Introduction: Navigating the Global Market for hurco parts

In the intricate landscape of global manufacturing, sourcing high-quality Hurco parts presents a significant challenge for international B2B buyers. From Africa to South America, the Middle East to Europe, companies often face hurdles related to availability, authenticity, and the right fit for their specific machinery needs. This guide aims to address these challenges by offering a comprehensive overview of Hurco parts, detailing the various types available—from motors and control boards to tool holders and accessories—and their applications in different manufacturing processes.

Understanding the nuances of purchasing Hurco parts is crucial for optimizing operational efficiency and minimizing downtime. This guide not only outlines the critical aspects of sourcing these components but also delves into effective supplier vetting processes, cost considerations, and the importance of warranties and after-sales support. By equipping B2B buyers with actionable insights, we empower them to make informed decisions, ensuring they invest in reliable parts that enhance their production capabilities.

Whether you’re operating in bustling markets like Vietnam or navigating the evolving industrial landscape in Nigeria, this guide serves as your essential resource. Embrace the opportunity to streamline your procurement process and elevate your manufacturing operations with the right Hurco parts, tailored to your unique business needs.

Understanding hurco parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Controllers | Advanced user interface, programmable features, integration with various machines | Precision machining, automation | Pros: High precision, customizable; Cons: Higher initial investment |

| Servo Motors | High torque, precision control, compatibility with Hurco systems | CNC machining, robotics | Pros: Enhanced performance; Cons: Requires specific compatibility checks |

| Tool Holders | Variety of sizes and styles, automatic tool changing options | Machining centers, milling operations | Pros: Increased efficiency; Cons: May require additional investment for automatic systems |

| Circuit Boards | Specific to Hurco models, essential for machine operation | Machinery repair and upgrades | Pros: Essential for functionality; Cons: Can be costly if not sourced correctly |

| Operator Panels | User-friendly interfaces, various configurations available | Machine operation, programming | Pros: Improved usability; Cons: Limited availability for older models |

What Are CNC Controllers and Their B2B Relevance?

CNC controllers are critical components in modern machining operations, allowing for precise control of machinery. They come equipped with advanced programming capabilities that enable businesses to automate processes and enhance productivity. For B2B buyers, investing in a high-quality CNC controller can lead to significant cost savings through reduced labor and improved operational efficiency. However, the initial investment can be substantial, and compatibility with existing machinery must be confirmed.

Why Invest in Servo Motors for Your Operations?

Servo motors are integral for applications that require high precision and torque, such as CNC machining and robotics. These motors allow for fine control over speed and position, making them ideal for complex manufacturing tasks. B2B buyers should consider the performance benefits of servo motors, as they can lead to increased productivity and better product quality. However, buyers must ensure compatibility with their specific Hurco systems to avoid costly integration issues.

How Tool Holders Enhance Machining Efficiency?

Tool holders play a crucial role in the efficiency of machining operations by securely holding cutting tools in place. They come in various sizes and styles, including options for automatic tool changers, which can significantly speed up production times. For businesses looking to enhance their machining capabilities, investing in the right tool holders is vital. While they can improve operational efficiency, buyers should be mindful of the potential additional costs associated with automatic systems.

What Should You Know About Circuit Boards?

Circuit boards are essential for the operation of Hurco machinery, serving as the backbone for electrical connectivity and control. Each board is specific to certain models, making it important for buyers to source the correct parts for repairs or upgrades. While these components are necessary for maintaining functionality, they can be expensive, and sourcing them from reliable suppliers is crucial to ensure quality and compatibility.

How Operator Panels Improve Machine Usability?

Operator panels provide a user-friendly interface for machine operation and programming. With various configurations available, they facilitate easier interaction with complex machinery, which can lead to reduced training times and increased productivity. B2B buyers should consider the usability features of operator panels when making purchasing decisions. However, the availability of panels for older Hurco models can be limited, potentially complicating replacement efforts.

Key Industrial Applications of hurco parts

| Industry/Sector | Specific Application of hurco parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace Manufacturing | Precision machining of aircraft components | Enhanced accuracy and reduced material waste | Ensure compatibility with specific Hurco machine models |

| Automotive Production | Production of intricate engine components | Improved production speed and cost-efficiency | Verify availability of critical spare parts |

| Medical Devices | Fabrication of surgical instruments and implants | High precision and compliance with safety standards | Look for certified suppliers and warranty options |

| Electronics Assembly | Assembly of electronic housing and components | Faster turnaround times and reduced downtime | Check for international shipping capabilities |

| Oil & Gas Industry | Custom machining of drilling equipment and parts | Increased reliability and operational efficiency | Consider sourcing local suppliers for quicker delivery |

How are Hurco Parts Used in Aerospace Manufacturing?

In the aerospace sector, Hurco parts play a critical role in the precision machining of aircraft components, such as turbine blades and structural elements. These parts, including CNC controllers and spindle motors, are essential for achieving the high tolerances required in aerospace applications. International buyers from regions like Africa and Europe must ensure that the parts are compatible with their existing machinery to maintain efficiency and reduce operational downtime.

What is the Role of Hurco Parts in Automotive Production?

Hurco parts are extensively utilized in automotive production for the manufacturing of intricate engine components, such as cylinder heads and crankshafts. The precision and reliability of these parts contribute to improved production speeds and cost-efficiency, which are vital in a competitive market. Buyers should focus on sourcing high-quality components that can withstand rigorous production demands, ensuring they meet the specific needs of their manufacturing processes.

How are Hurco Parts Essential for Medical Device Fabrication?

In the medical device industry, Hurco parts are crucial for the fabrication of surgical instruments and implants, where precision and adherence to safety standards are non-negotiable. The use of high-quality CNC machines equipped with Hurco parts allows manufacturers to produce consistent, high-precision products. International buyers must prioritize suppliers that provide certified parts and have a strong reputation for quality to ensure compliance with regulatory requirements.

What Benefits Do Hurco Parts Provide in Electronics Assembly?

Within electronics assembly, Hurco parts are used for the assembly of electronic housings and components, facilitating faster turnaround times and reducing downtime. The integration of advanced Hurco technologies enhances the efficiency of assembly lines, which is critical in meeting the demands of rapid product development cycles. Buyers should consider suppliers that offer robust support and fast shipping options to minimize lead times and ensure operational continuity.

Why are Hurco Parts Important for the Oil & Gas Industry?

In the oil and gas sector, Hurco parts are instrumental in the custom machining of drilling equipment and related components. The reliability and efficiency gained from high-quality Hurco parts contribute to the overall operational effectiveness of drilling operations. For buyers in this industry, sourcing from local suppliers may provide significant advantages in terms of lead times and support services, which are crucial for maintaining equipment uptime in remote locations.

3 Common User Pain Points for ‘hurco parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Genuine Hurco Parts

The Problem: B2B buyers often struggle to find authentic Hurco parts amid a sea of counterfeit or substandard products. This is particularly challenging for companies in regions like Africa and South America, where access to reliable suppliers may be limited. The risk of purchasing inferior parts not only leads to operational inefficiencies but also compromises the integrity of machinery, resulting in costly downtime and potential safety hazards.

The Solution: To ensure the procurement of genuine Hurco parts, buyers should establish relationships with reputable suppliers and distributors who specialize in Hurco machinery. Conduct thorough research on suppliers by checking their certifications, customer reviews, and history in the industry. Utilize online platforms dedicated to Hurco parts, such as CNC Shopping or CNC Bote, which often list authentic products and provide warranty information. Additionally, consider leveraging Hurco’s official website or contacting their customer service to verify part numbers and specifications before making a purchase. By taking these proactive steps, buyers can mitigate the risk of counterfeit parts and ensure their machinery operates smoothly.

Scenario 2: Prolonged Downtime Due to Part Availability Issues

The Problem: A common pain point for B2B buyers is the prolonged downtime that occurs when essential Hurco parts are out of stock. This situation can be exacerbated by global supply chain disruptions, leading to delays in production schedules and increased operational costs. For manufacturers relying heavily on Hurco machines, such interruptions can significantly impact profitability and client satisfaction.

The Solution: To combat availability issues, buyers should adopt a proactive inventory management strategy. This includes maintaining a stock of critical parts that are frequently replaced or serviced. Buyers can analyze historical usage data to identify which parts are most crucial to their operations and preemptively order them from authorized suppliers. Moreover, establishing a direct line of communication with suppliers about lead times and stock levels can provide advance notice of potential shortages. Joining industry forums or networks can also facilitate knowledge sharing about reliable sources for hard-to-find parts, enabling buyers to make informed decisions quickly.

Scenario 3: Technical Challenges in Installing and Using Hurco Parts

The Problem: Another prevalent issue for B2B buyers involves the technical challenges associated with installing and using Hurco parts. Many buyers may lack the technical expertise required to correctly integrate new components into existing machinery. This can lead to improper installations, malfunctioning equipment, and ultimately, increased maintenance costs. For companies operating in regions with limited access to technical support, this issue can be particularly daunting.

The Solution: To address installation and operational challenges, buyers should invest in training and support resources. Engaging with suppliers that offer installation services or detailed technical documentation can be invaluable. Many authorized distributors provide installation guides, video tutorials, or even on-site training sessions for their customers. Additionally, buyers can take advantage of online platforms and communities where they can ask questions and share experiences with other Hurco machine users. Building a relationship with a local technician who specializes in Hurco equipment can also provide ongoing support and troubleshooting assistance, ensuring that machinery remains operational and efficient. Investing in proper training and resources will not only enhance operational efficiency but also extend the lifespan of the equipment.

Strategic Material Selection Guide for hurco parts

What Are the Key Materials Used in Hurco Parts?

When selecting materials for Hurco parts, it is essential to consider their properties, advantages, disadvantages, and how they align with specific applications. Here, we will analyze four common materials used in Hurco parts, focusing on their performance and suitability for international B2B buyers.

How Does Aluminum Benefit Hurco Parts Manufacturing?

Aluminum is a popular choice in the manufacturing of Hurco parts due to its lightweight and high strength-to-weight ratio. It exhibits excellent corrosion resistance, making it suitable for various environments, particularly in regions with high humidity or exposure to chemicals. The material can withstand moderate temperatures, which is often sufficient for machining applications.

Pros: Aluminum is relatively inexpensive and easy to machine, allowing for complex shapes and designs. Its lightweight nature reduces shipping costs and makes it easier to handle during installation.

Cons: However, aluminum has lower tensile strength compared to steel, which may limit its use in high-stress applications. It can also be prone to deformation under heavy loads.

Impact on Application: Aluminum is compatible with various media, including water and oils, making it suitable for cooling systems in machining centers.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with relevant standards, such as ASTM B221 for aluminum extrusions, to guarantee quality.

What Role Does Steel Play in Hurco Parts?

Steel, particularly stainless steel, is another common material for Hurco parts due to its high strength and durability. It offers excellent resistance to wear and corrosion, making it ideal for components subjected to harsh operating conditions.

Pros: The durability of steel ensures a longer lifespan for parts, reducing replacement frequency and associated costs. Additionally, steel can handle higher temperatures and pressures, making it suitable for demanding applications.

Cons: On the downside, steel is heavier than aluminum, which can increase shipping costs. It is also more challenging to machine, often requiring specialized tools and techniques.

Impact on Application: Steel is compatible with a wide range of media, including aggressive chemicals, making it versatile for various industrial applications.

Considerations for International Buyers: Buyers should be aware of the different grades of steel, such as ASTM A240 for stainless steel, to ensure they select the appropriate material for their specific needs.

Why is Composite Material Important for Hurco Parts?

Composite materials, such as carbon fiber reinforced plastics, are increasingly used in Hurco parts due to their unique properties. These materials offer high strength while being significantly lighter than metals, which can enhance the performance of machining equipment.

Pros: Composites are resistant to corrosion and can be engineered for specific applications, providing flexibility in design. They also offer excellent vibration damping, which can improve machining accuracy.

Cons: The primary drawback is the higher cost of composite materials compared to metals. Additionally, they may require specialized manufacturing processes, which can complicate production.

Impact on Application: Composites are particularly suited for applications where weight reduction is critical, such as in mobile or portable machining equipment.

Considerations for International Buyers: Compliance with industry standards, such as ASTM D3039 for tensile properties of composites, is crucial for ensuring quality and performance.

How Do Plastics Fit into the Hurco Parts Landscape?

Plastics, such as polycarbonate and nylon, are often used for non-structural components in Hurco parts. They offer excellent resistance to chemicals and moisture, making them suitable for various applications.

Pros: Plastics are lightweight and cost-effective, reducing overall production costs. They are also easy to mold into complex shapes, allowing for innovative designs.

Cons: However, plastics generally have lower strength and temperature resistance compared to metals, which may limit their use in high-stress environments.

Impact on Application: Plastics are ideal for components that require insulation or protection from moisture, such as covers and housings.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards, such as ASTM D638 for tensile properties of plastics, to guarantee product reliability.

Summary Table of Material Selection for Hurco Parts

| Material | Typical Use Case for hurco parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components, housings | Lightweight and corrosion-resistant | Lower tensile strength | Low |

| Steel | High-stress components | High strength and durability | Heavier and more challenging to machine | Medium |

| Composite | Lightweight structural parts | High strength-to-weight ratio | Higher cost and complex manufacturing | High |

| Plastics | Non-structural components | Cost-effective and easy to mold | Lower strength and temperature resistance | Low |

This guide provides valuable insights into material selection for Hurco parts, helping international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hurco parts

What Are the Key Stages in the Manufacturing Process of Hurco Parts?

The manufacturing of Hurco parts involves a series of well-defined stages, ensuring precision and quality. Understanding these stages can help B2B buyers appreciate the complexities involved and make informed decisions when sourcing parts.

Material Preparation: How Is the Right Material Chosen and Prepared?

The first stage in manufacturing Hurco parts is material preparation. High-quality materials, such as steel alloys and aluminum, are selected based on the specific requirements of the part being produced. This selection process is crucial as it directly impacts the durability and performance of the final product.

Once the materials are selected, they undergo processes like cutting and surface treatment to achieve the desired dimensions and surface quality. Advanced techniques such as laser cutting or waterjet cutting may be employed to ensure precision. The goal at this stage is to prepare the raw materials for subsequent forming processes while adhering to strict specifications.

What Forming Techniques Are Commonly Used in the Production of Hurco Parts?

Forming is the next critical step in the manufacturing process. Various techniques are employed depending on the part’s complexity and specifications. Common methods include:

-

CNC Machining: This is a cornerstone technique for producing Hurco parts. CNC (Computer Numerical Control) machining allows for high precision and repeatability, essential for components that require tight tolerances.

-

Casting: For certain components, casting methods such as sand casting or die casting are utilized. These methods are ideal for creating complex shapes and are often used for parts that are challenging to machine.

-

Forging: This technique involves shaping metal using compressive forces, enhancing the part’s strength. Forged parts are often used in high-stress applications.

Each forming technique has its own set of advantages, and the choice depends on factors such as part geometry, material properties, and production volume.

How Is Assembly Conducted to Ensure Precision and Functionality?

Assembly is a pivotal stage where individual components are put together to create the final product. This step often involves:

-

Sub-Assembly: Smaller groups of parts may be assembled first, which then integrate into larger assemblies. This approach helps streamline the assembly process and minimize errors.

-

Quality Checks: During assembly, various checks are performed to ensure that components fit correctly and function as intended. This may involve visual inspections and functional tests.

-

Use of Jigs and Fixtures: To maintain accuracy during assembly, jigs and fixtures are often employed. These tools help position parts consistently and securely, reducing variability and enhancing quality.

What Finishing Techniques Are Applied to Enhance Product Quality?

The finishing stage is critical for ensuring that Hurco parts meet aesthetic and functional standards. Common finishing techniques include:

-

Surface Treatments: Processes such as anodizing, painting, or plating are applied to enhance corrosion resistance and improve appearance.

-

Polishing and Deburring: These processes remove any sharp edges or surface imperfections, ensuring that the parts are safe to handle and operate smoothly.

-

Final Inspection: A thorough inspection is conducted to verify that the finished parts meet all specifications and quality standards before packaging and shipping.

What Quality Assurance Standards Are Relevant for Hurco Parts Manufacturing?

Quality assurance is integral to the manufacturing process, ensuring that every part meets rigorous standards. International and industry-specific standards play a vital role in this aspect.

Which International Standards Are Commonly Implemented?

ISO 9001 is one of the most recognized international quality management standards, focusing on continuous improvement and customer satisfaction. Manufacturers of Hurco parts often adopt ISO 9001 to enhance their processes and meet customer expectations.

In addition to ISO standards, other certifications such as CE marking for products sold in the European Economic Area and API standards for oil and gas components may be relevant. These certifications indicate compliance with safety and performance standards, which can be crucial for B2B buyers in various industries.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves systematic checks at different manufacturing stages to ensure that products meet established standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor the quality of work and identify any deviations from specifications early on.

-

Final Quality Control (FQC): Before products are shipped, a final inspection ensures that they meet all required specifications and quality standards. This step may involve functional testing, dimensional checks, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some methods to ensure quality:

What Steps Should Buyers Take to Conduct Supplier Audits?

-

Request Documentation: Buyers should ask suppliers for quality assurance documentation, including certificates, quality manuals, and standard operating procedures.

-

On-Site Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, review processes, and verify compliance with quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These services can conduct inspections at various stages of the manufacturing process, offering peace of mind to buyers.

What Are the Challenges and Considerations for International B2B Buyers?

International buyers must be aware of the nuances in quality control certifications and standards across different regions. For instance, a supplier may have ISO certification but may not comply with specific regional standards that are critical for certain applications.

Moreover, language barriers and cultural differences can pose challenges in communication. Buyers should consider working with local representatives or consultants who understand the regional nuances and can facilitate effective communication with suppliers.

Conclusion

Understanding the manufacturing processes and quality assurance practices for Hurco parts equips B2B buyers with the knowledge needed to make informed sourcing decisions. By recognizing the importance of material preparation, forming techniques, assembly, and finishing, along with the critical role of quality assurance standards and verification methods, buyers can establish strong partnerships with suppliers that ensure the delivery of high-quality components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hurco parts’

Introduction

This sourcing guide aims to equip international B2B buyers with a practical checklist for procuring Hurco parts effectively. Whether you’re based in Africa, South America, the Middle East, or Europe, following these steps will help ensure a smooth and successful procurement process.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical specifications required for your Hurco parts. This includes part numbers, compatibility with existing machinery, and performance requirements. A well-defined specification helps streamline the sourcing process and minimizes the risk of purchasing incorrect or incompatible components.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify reputable suppliers of Hurco parts. Utilize online platforms, industry forums, and trade associations to gather information. Look for suppliers with a proven track record, positive customer reviews, and experience in your region.

- Tip: Check if the supplier specializes in Hurco products to ensure they have the necessary expertise.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Don’t just rely on their website; reach out to previous clients to gain insights into their reliability and service quality.

- Tip: Ask suppliers about their experience in your specific region, as local market conditions can affect logistics and support.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you are considering comply with international standards and certifications relevant to your industry. This might include ISO certifications or specific compliance with safety and quality standards.

- Why it matters: Compliance not only ensures product quality but also minimizes risks associated with legal and operational challenges.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, lead times, shipping options, and payment terms. A comprehensive quote allows for better comparison and aids in negotiating favorable terms.

- Tip: Be clear about your delivery timelines and any urgency in your request to ensure the suppliers provide realistic timelines.

Step 6: Assess After-Sales Support and Warranty Options

Evaluate the after-sales support and warranty options offered by the suppliers. Good after-sales service can significantly reduce downtime in case of issues with the parts.

- What to consider: Inquire about return policies, technical support availability, and warranty duration to ensure you are covered in case of defects or compatibility issues.

Step 7: Finalize Order and Establish Communication Channels

Once you have selected a supplier, finalize your order and establish clear communication channels. Confirm all details regarding delivery, tracking, and support. Open lines of communication will facilitate any necessary adjustments during the order process.

- Why this is critical: Effective communication helps prevent misunderstandings and ensures that both parties are aligned on expectations and timelines.

By following this checklist, B2B buyers can enhance their sourcing efficiency for Hurco parts, ensuring they acquire the right components for their machinery while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for hurco parts Sourcing

What Are the Key Cost Components in Hurco Parts Sourcing?

When sourcing Hurco parts, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials can fluctuate based on market conditions. For Hurco parts, components such as motors and control boards often utilize specialized materials that may be subject to supply chain volatility.

-

Labor: Labor costs vary by region, with countries in Africa, South America, and the Middle East often experiencing lower labor costs compared to Europe. However, the skill level required for assembly and quality checks can influence these costs significantly.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, thus affecting overall pricing.

-

Tooling: Investment in tooling for specific Hurco parts can represent a significant upfront cost. Custom tooling for specialized components can increase initial expenses but may result in cost savings over time through enhanced efficiency.

-

Quality Control: Ensuring parts meet stringent quality standards incurs costs related to testing and certification. This is particularly important for international buyers who require compliance with various standards.

-

Logistics: Shipping costs can vary widely based on the chosen Incoterms, shipping method, and distance. Buyers should consider whether they will be responsible for shipping costs or if these are included in the supplier’s pricing.

-

Margin: Suppliers will typically add a margin to cover their operating costs and profit. Understanding the standard margins in the industry can aid buyers in evaluating supplier pricing.

How Do Price Influencers Impact Hurco Parts Pricing?

Several factors can influence the pricing of Hurco parts, including:

-

Volume/MOQ: Larger orders often qualify for bulk pricing, which can lead to significant savings. Buyers should negotiate minimum order quantities (MOQ) to align with their purchasing capabilities.

-

Specifications and Customization: Custom parts may incur additional costs for design and manufacturing. Buyers should weigh the benefits of tailored solutions against the potential increase in price.

-

Materials and Quality Certifications: Higher-quality materials and certifications can drive up costs. However, investing in quality can reduce maintenance and replacement costs over time, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Local suppliers may offer lower shipping costs and faster delivery times, which can be advantageous.

-

Incoterms: The choice of Incoterms determines who is responsible for shipping costs and risks. Understanding these terms can help buyers manage costs effectively.

What Buyer Tips Can Help Achieve Cost-Efficiency?

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Highlighting your potential as a long-term customer may incentivize suppliers to offer discounts.

-

Cost-Efficiency Strategies: Consider the Total Cost of Ownership rather than just the upfront price. Evaluate long-term operational costs, including maintenance and downtime associated with lower-quality parts.

-

Understand Pricing Nuances for International Purchases: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations and potential tariffs that could affect final costs. Establishing relationships with suppliers who understand regional market dynamics can lead to better pricing.

-

Research and Compare Suppliers: Take time to compare various suppliers not only on price but also on service, quality, and reliability. Utilizing platforms that aggregate supplier information can simplify this process.

-

Request Quotes Regularly: Prices can change due to market conditions. Regularly requesting quotes ensures that you are aware of any price fluctuations and can make informed purchasing decisions.

Disclaimer on Indicative Prices

Please note that the prices for Hurco parts can vary widely based on the factors mentioned above. It is advisable for buyers to conduct thorough research and request specific quotes from suppliers to obtain accurate pricing information tailored to their needs.

Alternatives Analysis: Comparing hurco parts With Other Solutions

Understanding Alternatives in the Context of Hurco Parts

When sourcing components for CNC machines, particularly Hurco parts, buyers often explore various alternatives to ensure they select the most effective solution for their specific operational needs. This analysis focuses on comparing Hurco parts with two viable alternatives: Fanuc Parts and Mitsubishi Parts. Each option presents unique advantages and challenges that can significantly impact a buyer’s decision-making process.

Comparison Table

| Comparison Aspect | Hurco Parts | Fanuc Parts | Mitsubishi Parts |

|---|---|---|---|

| Performance | High precision and reliability | Industry-leading performance | Robust performance with versatility |

| Cost | Moderate, with options for used parts | Generally higher due to brand reputation | Competitive pricing, especially for used options |

| Ease of Implementation | Requires specific knowledge of Hurco systems | Widely supported, with extensive documentation | User-friendly, with solid support |

| Maintenance | Moderate maintenance needs | Low maintenance due to durability | Moderate, with good availability of parts |

| Best Use Case | Ideal for Hurco CNC machines | Best for high-volume production | Versatile applications across various industries |

In-Depth Analysis of Alternatives

1. Fanuc Parts

Fanuc is known for its innovative technology in CNC systems and robotics. The performance of Fanuc parts is regarded as top-tier within the industry, often leading the market in precision and speed. While the initial cost may be higher, the durability and low maintenance requirements can lead to long-term savings. However, the complexity of Fanuc systems may require specialized training for operators, which could delay implementation.

Pros:

– Exceptional performance and reliability.

– Lower maintenance frequency.

– Extensive global support network.

Cons:

– Higher initial investment.

– Complexity may require additional training for staff.

2. Mitsubishi Parts

Mitsubishi offers a solid alternative with competitive pricing, particularly in the used parts market. Known for their robust performance, Mitsubishi parts are versatile and can be utilized across various applications, making them suitable for businesses looking to diversify their machinery. The ease of implementation is another strong point, as many technicians find Mitsubishi products user-friendly. However, while generally reliable, the performance may not match that of Hurco or Fanuc in specialized tasks.

Pros:

– Competitive pricing, especially for second-hand parts.

– Versatile applications across different industries.

– Generally easy to implement.

Cons:

– Performance may not meet the highest standards of precision.

– Maintenance might be moderate, depending on the application.

Making the Right Choice: How to Select the Best Solution for Your Business

When selecting the right parts for CNC machines, buyers should evaluate their specific operational needs, budget constraints, and the technical expertise of their workforce. Hurco parts are ideal for those already invested in the Hurco ecosystem, while Fanuc parts may suit businesses focused on high-precision, high-volume production. Mitsubishi parts can be an excellent choice for companies seeking flexibility at a competitive price point. Ultimately, the decision should align with both immediate operational goals and long-term strategic planning, ensuring a solution that enhances productivity and efficiency.

Essential Technical Properties and Trade Terminology for hurco parts

What Are the Essential Technical Properties of Hurco Parts?

When considering the purchase of Hurco parts, several technical specifications are critical for ensuring compatibility and performance. Here are some of the key properties to understand:

-

Material Grade

The material grade of Hurco parts, such as steel, aluminum, or specialized alloys, determines their strength, durability, and suitability for specific applications. Understanding the material grade is essential for B2B buyers as it impacts the part’s lifespan and resistance to wear and tear, ultimately affecting maintenance costs. -

Tolerance Levels

Tolerance levels refer to the permissible limits of variation in a part’s dimensions. For Hurco parts, maintaining tight tolerances is crucial for precision machining. Buyers must consider tolerance specifications to ensure that the parts will fit correctly and function as intended, thereby reducing the risk of operational failures. -

Power Specifications

Many Hurco parts, especially motors and drives, have specific power requirements, including voltage and current ratings. These specifications are vital for ensuring that the components will operate correctly within the existing machinery. Incorrect power specifications can lead to inefficiencies or even damage to the equipment. -

Compatibility Standards

Compatibility with existing systems is a significant concern for B2B buyers. Hurco parts often need to adhere to specific standards to ensure they can be integrated seamlessly with current machinery. Understanding these standards helps avoid costly misalignments and operational downtime. -

Load Capacity

Load capacity indicates the maximum weight or force that a part can handle without failure. For parts like tool holders and spindle motors, understanding load capacities is critical to ensure safe and efficient operation under expected working conditions. -

Warranty and Support

Warranty terms and post-purchase support are also essential technical properties. B2B buyers should look for warranties that cover defects and offer comprehensive support options. This can provide peace of mind and protect against unexpected costs associated with part failures.

What Are Common Trade Terms Associated with Hurco Parts?

Understanding the terminology used in the trade of Hurco parts can significantly enhance communication and negotiation processes. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts that are used in another company’s end product. In the context of Hurco parts, knowing whether a part is OEM or aftermarket can influence decisions regarding quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. B2B buyers should be aware of MOQs when planning purchases, as this can affect inventory management and cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for a specific quantity of goods. For buyers of Hurco parts, submitting an RFQ can help gather competitive pricing and terms from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Understanding Incoterms is crucial for B2B transactions as they clarify shipping costs, risk, and insurance responsibilities. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For Hurco parts, knowing the lead time helps businesses plan their production schedules and inventory levels effectively. -

Aftermarket Parts

These are parts that are not made by the original manufacturer but are designed to fit and function similarly. B2B buyers should consider the potential cost savings of aftermarket parts against the risks of quality and compatibility issues.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing Hurco parts, ultimately leading to better operational efficiency and cost management.

Navigating Market Dynamics and Sourcing Trends in the hurco parts Sector

What Are the Current Market Dynamics and Key Trends in the Hurco Parts Sector?

The global market for Hurco parts is driven by several key factors, including the increasing demand for precision machining and the ongoing industrial automation revolution. As manufacturing processes become more sophisticated, the need for high-quality spare parts, such as servo motors and CNC boards, has surged. This trend is particularly pronounced in emerging markets across Africa, South America, the Middle East, and parts of Europe, where manufacturing capabilities are expanding rapidly.

International B2B buyers are increasingly leveraging digital platforms to source Hurco parts, utilizing online marketplaces that offer real-time inventory checks and price comparisons. The integration of technologies like AI and machine learning in supply chain management is also becoming prevalent, allowing buyers to forecast demand accurately and optimize their inventory levels. Additionally, as manufacturers seek to reduce downtime, there is a growing emphasis on just-in-time sourcing strategies, which prioritize the timely delivery of parts to enhance operational efficiency.

Another significant trend is the shift towards multi-supplier strategies. Buyers are diversifying their supplier base to mitigate risks associated with supply chain disruptions, which have become a pressing concern post-pandemic. This approach not only enhances supply chain resilience but also fosters competitive pricing, enabling buyers to secure the best deals for Hurco parts.

How Is Sustainability and Ethical Sourcing Influencing the Hurco Parts Market?

Sustainability has emerged as a crucial consideration in the sourcing of Hurco parts. With increasing awareness of environmental impacts, B2B buyers are prioritizing suppliers that adhere to sustainable practices. This includes the use of eco-friendly materials and manufacturing processes that minimize waste and energy consumption.

The importance of ethical supply chains cannot be overstated, particularly in regions where labor standards may vary. Buyers are now more vigilant about the sourcing practices of their suppliers, seeking certifications that demonstrate compliance with international labor laws and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming critical in supplier selection processes.

Furthermore, many buyers are looking for ‘green’ materials that can reduce the carbon footprint of their operations. The development of recyclable components and energy-efficient manufacturing techniques is not only appealing from a regulatory standpoint but also enhances brand reputation. This focus on sustainability and ethical sourcing is reshaping the landscape of the Hurco parts market, encouraging a shift towards more responsible business practices.

What Is the Historical Context of Hurco Parts in the B2B Landscape?

The Hurco brand has a rich history in the CNC machining industry, dating back to its founding in 1968. Initially focused on developing innovative control technology, Hurco quickly established itself as a leader in the market for CNC machines. Over the decades, the company expanded its product line to include a wide range of spare parts and accessories essential for maintaining and optimizing machining operations.

As the demand for precision engineering grew, so did the need for high-quality replacement parts. The evolution of Hurco parts reflects broader trends in manufacturing technology and the increasing complexity of machining processes. Today, the Hurco parts sector is characterized by a commitment to quality and innovation, with a focus on meeting the diverse needs of international B2B buyers across various industries. This historical context underscores the importance of sourcing reliable parts to ensure operational efficiency and product quality in an increasingly competitive global market.

Frequently Asked Questions (FAQs) for B2B Buyers of hurco parts

-

How do I solve issues with my Hurco machine parts?

To address issues with your Hurco machine parts, first, identify the specific problem you’re encountering, such as malfunctioning components or compatibility issues. Consult the machine’s user manual for troubleshooting steps or common error codes. If the problem persists, reach out to your supplier for technical support or to request replacement parts. It’s also beneficial to maintain regular maintenance schedules to prevent future issues. Engaging with experienced technicians who specialize in Hurco machinery can provide additional insights and solutions. -

What is the best way to source Hurco parts internationally?

Sourcing Hurco parts internationally involves identifying reputable suppliers who specialize in CNC machinery components. Start by researching suppliers with a strong track record in your region, focusing on their inventory, warranty options, and customer reviews. Utilize platforms that allow for comparison of prices and availability, and consider suppliers that offer multilingual support for ease of communication. Ensure that they comply with international shipping regulations and can handle customs processes efficiently to avoid delays. -

What are the minimum order quantities (MOQ) for Hurco parts?

Minimum order quantities for Hurco parts can vary significantly depending on the supplier and the specific parts being ordered. Some suppliers may allow single-item purchases, while others might set an MOQ to optimize their shipping and handling processes. It’s advisable to check directly with the supplier about their policies regarding MOQ. If you’re working on a large project, consider negotiating terms that suit your purchasing needs, especially for bulk orders. -

What payment terms should I expect when buying Hurco parts?

When purchasing Hurco parts, payment terms can differ among suppliers. Common options include upfront payment, partial payments, or payment upon delivery. International transactions may require wire transfers or letters of credit to ensure secure payment. Always clarify payment terms before finalizing orders and look for suppliers who offer flexibility, such as payment plans or financing options, especially for larger orders. -

How can I vet suppliers for Hurco parts?

To vet suppliers for Hurco parts, conduct thorough research by checking their industry reputation, customer reviews, and years of operation. Request references from past clients and verify their experience with international shipping. Additionally, ensure they provide warranties and return policies for their parts. Engaging with suppliers at trade shows or industry events can also provide insight into their reliability and product quality. -

What quality assurance measures should I look for in Hurco parts?

When sourcing Hurco parts, look for suppliers who adhere to strict quality assurance measures. This may include certifications such as ISO 9001, which indicates a commitment to quality management. Ask about their inspection processes, warranty terms, and the origin of their parts. Reliable suppliers will often provide testing results or certifications for critical components, ensuring that you receive high-quality, reliable parts. -

What logistics considerations are important for shipping Hurco parts internationally?

Logistics considerations for shipping Hurco parts internationally include selecting a reliable freight forwarder who can handle customs clearance and import/export regulations. Assess shipping costs, delivery times, and the supplier’s ability to provide tracking information. Additionally, consider the packaging of parts to prevent damage during transit. It’s also beneficial to familiarize yourself with local regulations in your country regarding the import of machinery parts. -

Can I customize Hurco parts for my specific machinery needs?

Customization of Hurco parts is often possible, depending on the supplier’s capabilities. If you require specific modifications, communicate your needs clearly to the supplier to determine their ability to accommodate custom orders. Some suppliers may offer bespoke manufacturing services or allow for adjustments to existing parts. Be prepared to discuss timelines and any additional costs associated with customization to ensure the solution meets your operational requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Hurco Parts Manufacturers & Suppliers List

1. Hurco – CNC Machine Support Services

Domain: hurco.com

Registered: 1994 (31 years)

Introduction: Hurco offers comprehensive service and support for their CNC machines, emphasizing the importance of post-sale service. Key offerings include: 1. **Support Line**: 800-638-1849 for direct assistance. 2. **Support Ticket Submission**: Customers can submit tickets for support and parts requests. 3. **Machine Manuals**: Access to getting started, operation, and service manuals. 4. **Training Options*…

2. Hurco – Customer Support

Domain: forms.hurco.com

Registered: 1994 (31 years)

Introduction: This company, Hurco – Customer Support, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

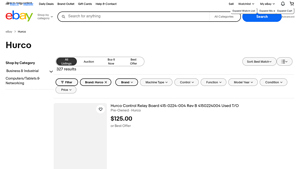

3. Hurco – CNC Milling Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Hurco products for sale on eBay include various CNC and machining equipment such as Hurco milling machines, CNC controllers, and other industrial machinery. Key product types mentioned include:

– Hurco CIMR-MT Transistor Inverter (Pre-Owned) priced at $1,299.00 with $67.31 shipping.

– Hurco CNC PC board 208-flexible disc controller (Pre-Owned) priced at $300.00 with $24.25 shipping.

– Hurco 415…

4. HURCO – Key Product Details

Domain: sepmo.fr

Registered: 2012 (13 years)

Introduction: Key product details for HURCO from SEPMO include: 1. Motors: YASKAWA ELECTRIC UAASKD-15LHB21 SPINDLE MOTOR (Out-of-Stock), previously mounted on HURCO VMX 40 machining center. 2. Tool holders: Tool magazine with 24 positions for HURCO machining center (Out-of-Stock), previously mounted on HURCO VMX 40. 3. Cards: HURCO 415-0628-901 board for flat panel (Out-of-Stock), needs to be mounted in the bac…

5. HURCO – DELTRON 11102XB Power Supply

Domain: cnc-shopping.us

Registered: 2016 (9 years)

Introduction: HURCO Spare parts (Ultimax, Machine-Tools parts) available for purchase. Key products include: 1. HURCO 4130008011 DELTRON 11102XB Power supply – Out of stock, Refurbished, Starting at $610.50. 2. HURCO 415-0228-004 Power Supply board – Out of stock, Confirmation of shipping time on request, Refurbished, Starting at $721.50. 3. HURCO AUTOCON 415-0604-902 Console Interface Node – Out of stock, Conf…

6. PC Controls – Used CNC Electronics

Domain: pccontrols.net

Registered: 1999 (26 years)

Introduction: This company, PC Controls – Used CNC Electronics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Hurco – Ultimax 4 Control Units & Accessories

Domain: cncbote.de

Introduction: [{‘name’: ‘Hurco Ultimax 4 Manual Control Unit’, ‘condition’: ‘Used’, ‘price’: ‘1.548,90 €’, ‘availability’: ‘Item is in stock’}, {‘name’: ‘Hurco Ultimax 4 TFT-Monitor’, ‘condition’: ‘Used’, ‘price’: ‘1.128,60 €’, ‘availability’: ‘Item is in stock’}, {‘name’: ‘Hurco Ultimax 4 Floppy Disk Drive’, ‘condition’: ‘Used’, ‘price’: ‘208,90 €’, ‘availability’: ‘Item is in stock’}, {‘name’: ‘Hurco Ultimax …

8. HURCO – VM1 Utility Box Plate

Domain: gaec.com

Registered: 1998 (27 years)

Introduction: {“Type”:”Metalworking Equipment Replacement Parts”,”Manufacturer”:”HURCO”,”Model”:”803-0100-010″,”Stock Number”:”Q11759″,”Status”:”For Sale”,”Description”:”HURCO VM1 UTILITY BOX PLATE, Part Number 803-0100-010, New!”,”Specifications”:{“Mfr Part Number”:”803-0100-010″,”Approximate Dimensions”:”15″ x 13″”,”Approximate Height”:”10″”,”Approximate Weight”:”18 LBS”},”Condition”:”New”,”Location”:”Cincinn…

Strategic Sourcing Conclusion and Outlook for hurco parts

In navigating the complex landscape of sourcing Hurco parts, international B2B buyers can leverage strategic sourcing to optimize their procurement processes. Understanding the availability and specifications of critical components—from motors to control boards—can significantly impact operational efficiency and machine uptime. By establishing strong relationships with reliable suppliers across Africa, South America, the Middle East, and Europe, businesses can ensure timely access to genuine Hurco parts, ultimately enhancing productivity and reducing downtime.

Moreover, as the global market continues to evolve, it is crucial for buyers to stay informed about emerging trends and technologies within the CNC machining sector. This proactive approach not only fosters resilience against supply chain disruptions but also positions companies to capitalize on new opportunities as they arise.

As you consider your sourcing strategies, remember that investing in quality parts and dependable suppliers is an investment in your business’s future. Engage with reputable vendors, explore diverse marketplaces, and prioritize transparency in transactions to ensure you are well-equipped for the challenges ahead. The path to operational excellence begins with strategic sourcing—take the first step today.