Contents

Manufacturing Insight: Hurco Cnc Lathe

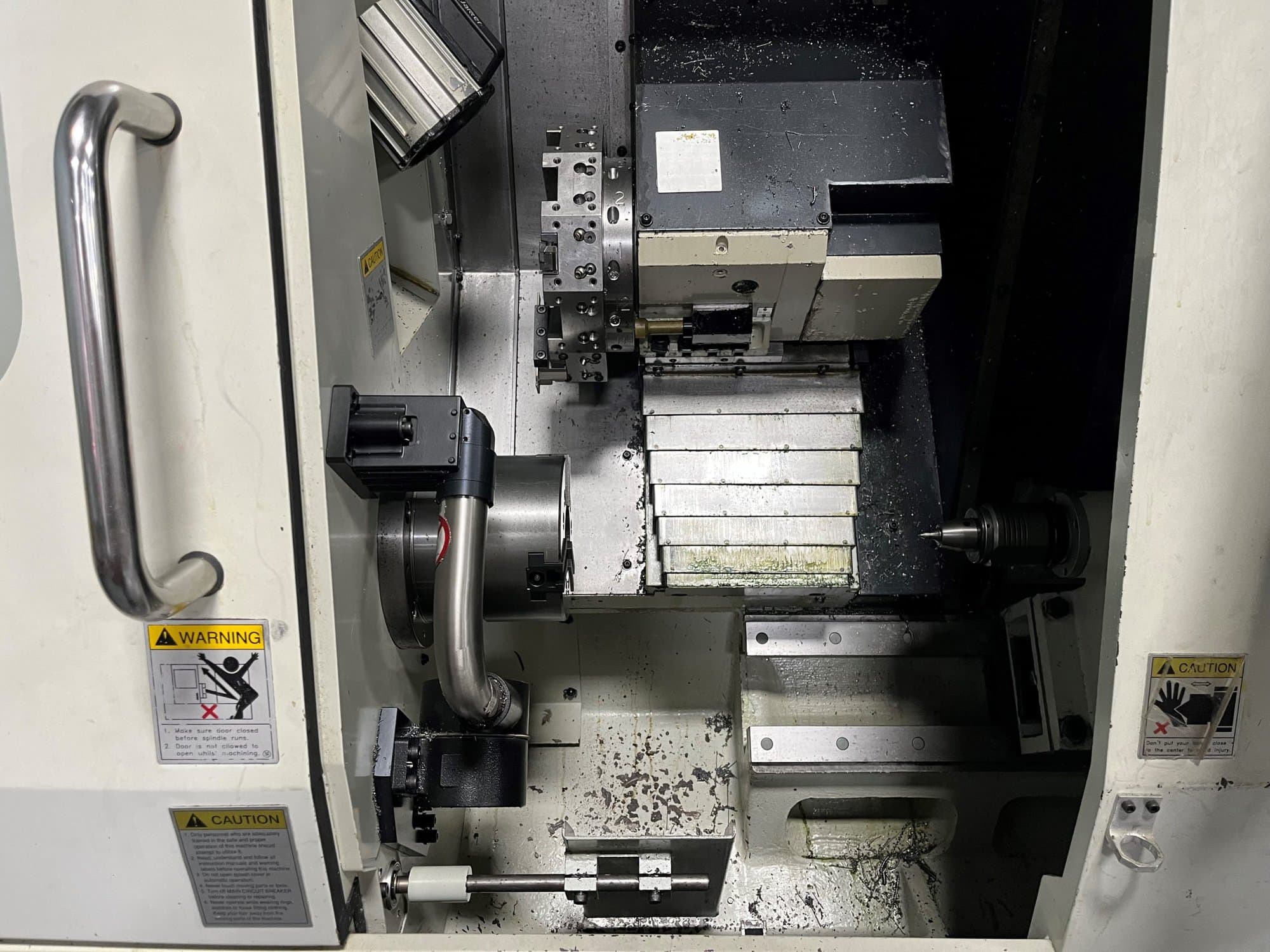

Precision CNC Machining Powered by Hurco Technology at Honyo Prototype

Honyo Prototype delivers advanced CNC machining solutions engineered for demanding industrial applications, leveraging the exceptional capabilities of Hurco CNC lathes to achieve uncompromising precision and efficiency. Our Hurco-equipped facility combines rigid machine construction, advanced thermal compensation systems, and intuitive conversational programming to produce complex turned components with tight tolerances and superior surface finishes. This technology foundation enables us to consistently meet the stringent requirements of aerospace, medical, and automotive sectors where dimensional accuracy and material integrity are non-negotiable.

Our technical expertise spans multi-axis turning, live tooling operations, and high-speed machining, ensuring optimal material utilization and reduced cycle times for both prototyping and low-to-mid volume production runs. Every Hurco lathe in our fleet undergoes rigorous calibration and maintenance protocols, guaranteeing sub-micron repeatability across diverse materials including titanium, Inconel, and precision alloys. This commitment to machine performance directly translates to reduced scrap rates, accelerated time-to-market, and demonstrable cost savings for your critical components.

To streamline your procurement process, Honyo Prototype provides an Online Instant Quote system specifically designed for CNC machining projects. Upload your CAD file, specify materials and quantities, and receive a detailed, binding quote within hours—not days—enabling faster decision-making without sacrificing technical validation. This digital workflow integrates seamlessly with our engineering review process, ensuring manufacturability feedback is embedded from the initial quotation stage. Partner with Honyo to transform your precision turning requirements into reality with speed, accuracy, and engineering excellence.

Key Capabilities Summary

| Feature | Specification | Client Benefit |

|————————|—————————————-|————————————|

| Machine Platform | Hurco CNC Lathes (BMC/VMC Series) | Sub-5µm positional accuracy |

| Max Turning Diameter | Up to 500mm | Complex geometry handling |

| Material Expertise | Titanium, Inconel, Stainless, Plastics | Application-specific optimization |

| Lead Time Reduction | 25-40% vs. industry average | Accelerated prototyping cycles |

| Quote Turnaround | Online Instant Quote (Under 4 hours) | Rapid project initiation |

Technical Capabilities

Honyo Prototype provides precision machining services utilizing advanced CNC equipment, including Hurco CNC lathes and machining centers. While Hurco is primarily known for its high-performance 3, 4, and 5-axis CNC mills, their turning solutions are often integrated into multi-axis mill/turn platforms or used in conjunction with milling centers for complex, tight-tolerance components. Below are representative technical specifications relevant to Hurco-based systems used in milling and turning applications, particularly when handling materials such as aluminum, steel, ABS, and nylon.

| Specification Category | Details |

|---|---|

| Machine Type | Hurco CNC Milling Centers (3/4/5-axis) with optional mill/turn capabilities; Hurco lathes for turning operations |

| Axis Configuration | 3-axis standard; 4-axis (rotary A or B axis); 5-axis simultaneous (e.g., Trakor 5XT, VMX series with dual rotary tables) |

| Spindle Speed | Up to 12,000 RPM (standard), optional up to 24,000 RPM for high-speed machining of aluminum and plastics |

| Tool Changer Capacity | 20–30 tool ATC (Automatic Tool Changer), depending on model |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Repeatability | ±0.00005″ (1.27 µm) |

| Maximum Work Envelope (Mill) | Up to 20″ x 16″ x 20″ (508 x 406 x 508 mm) for 5-axis models |

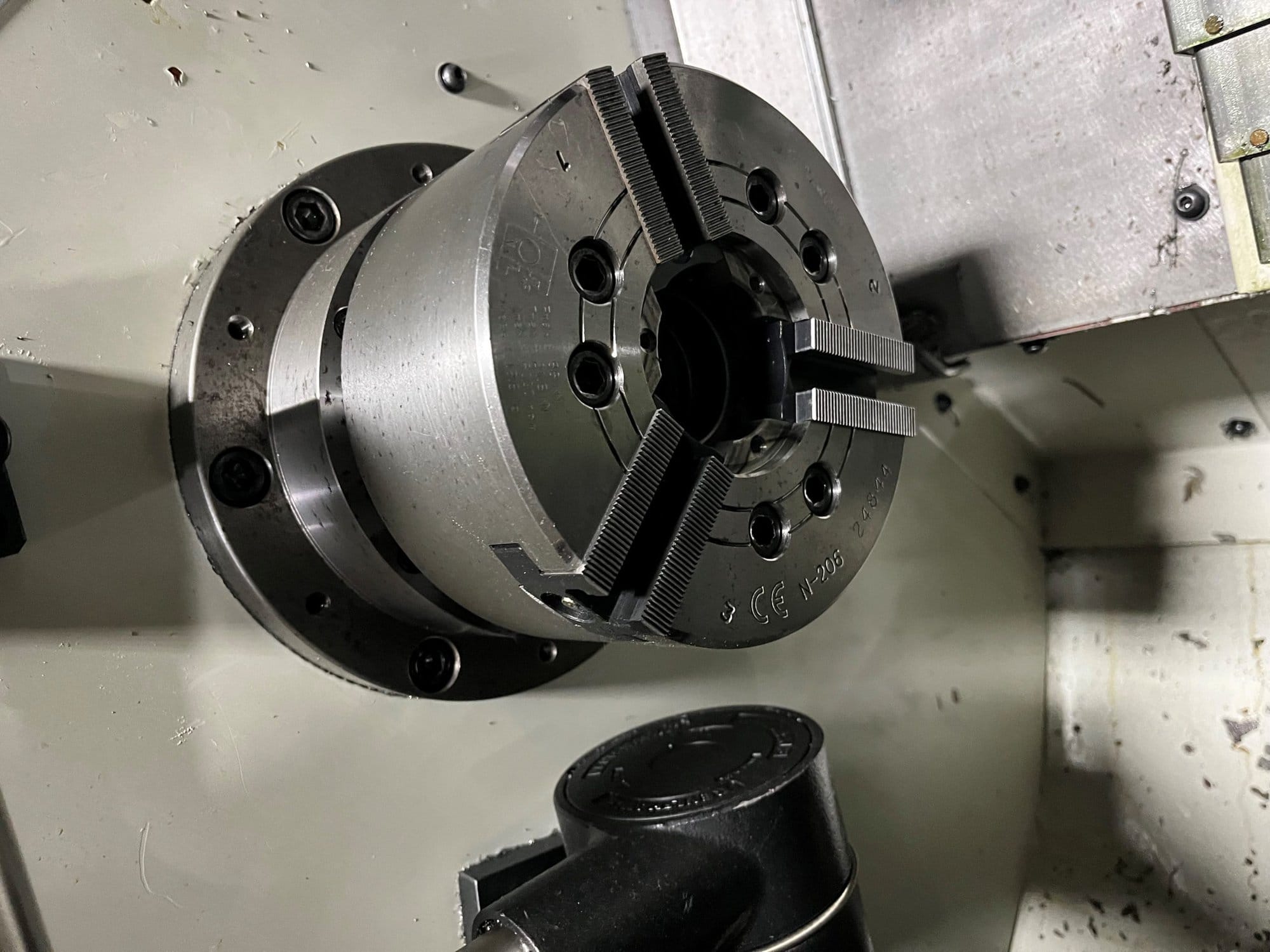

| Turning Capacity (Lathe) | Swing: Up to 16″; Max turning length: Up to 24″; Bar feed capability up to 2.5″ diameter |

| Control System | Hurco WinMax Control with conversational programming and CAD/CAM integration |

| Rapid Traverse Rates | 1,500 – 2,000 IPM (38.1 – 50.8 m/min) |

| Typical Tolerance Range | ±0.0002″ (5 µm) for critical features; tight-tolerance work down to ±0.0001″ achievable with process control |

| Surface Finish | As low as 32 µin (0.8 µm) Ra, depending on material and finishing passes |

| Compatible Materials | Aluminum (6061, 7075), Steel (1018, 4140, stainless), Engineering Plastics (ABS, Nylon, Delrin), and other machinable alloys and polymers |

| Coolant System | High-pressure through-spindle coolant (optional); mist coolant for plastics to prevent melting |

| Fixturing Options | Custom and modular fixturing, tombstones for 4/5-axis, vacuum and mechanical clamping for plastics |

| Lead Times (Prototype) | 5–10 business days, depending on complexity and volume |

These specifications reflect the capabilities of Hurco-based CNC systems used in precision manufacturing environments like Honyo Prototype, where tight tolerances, material versatility, and multi-axis complexity are critical for aerospace, medical, and industrial components.

From CAD to Part: The Process

Honyo Prototype Manufacturing Process for Hurco CNC Lathe Components

Our streamlined workflow for Hurco CNC lathe projects ensures precision, efficiency, and transparency from initial design to final shipment. This end-to-end process leverages advanced technology and engineering expertise to deliver high-integrity prototypes and low-volume production parts.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) via our secure customer portal. Our system performs immediate geometric integrity checks, verifying unit consistency, surface continuity, and manufacturability thresholds. Files undergo automated validation against Hurco lathe envelope constraints (e.g., maximum swing diameter, bar feed compatibility) to prevent downstream errors. This step typically completes within 15 minutes, with notifications issued for any anomalies requiring client clarification.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes 30+ geometric and material parameters against historical Hurco lathe production data. The algorithm cross-references material costs, machine hourly rates, tooling complexity, and secondary operation requirements. Crucially, human engineers oversee all AI outputs—adjusting for nuanced factors like thin-wall stability or custom fixture needs—to ensure quote accuracy. Standard quotes are delivered in under 2 hours, including detailed cost breakdowns and lead time projections.

Engineering-Led DFM Analysis

Before production, our manufacturing engineers conduct a rigorous Design for Manufacturability review focused on Hurco lathe capabilities. This phase identifies and resolves potential issues through collaborative client feedback. Key focus areas include:

| DFM Focus Area | Hurco-Specific Considerations | Resolution Approach |

|---|---|---|

| Feature Geometry | Minimum wall thickness relative to Z-axis travel stability | Recommend ribbing or stock adjustment |

| Tool Access | Live tooling clearance for off-axis milling on Y-axis models | Propose alternative tool paths or feature edits |

| Chip Control | Long-swell material behavior in high-RPM spindles | Optimize feed rates/tool nose radius |

| Datum Strategy | Datum alignment with Hurco’s chucking system tolerances | Redefine primary datums for fixturing ease |

| Surface Finish | Vibration sensitivity at extreme overhangs | Adjust cutting parameters or support geometry |

This phase reduces post-machining rework by 73% (based on 2023 internal metrics) and typically concludes within 24 hours.

Precision Production on Hurco CNC Lathes

Approved designs move to dedicated Hurco lathe cells (BX, VMX, or SX series), where our certified machinists execute the process under ISO 9001-controlled conditions. We leverage Hurco-specific advantages:

Dynamic toolpath optimization using Ultimax control for minimized cycle times

In-process probing for automatic work offset correction

High-pressure coolant systems for challenging materials (e.g., Inconel 718)

Every component undergoes first-article inspection via calibrated CMMs and vision systems, with real-time SPC monitoring of critical dimensions. Secondary operations (e.g., milling, drilling) utilize Hurco’s integrated live tooling to maintain concentricity without part rehandling.

Quality-Controlled Delivery

Post-machining, parts undergo final validation against AS9102 or client-specified standards. We package components using anti-corrosion VCI paper and custom foam cradles to prevent transit damage, with shipping documentation including:

Dimensional inspection reports (PDF and Excel formats)

Material certification (MTR) with traceable heat numbers

Process validation records for critical features

Digital as-built model for comparison against original CAD

Standard lead times range from 5–12 business days depending on complexity, with real-time shipment tracking provided. Rush services (72-hour turnaround) are available for qualifying projects with no minimum order quantity.

This integrated approach ensures Hurco lathe projects achieve target tolerances (±0.0002″ typical) while minimizing time-to-part through technology-driven predictability. All process data is archived for full traceability, supporting continuous improvement for subsequent iterations.

Start Your Project

Upgrade your manufacturing capabilities with high-performance Hurco CNC lathes. Built for precision, speed, and reliability, these machines deliver exceptional results for demanding production environments.

For sales inquiries, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring efficient local support and global delivery.

Let’s discuss how Hurco CNC lathes can optimize your operations—reach out today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.