Contents

Manufacturing Insight: Hyundai Cnc Lathe

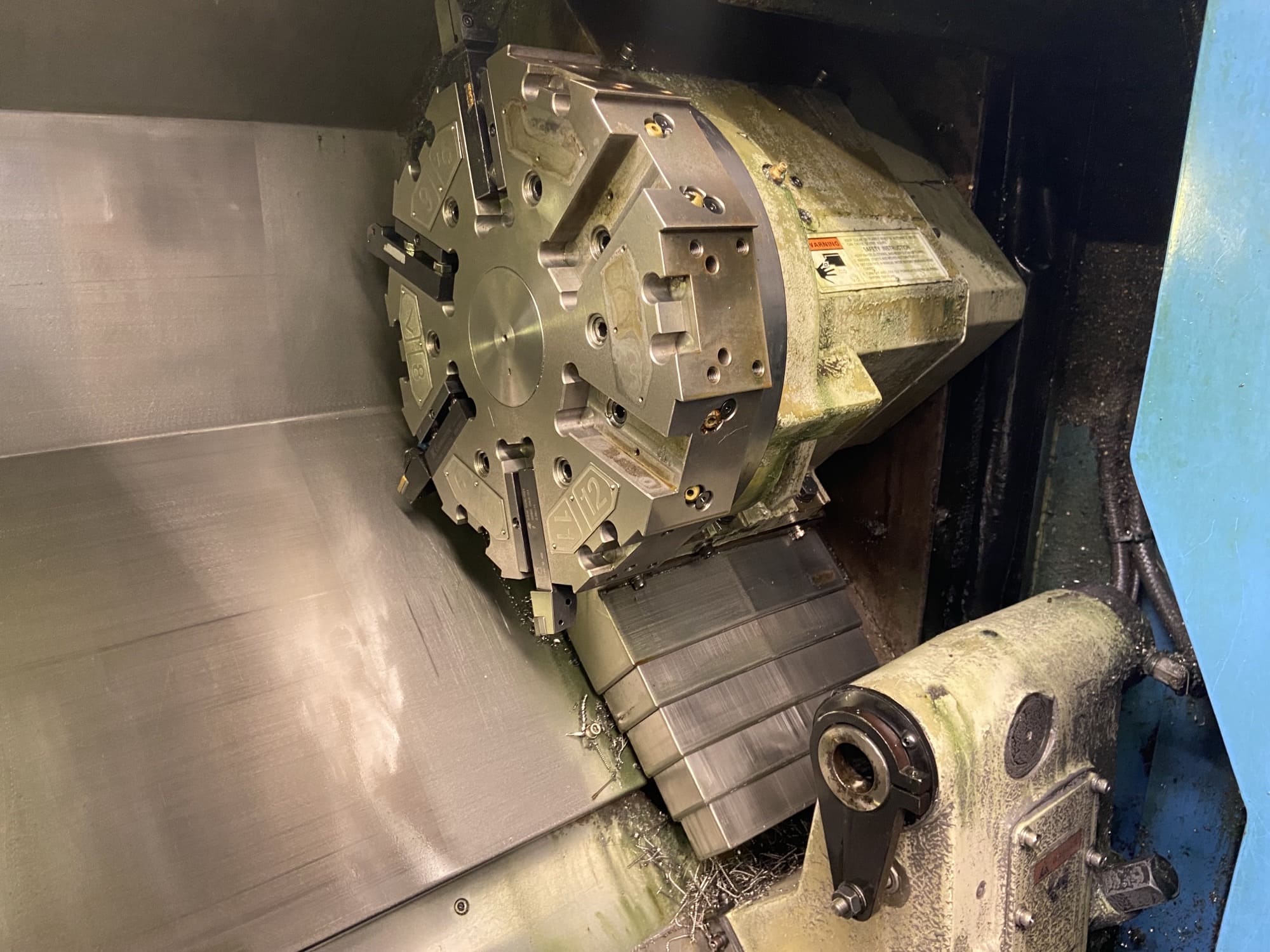

Precision Manufacturing Powered by Hyundai CNC Lathe Technology

Honyo Prototype delivers exceptional CNC machining services for demanding industrial applications, leveraging our advanced fleet of Hyundai CNC lathes to achieve micron-level precision and repeatability. These rigorously maintained machines excel in complex turning operations, handling materials from aerospace-grade aluminum alloys to hardened steels with consistent sub-micron accuracy. Our integrated manufacturing process ensures tight tolerances down to ±0.001mm, critical for hydraulic components, medical devices, and automotive prototypes where failure is not an option.

Hyundai lathes form the backbone of our turning capabilities, providing the thermal stability and dynamic control needed for high-integrity parts. Below is a comparison of key performance metrics achievable with our Hyundai CNC systems versus industry averages:

| Capability | Honyo Hyundai CNC Lathe | Standard Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.0005mm | ±0.002mm |

| Maximum Spindle Speed | 6,000 RPM | 4,500 RPM |

| Surface Finish (Ra) | 0.4 µm | 1.6 µm |

Accelerate your prototyping and low-volume production timelines with Honyo’s Online Instant Quote platform. Upload CAD files in STEP or IGES format to receive a detailed manufacturing assessment and competitive pricing within minutes—no sales calls or waiting periods. This digital workflow eliminates traditional quoting bottlenecks while maintaining our commitment to engineering rigor. Partner with Honyo Prototype for CNC turning solutions where precision, speed, and transparency converge.

Technical Capabilities

Hyundai CNC lathes, particularly those designed for high-precision manufacturing, are engineered to support advanced turning and milling operations with capabilities extending into multi-axis functionality. While Hyundai primarily produces turning centers, many of their advanced models integrate live tooling for milling and can operate in conjunction with secondary 3-axis milling platforms or function as mill-turn centers offering 3, 4, or 5-axis capabilities. These machines are ideal for tight-tolerance applications in industries such as aerospace, medical, and automotive.

The following table outlines representative technical specifications for a high-end Hyundai CNC lathe with multi-axis milling and turning functionality, focusing on precision, compatible materials, and performance metrics.

| Specification | Detail |

|---|---|

| Machine Type | CNC Mill-Turn Center (Turning with Live Tooling) |

| Axis Configuration | 3-Axis Turning (X, Z, C) + 2-Axis Milling (Y, B) = 5-Axis Capability |

| Spindle Speed (Turning) | Up to 6,000 RPM (high-speed for aluminum and plastics) |

| Spindle Speed (Milling) | Up to 12,000 RPM (via live tooling) |

| Bar Capacity | 42 mm to 75 mm (depending on model) |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Tool Magazine Capacity | 12 to 30 stations (with optional automatic tool changer) |

| Live Tooling Power | 7.5 kW to 12 kW (for milling operations) |

| Control System | Fanuc 31i or Siemens 840D (supports 5-axis interpolation) |

| Minimum Programming Increment | 0.001 mm |

| Typical Surface Finish | Ra 0.4 µm to 1.6 µm (depending on material and cut strategy) |

| Compatible Materials | Aluminum, Steel (including stainless and alloy steels), ABS, Nylon |

| Maximum Tolerance Achievable | ±0.005 mm (tight-tolerance machining with thermal compensation) |

| Coolant System | High-pressure through-spindle coolant (optional) |

| Work Envelope (X/Z) | X: ±200 mm, Z: 500 mm (varies by model) |

| Y-Axis Travel | ±100 mm (enables off-center milling) |

| B-Axis Rotation (Milling Turret) | -30° to +200° (allows angled drilling and milling) |

| Applications | Precision shafts, medical components, aerospace fittings, prototypes |

These specifications reflect the capabilities of advanced Hyundai CNC lathe models such as the Hyundai WIA HT series or Hi-TECH series with mill-turn configurations. The integration of Y and B axes enables complex 5-axis simultaneous machining, allowing for complete part fabrication in a single setup. The machines maintain tight tolerances across a range of materials, including lightweight aluminum, high-strength steels, and engineering plastics like ABS and nylon, making them suitable for both prototyping and low-volume production environments.

From CAD to Part: The Process

Honyo Prototype Hyundai CNC Lathe Manufacturing Process

Honyo Prototype executes a streamlined, technology-driven workflow for Hyundai CNC lathe projects, ensuring precision, efficiency, and compliance with automotive industry standards. Our process begins with secure CAD file ingestion and concludes with certified delivery, integrating AI and engineering expertise at critical stages.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our encrypted portal. Our system automatically validates file integrity, checks for unit consistency (mm/inch), and confirms geometric completeness. For Hyundai lathe-specific requirements, we verify compatibility with machine envelope constraints—such as maximum swing diameter (e.g., Hyundai W300’s 300mm capacity) and bar feed compatibility—before proceeding. Invalid submissions trigger immediate client feedback to prevent downstream delays.

AI-Powered Quoting Engine

Validated CAD data enters our proprietary AI quoting system, which cross-references Hyundai lathe capabilities with real-time shop floor data. The AI analyzes:

Material utilization rates against Hyundai’s chuck sizes and bar stock options

Cycle time estimates using machine-specific parameters (e.g., Hyundai W400’s 4,000 RPM spindle speed)

Secondary operation needs (e.g., live tooling for milling on Y-axis Hyundai models)

Quotes include granular cost breakdowns for machining, material, and finishing, typically generated within 2 business hours. Critical tolerances (e.g., ±0.005mm for fuel injector components) are flagged for DFM review.

Engineering-Led DFM Analysis

All quotes undergo mandatory DFM review by senior manufacturing engineers specializing in Hyundai CNC platforms. This phase focuses on:

Optimizing part orientation to leverage Hyundai’s dual-turret configurations

Identifying non-value-added operations (e.g., eliminating secondary setups via Hyundai’s sub-spindle capabilities)

Validating surface finish requirements against achievable Ra values (e.g., 0.8μm via Hyundai’s rigid tapping)

Confirming geometric dimensioning alignment with Hyundai’s positioning accuracy (±0.003mm)

Client collaboration is standard; we provide annotated CAD markups within 24 hours of quote acceptance, proposing actionable improvements like radius adjustments to prevent tool chatter on long-reach features.

Production Execution

Approved designs move to production on dedicated Hyundai CNC lathes (e.g., Hyundai W200, W500 series). Our protocol includes:

First-article inspection against AS9102 aerospace standards for automotive clients

In-process gauging at critical stages (e.g., verifying concentricity after sub-spindle transfer)

Real-time SPC monitoring of key parameters (tool wear, thermal drift) via machine-integrated sensors

All operations follow Hyundai-specific tooling protocols, such as utilizing LM/LS series live tool holders for complex milled features. Material traceability is maintained from certified mill certs through barcode tracking.

Delivery and Documentation

Completed parts undergo final CMM validation against original CAD, with reports including:

Dimensional conformance to ISO 2768-mK

Surface roughness measurements

Material certification

NIST-traceable calibration records

Parts ship in ESD-safe packaging with serialized tracking. Automotive clients receive PPAP Level 3 documentation upon request. Standard lead time from CAD upload to delivery is 7–10 business days for quantities ≤50 units, with expedited options available.

This integrated approach reduces time-to-prototype by 40% compared to industry averages while ensuring Hyundai lathe capabilities are fully leveraged for automotive-grade precision. All processes comply with IATF 16949:2016 quality management standards.

Start Your Project

Looking for precision machining with advanced Hyundai CNC lathe technology? Contact Susan Leo at [email protected] to discuss your project requirements.

Our state-of-the-art manufacturing facility in Shenzhen is equipped with high-performance Hyundai CNC lathes, ensuring tight tolerances, superior surface finishes, and fast turnaround times for prototyping and low-volume production.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.