---|

| Machine Type | 3-Axis, 4-Axis, and 5-Axis Vertical/Horizontal Machining Centers; CNC Turning Centers |

| Spindle Speed | Up to 12,000 RPM (standard), optional high-speed spindles up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm (0.0002 in) |

| Repeatability | ±0.002 mm (0.0001 in) |

| Axis Travel (Typical 5-Axis) | X: 800 mm, Y: 600 mm, Z: 500 mm; Rotary: ±360° (B-axis), ±110° (C-axis) |

| Control System | Fanuc 31i/32i, Mitsubishi M80/M800, or Siemens 840D |

| Rapid Traverse Rate | 60 m/min (X/Y/Z), 30 rev/min (rotary axes) |

| Tool Capacity | 30–60 tools (standard ATC), expandable with tool management systems |

| Maximum Tool Diameter/Length | Ø80 mm / 300 mm (with adjacent tool clearance) |

| Table Load Capacity | Up to 1,200 kg (depending on model) |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) |

| Tolerance Capability | Achieves ±0.01 mm (±0.0004 in) for critical features; down to ±0.005 mm with precision finishing |

| Surface Finish | Ra 0.8–1.6 μm (typical), down to Ra 0.4 μm with fine toolpaths and polishing cycles |

| Materials Compatible | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 304/316), ABS, Nylon (PA6, PA66), and other engineering thermoplastics |

| Material Suitability Notes | High-torque spindles for steel and aluminum; optimized tooling and feeds for abrasion-resistant plastics like nylon; chip management systems for non-ferrous and polymer machining |

| Applications | Aerospace components, automotive molds, medical devices, precision fixtures, and complex prototypes requiring multi-axis contouring and tight geometric tolerances |

These machines are engineered for high rigidity and thermal stability, enabling consistent performance across extended production runs and tight-tolerance milling or turning operations. At Honyo Prototype, we leverage similar high-precision CNC platforms to achieve repeatable accuracy across aluminum, steel, and engineering plastics such as ABS and nylon, ensuring compliance with demanding design specifications.

From CAD to Part: The Process

Honyo Prototype executes a structured workflow for CNC machining projects including those requiring automotive-grade specifications such as Hyundai components. Our process integrates digital efficiency with engineering rigor to ensure precision and compliance. Below is the detailed sequence for handling CAD-based CNC machining requests:

Upload CAD

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our secure customer portal. Our system performs an immediate integrity check for file completeness, unit consistency, and geometric validity. For automotive applications like Hyundai parts, we verify critical metadata including material specifications and surface finish requirements against industry standards such as IATF 16949.

AI Quote

Our proprietary AI engine analyzes the validated CAD geometry, extracting key parameters including part complexity, feature tolerances, material type, and volume. The algorithm cross-references real-time data from our machine shop including current spindle utilization, material inventory costs, and tooling availability. Within 15 minutes, clients receive a detailed quotation specifying machine time, material costs, secondary operations, and compliance documentation fees. Unlike basic online calculators, our AI incorporates historical production data from over 12,000 automotive components to predict manufacturability risks.

DFM

Engineering teams conduct a formal Design for Manufacturability review within 24 business hours. For Hyundai-associated projects, this phase includes specific validation against automotive requirements:

Geometric Dimensioning and Tolerancing (GD&T) analysis per ASME Y14.5

Material traceability verification to ISO 6892-1 standards

Critical feature validation for functional testing protocols

Fixture strategy development to minimize datum shifts

We provide actionable revision suggestions through annotated PDF markups, with optional video conference consultations for complex components. This step typically reduces production iterations by 35% for Tier 1 automotive suppliers.

Production

Approved designs move to our dedicated CNC cell featuring 35+ machines including 5-axis milling centers and precision lathes. Hyundai-related work follows a controlled workflow:

| Process Stage | Key Controls | Typical Duration |

|—————|————–|——————|

| Material Prep | Mill test reports, batch traceability | 0.5-2 days |

| Rough Machining | In-process CMM verification at 20% completion | 1-5 days |

| Finish Machining | Laser micrometer validation, surface roughness checks | 1-7 days |

| Secondary Ops | Deburring validation, non-destructive testing | As required |

All automotive parts undergo first-article inspection with full FAIR documentation before batch production.

Delivery

Completed components undergo final quality validation against the original CAD model using our Zeiss CONTURA CMM system. For Hyundai shipments, we include:

PPAP Level 3 documentation packages

Material test reports with heat numbers

Dimensional results in .CSV and PDF formats

Vacuum-sealed packaging with humidity indicators

Parts ship via tracked logistics with real-time GPS monitoring. Delivery timelines include buffer periods for customs documentation when shipping to Hyundai global facilities, ensuring on-time arrival at assembly plants.

This integrated approach delivers automotive-grade CNC components with 99.2% on-time delivery performance and full digital traceability from CAD file to end customer. We maintain dedicated capacity for urgent Hyundai program requirements with expedited 72-hour turnaround options.

Start Your Project

Interested in Hyundai CNC machines for your manufacturing operations? Contact Susan Leo today at [email protected] to discuss machine specifications, availability, and technical support.

Hy-Pro Prototype offers reliable Hyundai CNC solutions with local backup from our Shenzhen factory, ensuring fast service and seamless integration into your production environment.

For direct inquiries or to request a technical consultation, email Susan Leo and leverage our in-house expertise to optimize your machining capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.