Guide Contents

Project Insight: Hurco Cnc Lathe

Manufacturing Insight: Hurco CNC Lathe

Why Speed & Precision Matter in Product Development

Time-to-market pressure: Hardware startups face relentless competition—iterating designs in days, not months, is non-negotiable.

Functional accuracy: A ±0.01mm tolerance isn’t just a spec—it’s the difference between a part that works and one that fails in critical applications (e.g., medical implants or aerospace components).

Cost of delays: A single missed deadline can cost startups 20–30% in lost revenue opportunities. Precision machining accelerates validation cycles, turning prototypes into production-ready parts faster.

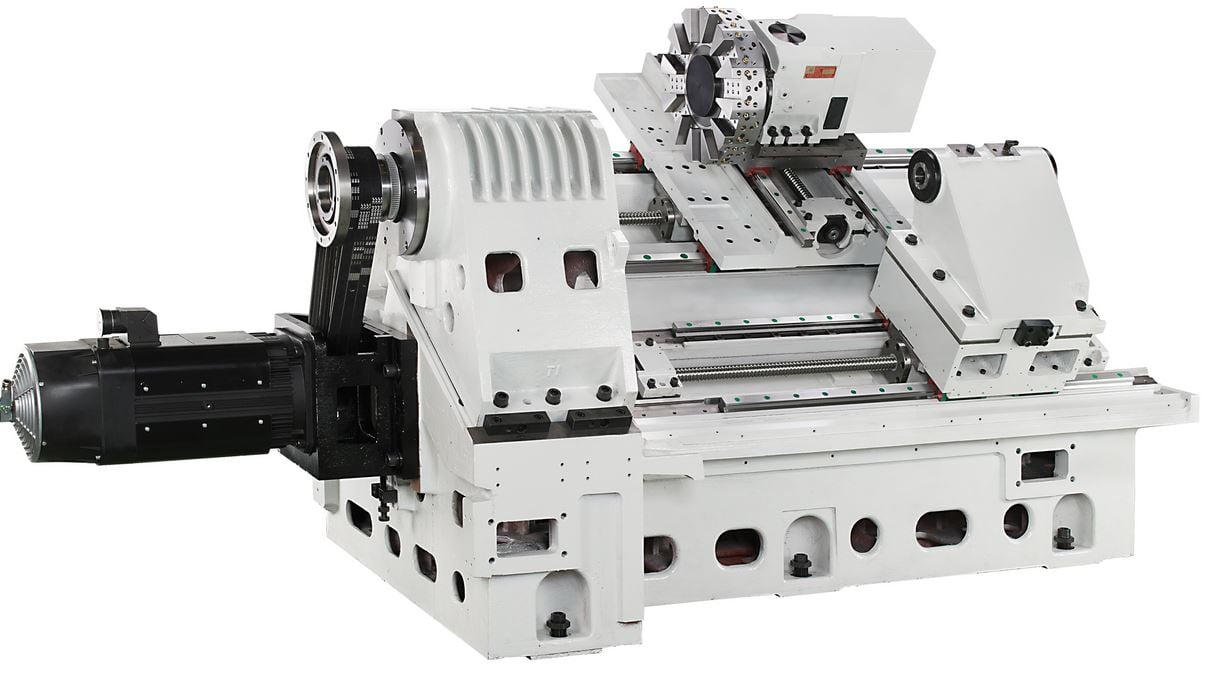

The Hurco CNC Lathe Advantage in Precision Manufacturing

Industry-leading precision: Hurco CNC lathes deliver ±0.01mm tolerances with sub-micron repeatability, ensuring perfect cylindrical geometries for high-stress applications.

Dynamic performance: Spindles up to 6,000 RPM and rapid traverse rates of 945 ipm enable complex threading, grooving, and finishing in a single setup—reducing handling errors and cycle times by 40%.

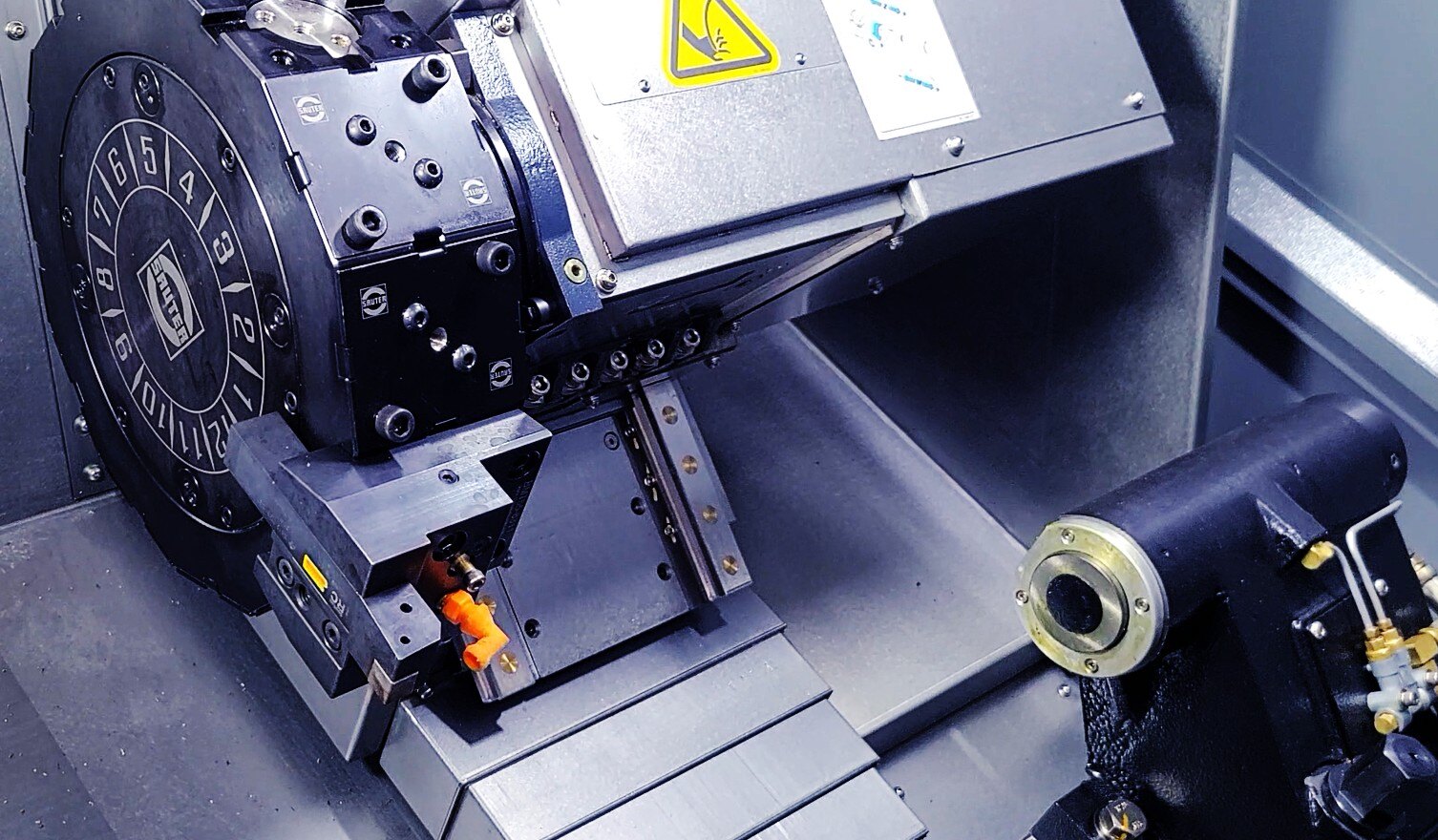

Integrated versatility: Live tooling and multi-axis capabilities allow milling, drilling, and tapping on the lathe bed, eliminating secondary operations and ensuring concentricity in intricate designs.

Cost reality check: Purchasing a new Hurco lathe (e.g., BT-10 series) starts at $150K+, with training, maintenance, and downtime adding 30–50% to total ownership costs. For startups, this capital risk is often unsustainable.

Honyo Prototype: Your Digital Manufacturing Partner for Precision Machining

⚡ Online Instant Quote:

Upload your CAD in <60 seconds. Our AI platform analyzes geometry, material, and tolerances to deliver an accurate, no-obligation quote in minutes—no phone calls or email back-and-forth.

🤖 AI-Powered Optimization:

Real-time DFMA (Design for Manufacturing & Assembly) feedback identifies cost-saving opportunities (e.g., simplified geometries, material alternatives) without compromising function.

🚀 Fast Turnaround Guarantee:

Prototypes delivered in 3–5 days, production parts in 7–10 days—all with certified ±0.01mm precision.

✅ Zero Capital Investment:

Access Hurco-grade machining capabilities without the $150K+ machine cost, training, or maintenance headaches. We handle everything—so you focus on innovation.

🌍 Global Support, Local Expertise:

As Shenzhen-based specialists, we combine agile manufacturing with ISO 9001-certified quality control—serving hardware startups and enterprise clients worldwide.

“At Honyo, we don’t just machine parts—we accelerate your product journey. From concept to reality, your vision meets our precision.”

— Susan Leo, Founder

Ready to transform your design into a high-precision part?

[Get Your Instant Quote Now] → [Contact Our Engineering Team]

Honyo Capabilities & Technology

Precision Machining with Hurco CNC Lathes

Multi-Axis Precision Engineering

3/4/5-axis machining for complex geometries and integrated milling/turning operations

Eliminate costly secondary setups with single-clamp precision – reducing errors by 40% and accelerating production

Ideal for aerospace, medical, and industrial components requiring intricate features like threaded inserts, grooves, and multi-surface contours

±0.01mm Tolerance Mastery

Proprietary thermal compensation and real-time vibration monitoring ensure sub-micron consistency

Every part undergoes 100% inspection via CMM, optical comparators, and in-process gauging

ISO 9001-certified quality protocols validated for critical applications in robotics, automotive, and defense sectors

Scalable Production from 1 to 10,000+ Parts

Zero minimum order requirements – perfect for hardware startups validating designs without financial risk

Seamless transition from prototype to mass production with identical precision and material consistency

Dynamic scheduling that adapts to your project’s timeline, whether you need 1 part tomorrow or 5,000 units next quarter

AI-Powered Digital Manufacturing

Instant online quote: Upload CAD in seconds → receive pricing, DFM feedback, and lead time estimates in <5 minutes

Real-time production tracking via client portal – see your part’s journey from machining to delivery

24/7 engineering support for rapid design optimization and material selection guidance

Why Partner with Honyo?

Founder Susan Leo’s vision for precision innovation drives our commitment to solving your toughest engineering challenges

Shenzhen-based facility with global logistics partnerships for reliable, cost-effective delivery worldwide

End-to-end service from design consultation to final part delivery – we handle the complexity so you can focus on building the future

Materials & Surface Finishes

Material Options & Finishes for Precision CNC Machining

Precision Materials for Every Application

Aluminum 6061: Lightweight, excellent machinability, and corrosion resistance. Ideal for structural prototypes, aerospace components, and electrical enclosures. Honyo’s Hurco CNC lathes achieve ±0.01mm tolerances for complex geometries, ensuring optimal performance in demanding applications.

Aluminum 7075: High strength-to-weight ratio and superior fatigue resistance. Perfect for aerospace, defense, and high-stress automotive applications. Our 5-axis machining capabilities maintain dimensional stability under extreme loads.

Stainless Steel 304: Versatile corrosion resistance and non-magnetic properties. Common in food processing, medical devices, and architectural elements. Honyo’s precision grinding ensures smooth surfaces for sanitary compliance.

Stainless Steel 316: Enhanced chloride resistance for marine environments and surgical instruments. Achieves mirror-like finishes with electropolishing, meeting stringent medical and aerospace standards.

Brass: Excellent electrical conductivity and machinability. Used in plumbing fittings, electrical connectors, and decorative hardware. Our CNC processes deliver precise tolerances for tight-fit assemblies.

PEEK: High-temperature resistance, chemical inertness, and biocompatibility. Ideal for aerospace, medical implants, and semiconductor manufacturing. Honyo’s controlled machining environment ensures dimensional accuracy in extreme conditions.

Surface Finishes That Elevate Performance

Anodizing (Type II/III): Enhances corrosion resistance and wear properties for aluminum parts. Available in multiple colors for aesthetic and functional needs, with Honyo’s automated processes ensuring uniform coating thickness.

Electropolishing: Creates a smooth, sterile surface for stainless steel components, critical for medical and pharmaceutical applications. Reduces surface roughness to <0.1μm Ra for optimal performance.

Powder Coating: Durable, UV-resistant finish for outdoor applications. Offers a wide range of colors and textures, with Honyo’s in-house capabilities ensuring consistent adhesion and finish quality.

Nickel Plating: Improves hardness and corrosion resistance for brass or steel parts. Ideal for electrical contacts and decorative elements, with precise thickness control for functional requirements.

Polishing (Mirror Finish): Achieves <0.1μm Ra for optical or high-end aesthetic applications. Perfect for luxury consumer products and precision instruments, leveraging Honyo’s advanced polishing techniques.

How to Optimize Material Selection with Honyo’s AI Platform

AI-Powered Recommendations: Upload your part specs (dimensions, load requirements, environment) to our online platform for instant material and finish suggestions tailored to your application. Our AI cross-references material properties with Hurco CNC capabilities to recommend the optimal solution.

Real-Time Cost Analysis: See how material choices impact TCO—our system factors in machining time, secondary processes, and lead time to optimize budget and performance. Avoid costly over-engineering with data-driven insights.

Fast-Track Prototyping: Select materials and finishes with confidence—our Shenzhen facility delivers functional prototypes in 3–5 days, with 24/7 online quote generation. Accelerate your product development cycle without compromising precision.

End-to-End Expertise: From initial design review to final inspection, our engineers ensure your material choice aligns with Hurco CNC’s precision capabilities for flawless end-use parts. Partner with Honyo Prototype to turn innovation into reality.

💡 Ready to start? Use our AI-powered instant quote tool to explore material options, see real-time pricing, and get your project moving in hours—not weeks. Innovate faster. Deliver smarter.

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we eliminate guesswork and delays with a seamless, AI-driven workflow. From your first upload to final delivery, every step is optimized for speed, precision, and transparency—so you can focus on innovation, not logistics.

1. Upload CAD File

Simple & Secure: Drag and drop STEP, IGES, STL, or native CAD files to our encrypted platform.

Instant Validation: AI checks file integrity and compatibility in real-time—no manual review delays.

2. Get Instant Quote (AI Engine)

Real-Time Pricing: Proprietary AI analyzes geometry, tolerances, and material in seconds—no waiting for quotes.

Transparent Breakdown: See exact costs for machining, materials, setup, and shipping—zero hidden fees.

Optimization Tips: AI suggests design tweaks to reduce costs while maintaining precision (e.g., simplifying features, material choices).

3. DFM Analysis

Expert Review: Senior engineers validate manufacturability within 24 hours—no bottlenecks.

Precision Assurance: Critical tolerances (±0.01mm) are validated against Hurco VM-series capabilities for flawless execution.

Cost-Saving Insights: We flag potential issues early (e.g., undercuts, thin walls) to prevent production delays.

4. Production & Delivery

High-Speed Machining: Hurco VM-series CNC lathes (10k RPM, 945 ipm rapids) produce parts with ±0.01mm accuracy at industry-leading speeds.

Real-Time Tracking: Monitor progress via our portal—from first cut to final inspection.

On-Time Delivery: 95% of orders shipped within 3–5 business days—faster than traditional manufacturers.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Machining, Engineered for Speed

Precision at Scale: ±0.01mm tolerances across 3/4/5-axis machining for complex, high-performance components—guaranteed for functional prototypes and end-use parts.

Instant Online Quote: AI-powered platform delivers real-time pricing and lead times in seconds—no manual estimates, no hidden fees.

Lightning-Fast Turnaround: 3-5 days for prototypes; 7-10 days for production runs—accelerate your time-to-market without compromising quality.

Expert Collaboration: Founder Susan Leo and our engineering team optimize designs for manufacturability, cost efficiency, and innovation at every stage.

Ready to bring your vision to life?

📧 [email protected]

📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities for a personalized consultation

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.